High-contact-ratio internal-gearing cycloidal gear mechanism

A cycloidal gear and internal gear technology, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of large pressure angle, poor force, and unsatisfactory meshing state of cycloidal gear and needle teeth. and other problems, to achieve the effect of improved bearing capacity, easy realization of manufacturing process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

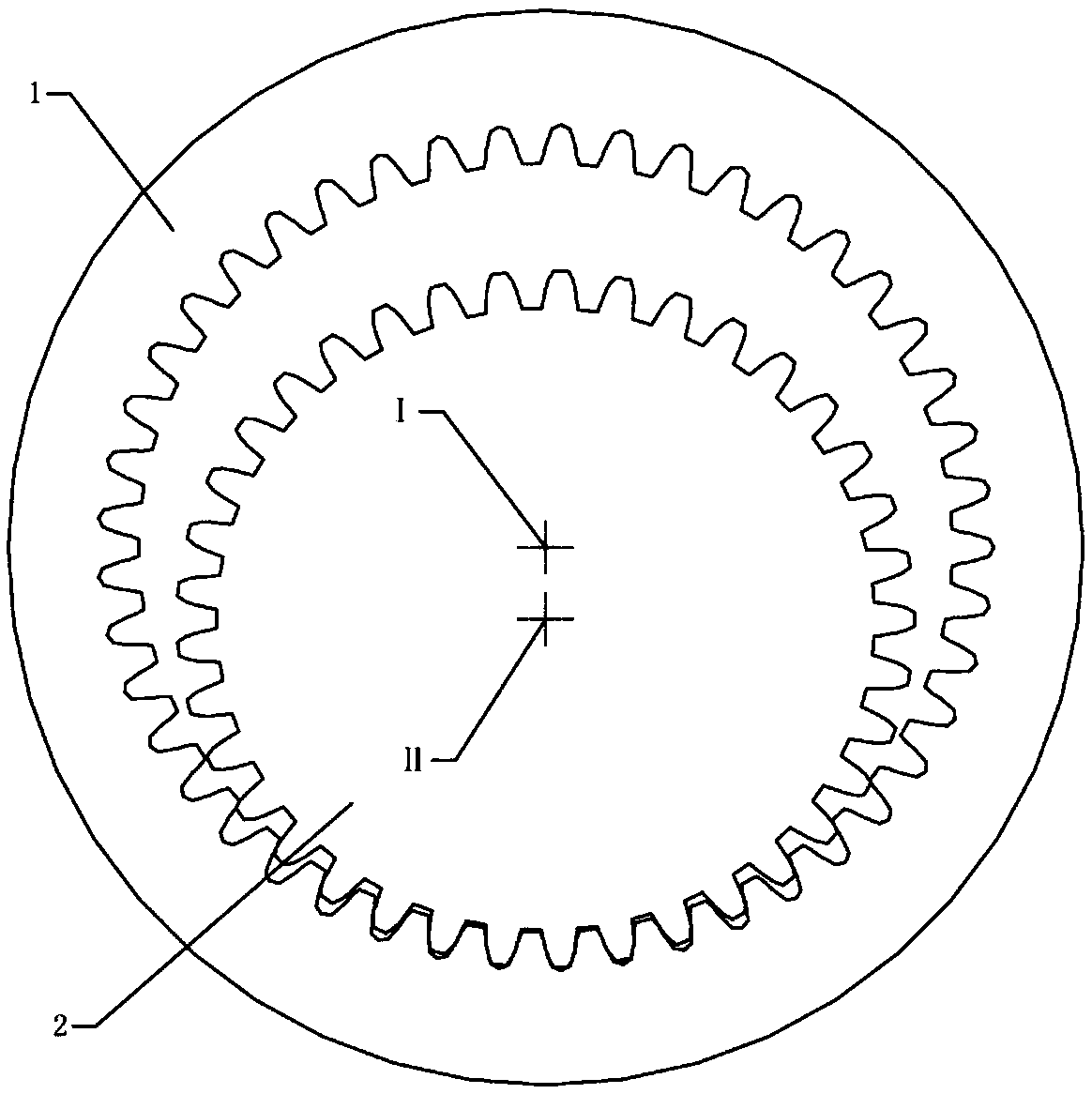

[0021] like figure 1 shown.

[0022] 1—cycloid internal gear, number of teeth z 1 =45, 2—cycloidal external gear, number of teeth z 2 =37, modulus m=5, take the arc radius of meshing line r=101.7683. It can be seen from the figure that no matter which direction the transmission is in, the number of meshing teeth reaches 7 pairs at the same time.

Embodiment 2

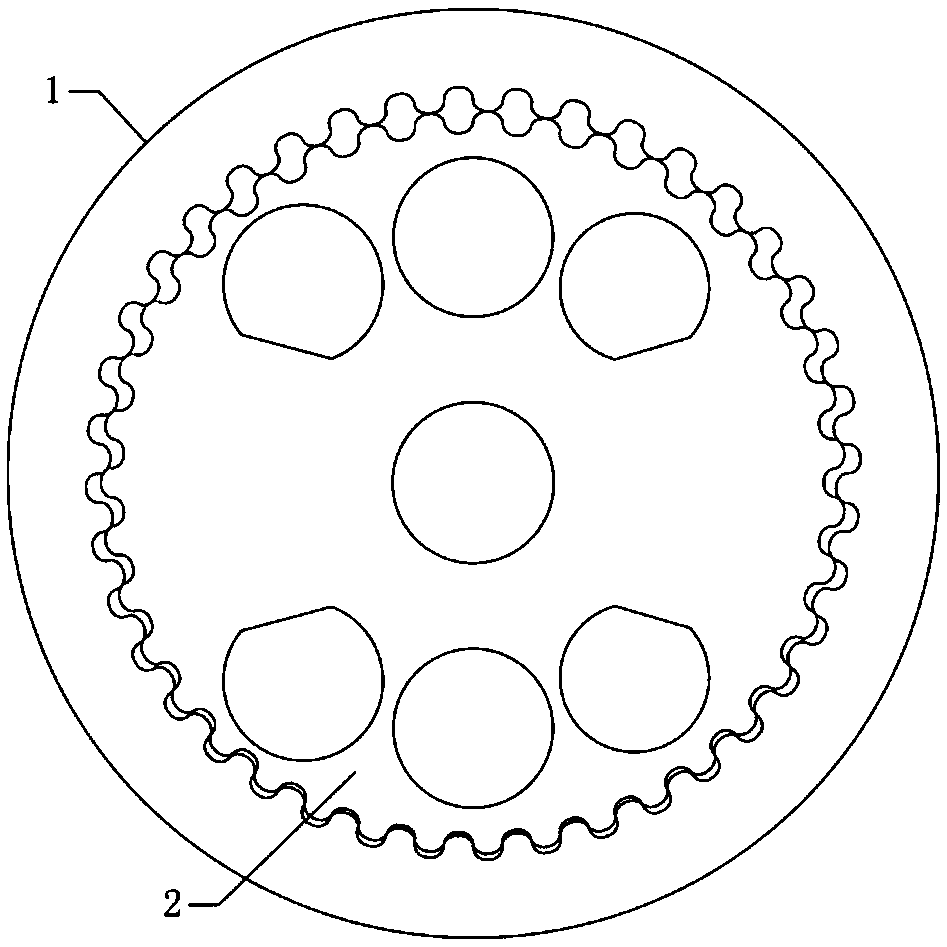

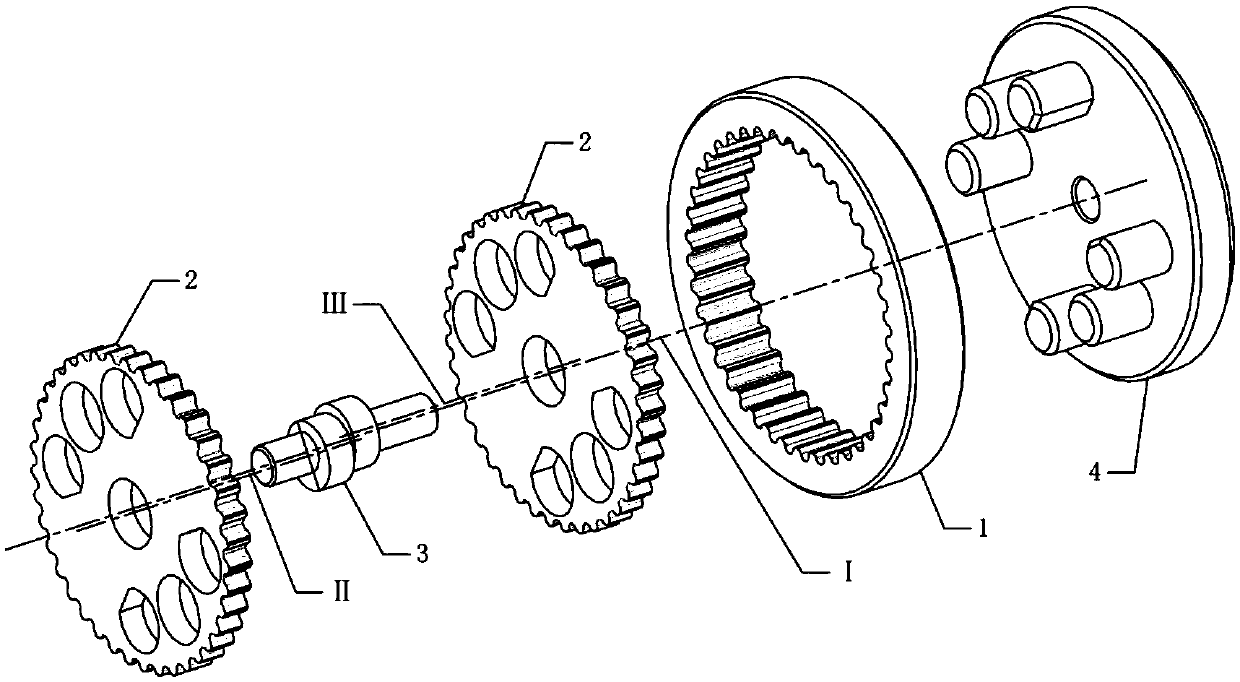

[0024] 1-tooth difference planetary gear mechanism, such as figure 2 , 3 shown.

[0025] 1—cycloid internal gear, number of teeth z 1 =40, 2—cycloid external gear, number of teeth z 2 =39, modulus m=3, take the arc radius of meshing line r=59.25. A pair of identical cycloidal external gears 2 are installed symmetrically, axially staggered, and meshed with the cycloidal internal gear 1 at the same time. image 3 Middle 3—two-way eccentric shaft, used to support two external gears 2 to mesh with internal gear 1 respectively. Assuming that the cycloidal internal gear 1 is fixed and the eccentric shaft 3 is used as the input shaft, that is, the motion is input from it, then the cycloidal external gear 2 will move in a plane, that is, it will perform a circular translation motion around the axis of the cycloidal internal gear 1, and because it is connected with the pendulum The internal gear 1 meshes to make a rotary motion around its own axis. 4—the output mechanism, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com