High-permeability friction nano sensor and preparation method thereof

A nano-sensor and high-permeability technology, which is applied in the direction of sensors, friction generators, and electric/magnetic devices to transmit sensing components, etc., can solve the problems of non-breathability, poor adhesion performance, and long single-use time. Achieve the effects of wearing convenience, avoiding inflammation and allergic symptoms, and enhancing signal acquisition and transmission capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

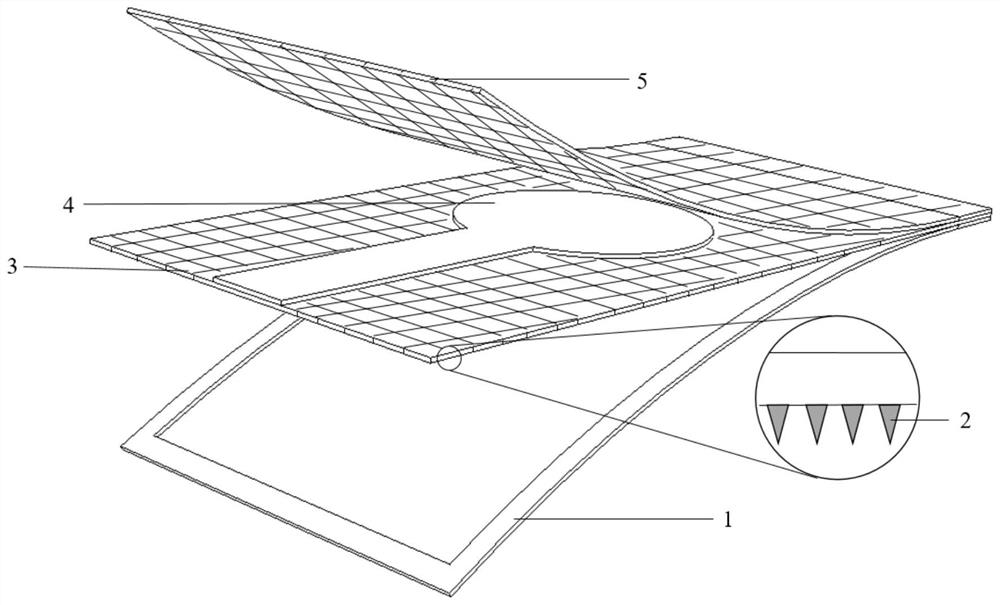

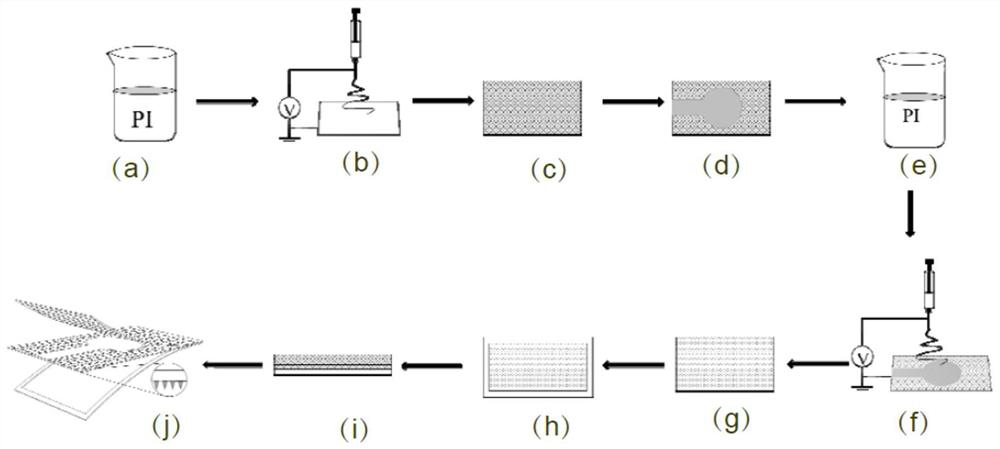

[0036] see figure 2 , the present invention also provides a preparation method of a high-permeability nanosensor, the preparation method mainly includes the following steps:

[0037] S1, preparation of tribological layer electrospinning solution: firstly, soluble PI powder was dissolved in organic solvent dimethylacetamide (DMAc), and then magnetically stirred at room temperature to obtain electrospinning solution. Wherein, the stirring time is preferably 2h-4h, and the concentration of the prepared PI electrospinning solution is preferably 20wt%-25wt%.

[0038]S2, preparation of friction layer film: use high-voltage electrospinning process, preferably DC voltage 8-10kV, receiving distance 5-15cm, injection flow range of spinning solution 8000-10000nl / min, relative humidity 60%, use 1ml syringe, inner diameter 0.51mm, outer diameter 0.82mm general stainless steel dispensing needle, prepare a layer of PI film on single-sided conductive ITO glass; then remove the film and keep...

Embodiment 1

[0048] S1, preparation of friction layer electrospinning solution: first dissolve soluble PI powder in the organic solvent dimethylacetamide (DMAc), and then perform magnetic stirring at room temperature, the stirring time is preferably 2h, the prepared PI electrospinning solution The concentration of is preferably 20wt%;

[0049] S2, preparation of friction layer film: use high-voltage electrospinning process, preferably DC voltage 8kV, receiving distance 10cm, injection flow rate 8000nl / min, relative humidity 60%, use 1ml syringe, general stainless steel point with inner diameter of 0.51mm and outer diameter of 0.82mm Glue needles, prepare a layer of PI film on the single-sided conductive ITO glass; then remove the film and hold it at 60°C for 4 hours to cure the PI material layer, and obtain a friction layer film with a thickness of 0.1mm;

[0050] S3, preparing the friction layer: use a blade to cut a piece of film with a relatively uniform thickness and a surface area of ...

Embodiment 2

[0058] S1, preparation of friction layer electrospinning solution: first dissolve soluble PI powder in the organic solvent dimethylacetamide (DMAc), and then perform magnetic stirring at room temperature, the stirring time is preferably 3h, the prepared PI electrospinning solution The concentration of is preferably 22wt%;

[0059] S2, preparation of friction layer film: use high-voltage electrospinning process, preferably DC voltage 9kV, receiving distance 12cm, injection flow rate 9000nl / min, relative humidity 60%, use 1ml syringe, general stainless steel point with inner diameter of 0.51mm and outer diameter of 0.82mm Glue needles, prepare a layer of PI film on the single-sided conductive ITO glass; then remove the film and hold it at 60°C for 5 hours to cure the PI material layer, and obtain a friction layer film with a thickness of 0.15mm;

[0060] S3, preparing the friction layer: use a blade to cut a piece of film with a relatively uniform thickness and a surface area of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com