Antireflection film, manufacturing method therefor, display panel, and display device

An anti-reflection film and display panel technology, which is applied in the field of display panels and display devices, and anti-reflection film, can solve the problems of high cost of anti-reflection film, complex bonding process, and easy generation of static electricity, so as to increase the overall thickness and production cost , The production process is easy to realize, avoiding bad effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

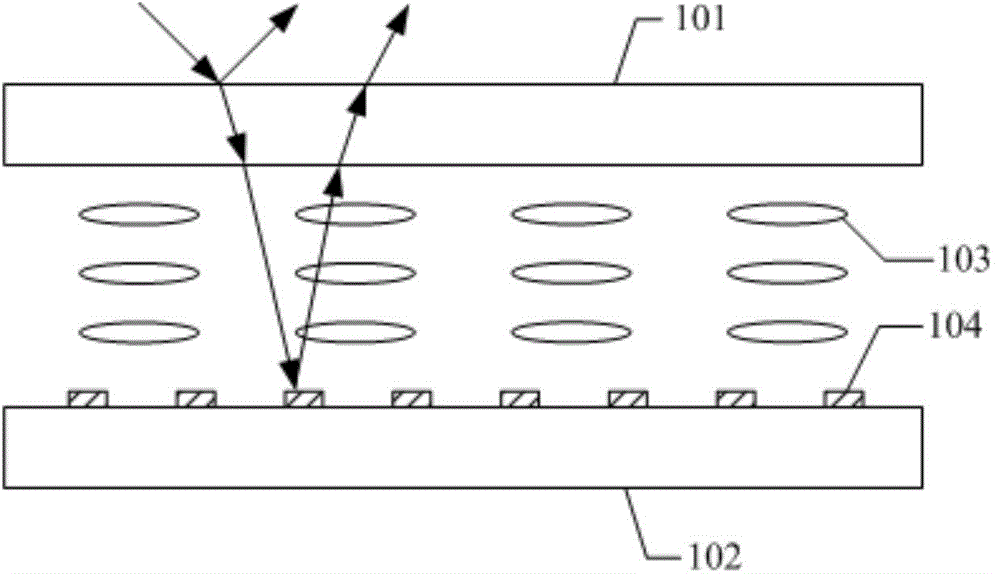

[0037] The specific implementation manners of an anti-reflection film, a manufacturing method thereof, a display panel and a display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0038] The shape and thickness of each film layer in the drawings do not reflect their true proportions, but are only intended to schematically illustrate the content of the present invention.

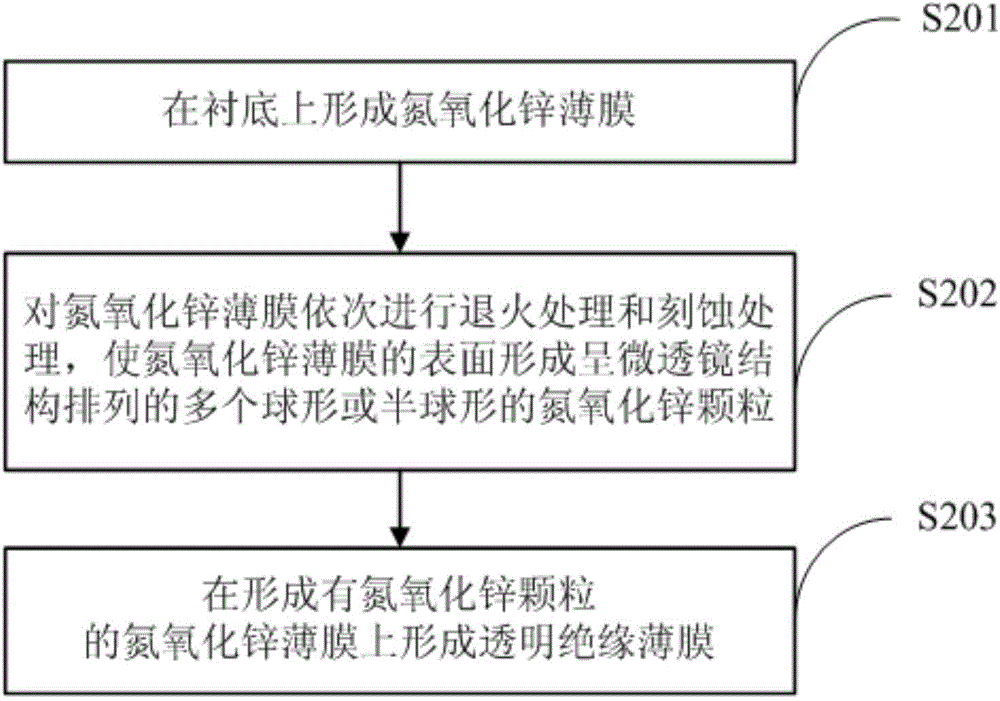

[0039] A kind of manufacturing method of anti-reflection film provided by the embodiment of the present invention, such as figure 2 shown, including the following steps:

[0040] S201, forming a zinc oxynitride film on the substrate;

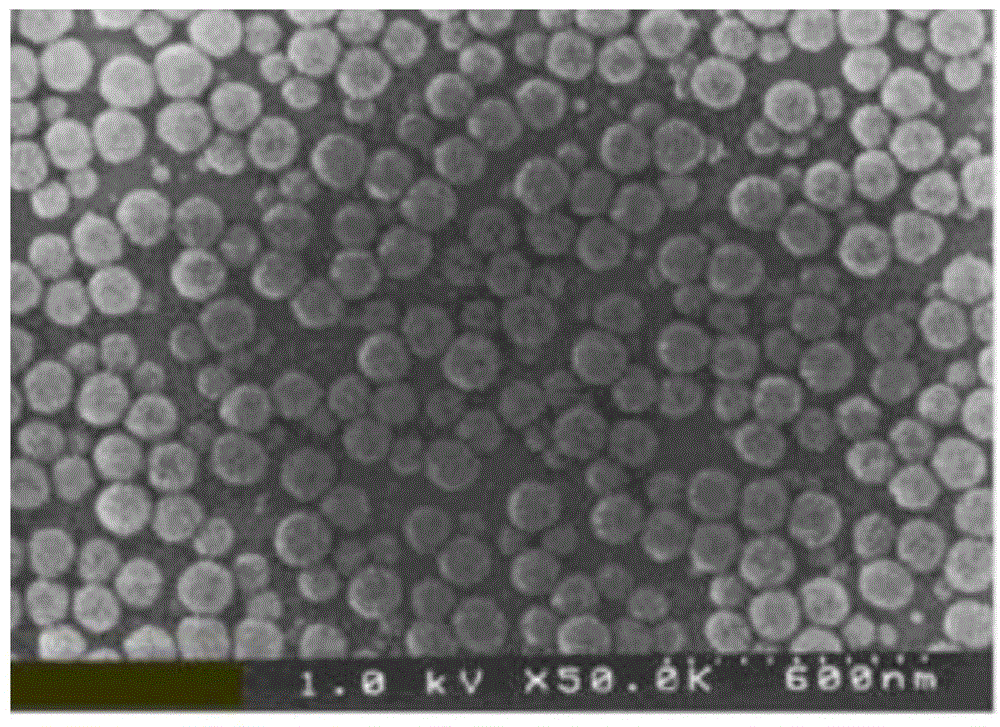

[0041] S202. Perform annealing treatment and etching treatment on the zinc oxynitride film in sequence, so that a plurality of spherical or hemispherical zinc oxynitride particles arranged in a micro-lens structure are formed on the surface of the zinc oxynitride film.

[0042] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com