Ultrahigh-strength steel with fatigue limit larger than 600 MPa for ocean engineering and preparation method thereof

A technology of fatigue limit and marine engineering, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of composition range and heat treatment temperature not within the scope of the present invention, and achieve easy manufacturing process, stable product performance, and excellent low temperature toughness Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

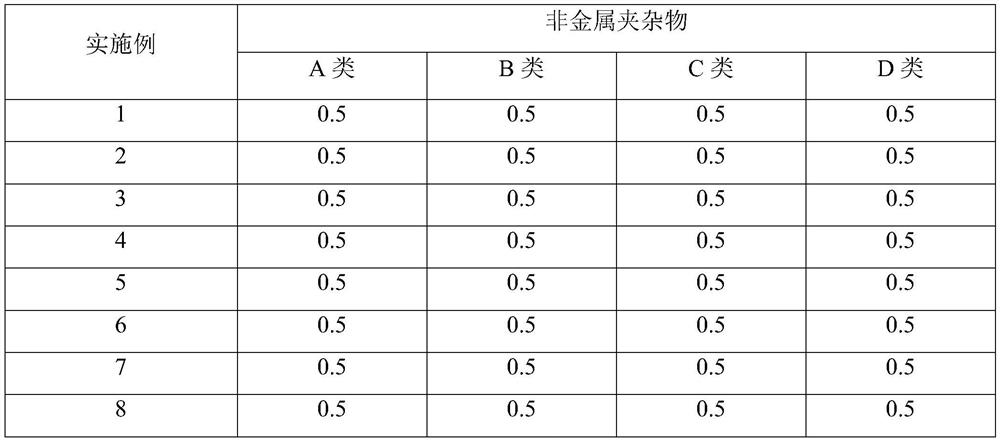

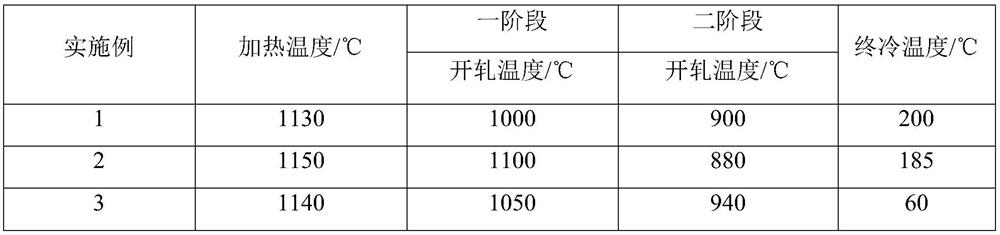

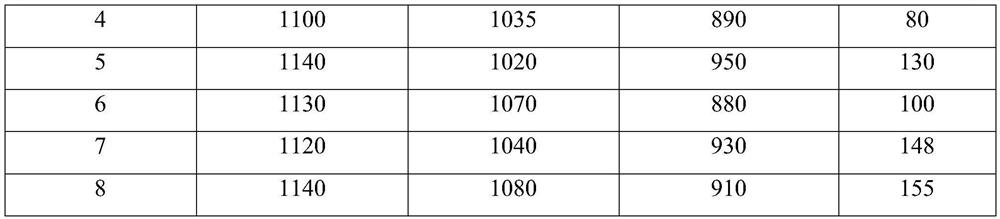

[0030] The chemical composition of the steel of the embodiment of the invention is shown in Table 1, the smelting process of the steel of the embodiment of the invention is shown in Table 2, the rolling process of the steel of the embodiment of the invention is shown in Table 3, the heat treatment process is shown in Table 4, and the mechanical properties are shown in Table 5.

[0031] Table 1 steel chemical composition of the embodiment of the present invention

[0032] Example C Si mn P S Cr Ni Mo V 1 0.10 0.27 0.88 0.002 0.001 0.62 6.80 0.80 0.06 2 0.08 0.35 0.95 0.001 0.001 0.50 7.50 0.85 0.05 3 0.09 0.20 0.75 0.001 0.0005 0.55 6.00 0.90 0.08 4 0.11 0.45 0.70 0.001 0.0005 0.70 7.00 0.87 0.07 5 0.08 0.50 0.85 0.001 0.0005 0.52 5.90 0.83 0.06 6 0.09 0.41 0.88 0.002 0.001 0.66 6.40 0.86 0.08 7 0.10 0.22 0.80 0.001 0.0005 0.57 8.00 0.88 0.06 8 0.09 0.37 1.00 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue limit | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com