Method for improving interlaminar shear strength of medium/low-temperature cured prepreg by using polyurethane prepolymer

A polyurethane prepolymer and prepreg technology, applied in the field of composite materials, can solve problems such as low bonding performance, and achieve the effects of high peel strength, excellent lap shear strength, and good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

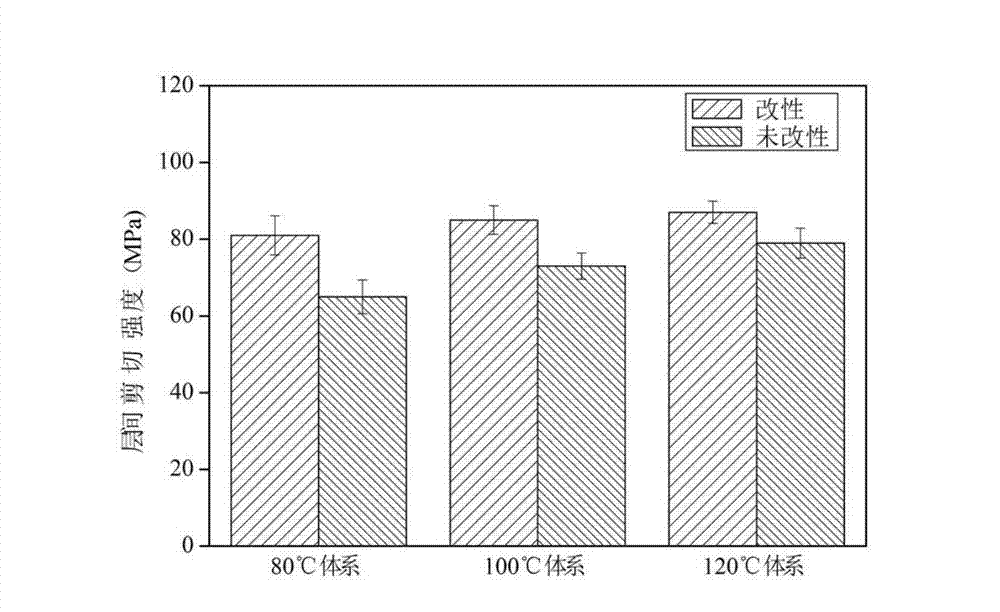

[0017] Add isophorone diisocyanate (IPDI) and polypropylene oxide into the reactor according to the molar ratio of 4:3, and react at 70°C for 6 hours to obtain an isocyanate-terminated polyurethane prepolymer with a molecular weight of 2500. Add 15 parts (mass The number of parts is calculated based on the final amount of epoxy resin used as 100 parts, the same below) The isocyanate-terminated polyurethane prepolymer and bisphenol A glycidyl ether epoxy resin are reacted in a stirred tank at 60°C for 8 hours, and then bisphenol A is added Stir glycidyl ether epoxy resin and glycidyl amine epoxy resin evenly to obtain a modified epoxy resin matrix, then add 10 parts of dicyandiamide curing agent and 5 parts of urea derivative accelerator, mix evenly and vacuum remove Bubble, epoxy resin system for prepreg preparation. The above resin system is coated with a film machine, and then compounded with reinforcing fibers through a compound machine to prepare a unidirectional carbon fi...

Embodiment 2

[0019] Add diphenylmethane diisocyanate (MDI) and polyethylene glycol into the reactor at a molar ratio of 5:3, and react at 70°C for 5 hours to obtain an isocyanate-terminated polyurethane prepolymer with a molecular weight of 1800. 10 parts of isocyanate-terminated React polyurethane prepolymer with bisphenol F glycidyl ether epoxy resin in a stirred tank at 80°C for 7 hours, then add bisphenol A glycidyl ether epoxy resin and novolac epoxy resin and stir evenly to obtain a modified epoxy resin Then add 6 parts of modified dicyandiamide curing agent and 3 parts of urea derivative accelerator, mix evenly and vacuum defoam to prepare epoxy resin system for prepreg. The above resin system is coated with a film machine, and then compounded with a reinforced fiber fabric through a compound machine to prepare a carbon fiber fabric prepreg. The cut prepreg is placed in a mold, and it is pressurized and cured at 100°C for 3 hours to obtain a composite. Material plate, the test inter...

Embodiment 3

[0021] Add toluene diisocyanate (TDI) and polyethylene glycol into the reactor at a molar ratio of 2:1, and react at 70°C for 4 hours to obtain an isocyanate-terminated polyurethane prepolymer with a molecular weight of 1000, and 5 parts of isocyanate-terminated polyurethane React the prepolymer with bisphenol A glycidyl ether epoxy resin in a stirred tank at 100°C for 5 hours, then add bisphenol A glycidyl ether epoxy resin and novolac epoxy resin and stir evenly to obtain a modified epoxy resin matrix , and then add 5 parts of dicyandiamide curing agent and 1 part of urea derivative accelerator, mix evenly and vacuum defoam to prepare the epoxy resin system for prepreg. The above resin system is coated with a film machine, and then compounded with reinforcing fibers through a compound machine to prepare a unidirectional carbon fiber prepreg. The cut prepreg is placed in a mold, and it is pressurized and cured at 120°C for 1.5 hours to obtain a composite Material plate, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com