Production process of rebar for concrete

A production process and concrete technology, applied in the field of production process of steel bars for concrete, can solve the problems of small tensile strength and yield strength, high yield ratio and low yield ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

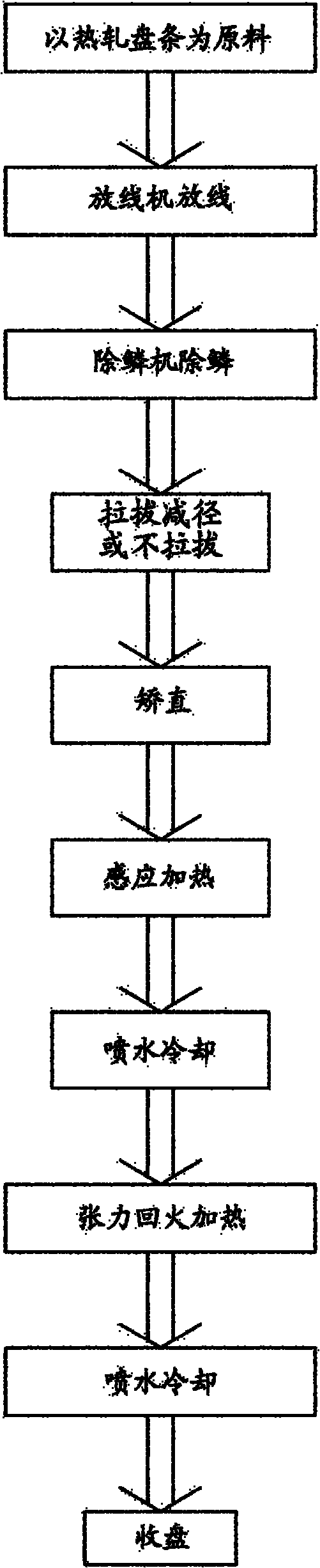

Method used

Image

Examples

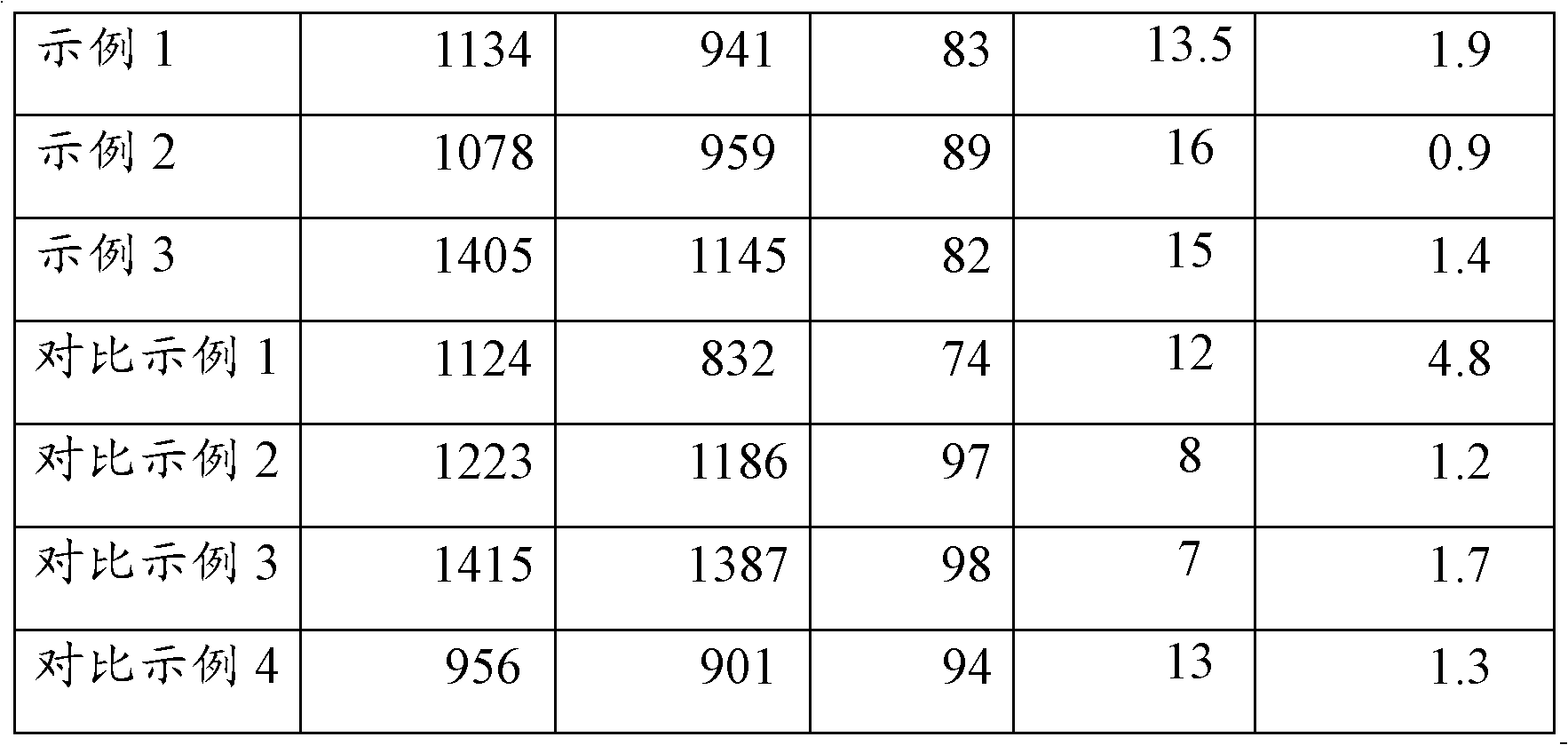

example 1

[0019] After the 30MnSi hot-rolled wire rod is released through the pay-off machine, it is descaled, and the mold is drawn and formed to be straightened. The hot-rolled wire rod is continuously passed through the heating ring and the cooling water ring by a high-frequency induction heating furnace to heat the steel. Austenitize to above Ac1, spray water quenching and cooling, then carry out continuous tempering treatment, and apply a certain tension to the steel on the tempering unit, wherein, the quenching temperature is 750°C, the tempering temperature is 350°C, the tension value 30% of the original breaking force, spray water to cool, and obtain the product.

example 2

[0021] After the 30MnSi hot-rolled wire rod is released through the pay-off machine, it is descaled and straightened without drawing. The hot-rolled wire rod is continuously passed through the heating ring and the cooling water ring by a high-frequency induction heating furnace to heat the steel. Austenitization shall be carried out above Ac1, continuous tempering shall be carried out after quenching and cooling by water spraying, and a certain tension shall be applied to the steel on the tempering unit, among which, the quenching temperature is 980°C, the tempering temperature is 600°C, 1% of the original breaking force, spray water to cool, and obtain the product.

example 3

[0023] After the 30MnSi hot-rolled wire rod is released through the pay-off machine, the scale is removed, the mold is drawn and formed, and then straightened. The hot-rolled wire rod is continuously passed through the heating ring and the cooling water ring by a high-frequency induction heating furnace, and the steel is heated to Ac1 or more to carry out austenitization, continuous tempering treatment after spray quenching and cooling, and a certain tension is applied to the steel on the tempering unit. Among them, the quenching temperature is 810°C, the tempering temperature is 480°C, and the tension value is 5% of the original breaking force, spray water to cool, and obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com