High-conductivity creep-resistant aluminium alloy cable conductor containing Hf and Ce and preparation method thereof

A cable conductor, high electrical conductivity technology, applied in the field of aluminum alloy materials, can solve the problems of poor high temperature resistance and creep performance, low electrical conductivity, strength loss, etc., to improve electrical performance and high temperature performance, improve heat resistance. and creep resistance, improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

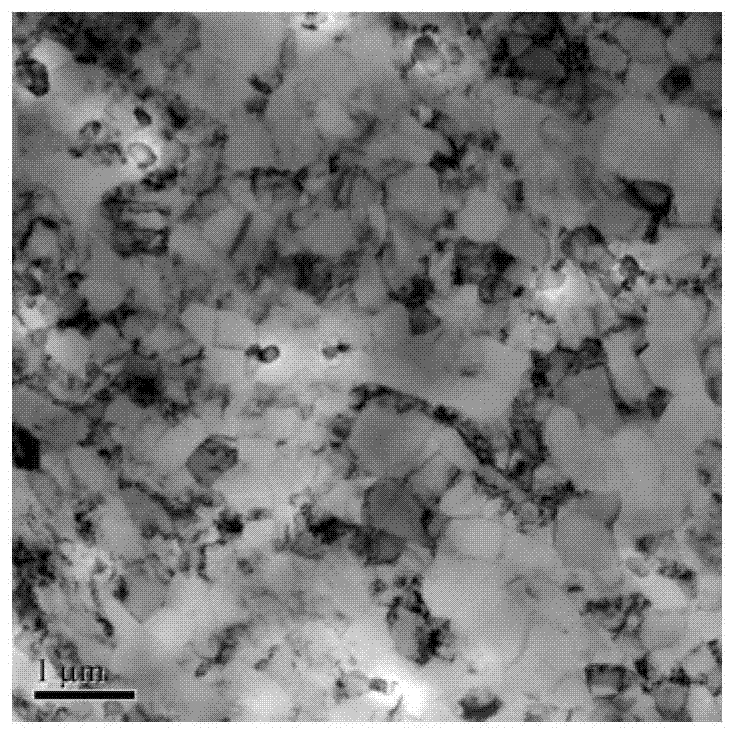

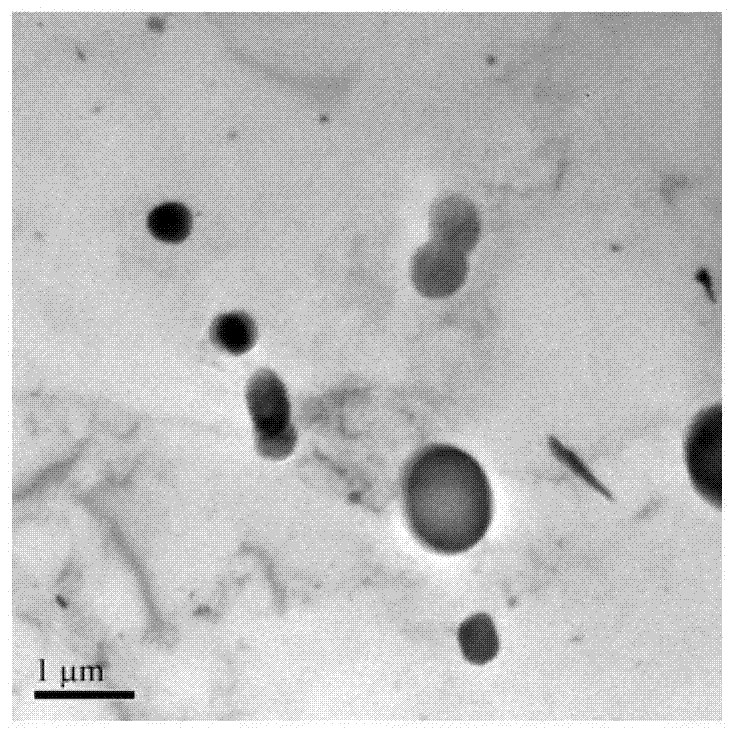

Image

Examples

Embodiment 1

[0041] Put pure aluminum with a mass fraction of 99.99% into the cupola, melt it into aluminum water at 750°C and keep it warm at 700°C, add sodium chloride as a covering agent, and then put in aluminum-iron master alloy, aluminum-copper master alloy, aluminum - Hafnium master alloy, aluminum-boron master alloy and aluminum-cerium master alloy, made into aluminum alloy liquid, adding hexachloroethane as a refining agent, stirring, slag removal, pouring in a mold from 715°C to 150°C, each element The content is (mass fraction): Fe 1.1%, Cu 0.1%, Ce 0.02%, Hf 0.01%, B 0.01%, and the rest is Al. After homogenization treatment at 500°C / 15h, it is cooled to 380°C with the furnace, and extruded in an extrusion die with a mold temperature of 300°C. The extrusion speed is 5m / min, and the extrusion ratio is 25:1. Drawing at a speed of 1 min, annealing at 250°C for 2 hours, and air cooling after taking out the furnace.

Embodiment 2

[0043] Put pure aluminum with a mass fraction of 99.99% into the cupola, melt it into aluminum water at 900°C and keep it warm at 750°C, add a mixed salt of sodium chloride, potassium chloride, calcium fluoride, and sodium carbonate (the mass ratio is 30 :30:25:15) As a covering agent, put in aluminum-iron master alloy, aluminum-copper master alloy, aluminum-hafnium master alloy, aluminum-boron master alloy and aluminum-cerium master alloy in turn to make aluminum alloy liquid, add Hexachloroethane is used as a refining agent, stirred and slag removed, poured in a mold from 725°C to 200°C, the content of each element is (mass fraction): Fe 0.3%, Cu 0.5%, Ce 0.1%, B 0.05%, Hf 0.2%, the rest is Al. After homogenization treatment at 550°C / 10h, it is cooled to 420°C with the furnace, and extruded in an extrusion die with a mold temperature of 420°C. The extrusion speed is 20m / min, and the extrusion ratio is 64:1. Min speed for drawing, annealing at 350 ° C for 1 h, air cooling ou...

Embodiment 3

[0045] Put pure aluminum with a mass fraction of 99.99% into the cupola, melt it into aluminum water at 850°C and keep it warm at 730°C, add a mixed salt of sodium chloride and potassium chloride (mass ratio 1:1) as a covering agent, Add aluminum-iron master alloy, aluminum-copper master alloy, aluminum-hafnium master alloy, aluminum-boron master alloy and aluminum-cerium master alloy in turn to make aluminum alloy liquid, add hexachloroethane as refining agent, stir, grill Slag, in the mold poured from 720°C to 180°C, the content of each element is (mass fraction): Fe 0.75%, Cu 0.25%, Ce 0.05%, B 0.03%, Hf 0.1%, and the rest is Al. After homogenization treatment at 530°C / 12h, it is cooled to 400°C with the furnace, and extruded in an extrusion die with a mold temperature of 400°C. The extrusion speed is 15m / min, and the extrusion ratio is 36:1. Min speed for drawing, annealing at 320 ° C for 1.5 h, air cooling out of the furnace.

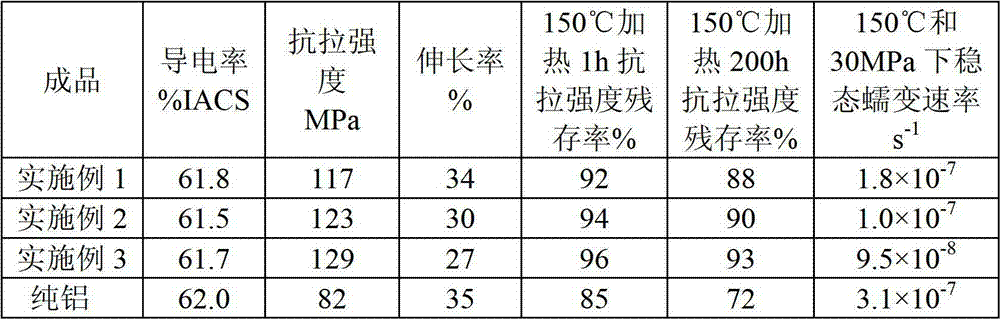

[0046] The product performance index that e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com