Infrared reflecting plate and infrared reflective bonded glass sheet

A technology of light reflection layer and infrared light, which is applied in windshield, glass/slag layered products, optics, etc., can solve the problems of film surface temperature rise and heat insulation performance reduction, and achieve improved reflection characteristics and excellent reflection characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] 3. Preparation method of infrared light reflector

[0105] The infrared light reflecting plate of the present invention is preferably produced by a coating method. An example of the production method is a production method including at least the following steps:

[0106] (1) A curable liquid crystal composition is applied on the surface of a substrate or the like to form a state of a cholesteric liquid crystal phase,

[0107] (2) The above-mentioned curable liquid crystal composition is irradiated with ultraviolet rays to cause a curing reaction to fix the cholesteric liquid crystal phase to form a light reflection layer.

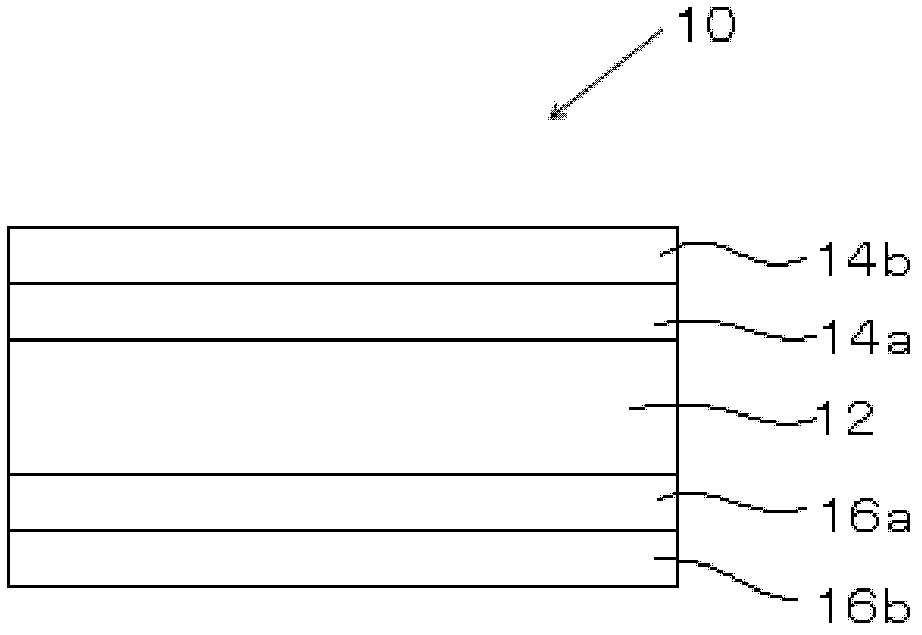

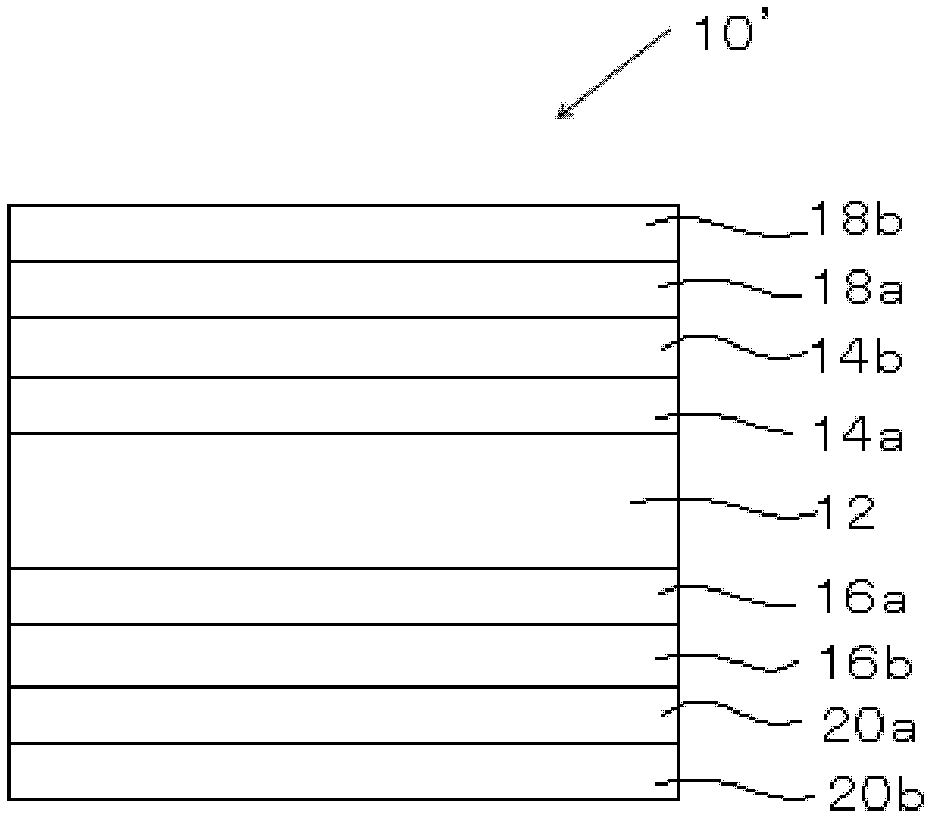

[0108] By repeating the steps (1) and (2) twice on one side of the substrate, and then repeating twice on the other side of the substrate; or repeating twice on both sides of the substrate at the same time, it is possible to produce issued with figure 1 The infrared light reflecting plate having the same configuration as shown is shown. In additi...

Embodiment

[0131] Examples and comparative examples are given below to more specifically describe the characteristics of the present invention. Materials, usage amounts, ratios, processing contents, processing procedures, and the like shown in the following examples can be appropriately changed within a range not departing from the gist of the present invention. Therefore, the scope of the present invention should not be limitedly interpreted by the specific examples shown below.

[0132] Coating solutions (A), (B), (C), (D), (E) and (F) having compositions shown in the following table were prepared respectively.

[0133] 【Table 1】

[0134] Composition of Coating Solution (A)

[0135] Material (type)

Material name (maker)

Prescription amount

rod-shaped liquid crystal compound

RM-257(Merck)

10.000 parts by mass

chiral reagent

LC-756(BASF)

0.293 parts by mass

polymerization initiator

Irg-819 (Ciba Specialty Chemicals)

0.419 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com