Yellow pigment able to reflect near infrared rays and preparation method thereof

A technology of yellow pigments and near-infrared rays, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of rising surface temperature and increasing the cost of air conditioning and refrigeration, so as to improve performance, facilitate scale and The effect of industrial production and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

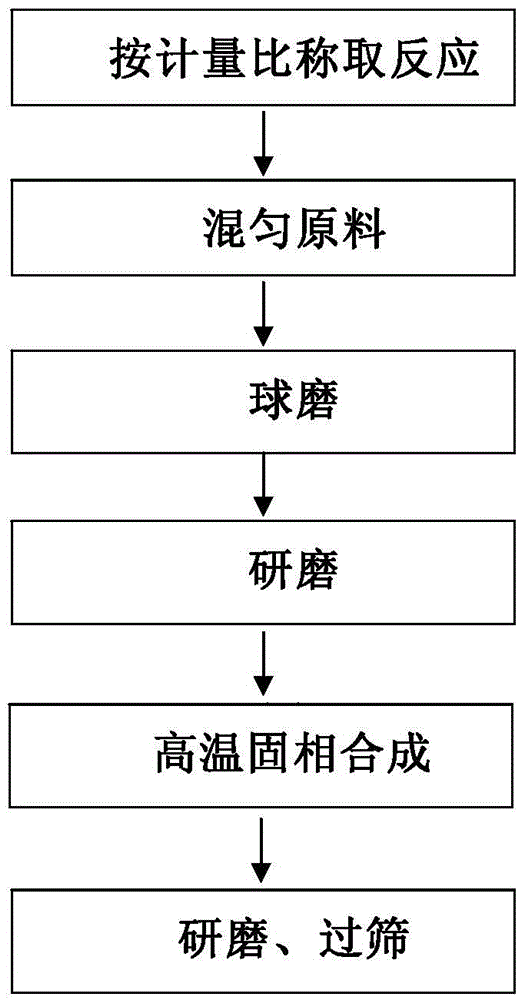

[0037] The preparation method flow chart of the present invention can reflect near-infrared ray yellow pigment is as follows figure 1 As shown, two implementations are included.

[0038] first implementation

[0039] It is prepared by the main phase, the doping phase and the mineralizer according to the mass ratio, wherein the main phase is 80-98% titanium dioxide, the doping phase is 1-10% basic nickel carbonate and 1-10% antimony oxide The mineralizer is boric acid, and the boric acid accounts for 0.5-3wt% of the total mass of the main phase and the doping phase.

[0040] 1) Ingredients: mix 80-98% of titanium dioxide, 1-10% of basic nickel carbonate, and 1-10% of antimony oxide according to mole percentage, and then add 0.5-3wt% of mineralizer boric acid accounting for the total mass of the mixture ;

[0041] 2) Ball milling: put the weighed mixture in step 1) into a ball mill, and use wet ball milling for 3 hours;

Embodiment 1

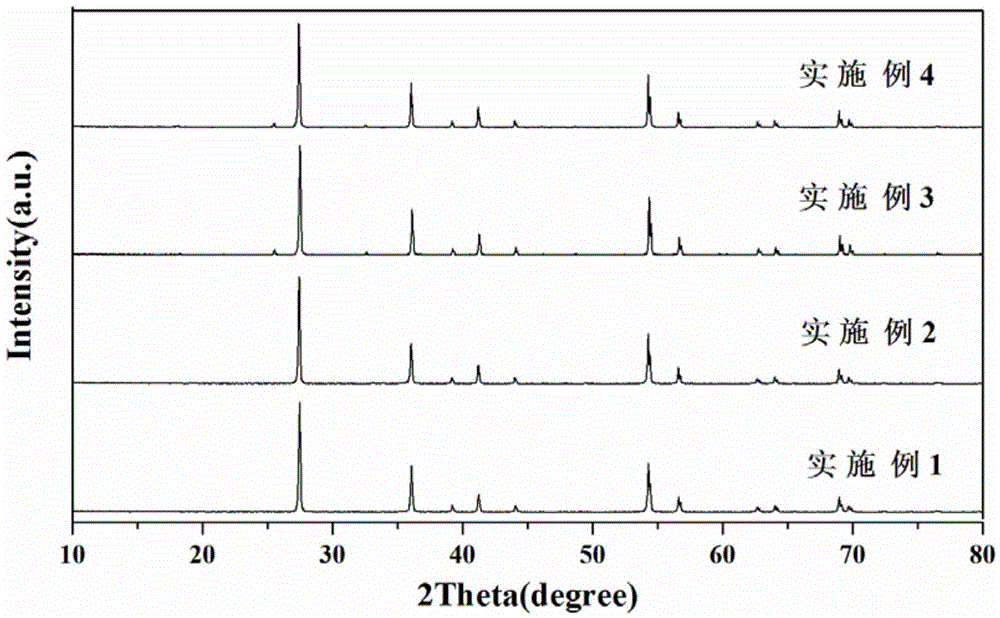

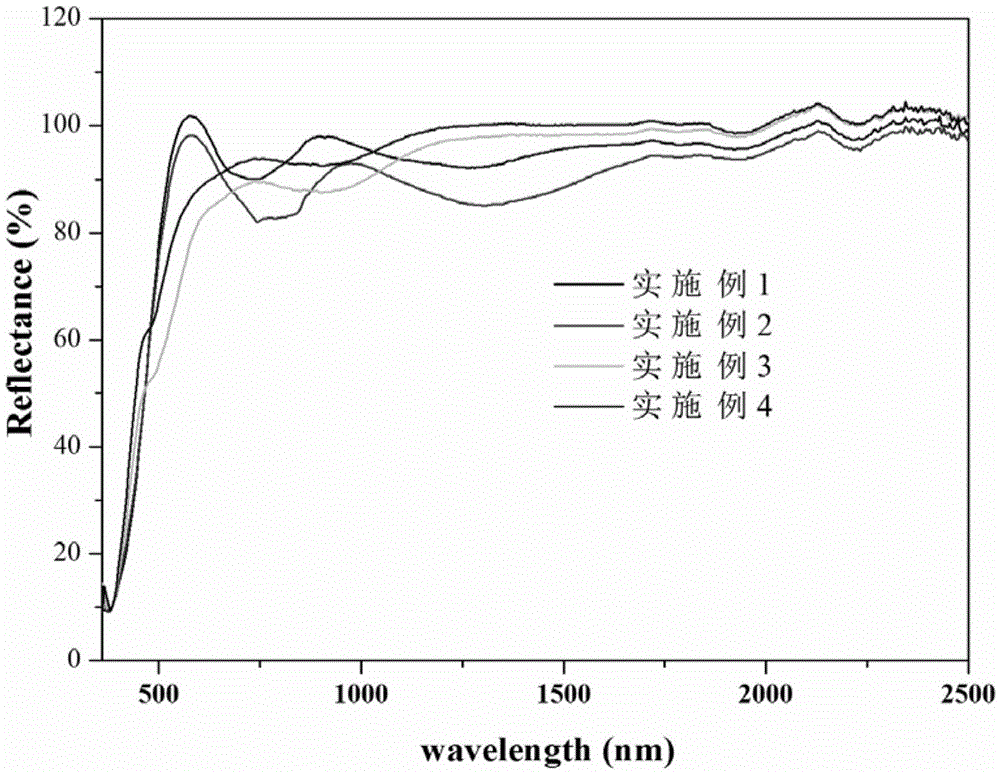

[0046] According to the molar percentages of 95%, 2%, and 3%, the main phase titanium dioxide, the doped phase basic nickel carbonate and antimony oxide were weighed respectively, and then the mineralizer boric acid was added, and the boric acid was 1 wt% of the total mass of the main phase and the doped phase. The weighed raw material samples were put into a ball mill and wet ball milled for 3 hours. During ball milling, acetone is used as the ball milling medium, the ball-to-material ratio is 4:1, and the material:acetone is 1:1. The slurry after ball milling is dried, crushed and then mixed and ground evenly. Then put the ground sample into a muffle furnace for sintering, and carry out a solid-phase synthesis reaction in an air atmosphere. The temperature is raised from room temperature at a rate of 5°C / min, and the temperature is raised to 1000°C, kept for 7 hours, and then Cool to room temperature at a cooling rate of 5°C / min. Finally, the powder is ground and passed th...

Embodiment 2

[0048]According to the molar percentages of 98%, 1%, and 1%, the main phase titanium dioxide, the doped phase basic nickel carbonate and antimony oxide were weighed respectively, and then the mineralizer boric acid was added, and the boric acid accounted for 3wt% of the total mass of the main phase and the doped phase. The weighed raw material samples were put into a ball mill and wet ball milled for 3 hours. During ball milling, acetone is used as the ball milling medium, the ball-to-material ratio is 4:1, and the material:acetone is 1:1. The slurry after ball milling is dried, crushed and then mixed and ground evenly. Then put the ground sample into a muffle furnace for sintering, and carry out a solid-phase synthesis reaction in an air atmosphere. The temperature is raised from room temperature at a rate of 5°C / min, and the temperature is raised to 1100°C, kept for 6 hours, and then Cool to room temperature at a cooling rate of 5°C / min. Finally, the powder is ground and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com