GaN-based luminous diode chip with current blocking structure and manufacturing method thereof

A technology of light-emitting diodes and current blocking, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of limited current expansion capacity of ITO electrodes and inability to bond wires, etc., to improve external quantum efficiency, reduce light absorption, and improve light effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

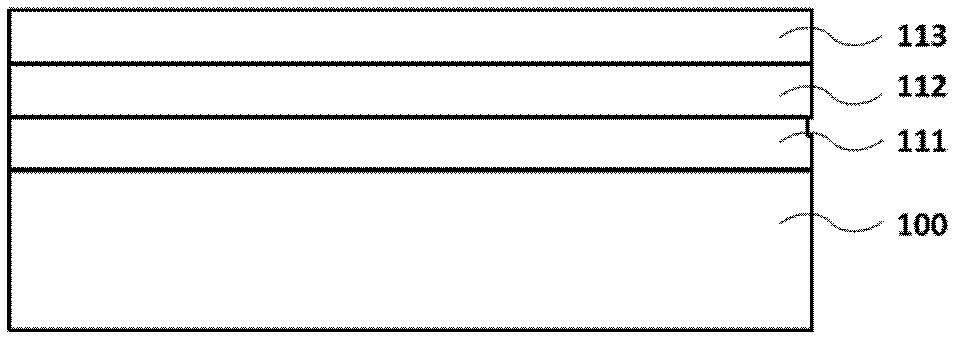

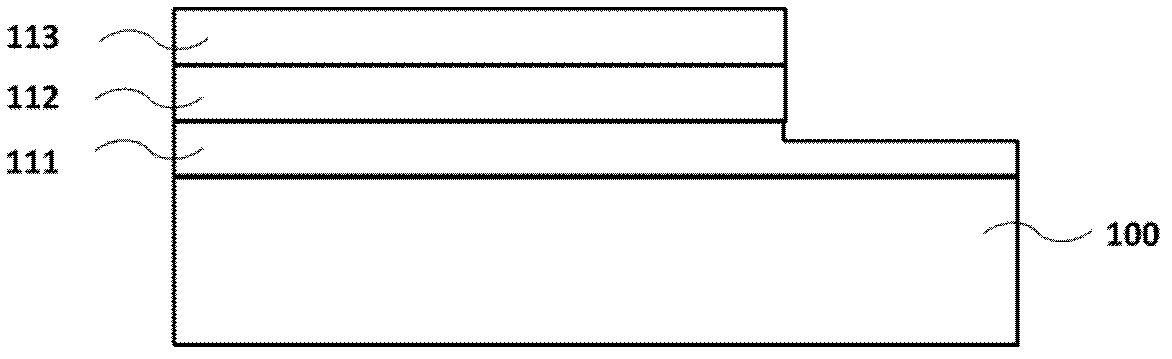

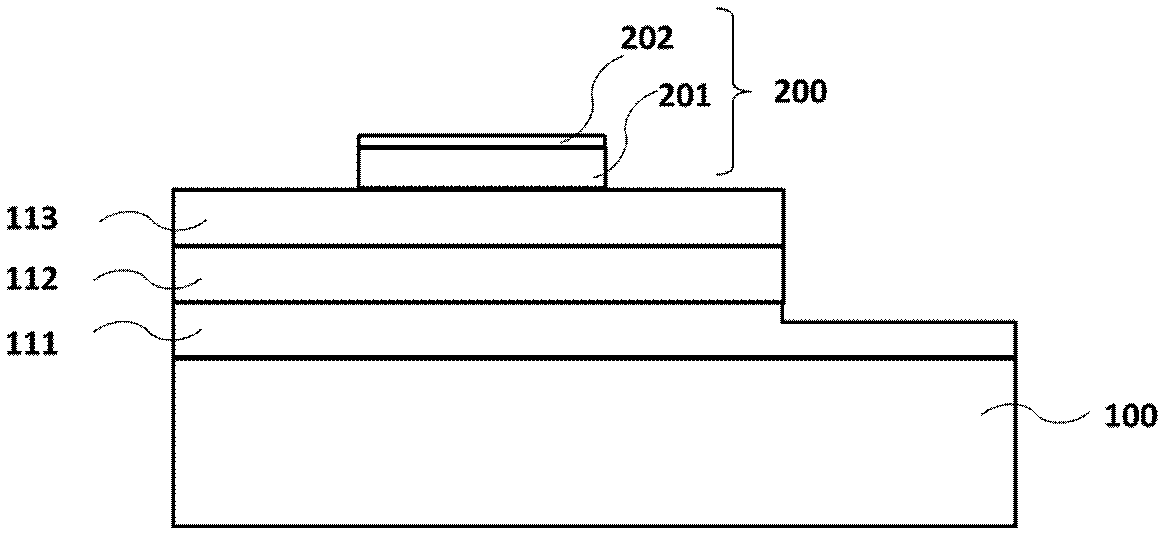

Embodiment 1

[0036]A GaN-based light-emitting diode chip with a current blocking structure, comprising an epitaxial layer structure, a p-electrode formed on the surface of the p-type GaN of the epitaxial layer structure, and an n-electrode formed on the surface of the n-type GaN of the epitaxial layer structure 400, the p-electrode is composed of an ITO transparent electrode 300 and a metal electrode 200, the metal electrode 200 is composed of upper and lower layers of metal materials, and the metal electrode is located between the ITO transparent electrode and p-type GaN and surrounded by the ITO transparent electrode In the middle, the lower layer 201 of the metal electrode is in Schottky contact with the p-type GaN surface, the metal electrode is in ohmic contact with the ITO transparent electrode, the ITO transparent electrode is in ohmic contact with the p-type GaN surface, and the ITO transparent electrode above the metal electrode is in ohmic contact. A window 301 is partly opened an...

Embodiment 2

[0048] A GaN-based light-emitting diode chip with a current blocking structure, as described in Embodiment 1, the difference is that the material of the upper layer of the metal electrode is chromium with a thickness of 100 nm, and the material of the lower layer of the metal electrode is aluminum with a thickness of 2.5 microns, The ITO transparent electrode part above the metal electrode has two windows and penetrates the upper layer of the metal electrode to expose the lower layer of the metal electrode, and the area of each window is 1 / 3 of the area of the metal electrode. The thickness of the ITO transparent electrode on the p-type GaN surface is 100 nm.

[0049] The n-electrode is different from the metal electrode, it is a Ti / Al electrode made separately, and Ti is located between the Al layer and n-GaN, the thickness of Ti is 100nm, and the thickness of Al is 2 microns.

[0050] The GaN-based light-emitting diode chip with the current blocking structure of this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com