High-response avalanche photodiode fabrication method

An avalanche photoelectric and diode technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of process complexity and high growth cost, and achieve the effect of increasing the light absorption length and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

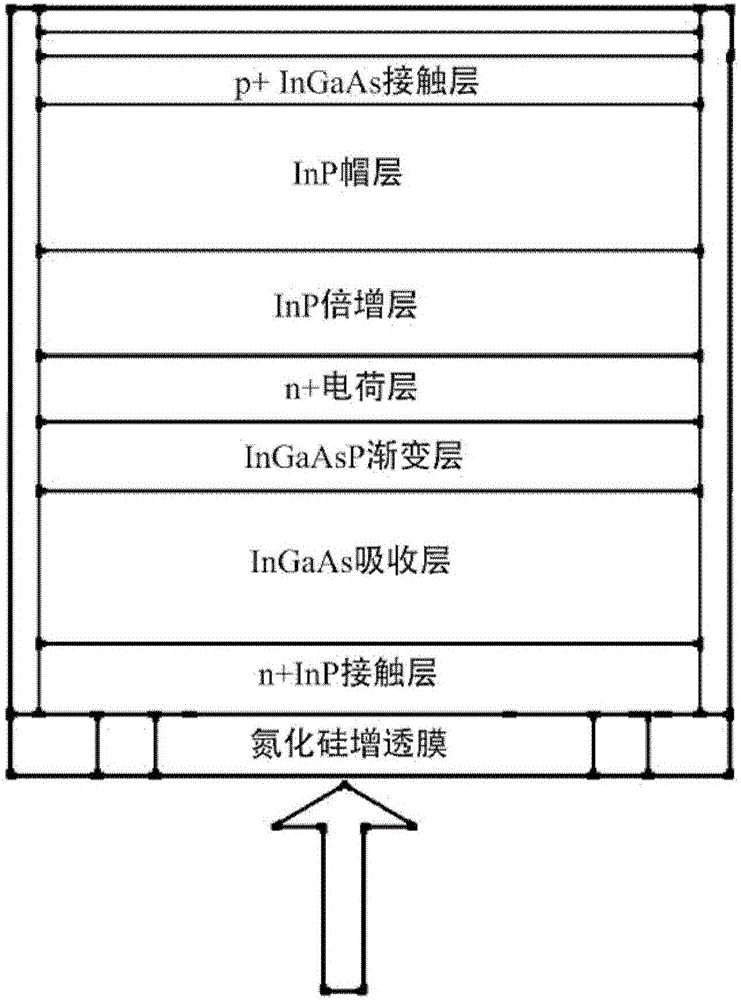

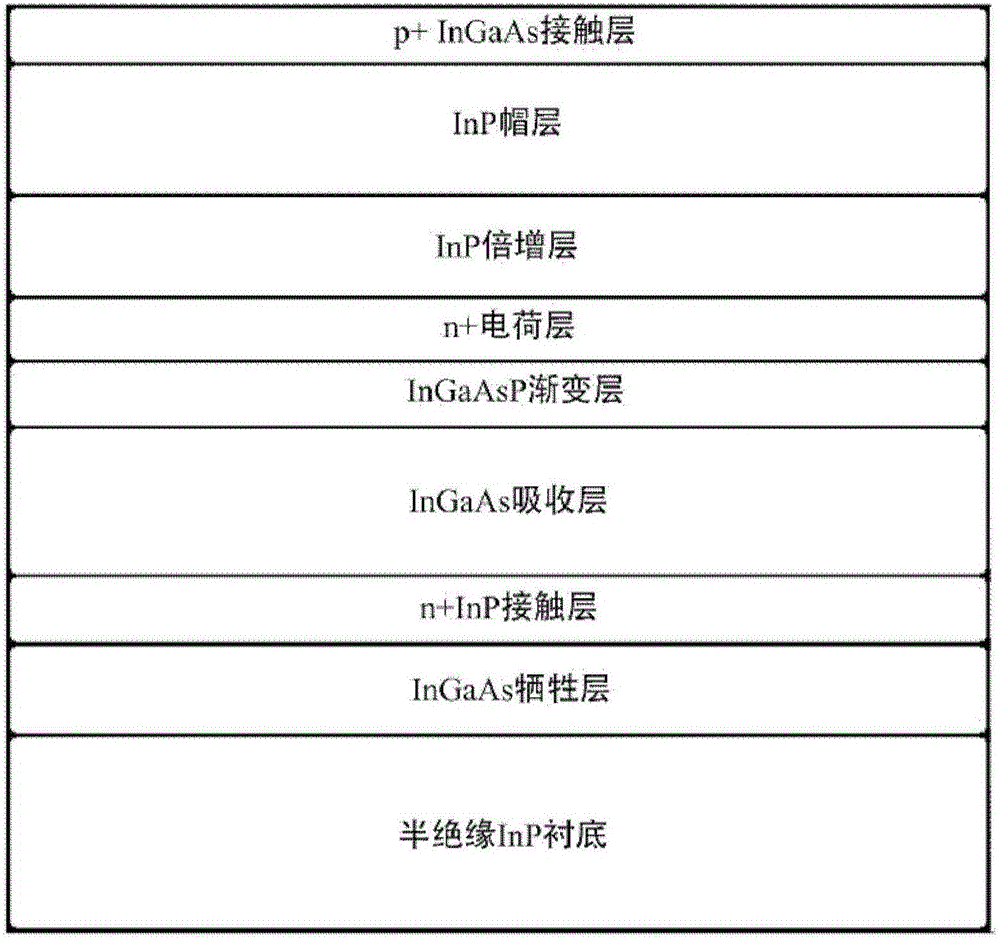

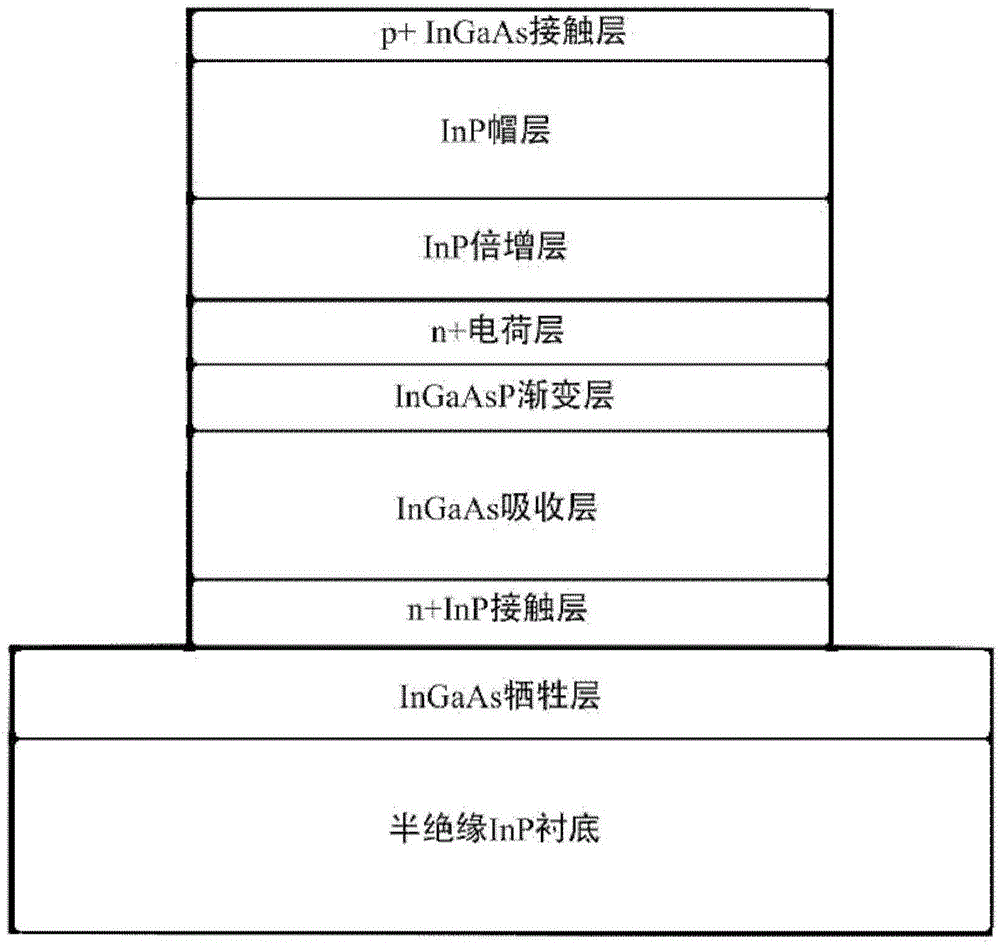

[0028] The invention proposes a manufacturing method of an avalanche photodiode, Figure 1-9 The process flow diagram corresponding to the manufacturing method is shown, see Figure 1-9 As shown, the method specifically includes the following steps:

[0029] Step 1: growing an epitaxial wafer, the structure of the epitaxial wafer specifically includes: a semi-insulating InP substrate, In 0.53 Ga 0.47 As sacrificial layer, N-type InP ohmic contact layer, In 0.53 Ga 0.47 As absorption layer, InGaAsP composition graded layer, thickness is 150nm, doping concentration is 1.5×10 17 cm -3 InP charge control layer, InP multiplication layer, InP cap layer, heavily doped P-type In 0.53 Ga 0.47 As ohmic contact layer;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com