Preparation method of transparent glass with intermediate infrared 3.9 mum luminescence characteristic at room temperature

A technology of luminous properties and transparent glass, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of small absorption coefficient, λ~888nm laser diode is not very effective, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

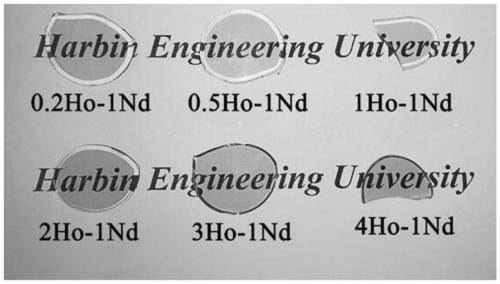

[0022] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] Table 1 shows the glass formulations of 6 examples of the present invention.

[0024] Table 1: the glass component of concrete 6 embodiments

[0025]

[0026] Embodiment 1 to embodiment 6 all adopt the same glass melting process, and its specific preparation process is as follows:

[0027] (1) Calculate the mass of each component according to the molar percentage (mol%) of the glass composition shown in Table 1, weigh the raw materials in a nitrogen-filled glove box, grind them for 20 minutes to make them fully mixed;

[0028] (2) Put the mixture into a platinum crucible and melt it in an electric furnace at 850 degrees Celsius for 30 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com