Nano structure yttrium aluminum garnet-based transparent ceramic material, preparation method and application thereof

A technology of yttrium aluminum garnet and transparent ceramics, which is applied in the field of nanostructure yttrium aluminum garnet-based transparent ceramic materials, and can solve problems such as the influence of light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

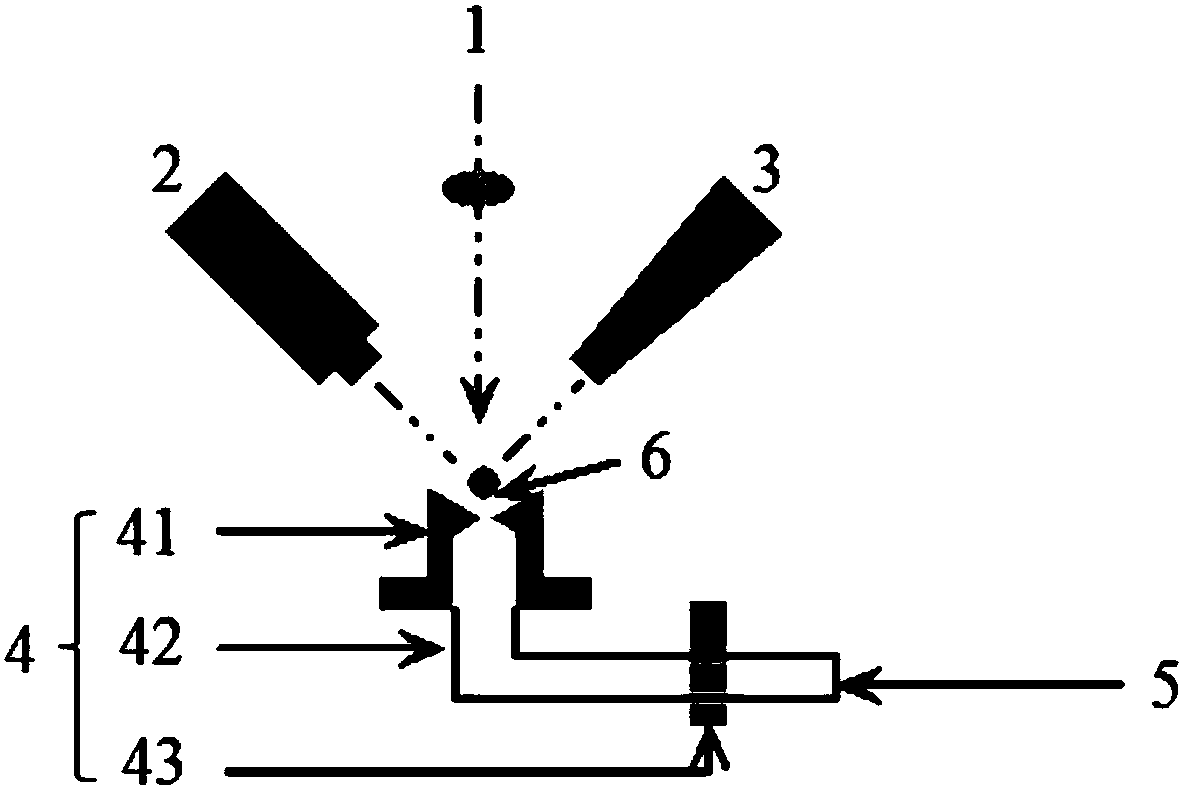

[0094] Example 1-12: Preparation of nanostructured YAG-based transparent ceramic material by pneumatic suspension without container solidification-amorphous crystallization method

[0095] First, the bulk glass precursor material was prepared by a pneumatic suspension container-free solidification method. The specific method is as follows:

[0096] (1) According to the raw material proportioning (molar percentage composition) of the embodiment 1-12 listed in table 1, take Y respectively 2 o 3 Raw materials, Al 2 o 3 Raw materials and optional other metal oxide raw materials Re 2 o 3 (where, Re 2 o 3 It is a rare earth oxide, specifically: cerium oxide (CeO 2 ), dysprosium oxide (Dy 2 o 3 ), erbium oxide (Er 2 o 3 ), europium oxide (Eu 2 o 3 ), gadolinium oxide (Gd 2 o 3 ), holmium oxide (Ho 2 o 3 ), lanthanum oxide (La 2 o 3 ), lutetium oxide (Lu 2 o 3 ), neodymium oxide (Nd 2 o 3 ), praseodymium oxide (Pr 6 o 11 ), samarium oxide (Sm 2 o 3 ), terbiu...

Embodiment 13

[0105] In the preparation process of the amorphous crystallization method, the heat treatment regime is heat treatment at 1100° C. for 2 hours, and the other preparation methods and conditions are the same as in Example 3 to obtain a nanostructured YAG-based transparent ceramic material.

[0106] figure 2 It is an optical photograph of the YAG-based transparent ceramic material of Example 13.

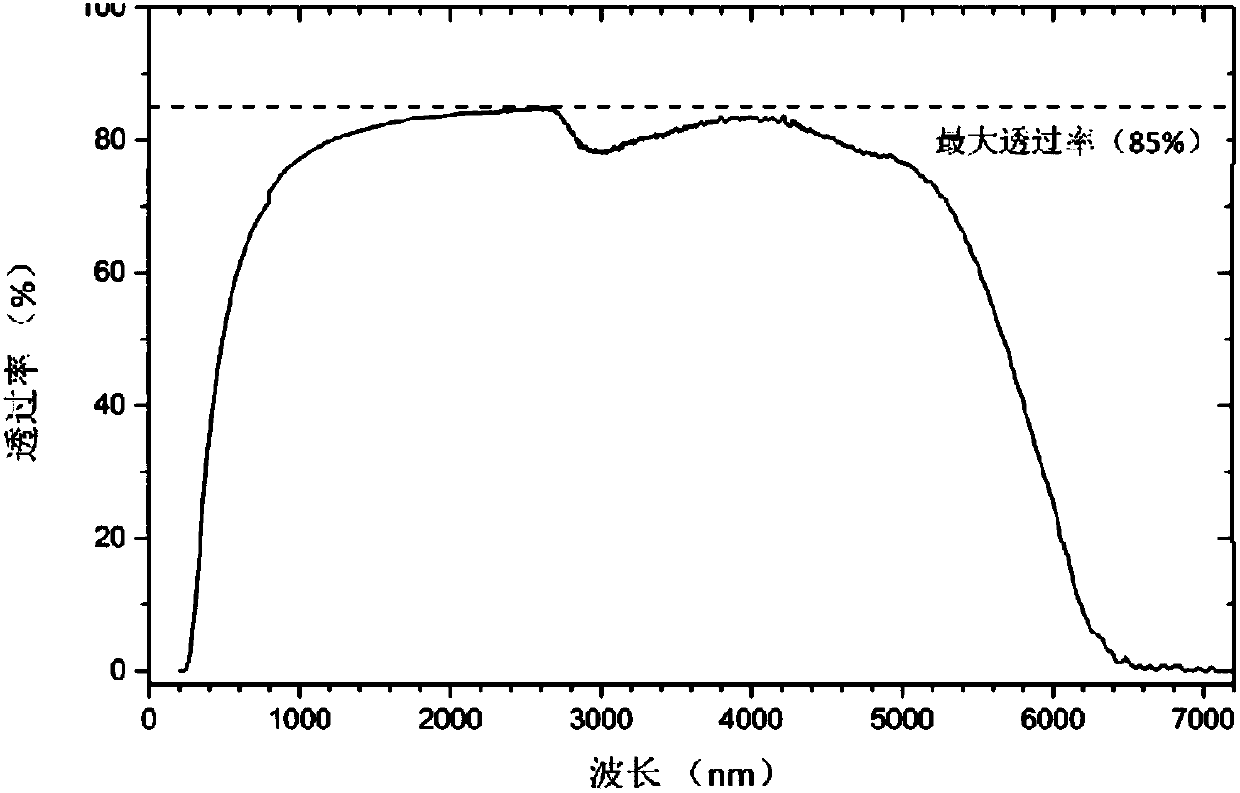

[0107] image 3 It is the transmittance curve of the YAG-based transparent ceramic material in the visible light to mid-infrared band in Example 13. It can be seen from the figure that the sample is highly transparent in the visible light to mid-infrared band, and the highest transmittance has reached that of a YAG single crystal. The theoretical maximum transmittance (85%), the infrared cut-off wavelength is as high as 6.5μm.

[0108] Figure 4 It is the microstructure photograph of the nanostructure YAG-based transparent ceramic material of the present embodiment 13, as can be see...

Embodiment 14-20

[0109] Example 14-20: Preparation of YAG-based transparent ceramic material by flame spray quenching-viscous sintering-amorphous crystallization method

[0110] First, the micron glass powder is prepared by the flame spray quenching method, the specific method is as follows:

[0111] (1) Synthetic crystalline raw material powder: according to the raw material proportioning (mol percentage) of the embodiment 14-20 listed in table 3, take Y respectively 2 o 3 Raw materials, Al 2 o 3 Feedstock and optional CeO 2 Raw material, the raw material is high-purity (99.99%) powder or analytically pure (98%) powder, after being fully mixed, heated to 1500 ° C in the air for reaction and kept for 2 hours, and the obtained powder is ball-milled to 1 μm-2 μm;

[0112] (2) The powder described in step (1) is granulated: prepare PVA, PAA, n-octanol and solids content to be respectively 0.5%, 0.5%, 0.5% and 65% granulation slurry, spray granulation The machine sprays and granulates the slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com