Material for photoelectric conversion element for use in imaging element, and photoelectric conversion element including same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Photoelectric Conversion Element and Evaluation Thereof

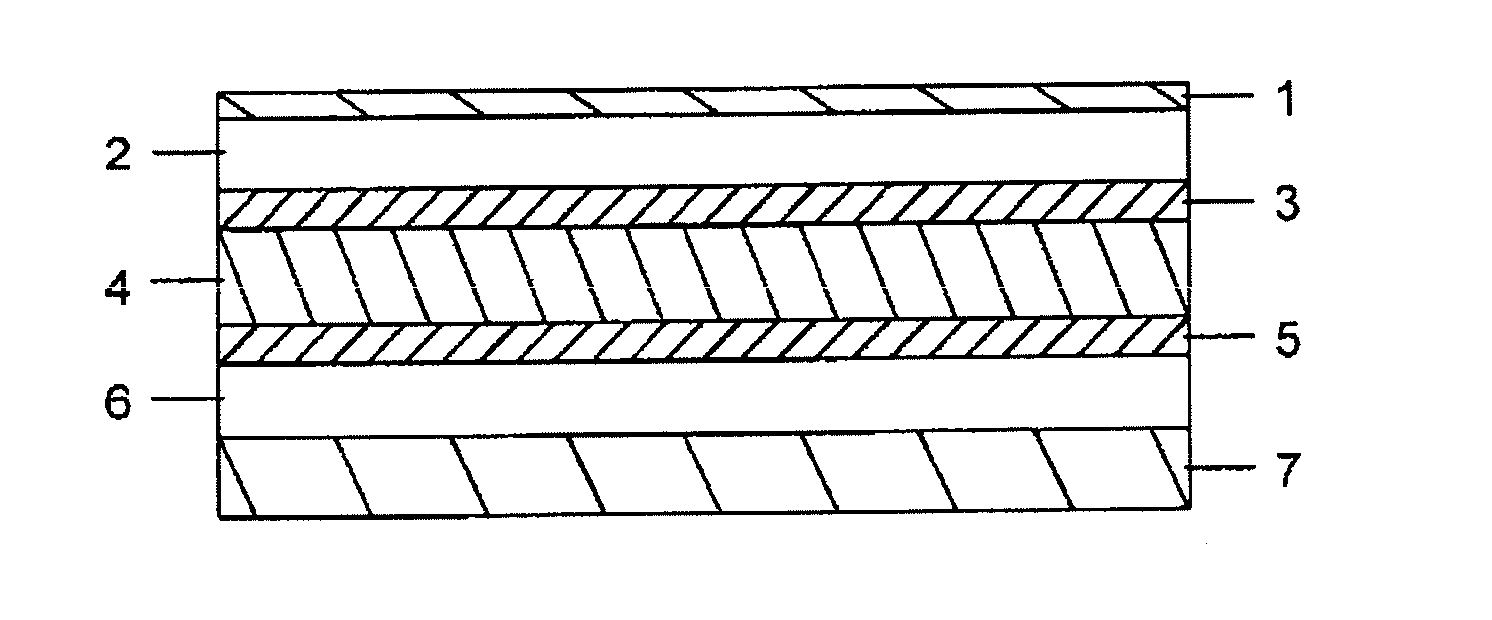

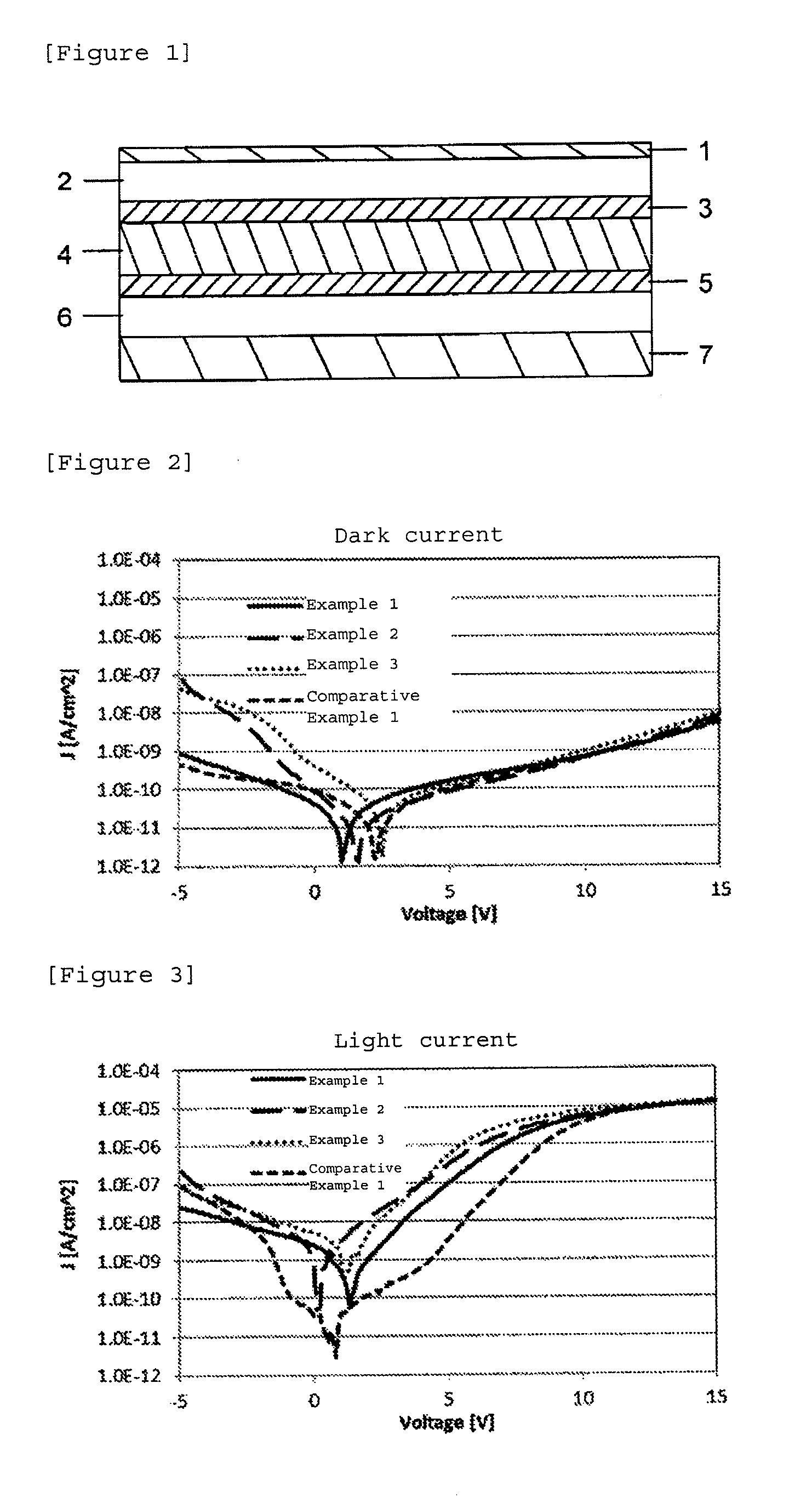

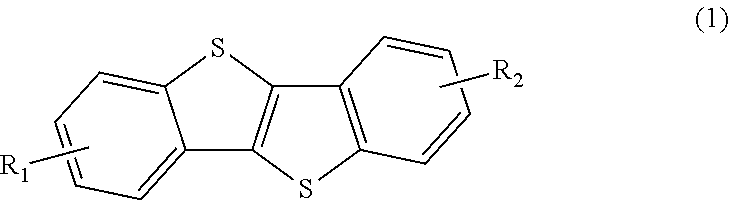

[0072]On ITO transparent conductive glass (manufactured by GEOMATEC Co., Ltd., ITO film thickness: 150 nm), a film of 2,7-diphenyl[1]benzothieno[3,2-b][1]benzothiophene (compound represented by the formula (11) in the specific examples described above) was formed as a blocking layer having a thickness of 50 nm by resistance heating vacuum vapor deposition. Next, on the blocking layer, a film of quinacridone was formed in vacuum as a photoelectric conversion layer having a thickness of 100 nm. Finally, on the photoelectric conversion layer, a film of aluminum was formed in vacuum as an electrode having a thickness of 100 nm to prepare the photoelectric conversion element for use in an imaging element of the present invention. When a voltage of 5 V was applied using the ITO and aluminum electrodes, the current in the dark was −1.68×10−10 A / cm2. When a voltage of 5 V was applied to the transparent conductive glass si...

example 2

Preparation of Photoelectric Conversion Element and Evaluation Thereof

[0073]On ITO transparent conductive glass (manufactured by GEOMATEC Co., Ltd., ITO film thickness: 150 nm), a film of 2,7-bis(4-methylphenyl)[1]benzothieno[3,2-b][1]benzothiophene (compound represented by the formula (14) in the specific examples described above) was formed as a blocking layer having a thickness of 50 nm by resistance heating vacuum vapor deposition. Next, on the blocking layer, a film of quinacridone was formed in vacuum as a photoelectric conversion layer having a thickness of 100 nm. Finally, on the photoelectric conversion layer, a film of aluminum was formed in vacuum as an electrode having a thickness of 100 nm to prepare the photoelectric conversion element for use in an imaging element of the present invention. When a voltage of 5 V was applied using the ITO and aluminum electrodes, the current in the dark was −8.85×10−11 A / cm2. When a voltage of 5 V was applied to the transparent conducti...

example 3

Preparation of Photoelectric Conversion Element and Evaluation Thereof

[0074]On ITO transparent conductive glass (manufactured by GEOMATEC Co., Ltd., ITO film thickness: 150 nm), a film of 2,7-bis(4-ethylphenyl)[1]benzothieno[3,2-b][1]benzothiophene (compound represented by the formula (15) in the specific examples described above) was formed as a blocking layer having a thickness of 50 nm by resistance heating vacuum vapor deposition. Next, on the blocking layer, a film of quinacridone was formed in vacuum as a photoelectric conversion layer having a thickness of 100 nm. Finally, on the photoelectric conversion layer, a film of aluminum was formed in vacuum as an electrode having a thickness of 100 nm to prepare the photoelectric conversion element for use in an imaging element of the present invention. When a voltage of 5 V was applied using the ITO and aluminum electrodes, the current in the dark was 1.41×10−10 A / cm2. When a voltage of 5 V was applied to the transparent conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com