Flat response composite filter and manufacturing method thereof

A composite filter and filter technology, which is applied in the field of soft X-ray radiation flow quantitative measurement, can solve the problems affecting the composite filter yield and response performance, high requirements for experimental calibration and use, and affecting the accuracy of radiation flow measurement. Achieve the effect of excellent surface flatness, high yield and low uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

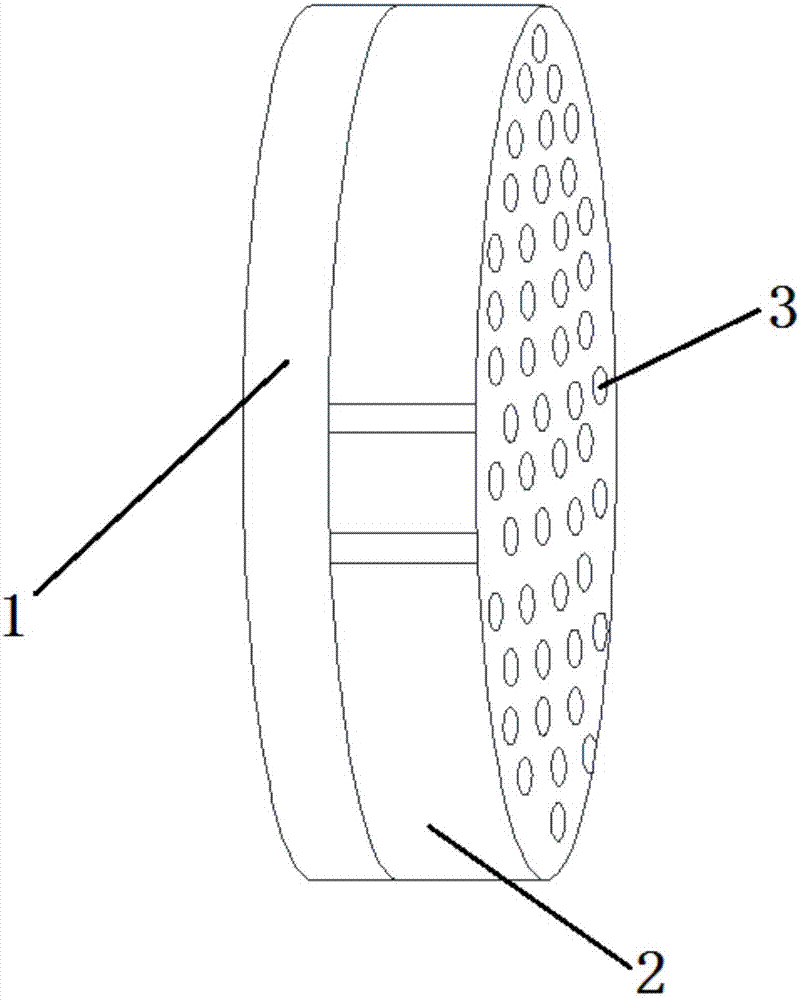

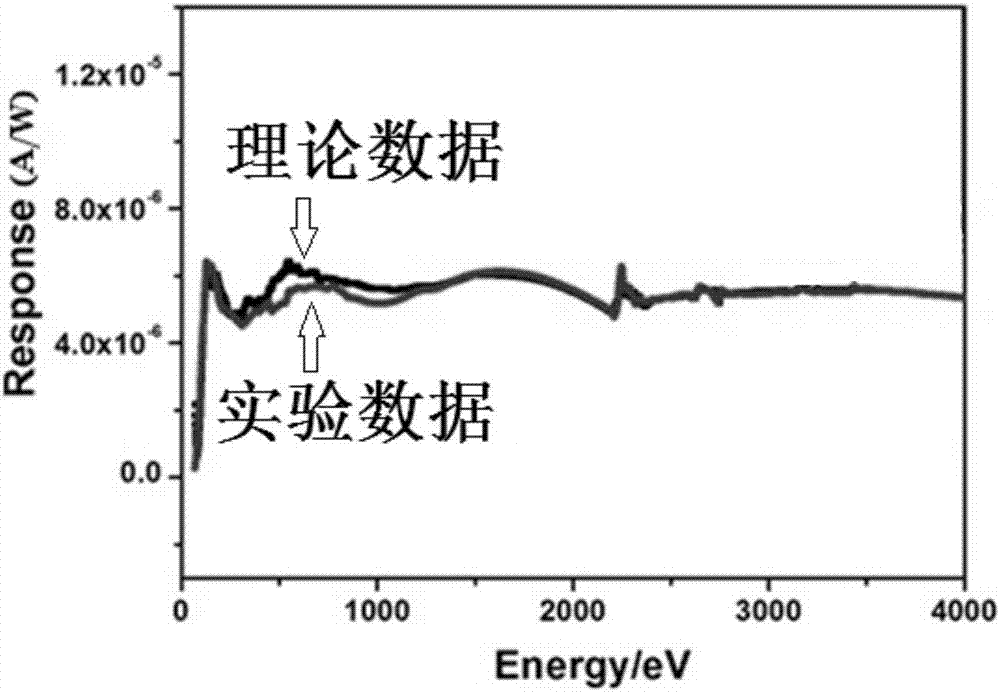

[0059] The preparation method of the flat response composite filter of the present invention is simple in process. The second gold layer 2 with a specific porous structure is prepared on one surface of the first gold layer 1, and a composite gold layer with a certain area ratio can be obtained. The composite filter has high yield and excellent surface smoothness, which can effectively complete the quantitative measurement of soft X-ray radiation flow in the field of inertial confinement fusion, such as black cavity physics, radiation transport, radiation ablation, radiation opacity, and implosion dynamics.

[0060] In a preferred embodiment of the present invention, the thickness of the first gold layer 1 is 45-55 nm, preferably 48-52 nm, and more preferably 50 nm.

[0061] In a preferred embodiment of the present invention, the thickness of the second gold layer 2 is 370-390 nm, preferably 375-385 nm, and more preferably 380 nm.

[0062] In a preferred embodiment of the present inve...

Embodiment 1

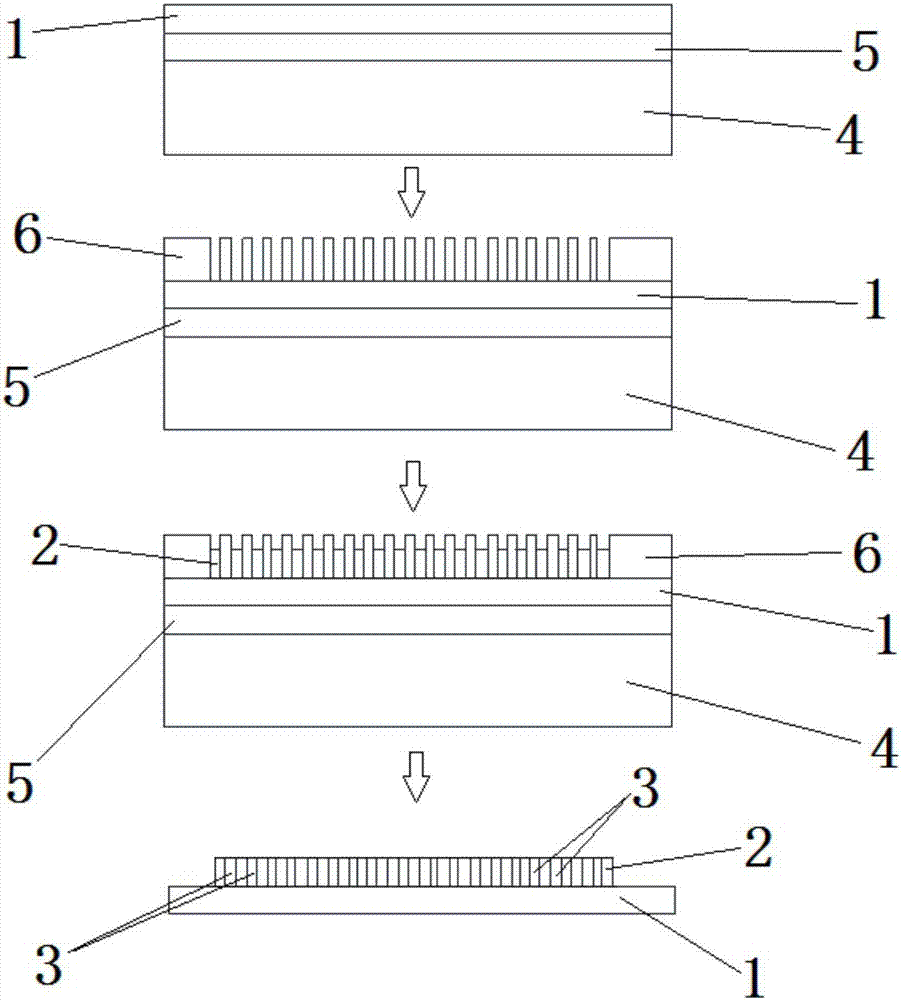

[0103] A method for preparing a flat response composite filter includes the following steps:

[0104] (1) Preparation of the first gold layer: heat the substrate silicon wafer at 140°C for 10 minutes, then spin-coat a polyimide corrosion barrier layer of about 1.5 μm thick and perform imidization treatment according to the set time and temperature ( The imidization is carried out by conventional heat treatment methods, specifically heat treatment at 85°C for 1 hour, heat treatment at 135°C for 1 hour, heat treatment at 185°C for 1 hour, heat treatment at 270°C for 4-6 hours, and natural cooling to room temperature). Magnetron sputtering deposition of 45nm thick gold on the imine film to obtain the first gold layer;

[0105] (2) Preparation of the second gold layer: spin-coated AZ5214 photoresist (produced by Changsha Jinxin Electronic Materials Co., Ltd.) with a thickness of about 1.4μm, heated at 80°C for 1 min, under the cover of a template with a preset pattern UV exposure was ...

Embodiment 2

[0108] A method for preparing a flat response composite filter includes the following steps:

[0109] (1) Preparation of the first gold layer: heat the substrate silicon wafer at 160°C for 20 minutes, and then spin-coat a 2μm thick polyimide corrosion barrier layer and perform imidization treatment according to the set time and temperature (using The conventional heat treatment method is used for imidization, specifically, heat treatment at 85°C for 1 hour, heat treatment at 135°C for 1 hour, heat treatment at 185°C for 1 hour, heat treatment at 270°C for 4-6 hours, and natural cooling to room temperature), in polyimide Depositing 55nm thick gold on the amine film by magnetron sputtering to obtain the first gold layer;

[0110] (2) Preparation of the second gold layer: spin-coated AZ5214 photoresist (produced by Changsha Jinxin Electronic Materials Co., Ltd.) with a thickness of about 1.8μm, heated at 100°C for 3 minutes, under the cover of a template with a preset pattern UV expo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com