Anti-electromagnetic radiation ultrathin film, device, preparation method and application

An anti-electromagnetic radiation, ultra-thin film technology, applied in sputtering coating, electrical components, magnetic field/electric field shielding, etc., can solve the problem of low transmittance in the visible light band, inability to realize ultra-broadband electromagnetic shielding, complex structure and manufacturing process and other problems, to achieve the effect of excellent electromagnetic shielding effect, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In a third aspect, the present invention provides a method for preparing the above-mentioned ultra-thin film for preventing electromagnetic radiation, comprising the steps of:

[0039] It is prepared by electron beam evaporation coating technology or magnetron sputtering technology.

[0040] In a fourth aspect, the present invention provides the application of the above-mentioned ultra-thin film for preventing electromagnetic radiation in observation windows of microwave anechoic chambers and electromagnetic compatibility rooms, or application in protective glass of secret rooms.

Embodiment 1

[0042] An ultra-thin film with high transmittance in the visible light band and high shielding property in the microwave band is prepared by using titanium oxide and metal silver.

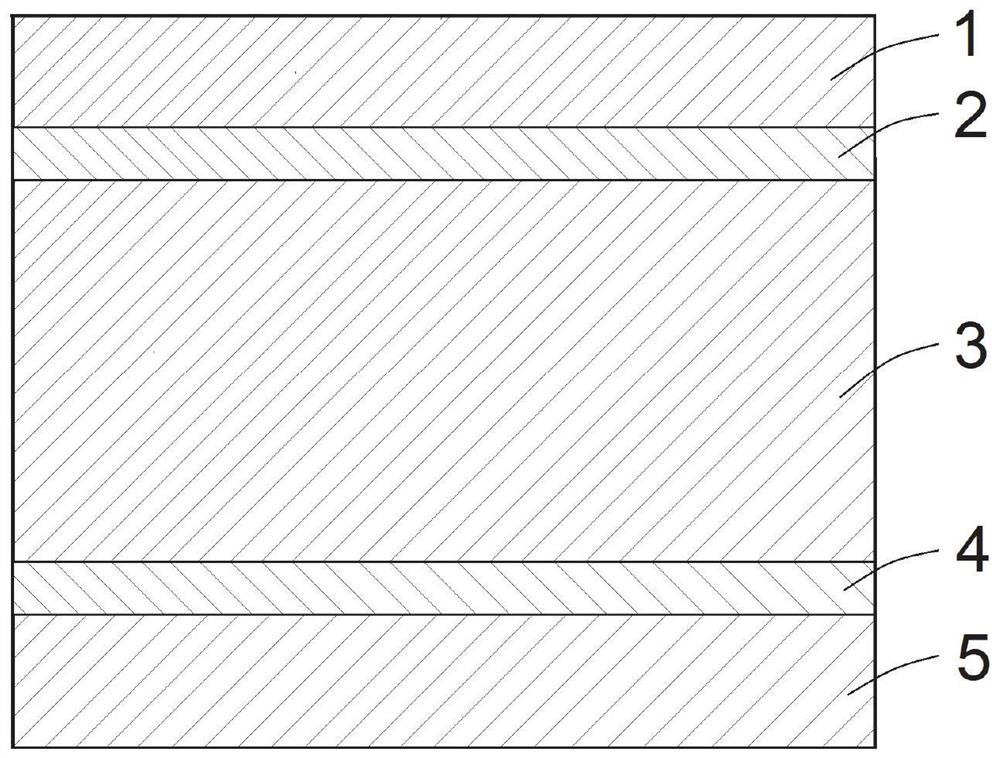

[0043] Such as figure 1 As shown, the first dielectric layer of the ultra-thin film is a 40nm titanium oxide layer, the first metal layer is a 12nm silver layer, the second dielectric layer is an 80nm titanium oxide layer, and the second metal layer is a 12nm silver layer. The third dielectric layer is a 40nm titanium oxide layer.

[0044] The ultra-thin film is integrally prepared on a glass substrate with a refractive index of 1.52 by electron beam evaporation process.

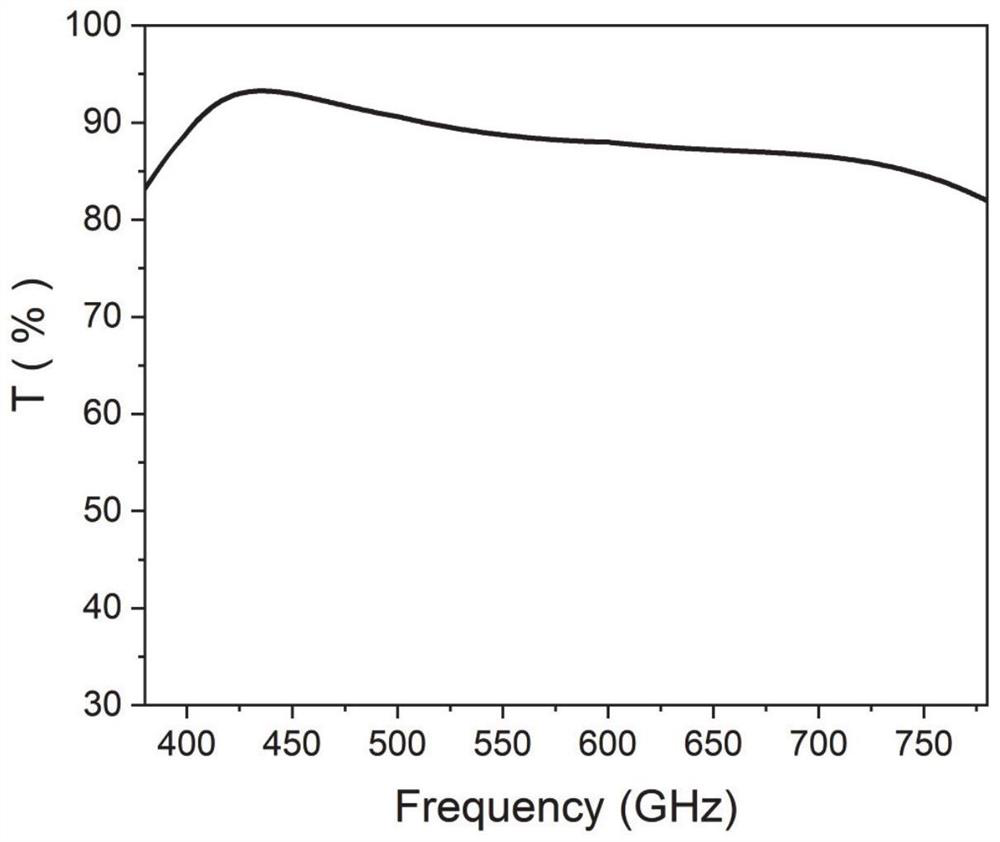

[0045] figure 2 Because of the transmission spectrum of the ultra-thin film in the visible light band, in the wavelength range of the visible light range (380-780nm), the transmittance exceeds 80%.

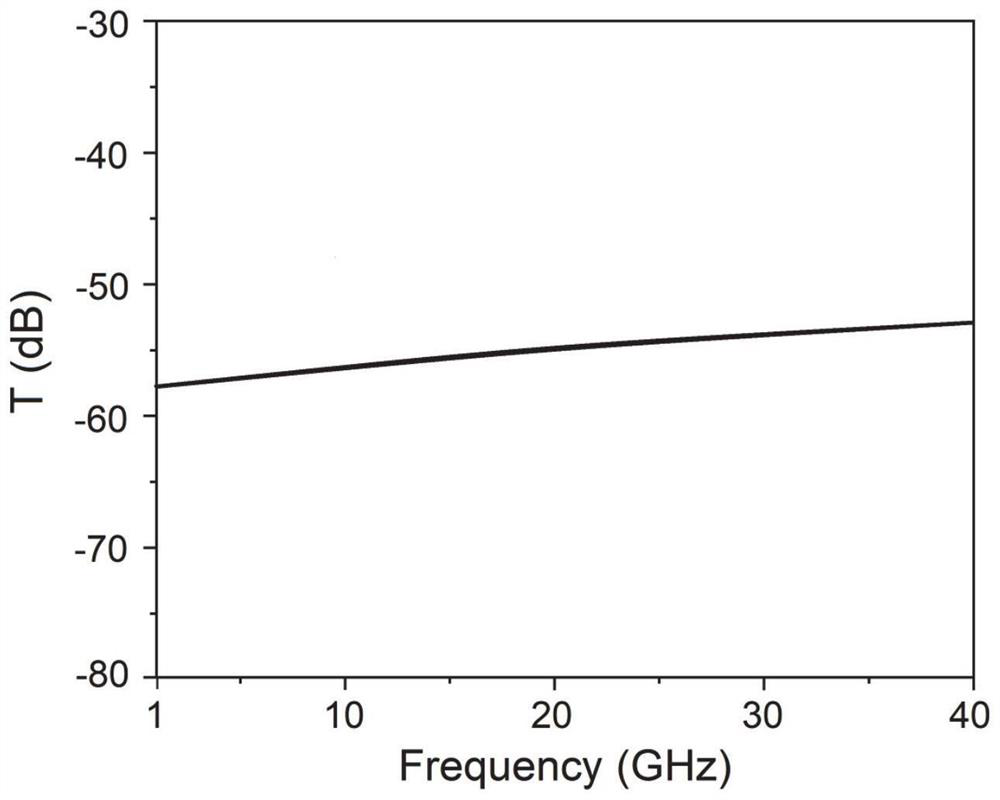

[0046] image 3 Because of the transmission spectrum of the ultra-thin film in the microwave section, the electromagnetic shie...

Embodiment 2

[0048] An ultra-thin film with high transmittance in the visible light band and high shielding property in the microwave band is prepared by using silicon oxide and metal silver.

[0049] The first dielectric layer of the ultra-thin film is a 50nm silicon oxide layer, the first metal layer is a 15nm gold layer, the second dielectric layer is a 100nm silicon oxide layer, the second metal layer is a 15nm gold layer, and the third dielectric layer is a 15nm gold layer. The layer is a 50nm silicon oxide layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com