Application of polybenzimidazole polymer containing side group in proton exchange membrane

A polybenzimidazole and proton exchange membrane technology, which is applied in the parts of fuel cells, solid electrolyte fuel cells, etc., can solve problems such as limited application and reduced proton conductivity, and achieve high doping level, high stability, Effects of high phosphoric acid doping levels and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Preparation of polybenzimidazole film containing benzene side group

[0032] Take 1.0000g polybenzimidazole polymer containing phenyl side groups, add 10ml DMSO, stir at room temperature until it completely dissolves into a homogeneous transparent brown solution, then pour the solution onto a clean 10cm×10cm glass plate, and Bake at 80°C for 12 hours, at 100°C for 12 hours, at 120°C for 12 hours, at 120°C for 24 hours under vacuum, and cool to room temperature to obtain a transparent polybenzimidazole film.

Embodiment 2

[0033] Example 2: Preparation of Phosphoric Acid Doped Polybenzimidazole Film Containing Benzene Side Groups

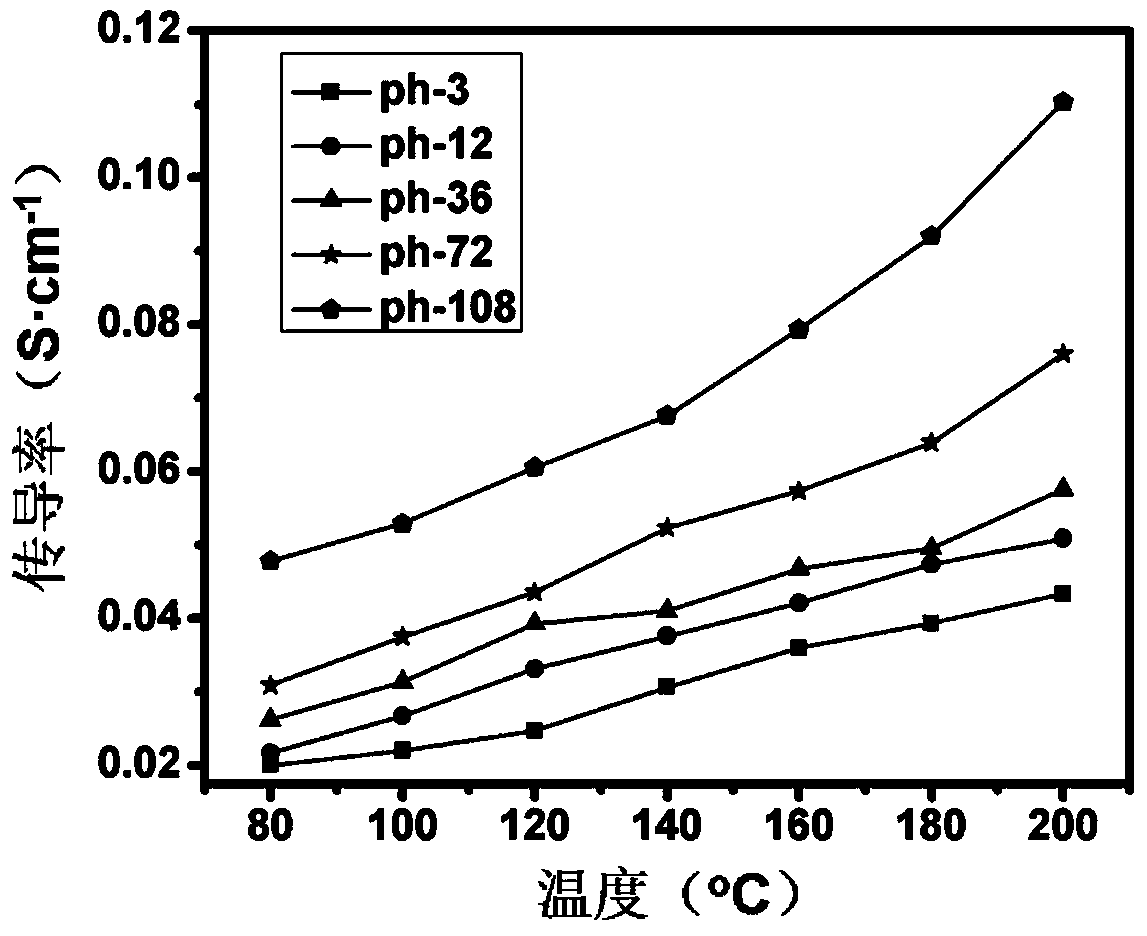

[0034] The polybenzimidazole film obtained in Example 1 was immersed in a petri dish filled with phosphoric acid with a mass concentration of 85%, and phosphoric acid adsorption was carried out at a high temperature of 160°C. Set different adsorption times, respectively: 3h, 12h, 36h, 72h, 108h, and filter the removed films (named: ph-3, ph-12, ph-36, ph-72, ph-108) with filter paper Wipe off the acid on the surface, and then bake in a vacuum oven at 100° C. for 5 hours to obtain polybenzimidazole films with different doping levels (see Table 1) containing benzene side groups.

Embodiment 3

[0035]Example 3: Testing of the proton conductivity of phosphoric acid-doped polybenzimidazole films containing benzene side groups

[0036] Using a Princeton Applied Research Model 2273 conductivity testing instrument model 2273, the conductivity of the membrane was tested by the four-electrode method. The test conditions were: the frequency of the AC impedance was 0.1-100kHz, and the amplitude was 10mV. The conductivities of films with different doping levels were tested in the temperature range of 80-200°C.

[0037] The test was carried out under dry conditions. A 50mm×10mm rectangular film sample was cut from the 5 films with different adsorption times obtained in Example 2, and the sample was fixed on a fixture to test its Proton conductivity in the temperature range of 80-200°C, among which the conductivity of the film with an adsorption time of 108h reaches 0.110S at 200°C. cm -1 , see figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com