IGBT module heat-radiation apparatus

A heat dissipation device and heat sink technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of no temperature uniformity structural design, long-term working reliability, uneven temperature distribution, etc., to increase wind speed, enhance Effect of gas turbulence and large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

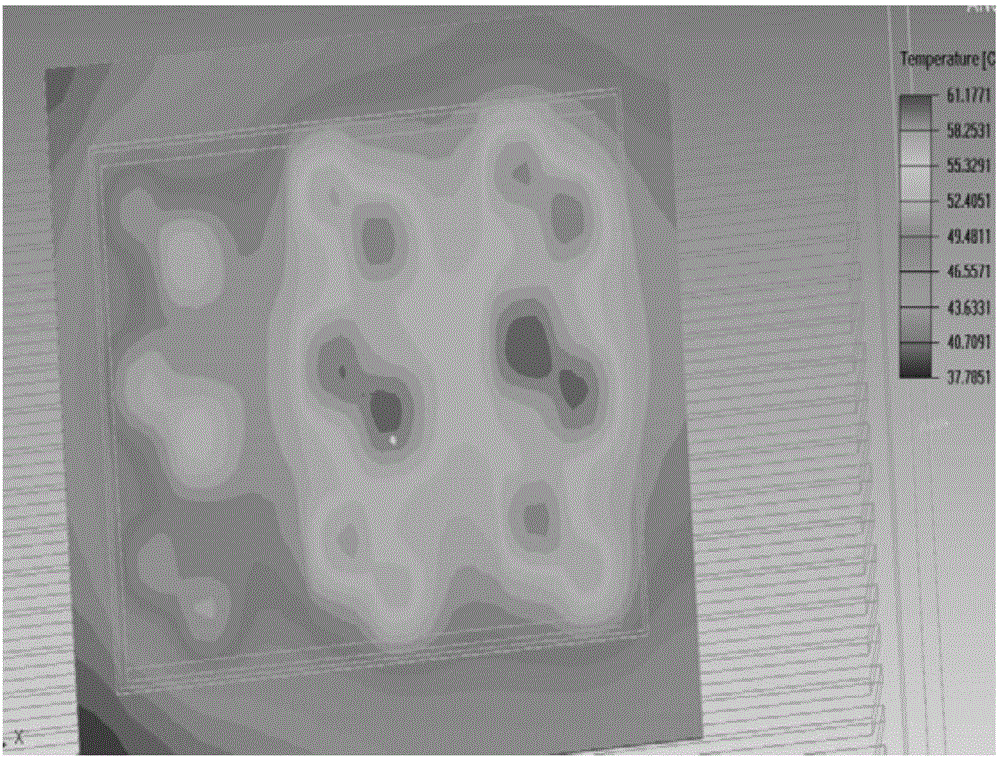

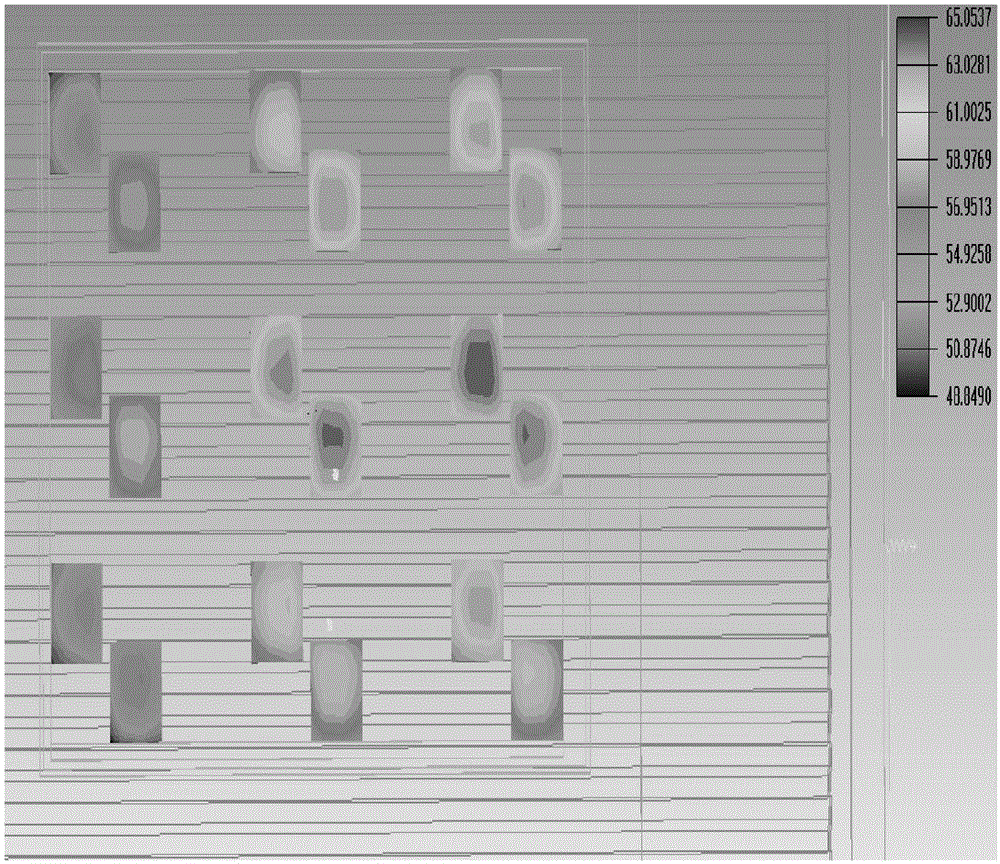

[0030] As mentioned in the background technology, in the existing IGBT module cooling device, when the airflow flows through the cooling device evenly, the temperature of the air inlet is relatively low, and the temperature of the air outlet is relatively high, so the temperature distribution of the entire radiator is uneven during the working process, and the IGBT module The thermal stress of each position of the bottom plate is different, and the reliability will be seriously affected after long-term operation.

[0031] Next, the specific technical solution of the present invention will be introduced in detail.

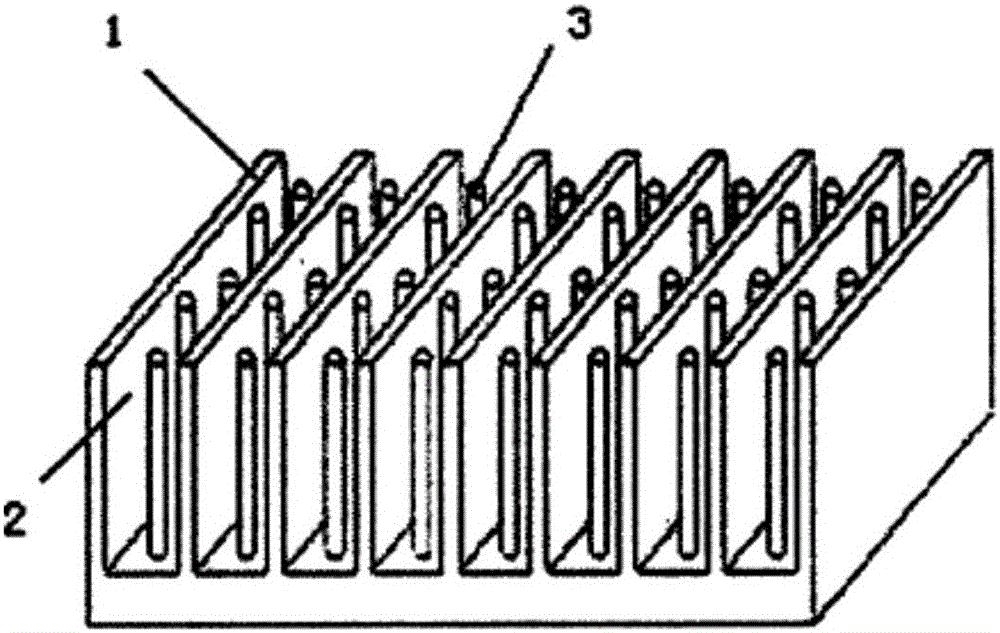

[0032] A kind of IGBT module cooling device 1, described cooling device 1 needs forced cooling, is provided with fan on one side of cooling device 1, and the thermal resistance of air-cooled radiator and flow resistance are the main parameters that measure radiator performance, in cooling device Under the same volume and heat dissipation conditions, heat sinks with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com