Water dephosphorization agent and preparation method thereof

A phosphorus removal agent and water body technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of large dosage of phosphorus removal agent, poor phosphorus removal effect, etc. The effect of increasing adsorption activity and reducing input amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

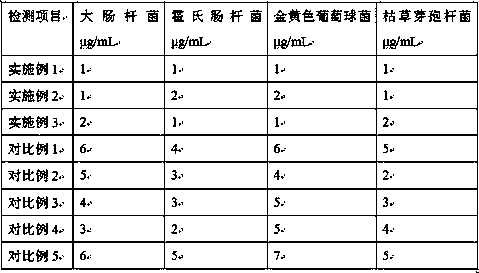

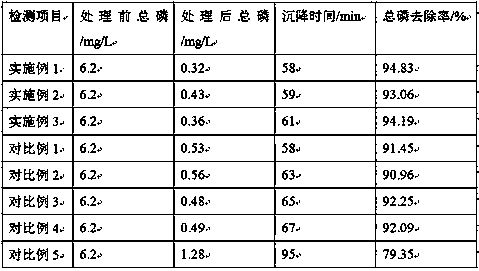

Examples

preparation example Construction

[0023] The preparation method of surfactant is:

[0024] (1) Take capric acid and add toluene at a mass ratio of 1~3:10~15, stir and mix at 20~25°C for 20~30min, then add N,N-dimethyl-1 with 50~60% capric acid mass, 3-Propylenediamine, stirred and mixed at 30~40°C for 1~3h, distilled under reduced pressure, took the reduced pressure distillate and added 1% sodium carbonate solution with a mass fraction of 1~5:10~20, stirred and mixed for 30 ~40min to obtain the stirred mixture, take the stirred mixture and add toluene according to the mass ratio of 2~5:10~15, let it stand for 30~50min, filter with suction, take the suction filter residue and distill under reduced pressure to obtain the vacuum distillate a;

[0025] (2) Take the vacuum distillate a and add acetone at a mass ratio of 1~3:5~10, stir and mix at 25~30°C for 20~40min, then add 1,3- Dibromopropane, stir and mix at 40~50°C for 2~4h, then rotovap, take the residue of rotovap and add 80% ethanol according to the mass r...

Embodiment 1

[0036] The preparation method of surfactant is:

[0037] (1) Take capric acid and add toluene at a mass ratio of 1:10, stir and mix at 20°C for 20 minutes, then add N,N-dimethyl-1,3-propylenediamine containing 50% capric acid mass, and stir at 30°C Mix for 1 hour, distill under reduced pressure, take the reduced-pressure distillate and add 1% sodium carbonate solution with a mass fraction of 1:10, stir and mix for 30 minutes to obtain a stirred mixture, take the stirred mixture and add toluene at a mass ratio of 2:10, statically Set aside for 30 minutes, filter with suction, take the suction filter residue and distill under reduced pressure to obtain the reduced-pressure distillate a;

[0038] (2) Take the vacuum distillate a and add acetone at a mass ratio of 1:5, stir and mix at 25°C for 20 minutes, then add 1,3-dibromopropane with 40% mass of the vacuum distillate a, stir and mix at 40°C for 2 hours , rotary evaporation, take the rotary evaporation residue and add 80% etha...

Embodiment 2

[0049] The preparation method of surfactant is:

[0050] (1) Take capric acid and add toluene at a mass ratio of 3:15, stir and mix at 25°C for 30 minutes, then add N,N-dimethyl-1,3-propylenediamine containing 60% capric acid mass, and stir at 40°C Mix for 3 hours, distill under reduced pressure, take the reduced-pressure distillate and add 1% sodium carbonate solution according to the mass ratio of 5:20, stir and mix for 40 minutes to obtain a stirred mixture, take the stirred mixture and add toluene according to the mass ratio of 5:15, statically Set aside for 50 minutes, filter with suction, and distill the residue under reduced pressure to obtain the reduced-pressure distillate a;

[0051] (2) Take the vacuum distillate a, add acetone at a mass ratio of 3:10, stir and mix at 30°C for 40 minutes, then add 1,3-dibromopropane with a mass ratio of 60% of the vacuum distillate a, and stir and mix at 50°C for 4 hours , rotary evaporation, take the rotary evaporation residue and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com