Preparation method of mold-proof water-resistant bamboo-plastic composite material

A composite material and water-resistant technology, which is applied in the field of bamboo-plastic composite material preparation, can solve the problems of poor compatibility between bamboo fiber and thermoplastics, decreased mechanical properties of composite materials, and poor melt fluidity of materials, so as to improve mechanical properties and improve dispersion The effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

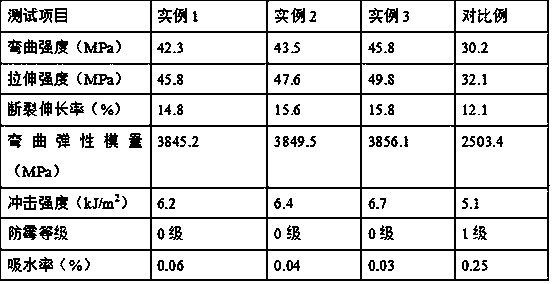

Examples

example 1

[0023]Weigh 10g of nano-zinc oxide with a particle size of 24nm and pour it into a beaker with 9mL of deionized water and 50mL of absolute ethanol, and ultrasonically disperse it for 30min with an ultrasonic disperser to obtain a nano-zinc oxide dispersion. The nano-zinc oxide dispersion and The silane coupling agent KH-550 is mixed in a beaker at a mass ratio of 3:1, stirred and reacted for 1 hour at a temperature of 75°C to obtain a mixed solution, and the mixed solution is put into a centrifuge at a speed of 1000r / Centrifuge for 45 minutes under the condition of 1 min, separate the precipitate, and wash the precipitate with absolute ethanol for 3 times, and finally put it into a vacuum drying oven, dry it at 65°C for 1 hour, cool and discharge, and obtain modified nano-zinc oxide; According to the mass ratio of 2:1:4, mix ibuprofen, isothiazolinone and distilled water in a beaker and stir for 6 minutes to obtain a mixed solution, and then add sodium lauryl sulfate of 1% of ...

example 2

[0025] Weigh 11g of nano-zinc oxide with a particle size of 28nm and pour it into a beaker with 95mL of deionized water and 55mL of absolute ethanol, and ultrasonically disperse it with an ultrasonic disperser for 33min to obtain a nano-zinc oxide dispersion. The nano-zinc oxide dispersion and Silane coupling agent KH-550 is mixed in a beaker at a mass ratio of 3:1, stirred and reacted for 1.5 hours at a temperature of 80°C to obtain a mixed solution, and the mixed solution is put into a centrifuge at a speed of 1100r Centrifuge for 53 minutes under the condition of 1 / min, separate the precipitate, wash the precipitate with absolute ethanol 4 times, and finally put it in a vacuum drying oven, dry it at 70°C for 1.5 hours, cool and discharge the material, and obtain the modified nano-oxidized Zinc; mix ibuprofen, isothiazolone and distilled water in a beaker with a mass ratio of 2:1:4 and stir for 7 minutes to obtain a mixed solution, and then add 1% dodecyl dodecyl compound to ...

example 3

[0027] Weigh 12g of nano-zinc oxide with a particle size of 32nm and pour it into a beaker with 100mL of deionized water and 60mL of absolute ethanol, and ultrasonically disperse it with an ultrasonic disperser for 36min to obtain a nano-zinc oxide dispersion. The nano-zinc oxide dispersion and Silane coupling agent KH-550 was mixed in a beaker at a mass ratio of 3:1, stirred and reacted for 2 hours at a temperature of 85°C to obtain a mixed solution, and the mixed solution was put into a centrifuge at a speed of 1200r / Centrifuge for 60 minutes under the condition of 1 min, separate the precipitate, wash the precipitate with absolute ethanol 5 times, and finally put it into a vacuum drying oven, dry it at 75°C for 2 hours, cool and discharge the material, and obtain the modified nano-zinc oxide; According to the mass ratio of 2:1:4, mix ibuprofen, isothiazolinone and distilled water in a beaker and stir for 8 minutes to obtain a mixed solution, and then add sodium lauryl sulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com