Reciprocating dry-type magnetic separator

A magnetic separation, reciprocating technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of waste of water resources, damage to the box, waste of raw materials, etc., to facilitate separation, reduce machine failure rate, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

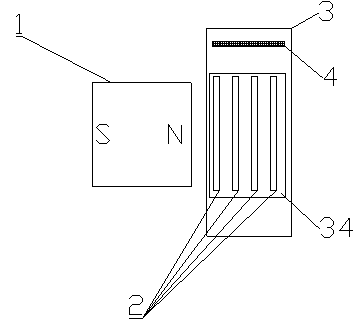

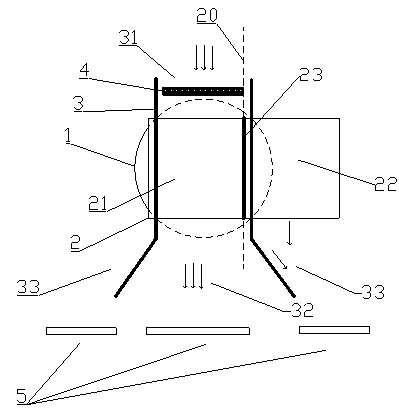

[0023] like figure 1 As shown, the present invention provides a reciprocating dry magnetic separator, comprising a superconducting magnet 1 and a sorting mechanism whose magnetic force lines diverge; the superconducting magnet 1 forms divergent magnetic force lines at two ends, and multiple The layer can penetrate the flat plate (sorting disk) of the magnetic force line; the sorting mechanism includes at least one adsorption piece 2 that moves horizontally, and there is a gap between the connected adsorption pieces 2 when there are multiple pieces; the superconducting magnet 1-magnetic end surface The lines of magnetic force pass through the adsorption sheet 2; the magnetic field strength at the adsorption sheet 2 can be above 0.1T. In order to obtain a better production effect, the field strength is preferably greater than 0.2T. The adsorption sheet 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com