Solid loose powder and preparation method thereof

A solid, loose powder technology, applied in body powder, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of powder loss and poor application effect, and achieve the effect of improving application effect, increasing protection, and increasing skin nourishment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

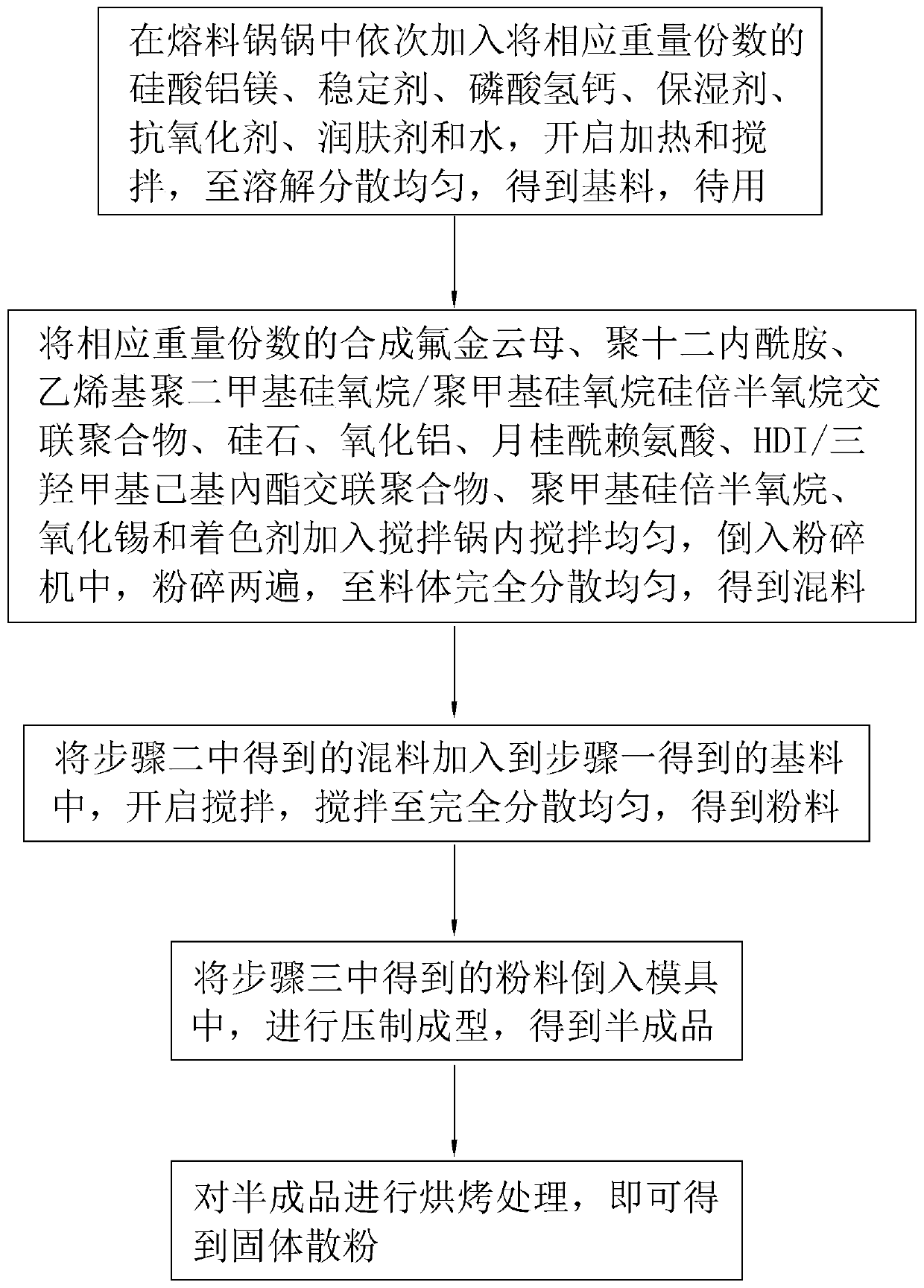

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: A kind of solid loose powder, each component and its corresponding parts by weight are shown in Table 1, and are prepared by the following steps:

[0057] Step 1: Add aluminum magnesium silicate, polysorbate-20, calcium hydrogen phosphate, glycerin, tocopherol, pentaerythritol tetraisostearate and water in corresponding parts by weight in sequence, and start heating and stirring, until dissolved and dispersed evenly, to obtain the base material and set aside;

[0058] Step 2, synthetic fluorine phlogopite, polylaurolactam, vinyl polydimethylsiloxane / polymethylsiloxane silsesquioxane crosslinked polymer, silica, aluminum oxide in corresponding parts by weight , lauroyl lysine, HDI / trimethylol hexyl lactone cross-linked polymer, polymethylsilsesquioxane, tin oxide and colorant are added into the stirring pot and stirred evenly, poured into the grinder, and crushed into two Repeat until the material body is completely dispersed and evenly mixed to obtain a m...

Embodiment 2-8

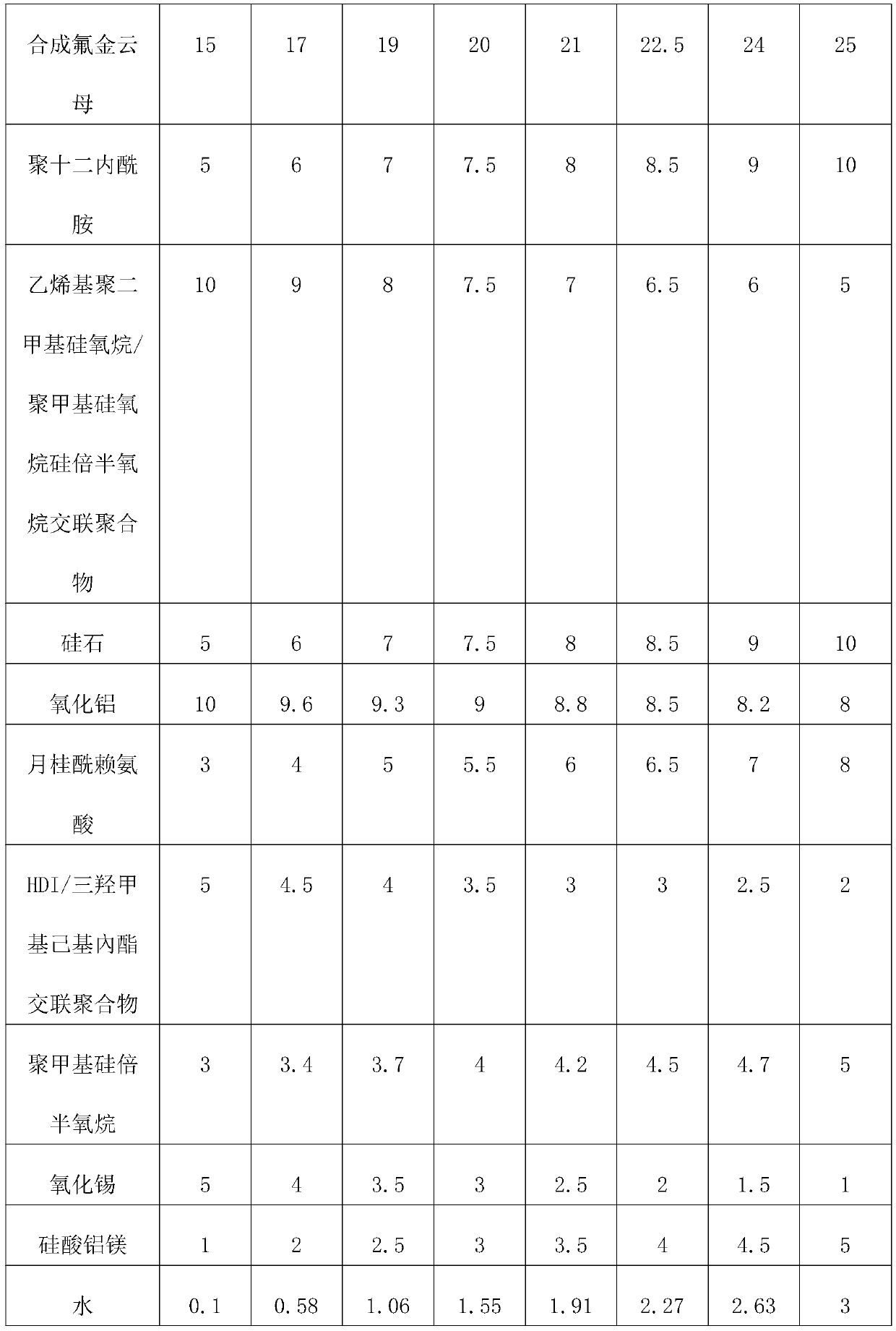

[0063] Example 2-8: a solid loose powder, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0064] Each component and parts by weight thereof in table 1 embodiment 1-8

[0065]

[0066]

[0067]

Embodiment 9

[0068] Embodiment 9: a kind of solid loose powder, the difference from embodiment 1 is that in step 1, 8 parts by weight of pentaerythritol tetraisostearate are replaced by polydimethylsiloxane of equal mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com