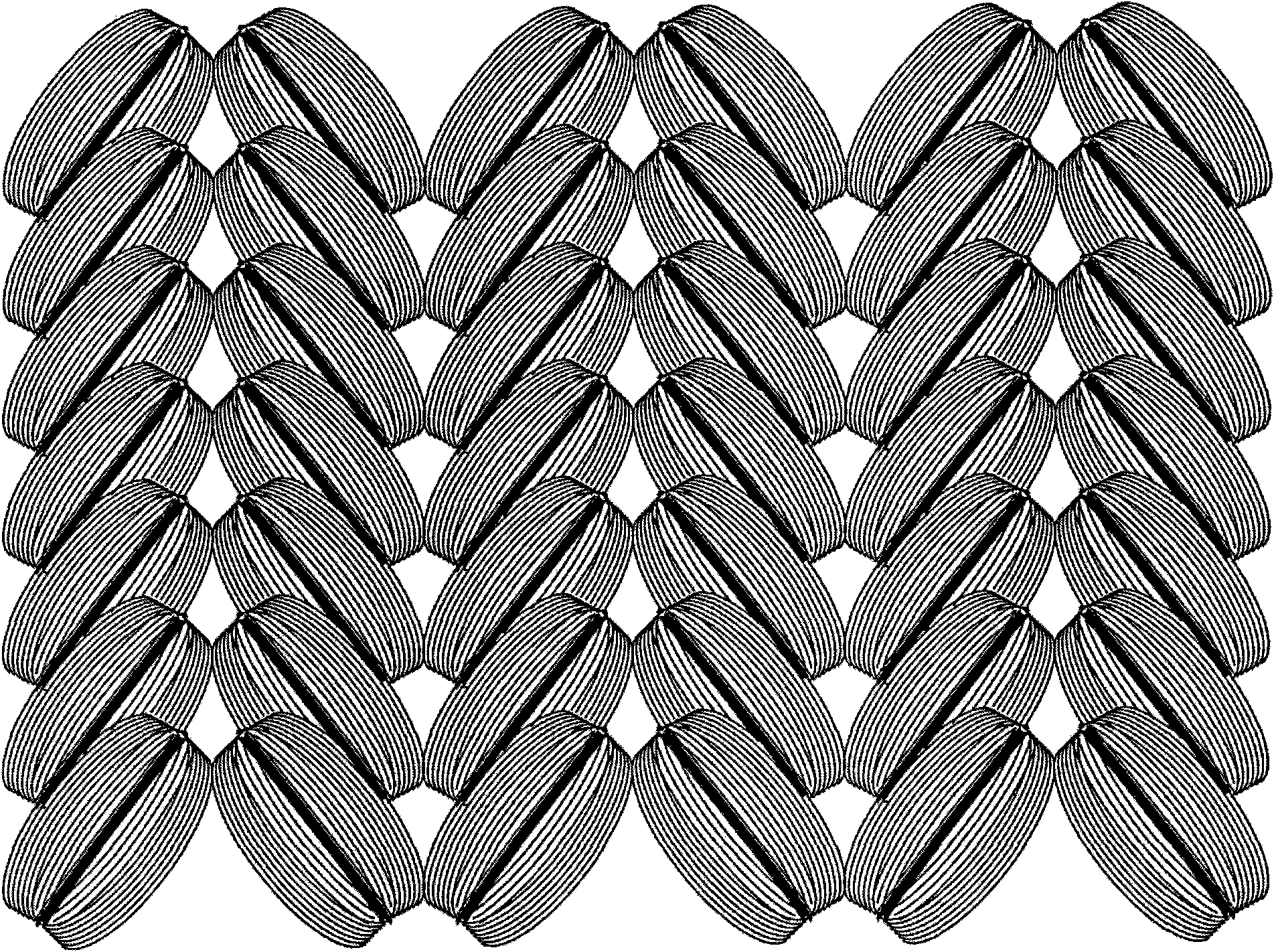

High-density low-dust-generation wiping cloth used for dust-free room and manufacture method thereof

A manufacturing method and high-density technology, applied in the field of textile processing, can solve the problems of high production cost, large dust generation, and poor wiping performance of ultra-fine fiber dust-free wiping cloths, and achieve good wiping effect, low dust generation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

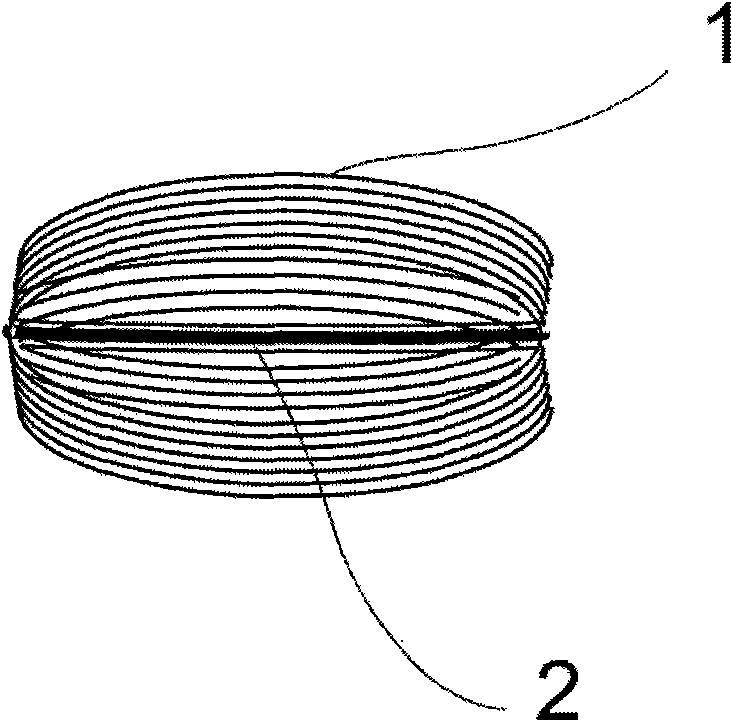

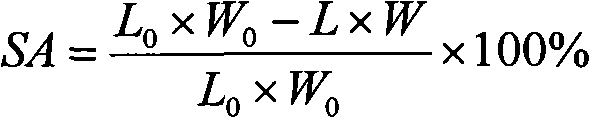

[0037] Example 1: A high-density and low-dust wiping cloth for a clean room, which is a high-shrinkage polyester filament with a boiling water shrinkage of 20% as the core yarn, and a low-shrinkage common polyester filament with a boiling water shrinkage of 5%. Covering, twist spinning to make core-spun yarn, and the core-spun yarn is made of fabric obtained by boiling water refining, steaming and tenter setting dyeing and finishing after weaving.

[0038] Manufacturing method of high density and low dust generation wiping cloth for clean room:

[0039] (1) Spinning: 20D / 12F high-shrinkage polyester filament is used as the core yarn, and 36F single-fiber fineness of 1.0D low-shrinkage polyester filament is coated and twist-spun to make core-spun yarn; among them, low-shrinkage polyester filament The boiling water shrinkage rate is 5%; the boiling water shrinkage rate of high-shrinkage polyester filament is 20%.

[0040] (2) weaving: the core-spun yarn of step (1) is woven int...

Embodiment 2

[0046] Example 2. A high-density, low-dust wiping cloth for a clean room is made of a high-shrinkage polyester filament with a boiling water shrinkage of 30% as the core yarn, and a low-shrinkage polyester filament with a boiling water shrinkage of 15%. Covering, twist spinning to make core-spun yarn, and the core-spun yarn is made of fabric obtained by boiling water refining, steaming and tenter setting dyeing and finishing after weaving.

[0047] Manufacturing method of high density and low dust generation wiping cloth for clean room:

[0048] (1) Spinning: 50D / 36F high-shrinkage polyester filament is used as the core yarn, and the 36F single fiber fineness is 2.1D low-shrinkage polyester filament is covered and twist-spun to make core-spun yarn; the low-shrinkage polyester filament is boiled in water The shrinkage rate is 15%; the shrinkage rate of high-shrinkage polyester filament in boiling water is 30%.

[0049] (2) weaving: the core-spun yarn of step (1) is woven into ...

Embodiment 3

[0055] Example 3. A high-density, low-dust wiping cloth for a clean room is made of a high-shrinkage polyester filament with a boiling water shrinkage of 50% as the core yarn, and a low-shrinkage nylon filament bag with a boiling water shrinkage of 10%. Covering, twist spinning to make core-spun yarn, and the core-spun yarn is made of fabric obtained by boiling water refining, steaming and tenter setting dyeing and finishing after weaving.

[0056] Manufacturing method of high density and low dust generation wiping cloth for clean room:

[0057] (1) Spinning: 30D / 24F high-shrinkage polyester filament is used as the core yarn, and 48F single-fiber fineness of 1.6D low-shrinkage nylon filament is coated and twist-spun to make core-spun yarn; among them, low-shrinkage nylon filament The boiling water shrinkage rate is 10%; the boiling water shrinkage rate of high-shrinkage polyester filament is 50%.

[0058] (2) weaving: the core-spun yarn of step (1) is woven into the gray clot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com