Mixed oil gas combustion adjuvant for ongine

A combustion aid and engine technology, applied in fuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of toxic exhaust gas, shortened spark plug life, and car damage due to oil, so as to increase the octane number of fuel and reduce mechanical damage. Wear and prolong life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

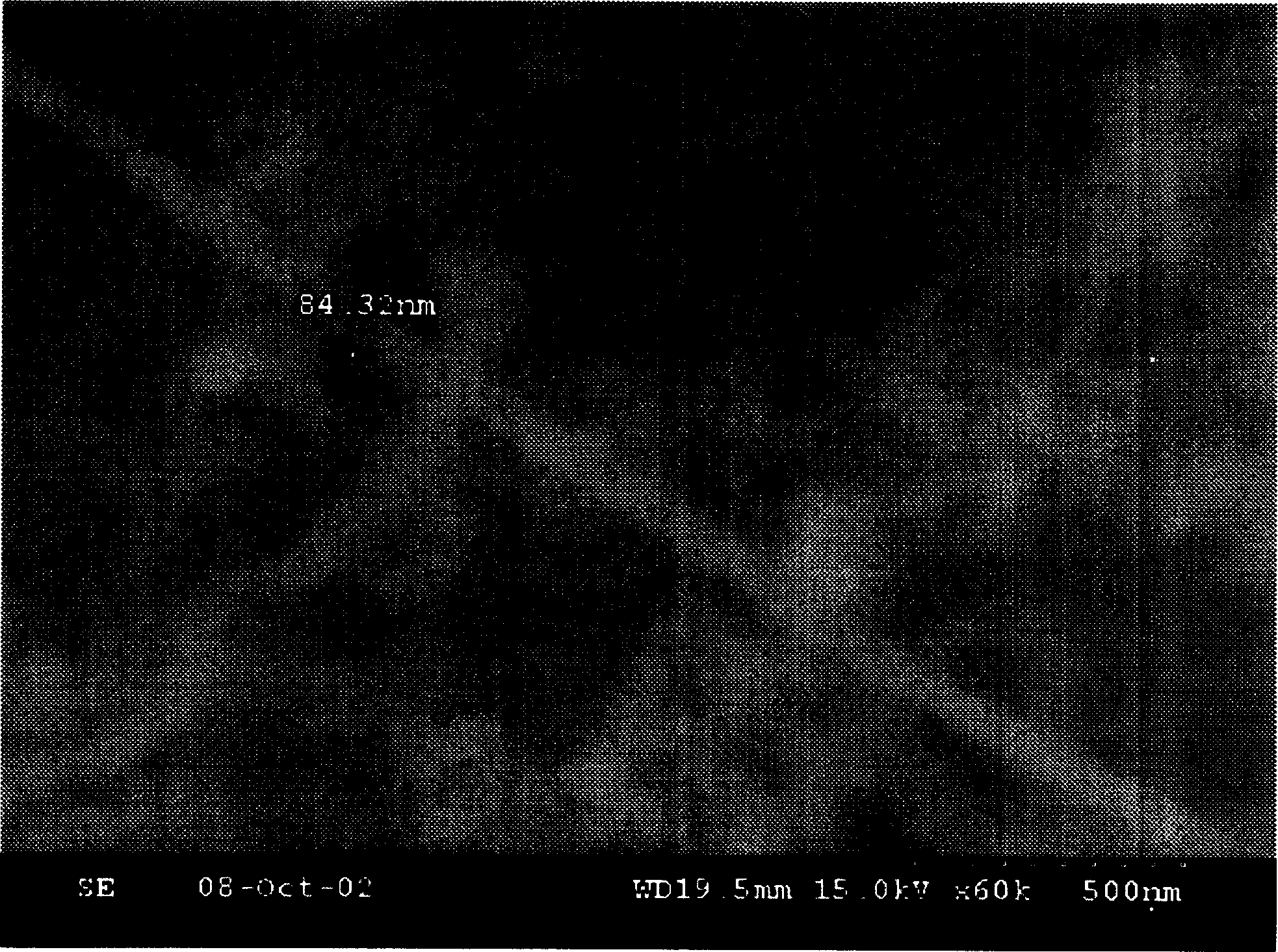

[0055] The present invention combines arc discharge, laser vaporization, solar thermal deposition, chemical vapor deposition, plasma-assisted chemical vapor deposition (PE-CVD)... The multi-layer carbon nanotubes or single-layer carbon nanotubes produced by the preparation of methods such as the engine are used as a combustion-supporting agent and a fuel-saving agent, a leak-repelling agent for the micro-pores of the intake and exhaust pipes, an environmental protection additive for reducing exhaust pollution, a fuel system cleaning agent, and an anti-corrosion agent. Explosive agent, lubricant between cylinder wall and piston, and sealing agent. The dosage is to add 0.0001mg to 1g of carbon nanotubes per liter of fuel. The specific adding method is:

[0056] 1. Add multi-layer carbon nanotubes or single-layer carbon nanotubes at a ratio of 0.0001mg to 1g per liter of fuel oil and directly mix them into fuel oil to make nano-electrocatalyst high-octane anti-knock environmenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com