Residual coal full-mechanized repeated mining method of near-distance inflammable seam gob

A goaf and coal seam technology, applied in surface mining, earthwork drilling, underground mining, etc., can solve problems such as resource loss and difficulty in spontaneously igniting gas discharge, achieve safe production, save dedicated gas drainage lanes, and be beneficial to The effect of excavation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

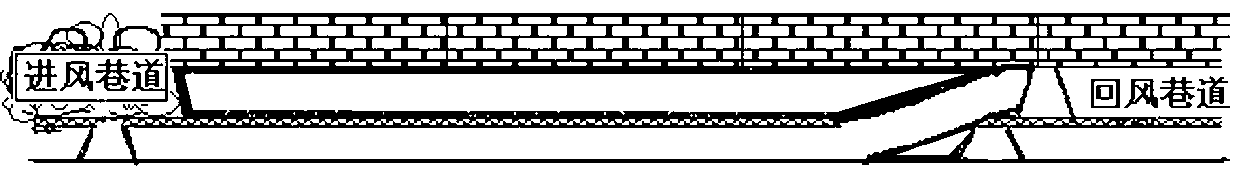

Image

Examples

Embodiment Construction

[0036] Below in conjunction with the actual situation of the Baijiazhuang Mine of the Coking Coal Group, the technical solution claimed in the present invention will be described in detail.

[0037] 1. Geological conditions of the working face

[0038] The ground position of the 39713 working face of Baijiazhuang Mine is located in the western mountainous area of Yeyu Fengjing, and the underground mine is located on the right wing of Nankeng 1001 level seven panels. The front part is an irregular subsidence column; the rear part is the roadway protection coal pillar; the left side of the front part is the 39501 mined working face, the left side of the middle and rear part is the unmined area, and the right part is a fault fracture zone and The 39701 working face; the 38502 cutter column goaf above the front; the layered goaf on the 38713 working face above the middle and rear.

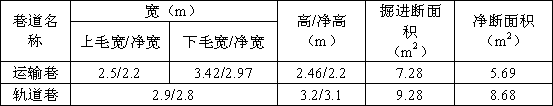

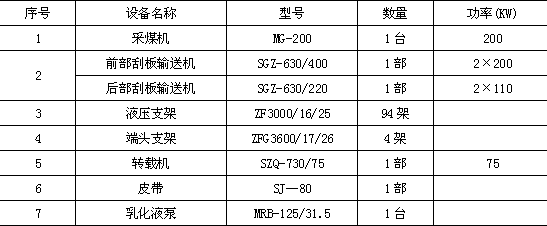

[0039] 1.1 Occurrence of coal seams

[0040] The mine 9 # Coal is a stable recoverable coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com