Anti-rolling tank control device

A technology for anti-rolling tanks, control devices, applied in the direction of reducing ship motion through displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

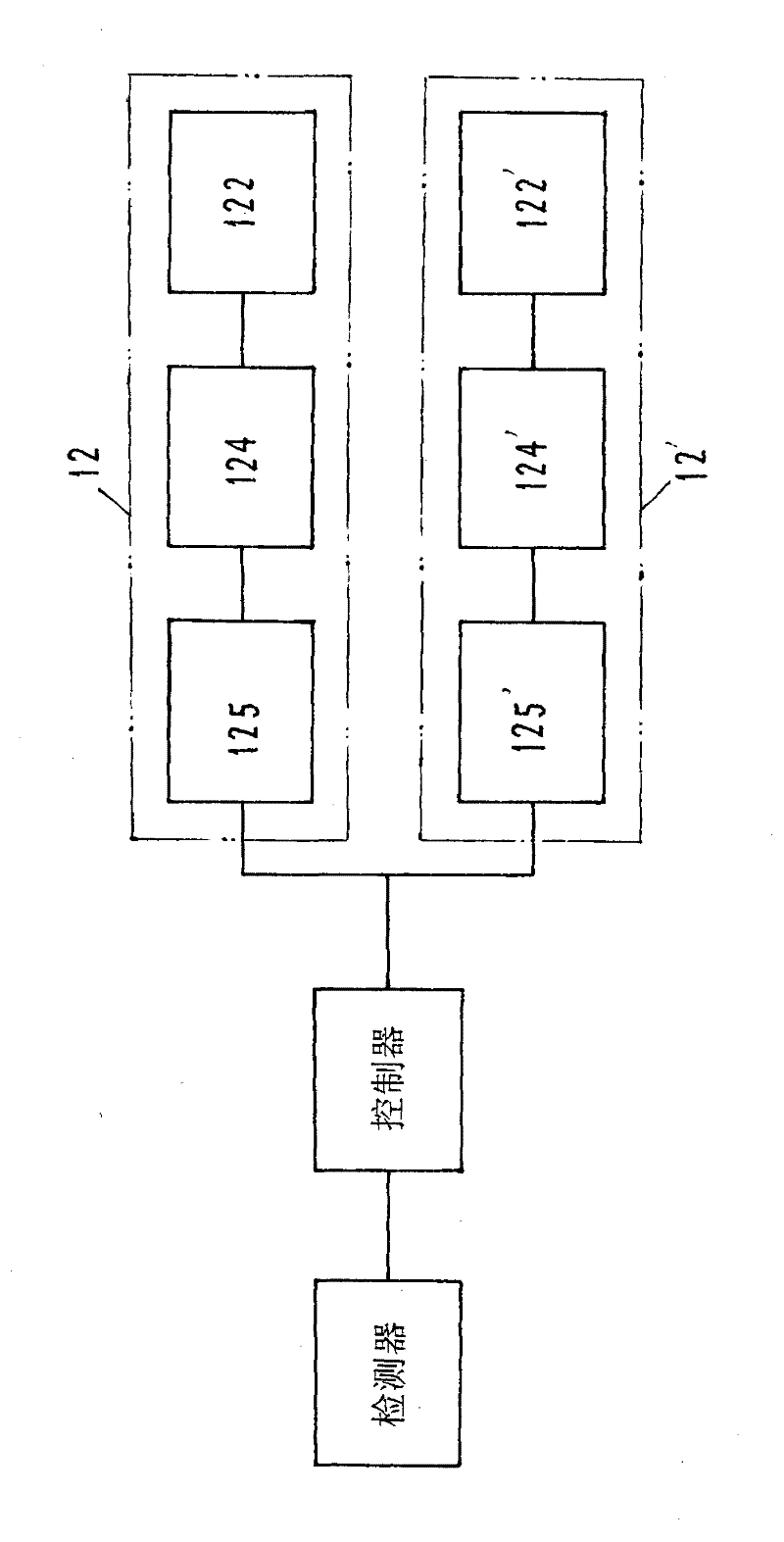

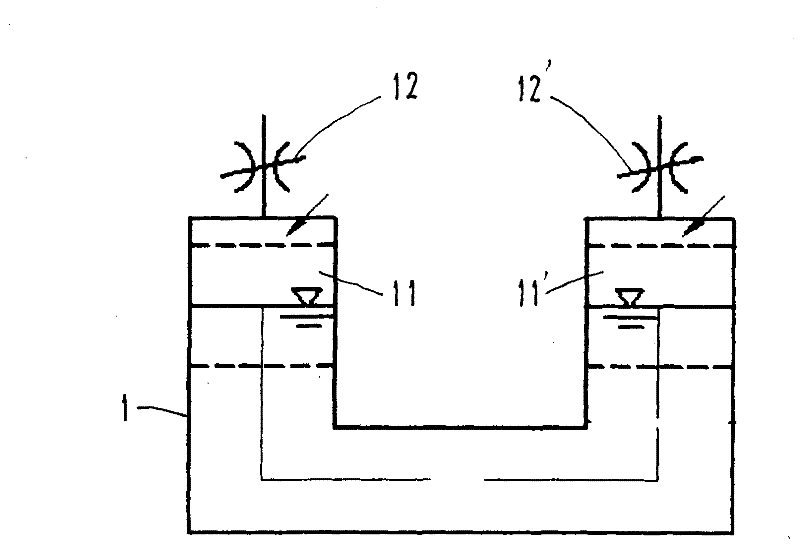

[0020] Reference figure 1 , 2 , Anti-rolling tank control device, including U-shaped anti-rolling tank 1, port side air chamber 11, starboard side air chamber 11', left throttle assembly 12, right throttle assembly 12', detector and controller.

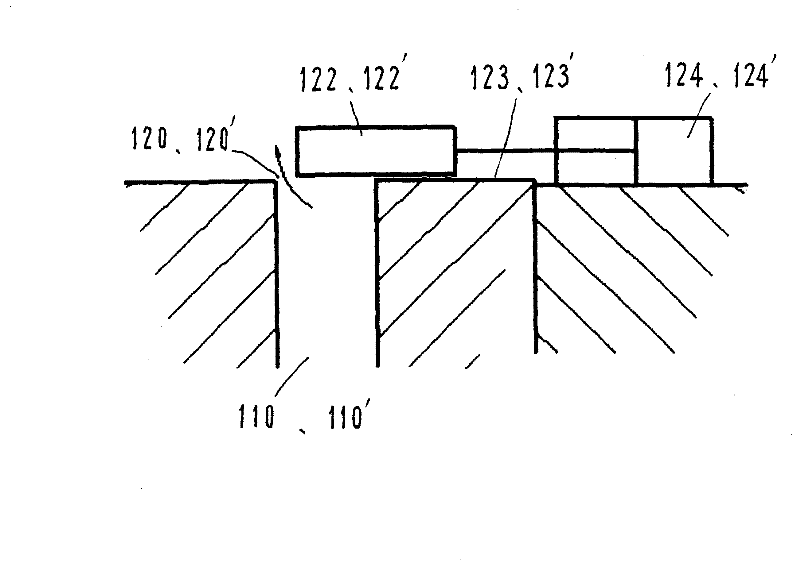

[0021] The U-shaped anti-rolling tank 1 has a structure similar to or the same as that of the prior art. A port side air chamber 11 and a starboard side air chamber 11' are formed on both sides of the U shape, and they are sealed in the left and right air chambers. The tops of 11 and 11' are respectively provided with a left throttle channel 110 and a right throttle channel 110' (e.g. image 3 , 5 ), the top ends of the left and right throttling channels 110, 110’ open to the atmosphere, that is, image 3 , 5 As shown in the left throttle opening 120 and the right throttle opening 120', the left and right throttle passages 110, 110' can be provided with a left throttle assembly 12 and a right throttle assembly 12'.

[0022] The left thrott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com