Patents

Literature

38results about How to "Lower effective resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

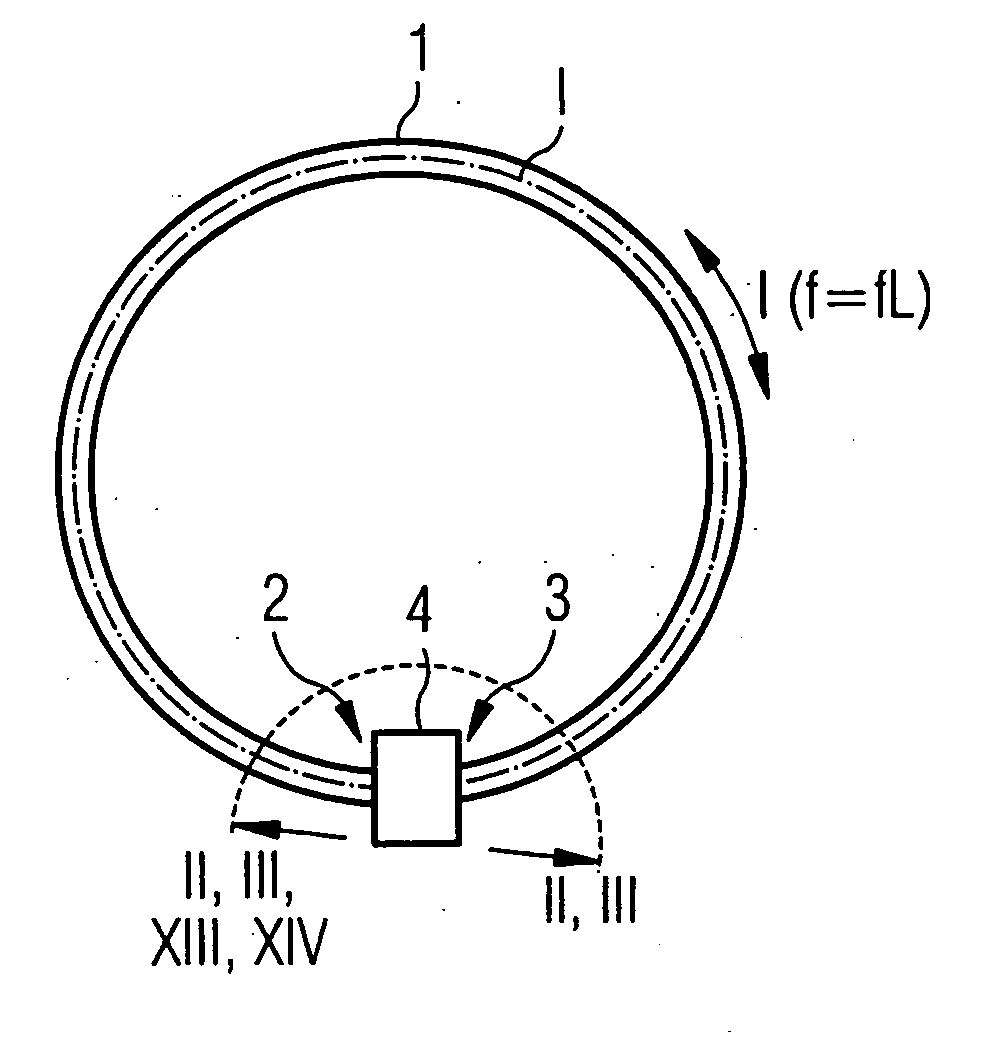

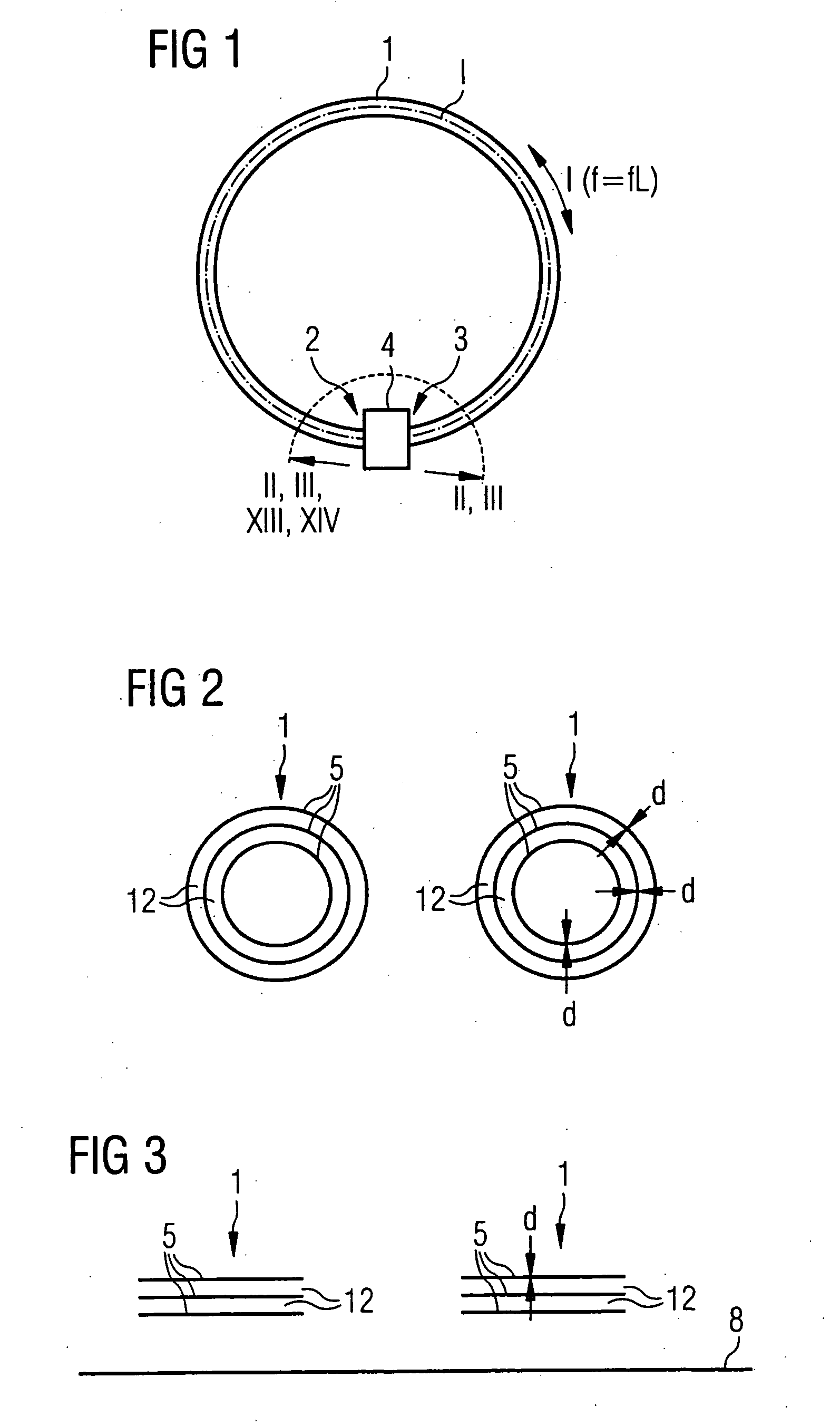

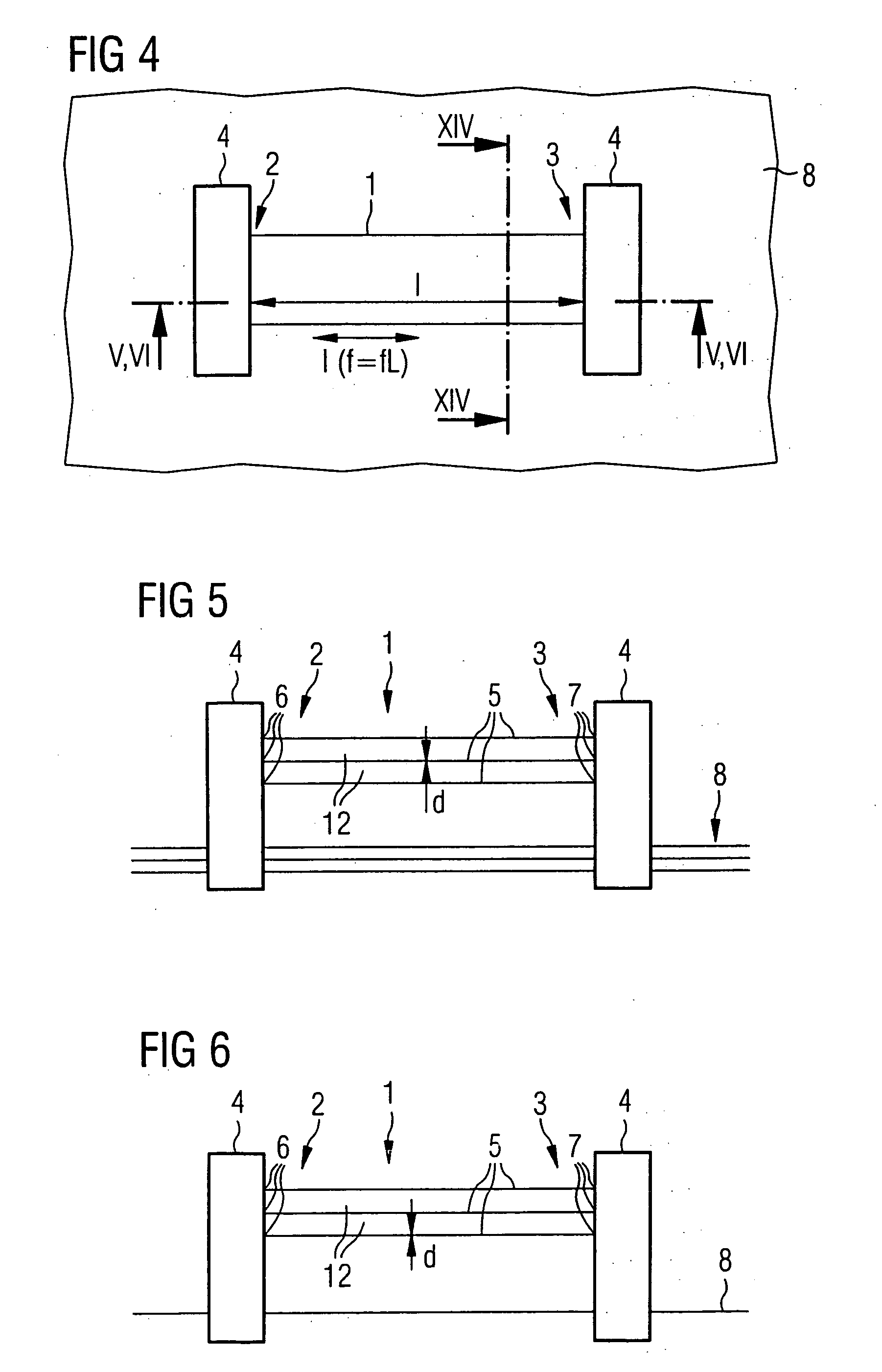

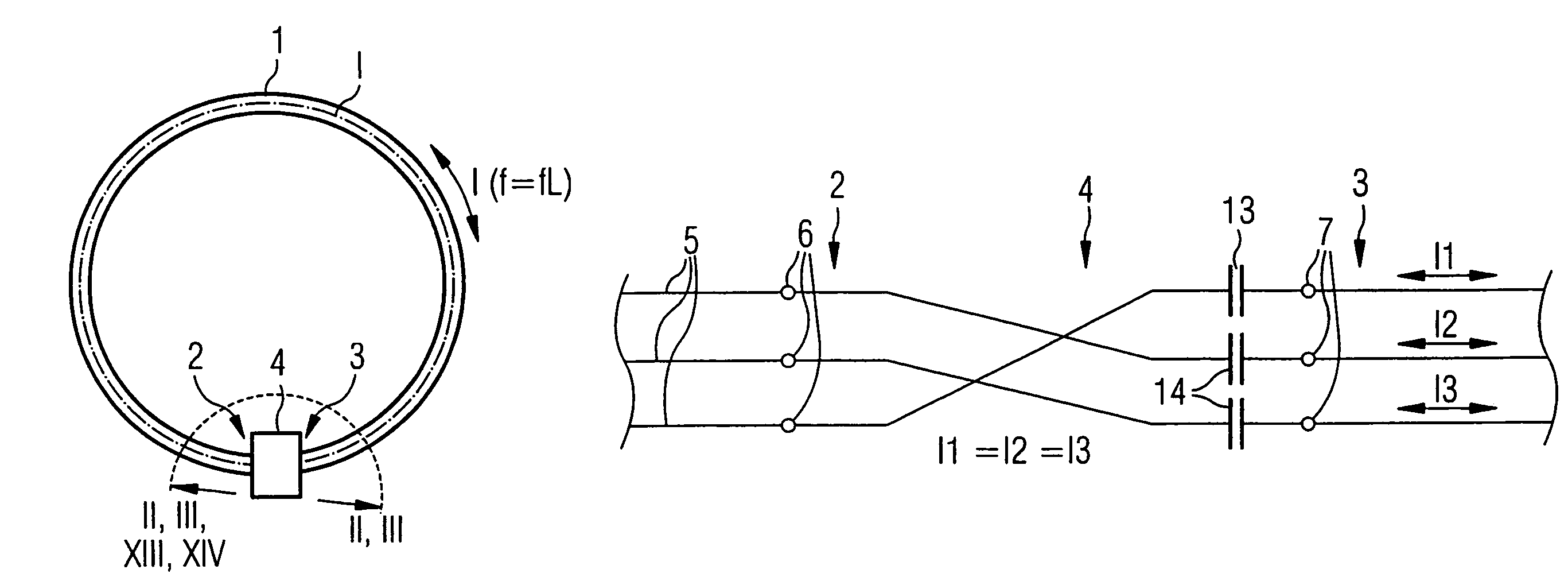

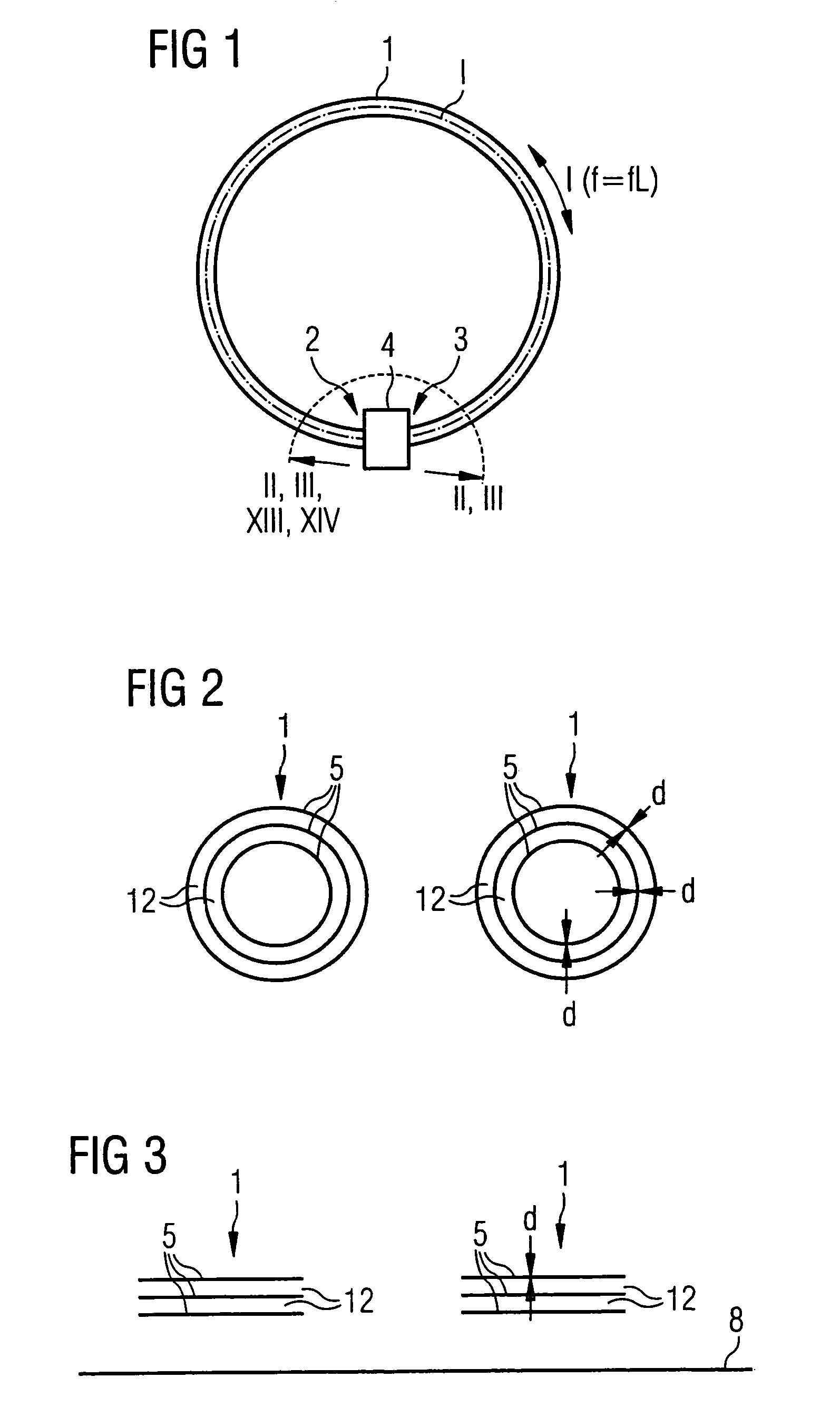

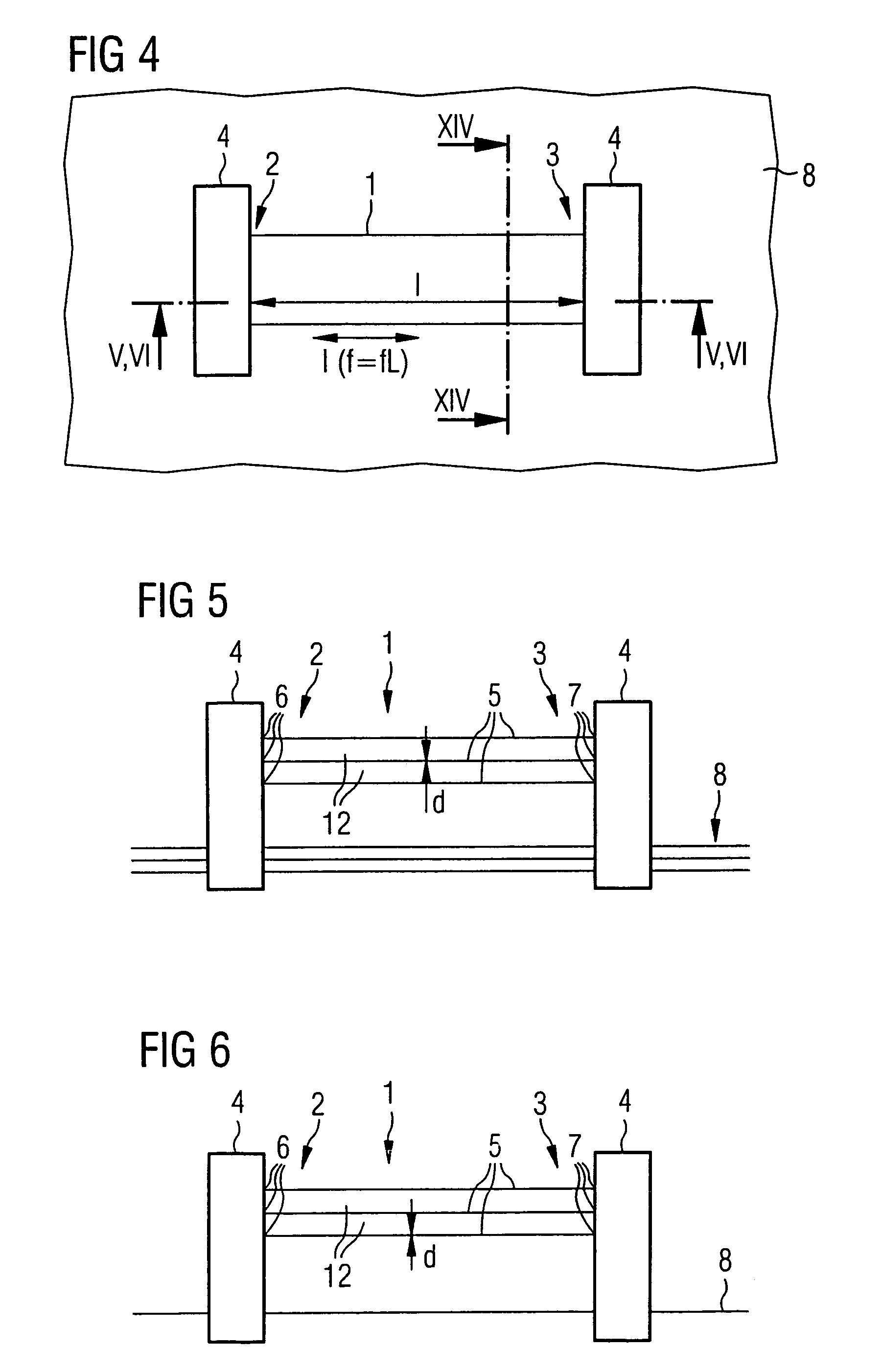

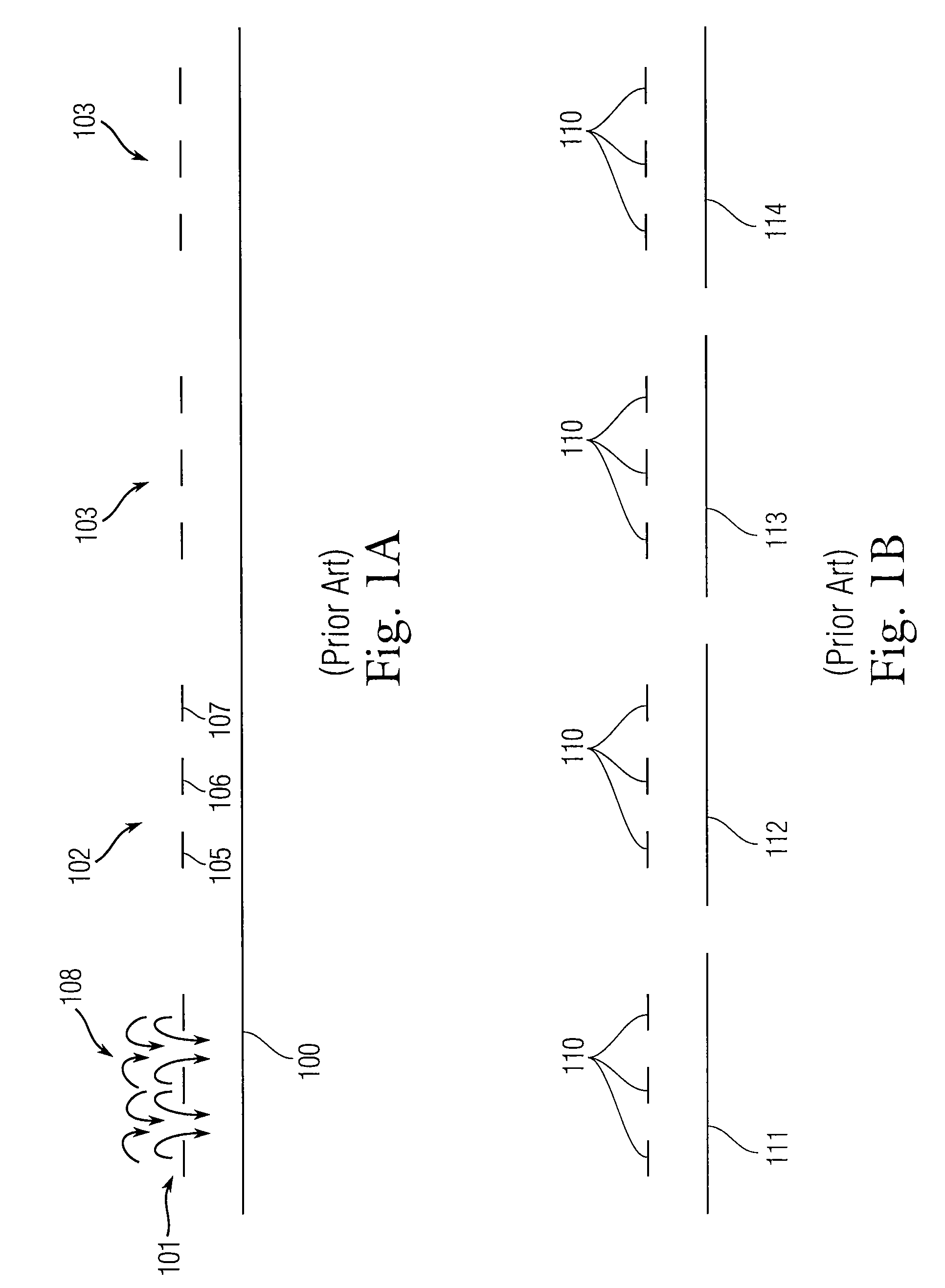

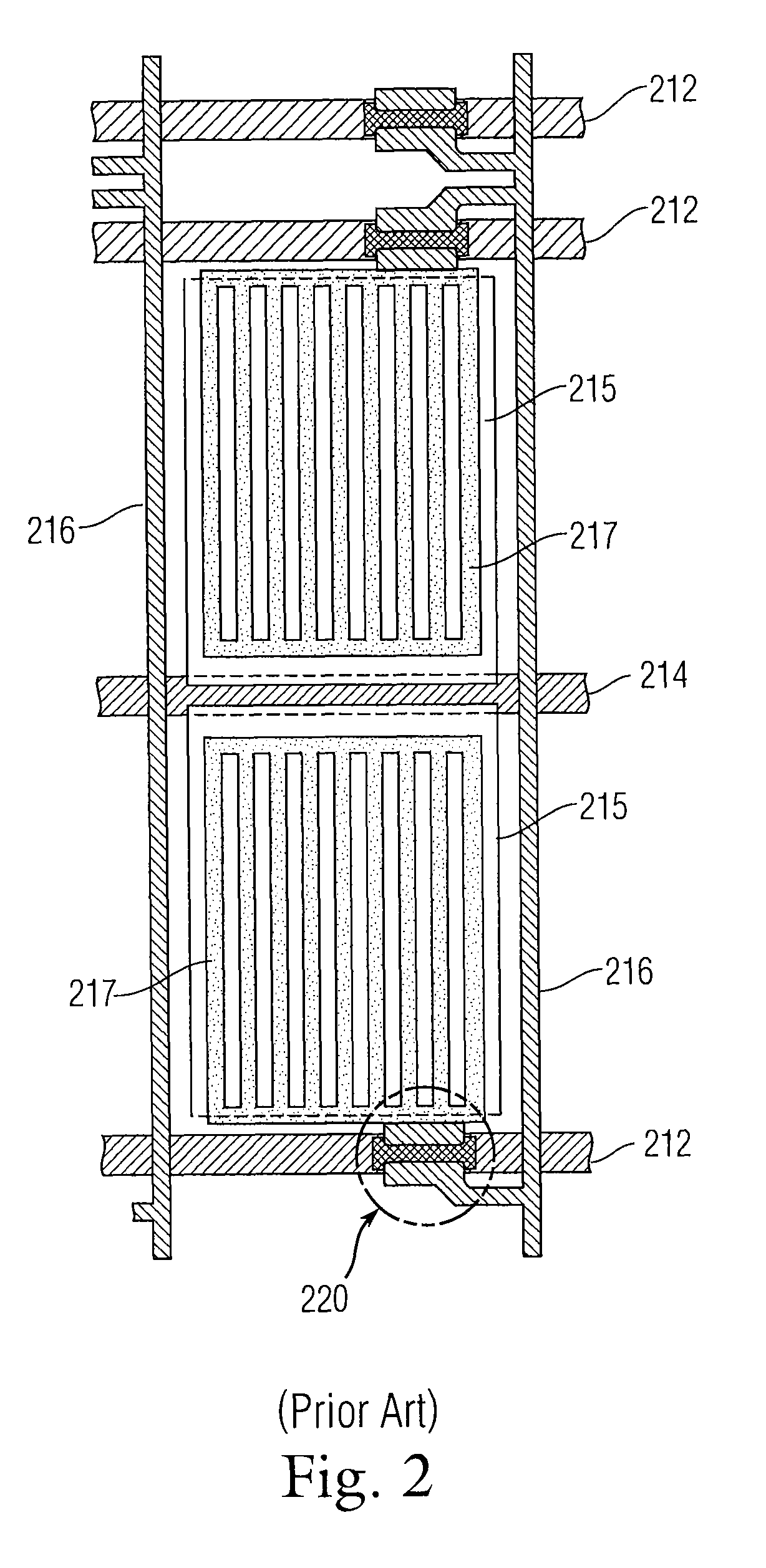

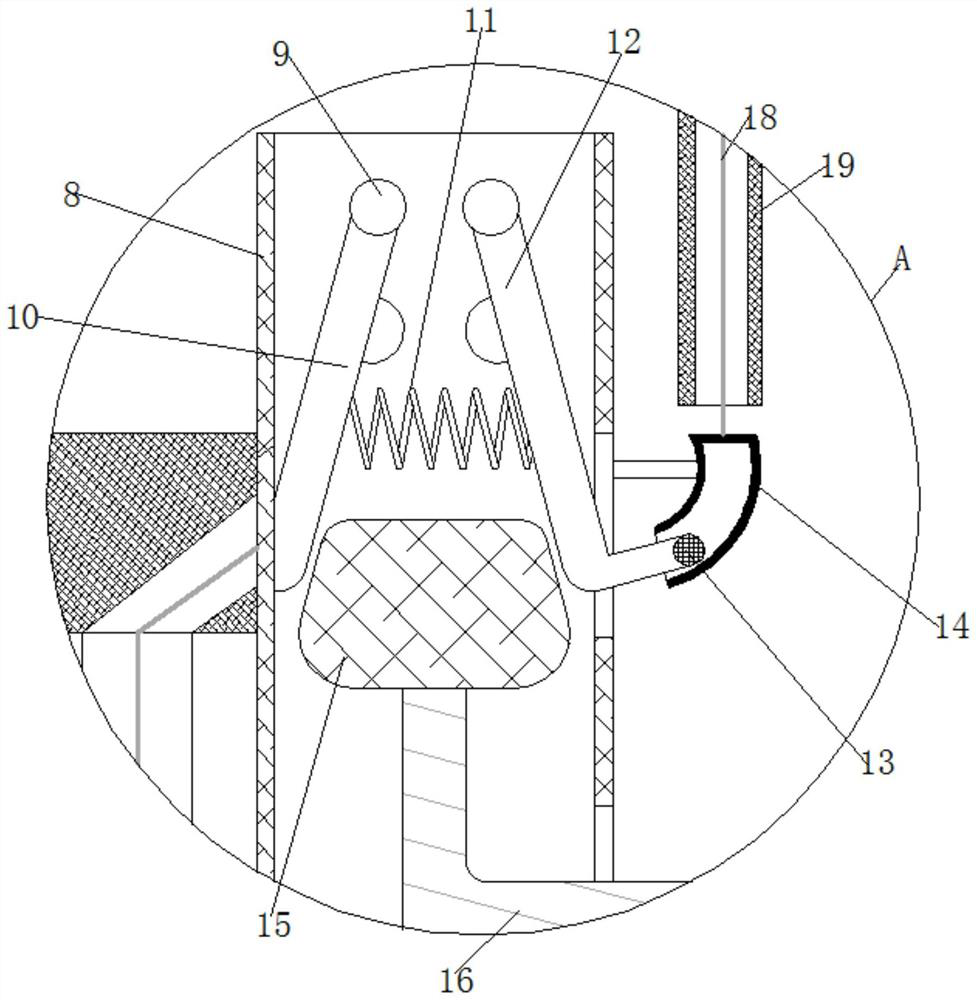

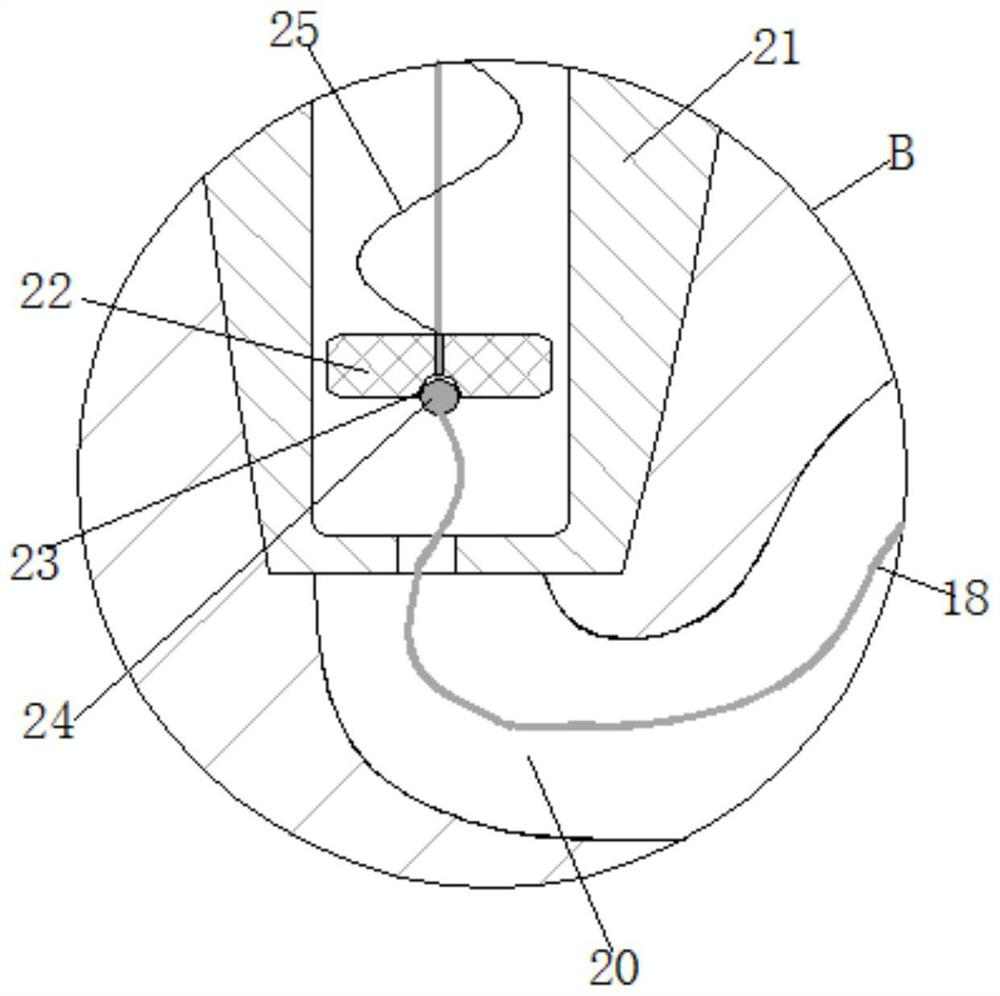

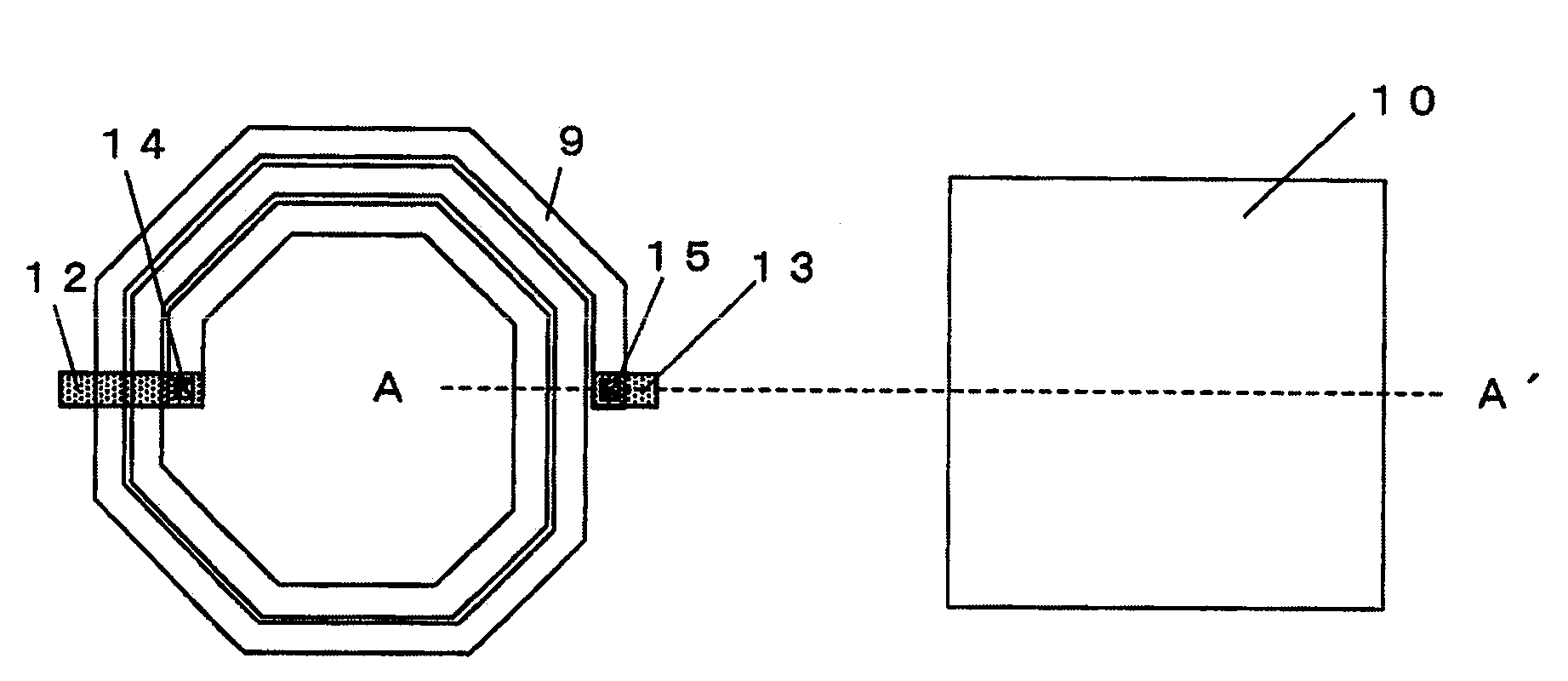

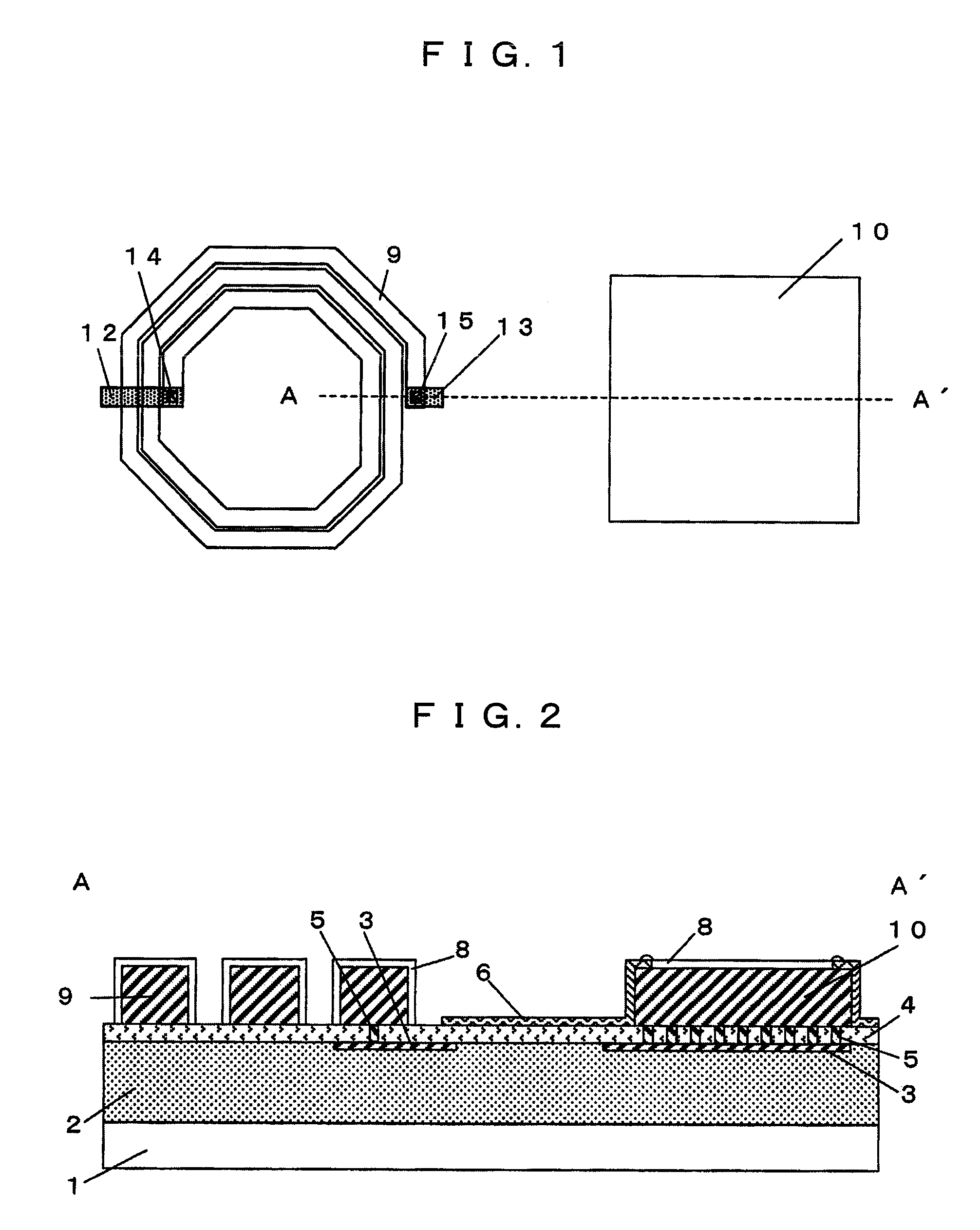

Resonator for magnetic resonance applications

InactiveUS20070120629A1Lower effective resistanceResonatorsElectric/magnetic detectionElectrical conductorResonance

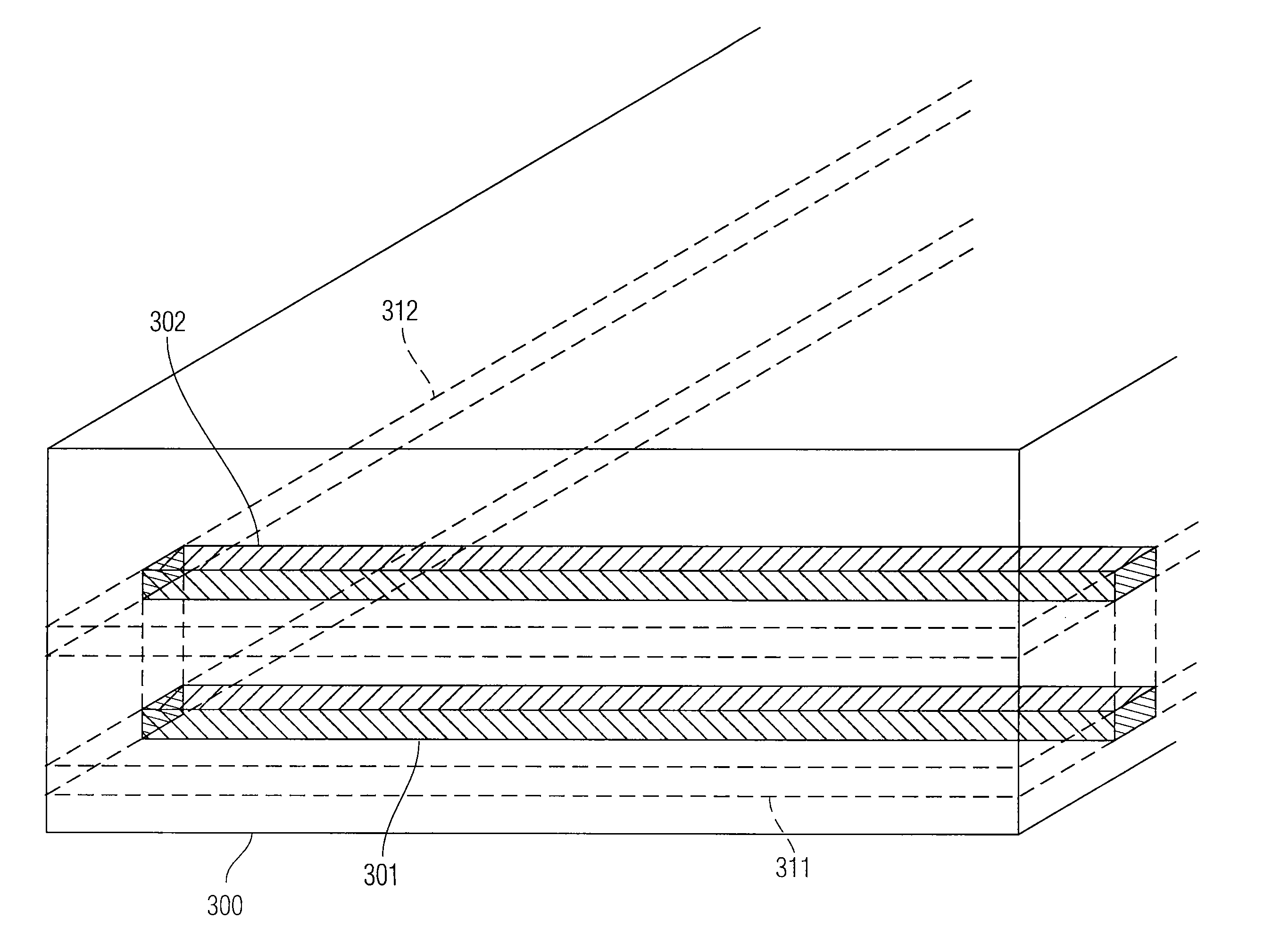

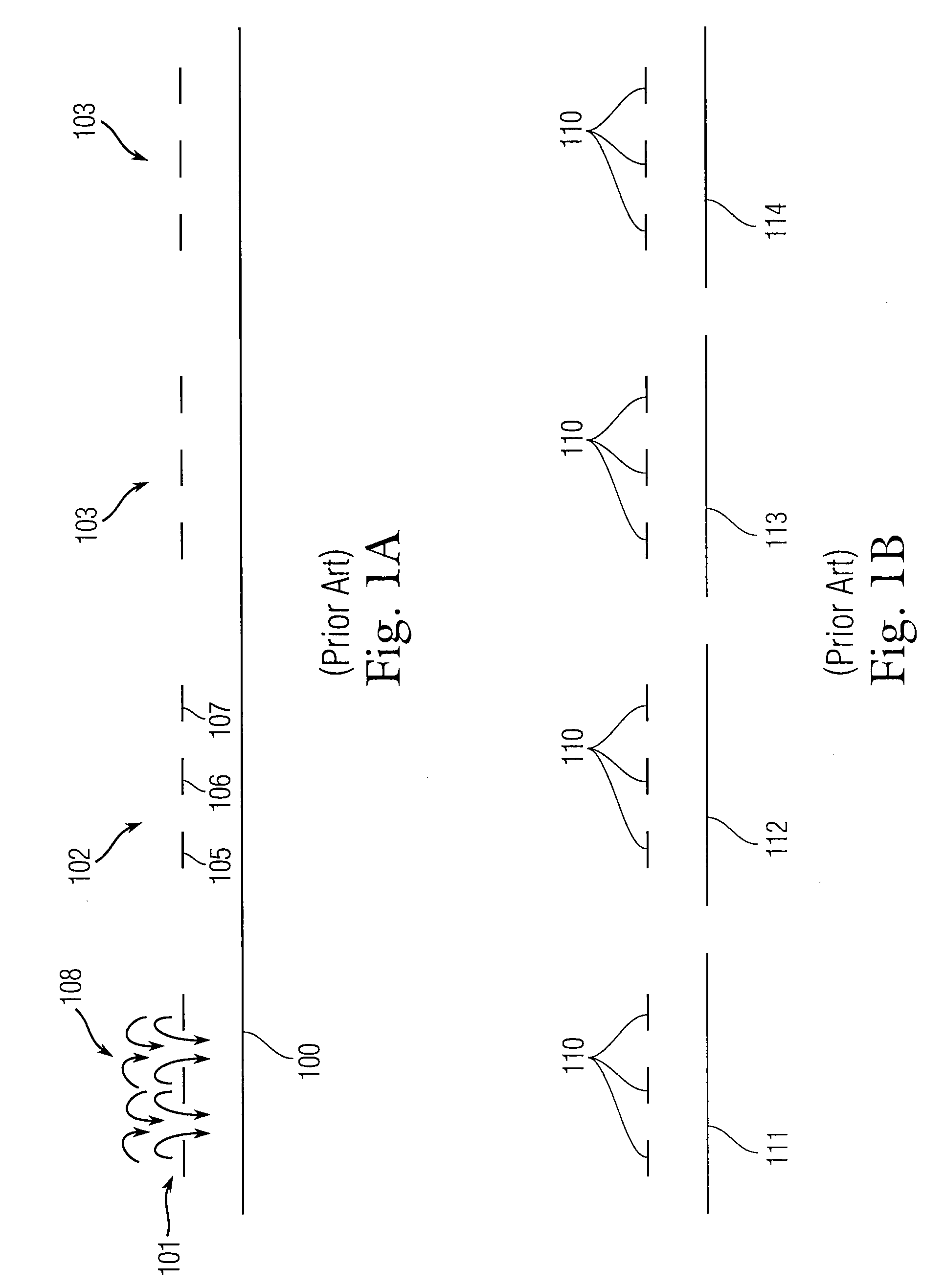

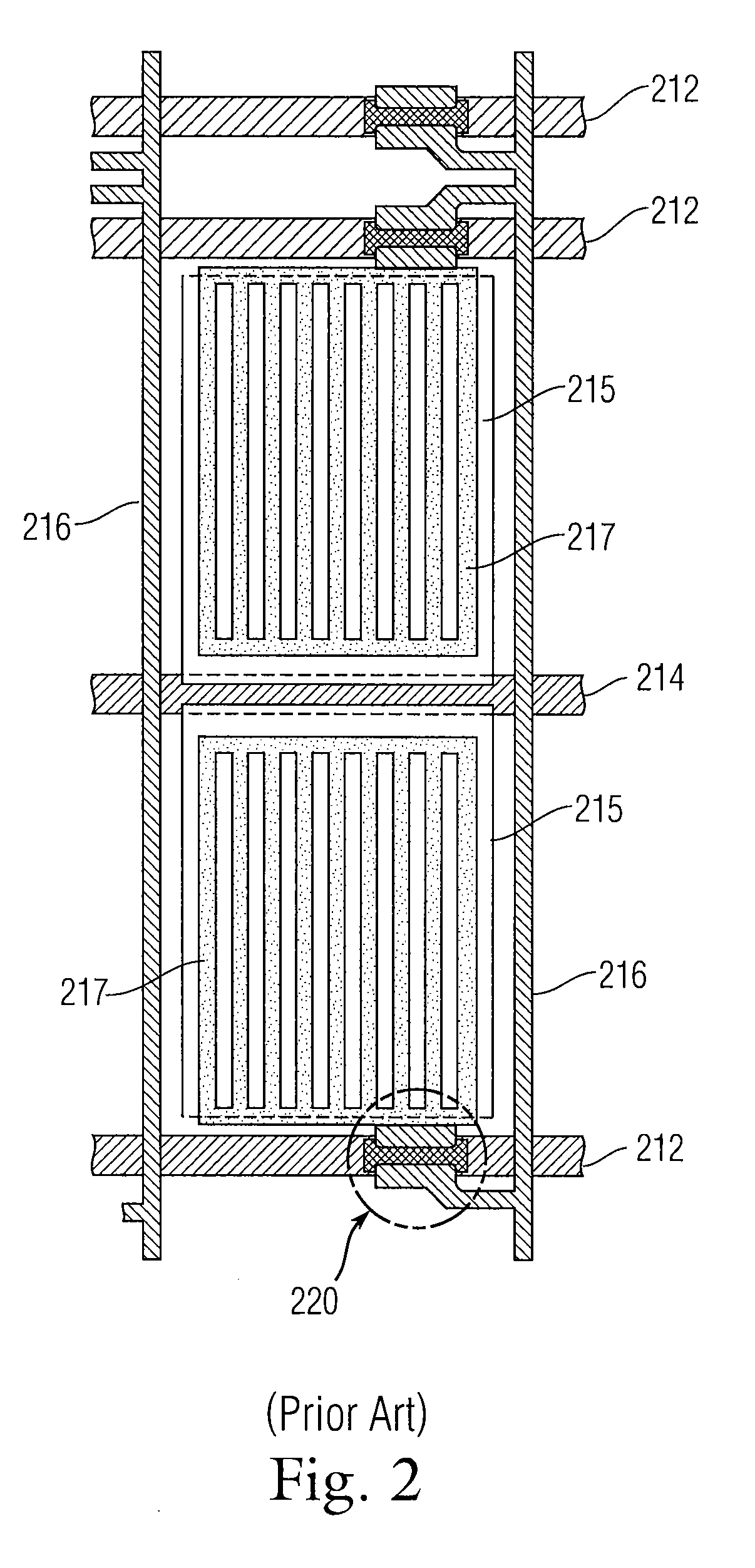

A resonator for magnetic resonance applications has a conductor element that extends from a first conductor end to a second conductor end. During operation of the conductor element at a resonance frequency, a resonance current oscillates from the first conductor end to the second conductor end and back. The conductor ends are coupled with one another via a circuit that tunes the conductor element to the resonance frequency. The conductor element is fashioned as a multi-layer conductor with a number of layers that exhibit layer ends at the conductor ends. The circuit causes layer currents that are of different magnitudes among one another to flow in the layers during operation of the conductor element at the resonance frequency.

Owner:SIEMENS HEALTHCARE GMBH

Multi-layer resonator for magnetic resonance applications with circuitry allowing equal magnitude current during active operation

InactiveUS7579835B2Lower effective resistanceResonatorsElectric/magnetic detectionElectrical conductorResonance

A resonator for magnetic resonance applications has a conductor element that extends from a first conductor end to a second conductor end. During operation of the conductor element at a resonance frequency, a resonance current-oscillates from the first conductor end to the second conductor end and back. The conductor ends are coupled with one another via a circuit that tunes the conductor element to the resonance frequency. The conductor element is fashioned as a multi-layer conductor with a number of layers that have first and second layer ends at the conductor ends. The circuit causes layer currents that are of equal magnitudes to flow in the layers themselves during active operation of the conductor element at the resonance frequency.

Owner:SIEMENS HEALTHCARE GMBH

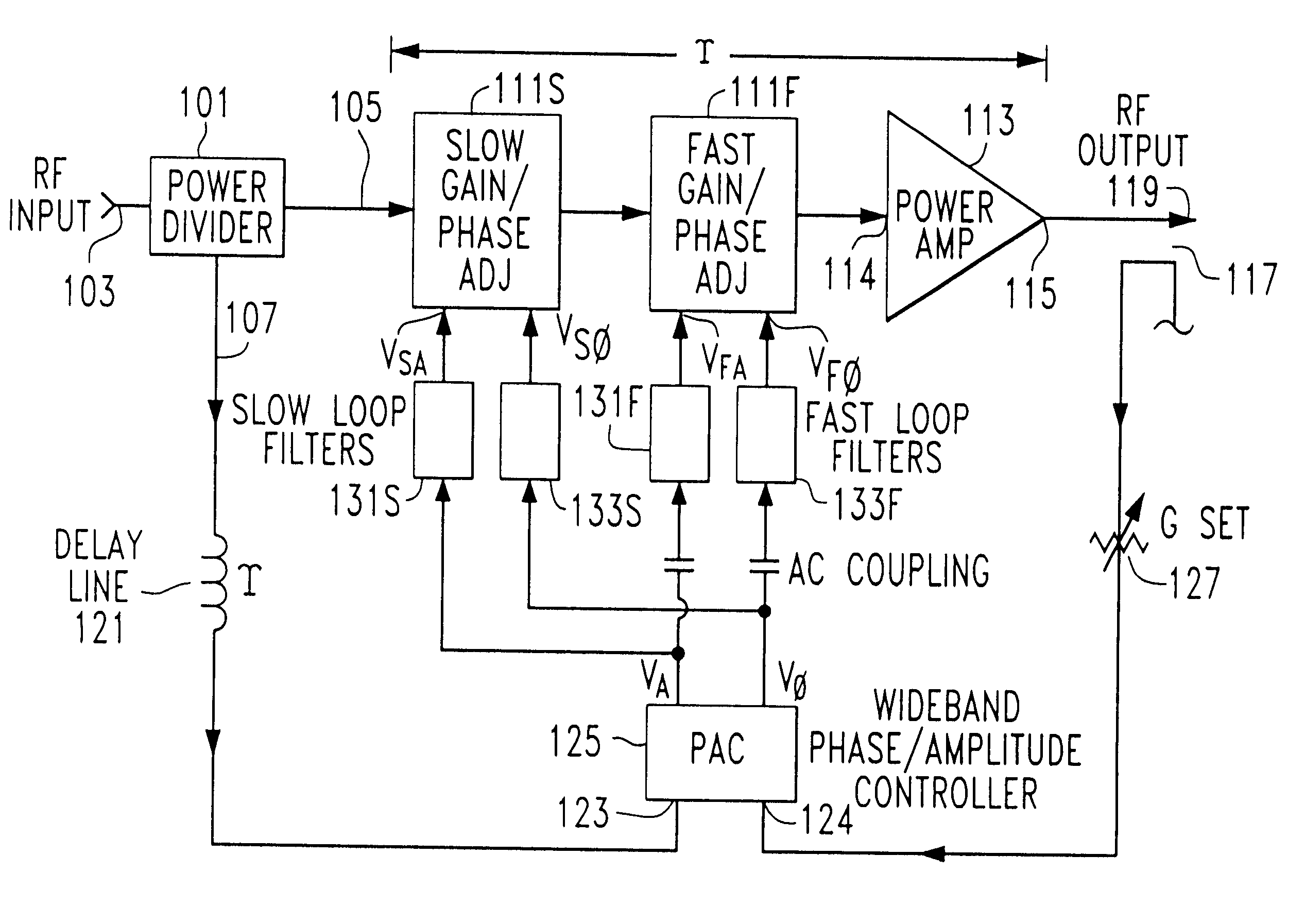

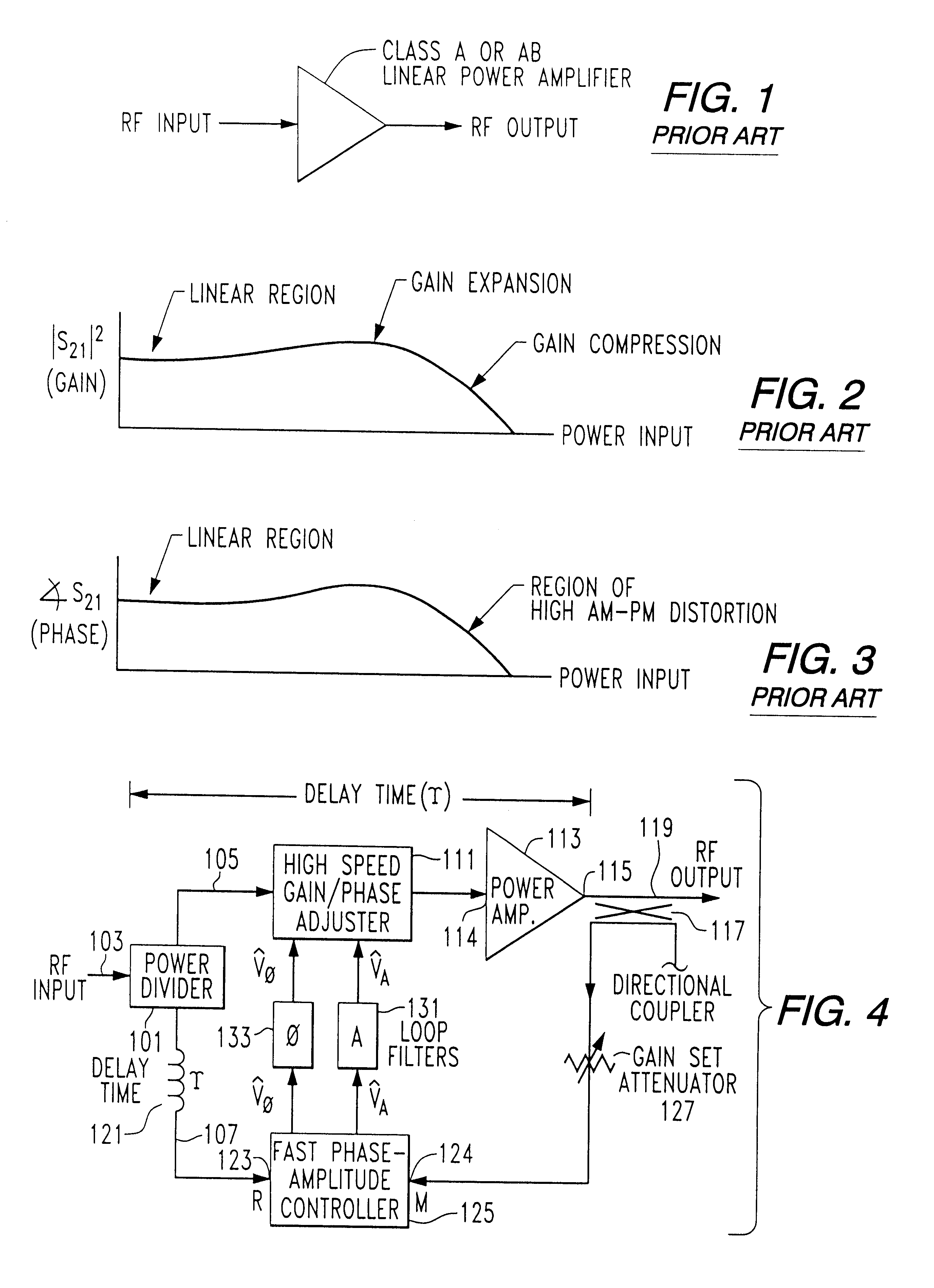

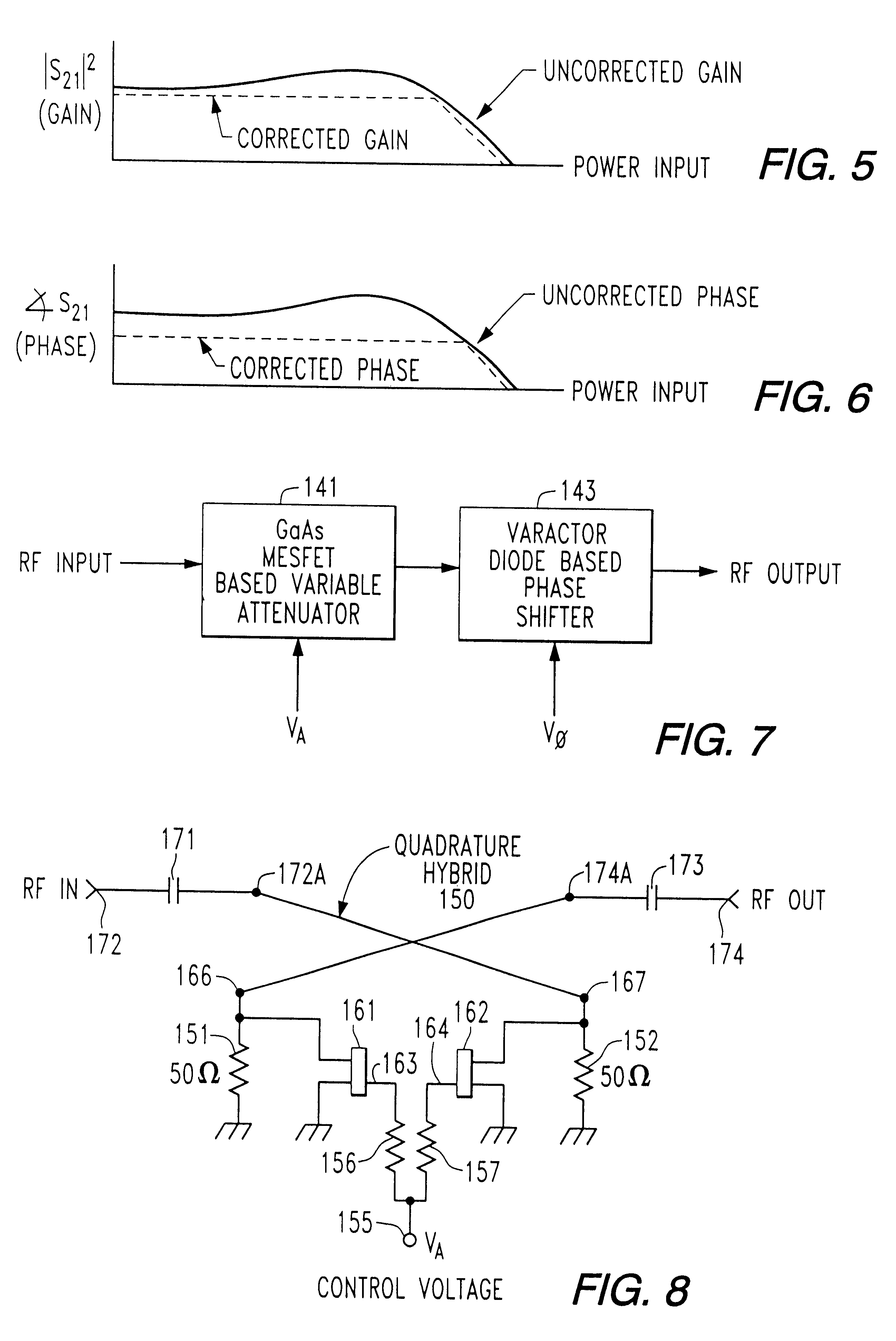

Polar envelope correction mechanism for enhancing linearity of RF/microwave power amplifier

InactiveUSRE37407E1Modest bandwidthImprove linearityAmplifier modifications to reduce non-linear distortionElectric devicesPhase distortionAudio power amplifier

Linearity of an RF / microwave power amplifier is enhanced by an amplitude and phase distortion correction mechanism based upon signal envelope feedback, that operates directly on the RF signal passing through the power amplifier. A phase-amplitude controller responds to changes in gain and phase through the RF / microwave power amplifier signal path caused by changes in RF input power, DC power supply voltages, time, temperature and other variables, and controls the operation of a gain and phase adjustment circuit, so as to maintain constant gain and transmission phase through the RF / microwave power amplifier.

Owner:INTEL CORP

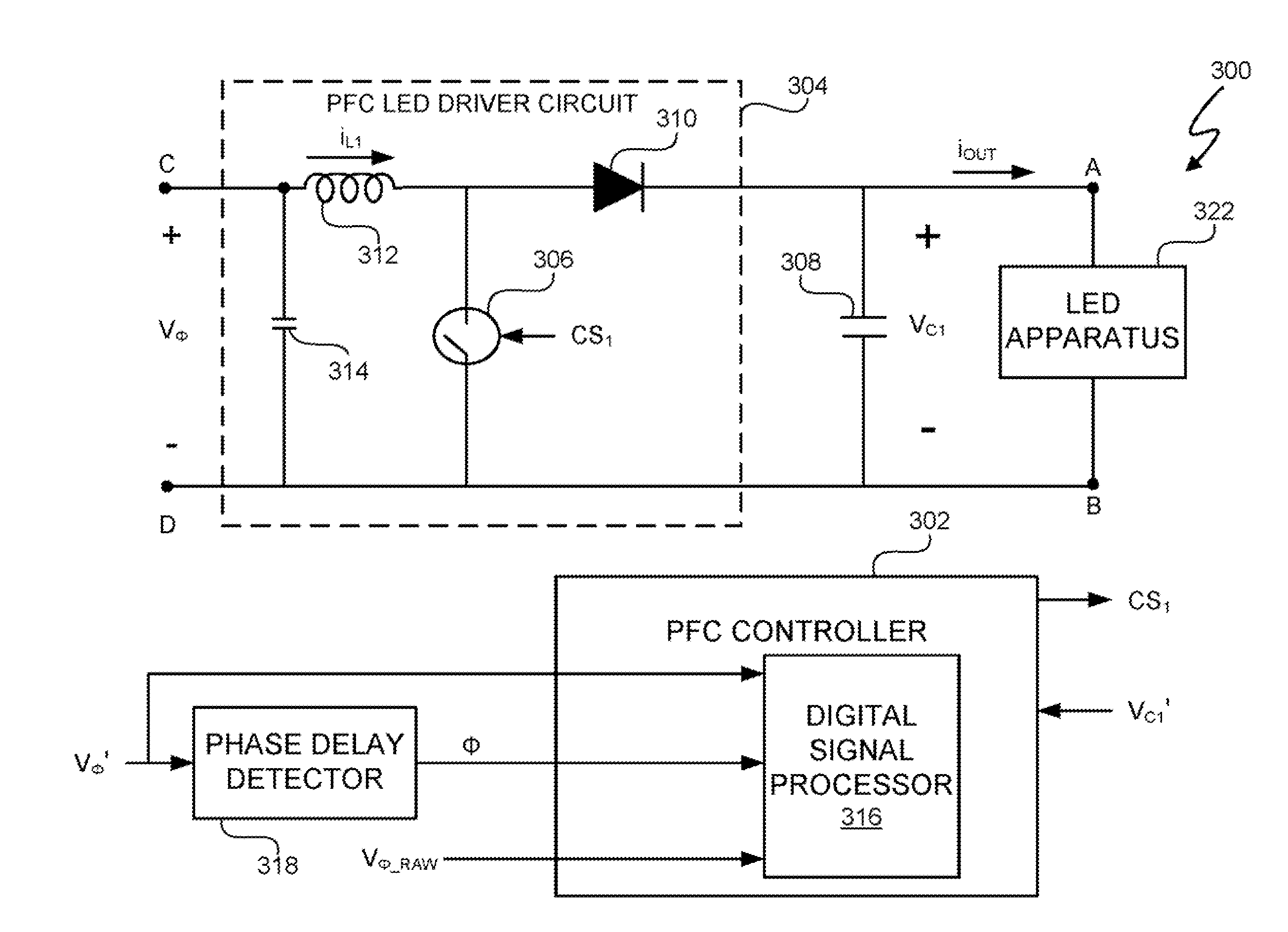

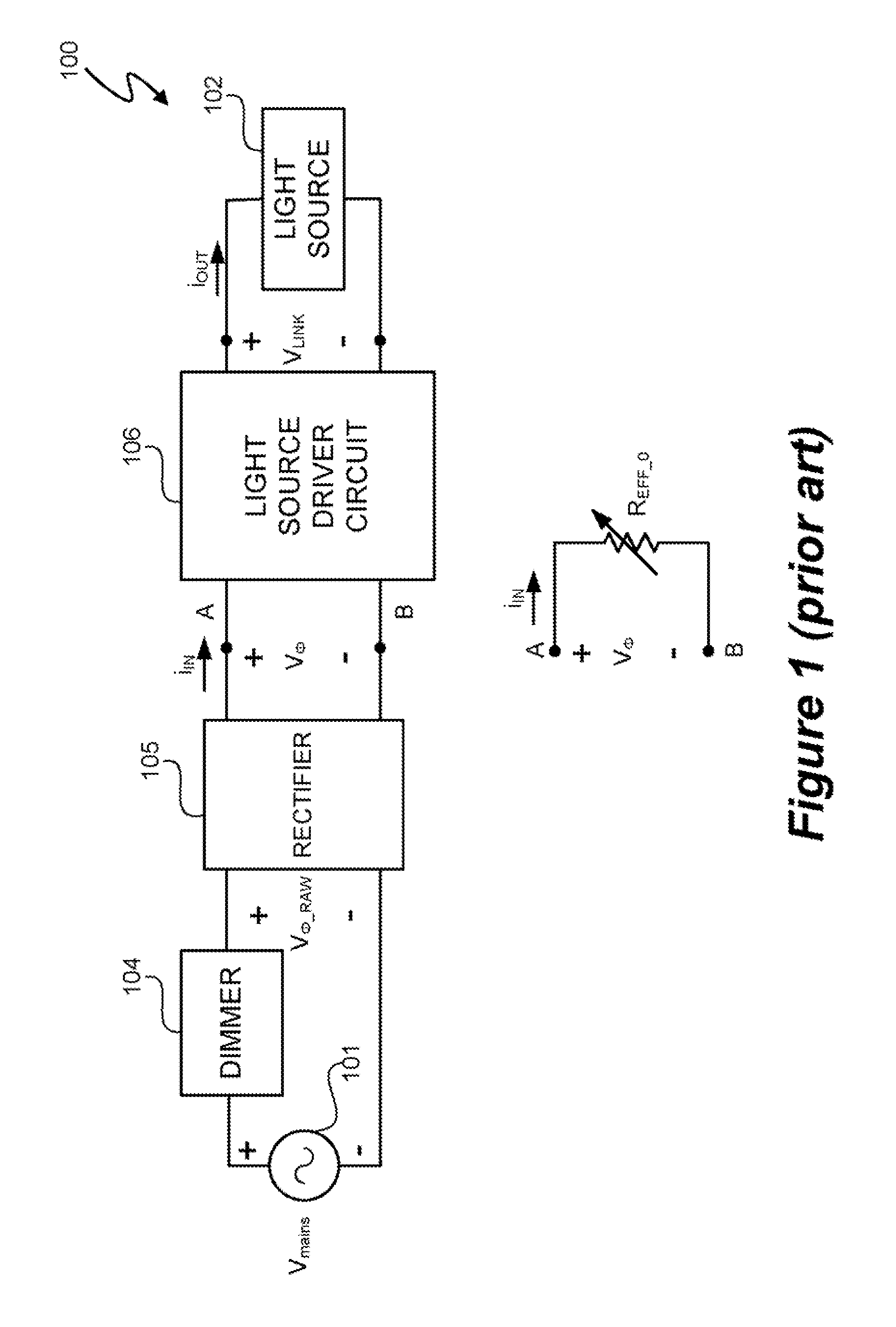

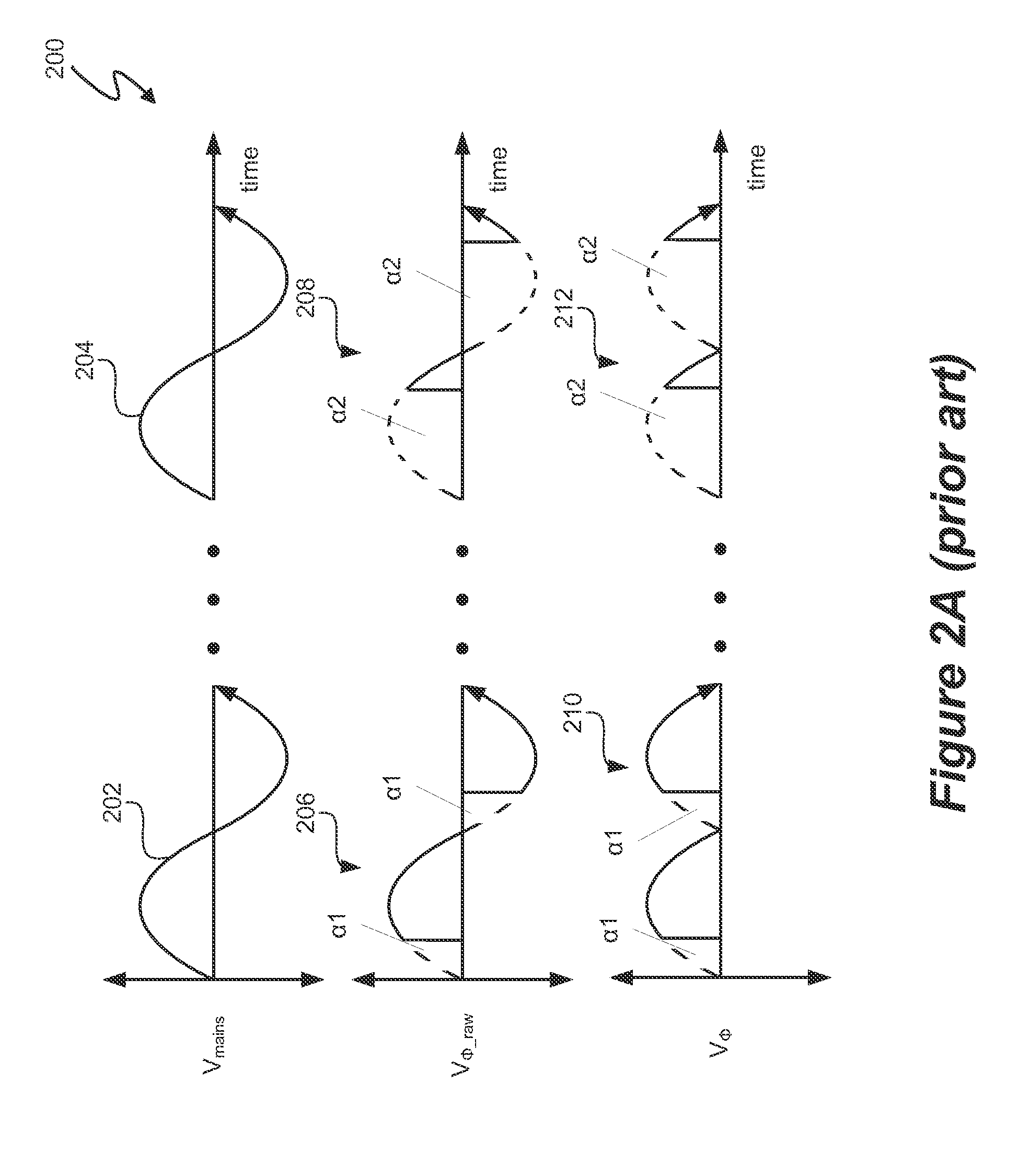

Lighting System With Power Factor Correction Control Data Determined From A Phase Modulated Signal

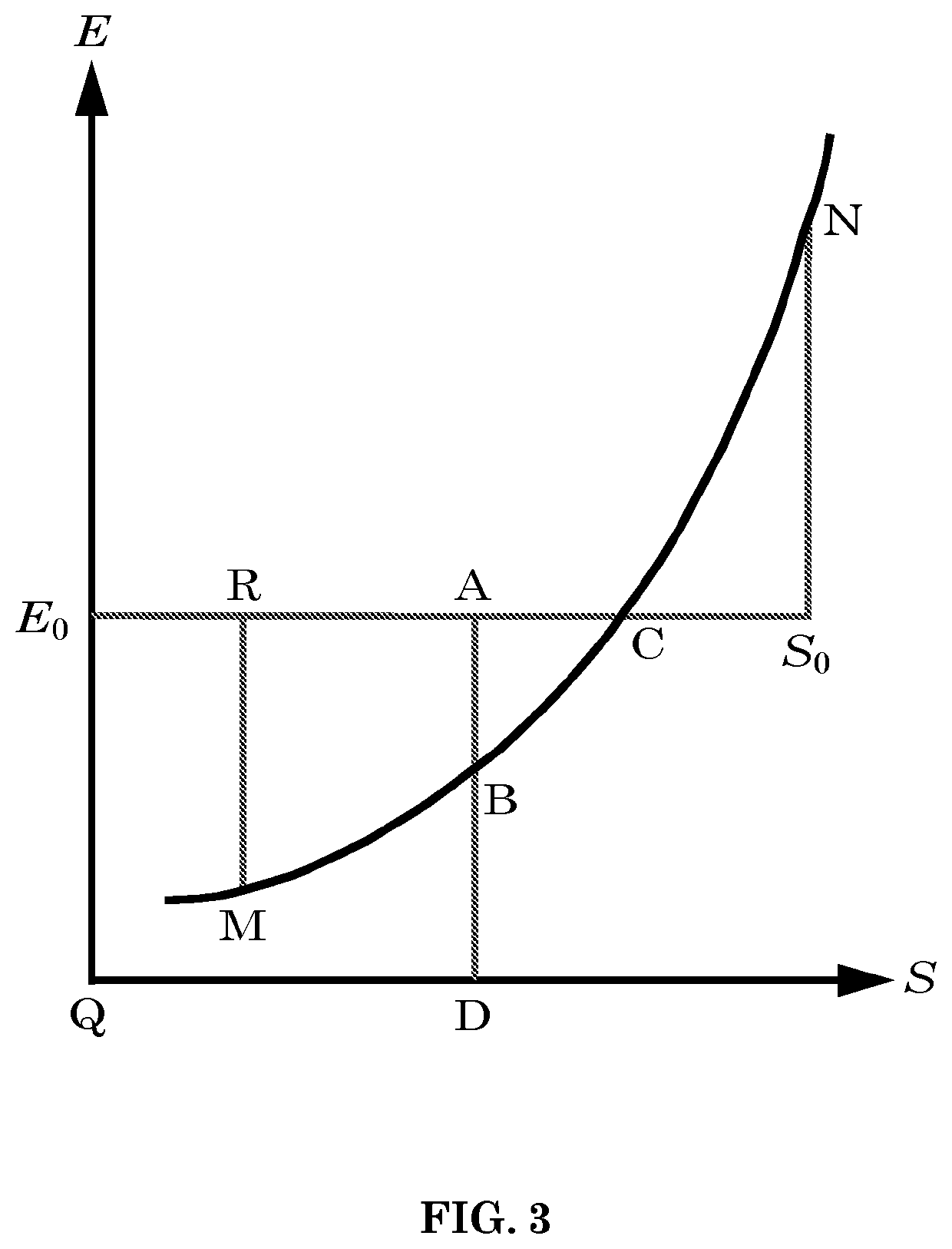

ActiveUS20120181946A1Lower effective resistanceElectroluminescent light sourcesPower supply linesControl powerActive power factor correction

A light emitting diode (LED) lighting system includes a power factor correction (PFC) controller that determines at least one power factor correction control parameter from phase delays of a phase modulated signal. In at least one embodiment, a peak voltage of the phase modulated signal is a PFC control parameter used by the PFC controller to control power factor correction and generation of a link voltage by a PFC LED driver circuit. The phase delays are related to a peak voltage of the phase modulated signal. Thus, in at least one embodiment, detecting the phase delay in one or more cycles of the phase modulated signal allows the PFC controller to determine the peak voltage of the phase modulated signal.

Owner:SIGNIFY HLDG BV

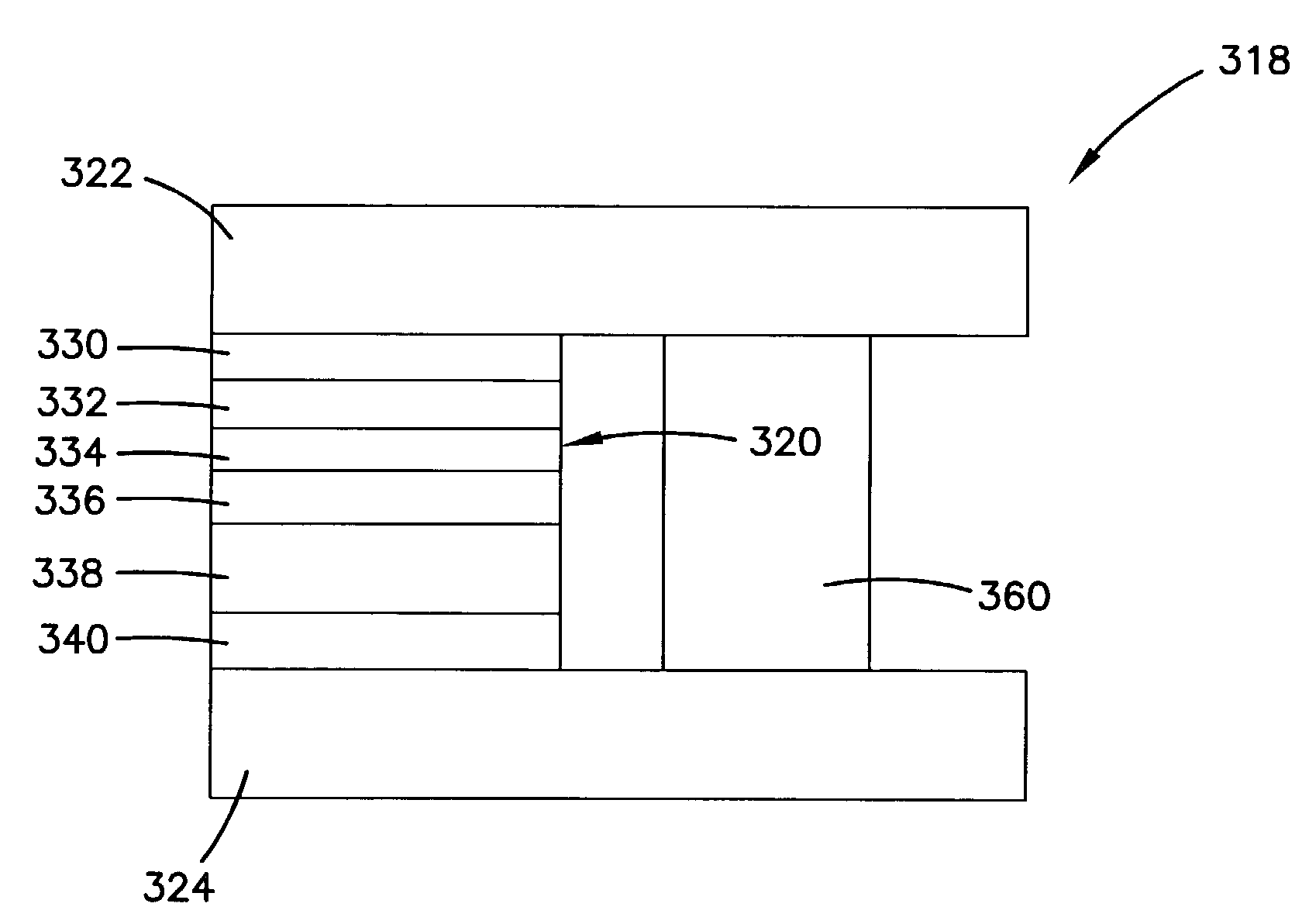

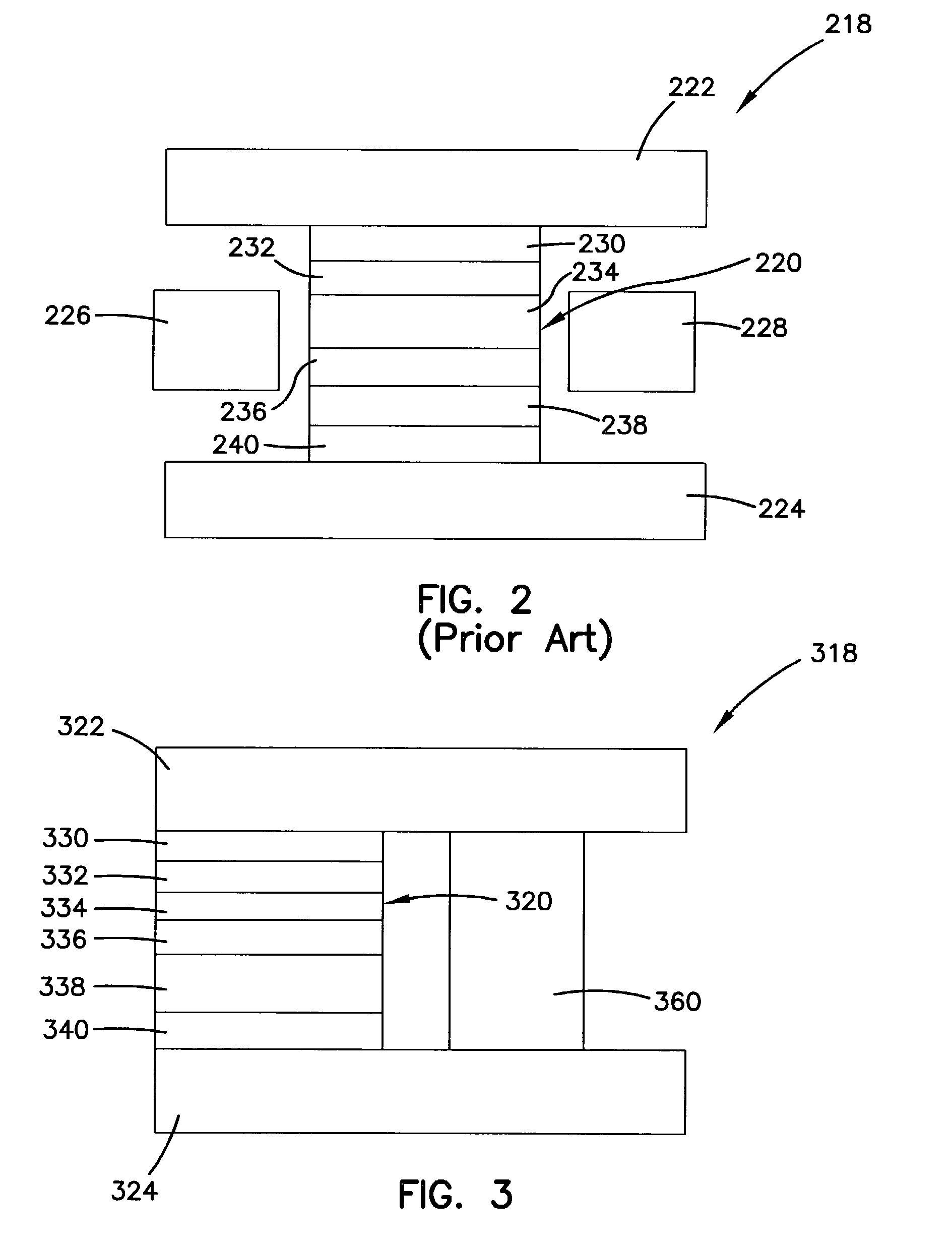

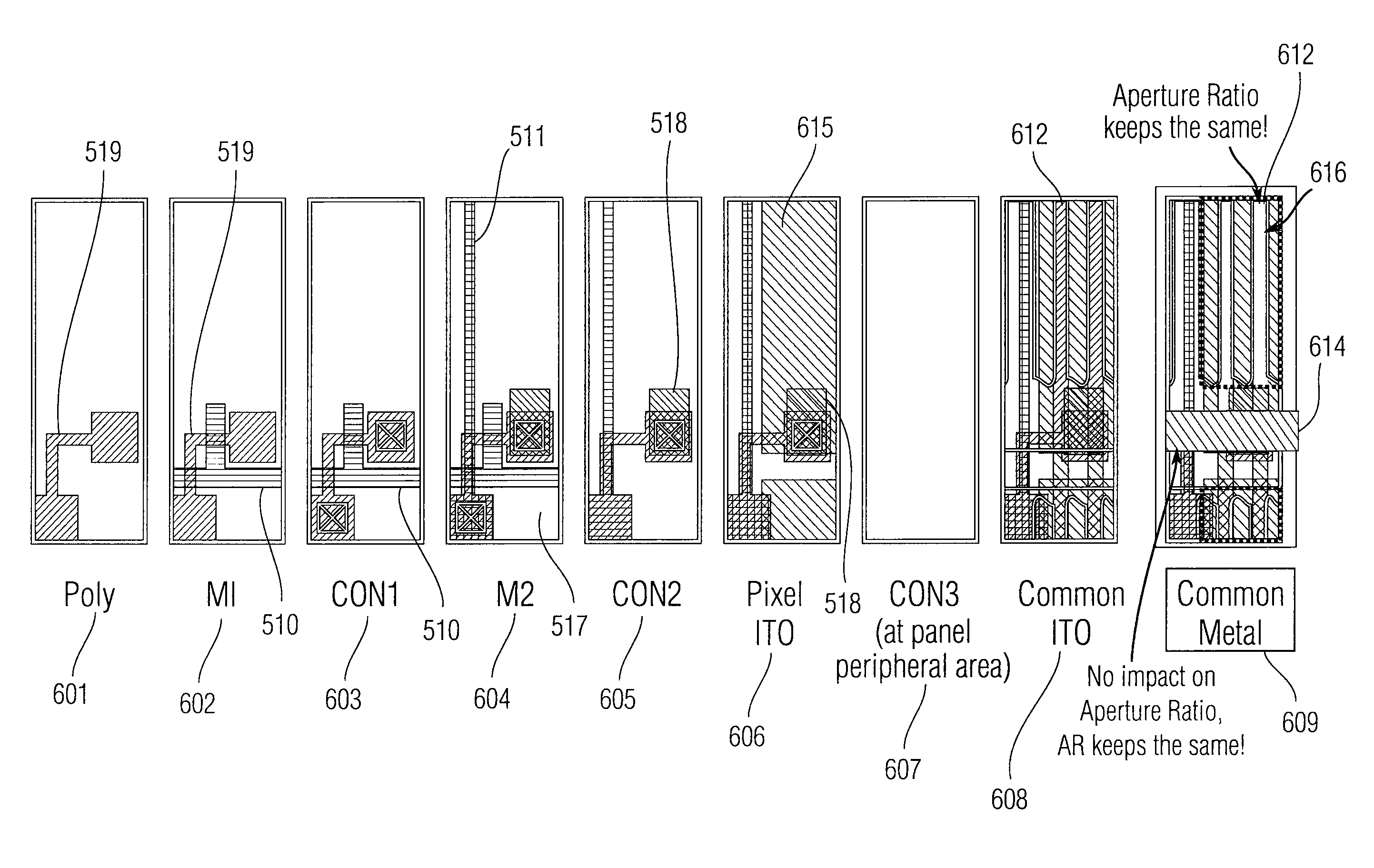

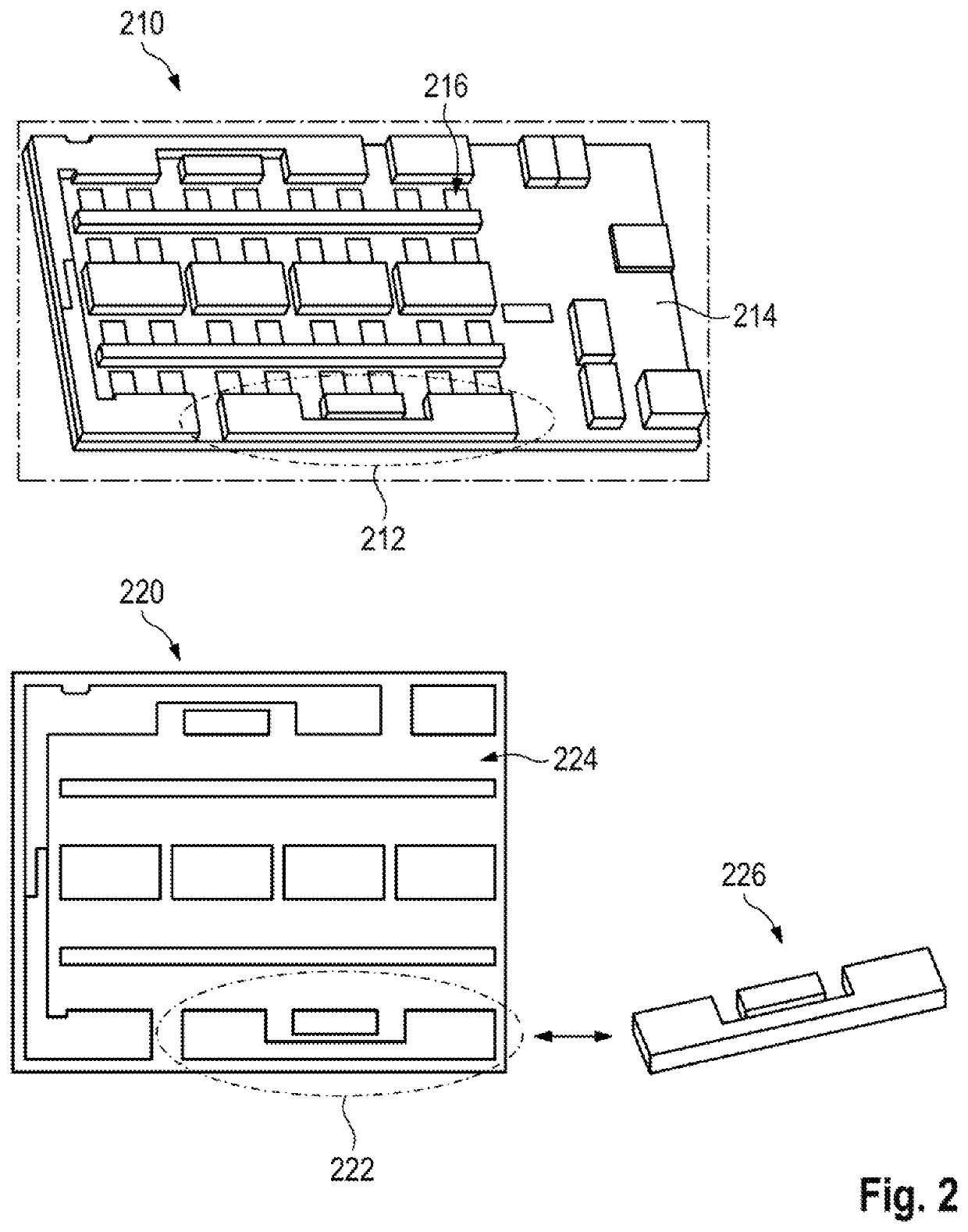

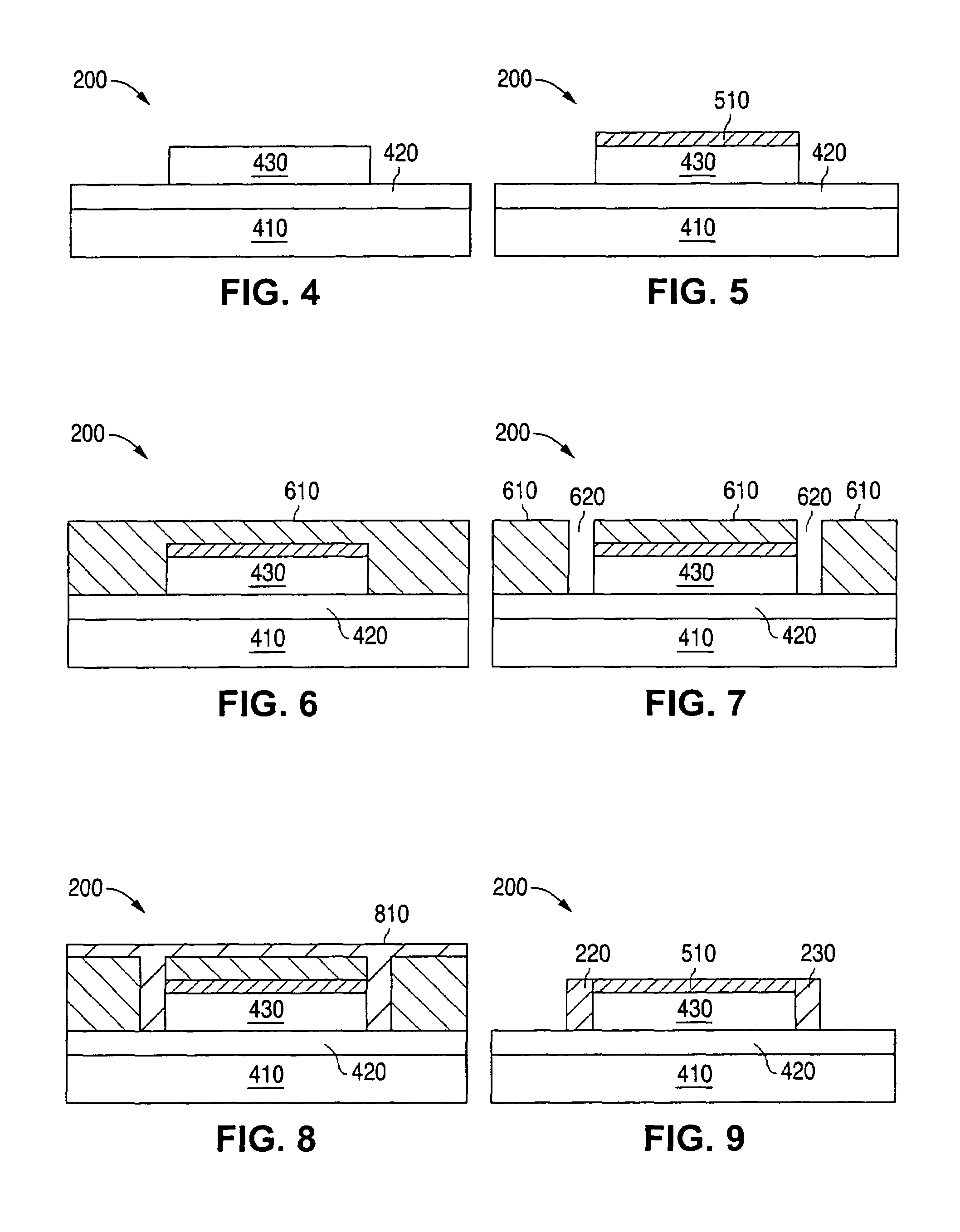

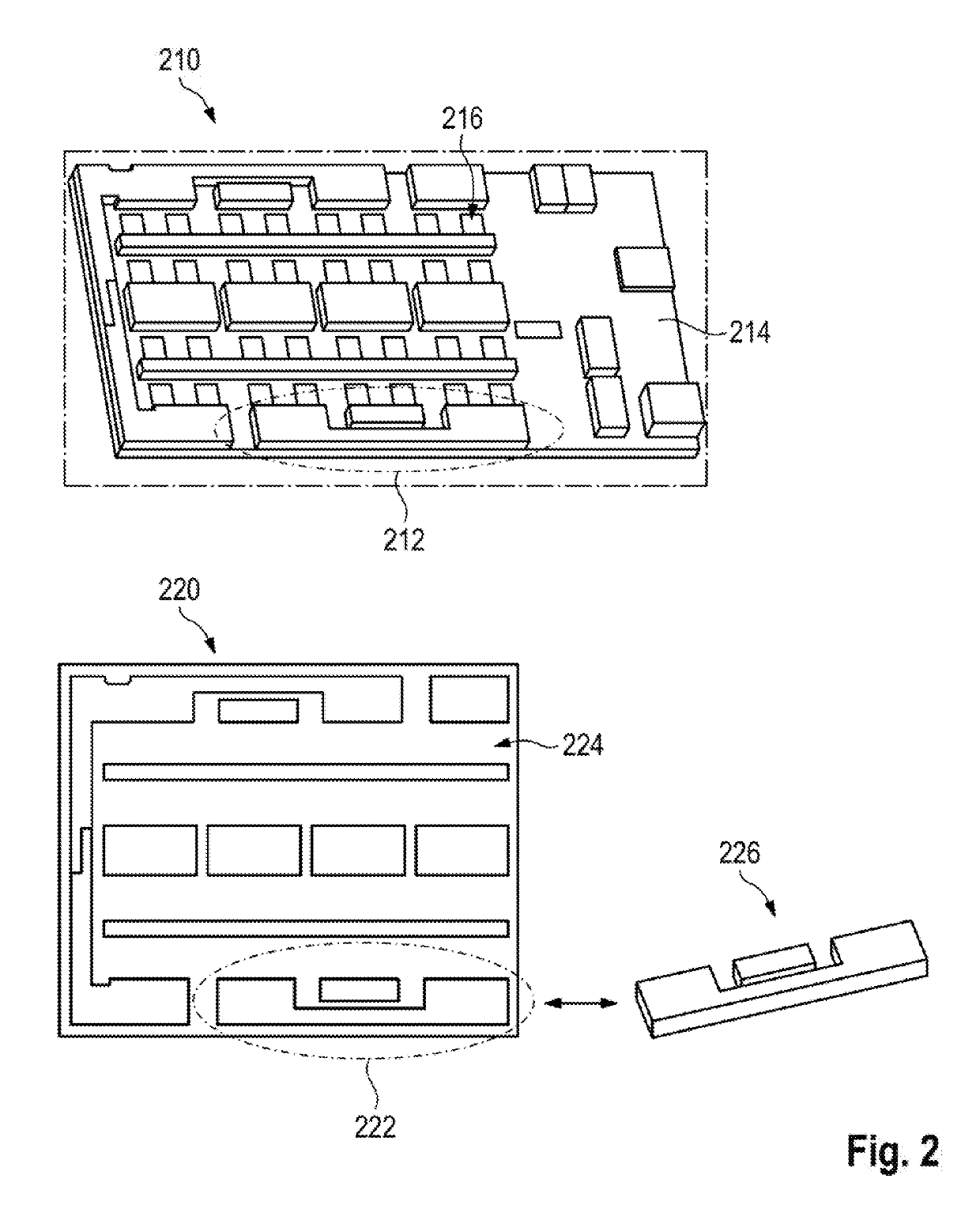

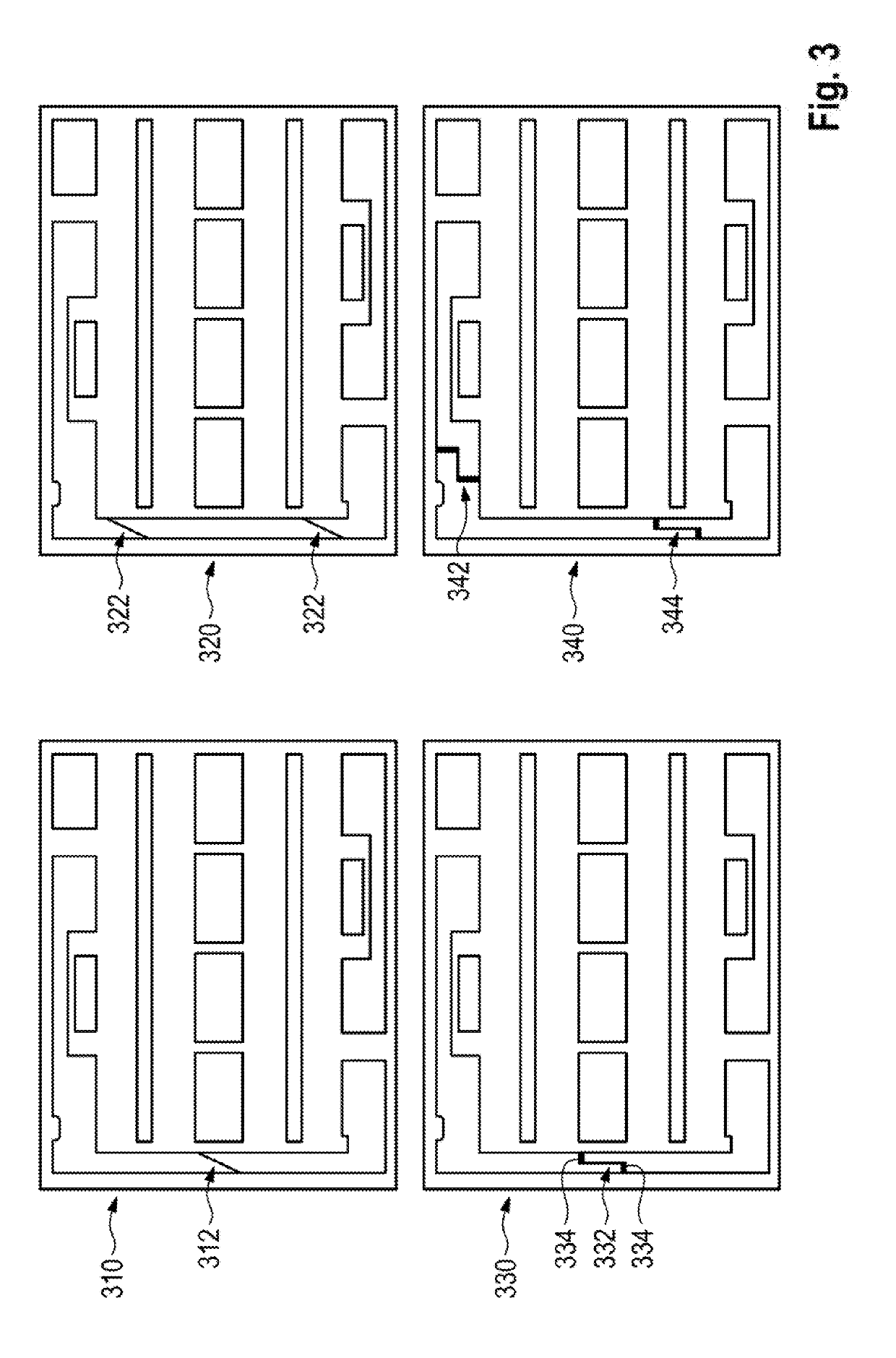

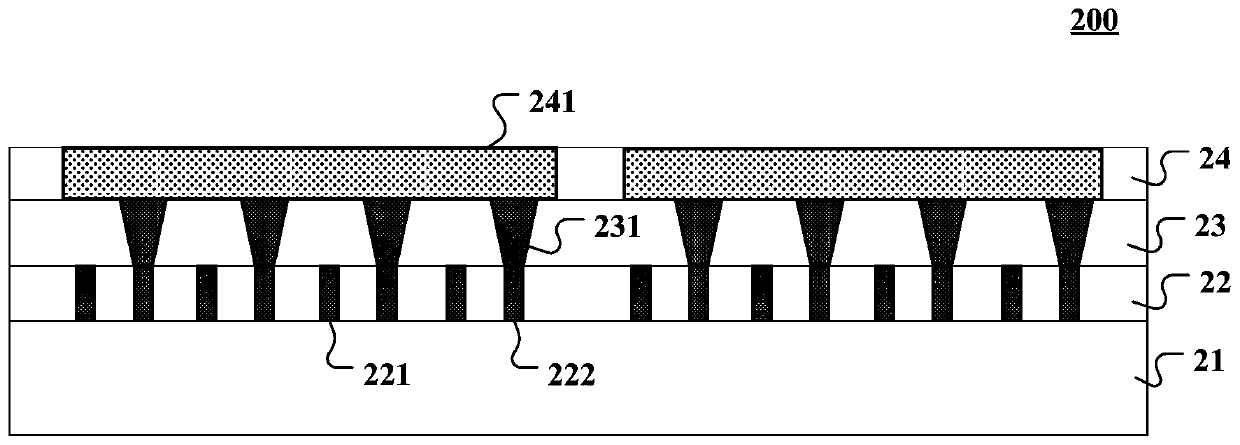

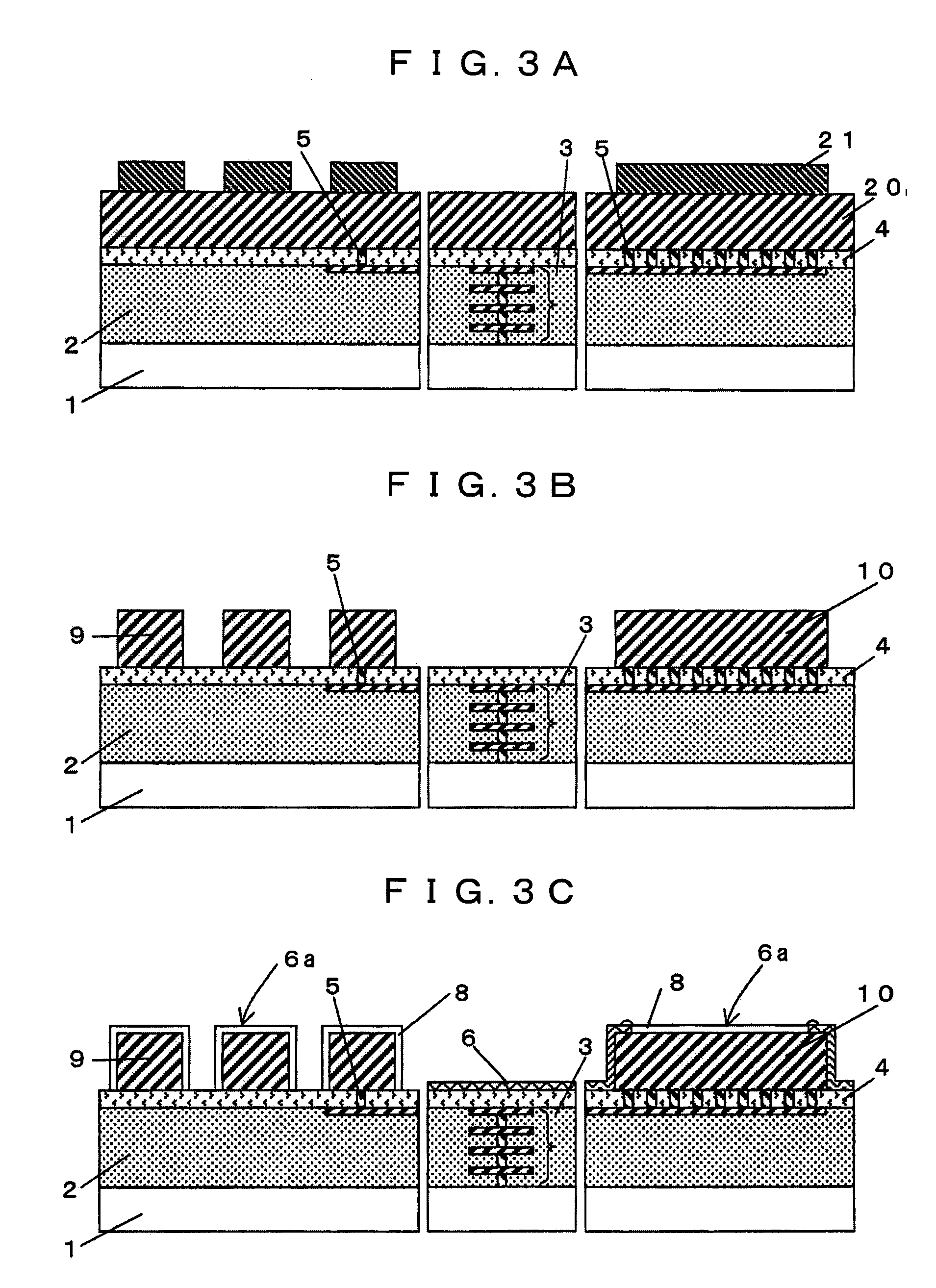

Common Bus Design for a TFT-LCD Display

ActiveUS20100123866A1High refresh rate without limiting the aperture of individual pixelsLower effective resistanceNon-linear opticsElectrical resistance and conductanceDisplay device

Embodiments of the present invention provide for a FFS TFT LCD with a high refresh rate without limiting the aperture of individual pixels. More specifically, embodiments of the invention provide for the use of common bus lines to reduce the effective resistance of the common electrode and to therefore allow for higher refresh rates of the display. Furthermore, the common bus lines can be positioned in such a manner so that they do not further reduce the aperture of the display. More specifically, the common bus lines can be positioned above or below existing elements of the display that are already opaque. Thus, adding the common bus lines need not reduce the aperture. The above can be achieved by, for example, placing the common bus lines above or below existing non-transparent lines, such as gate lines or data lines.

Owner:APPLE INC

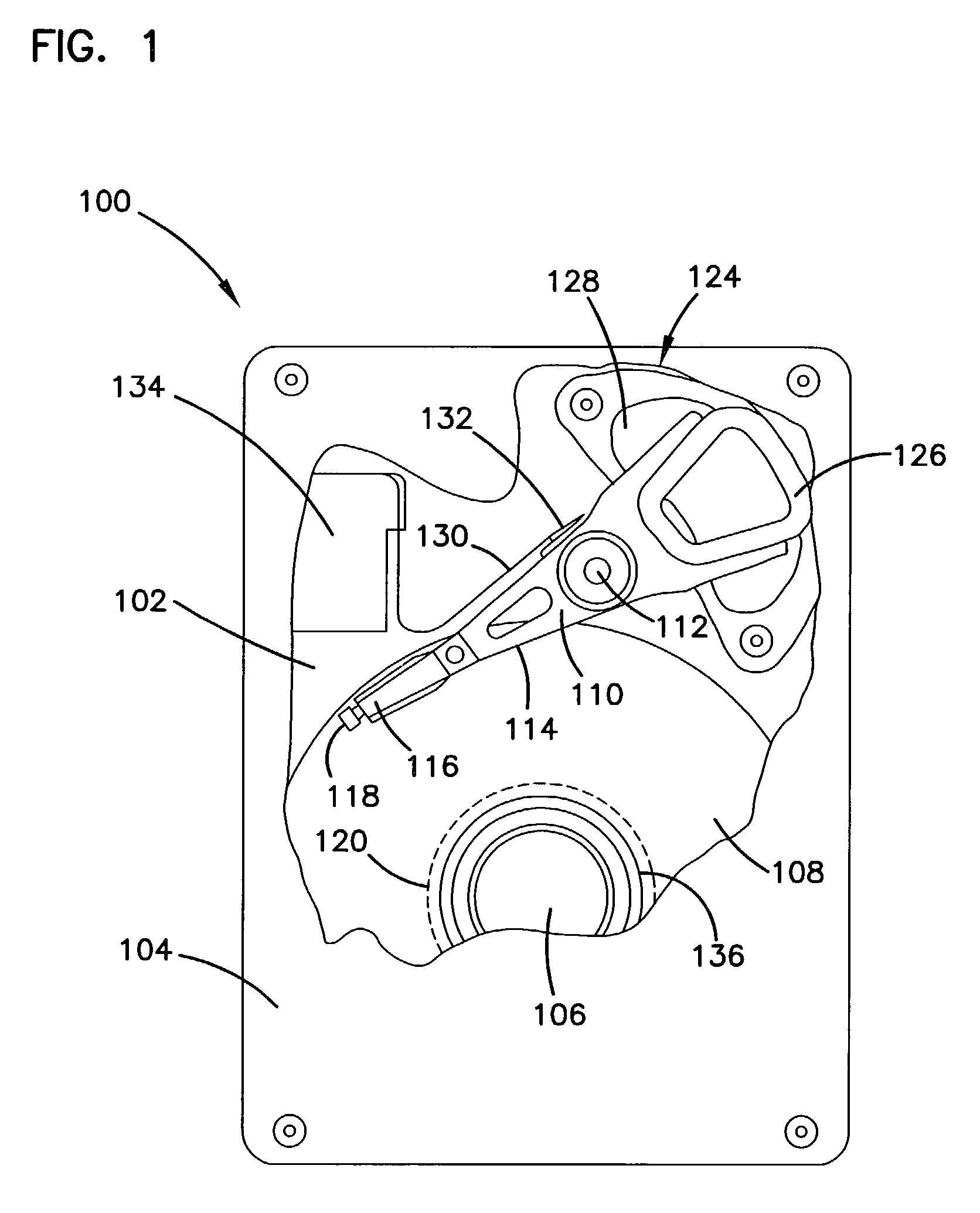

TMR head structure with conductive shunt

InactiveUS7151654B1Lower effective resistanceImprove reliabilityNanoinformaticsRecord information storageMagnetic reluctanceEngineering

The sensor of the present invention is a tunneling magnetoresistive read sensor that includes first and second electrodes, and a stack positioned between the electrodes. The stack includes at least one sense layer and a tunnel barrier. A shunt member is operatively coupled to the electrodes in parallel with the stack. The shunt member diverts current flowing from the first electrode to the second electrode when the sensor is operational so that current simultaneously flows through the stack and the shunt member to reduce the effective resistance of the sensor.

Owner:SEAGATE TECH LLC

Common bus design for a TFT-LCD display

ActiveUS8144295B2High refresh rate without limiting the aperture of individual pixelsLower effective resistanceNon-linear opticsElectrical resistance and conductanceDisplay device

Embodiments of the present invention provide for a FFS TFT LCD with a high refresh rate without limiting the aperture of individual pixels. More specifically, embodiments of the invention provide for the use of common bus lines to reduce the effective resistance of the common electrode and to therefore allow for higher refresh rates of the display. Furthermore, the common bus lines can be positioned in such a manner so that they do not further reduce the aperture of the display. More specifically, the common bus lines can be positioned above or below existing elements of the display that are already opaque. Thus, adding the common bus lines need not reduce the aperture. The above can be achieved by, for example, placing the common bus lines above or below existing non-transparent lines, such as gate lines or data lines.

Owner:APPLE INC

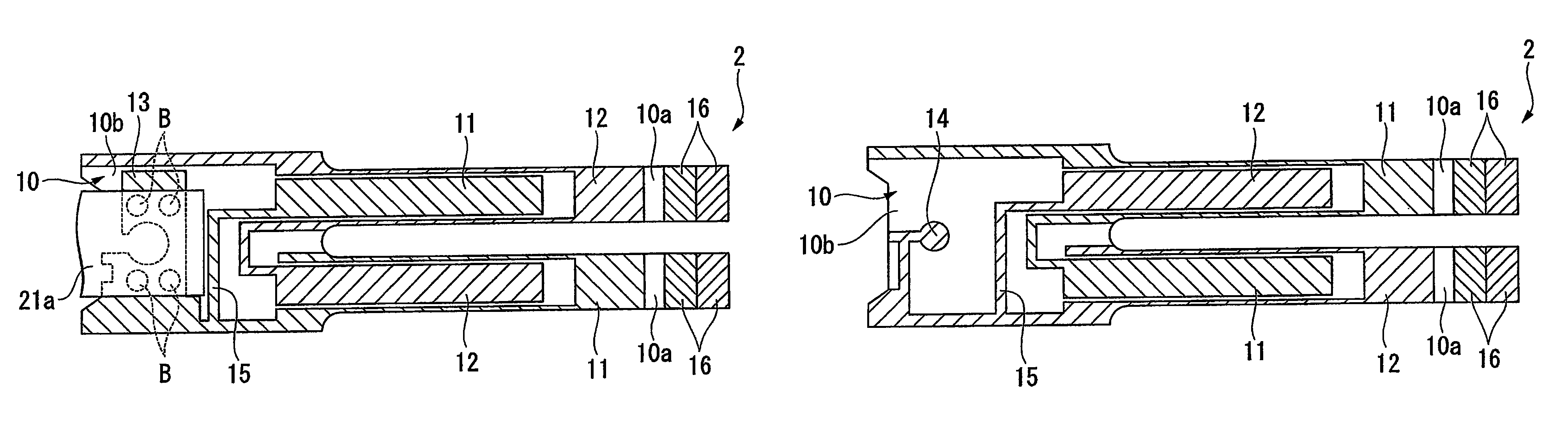

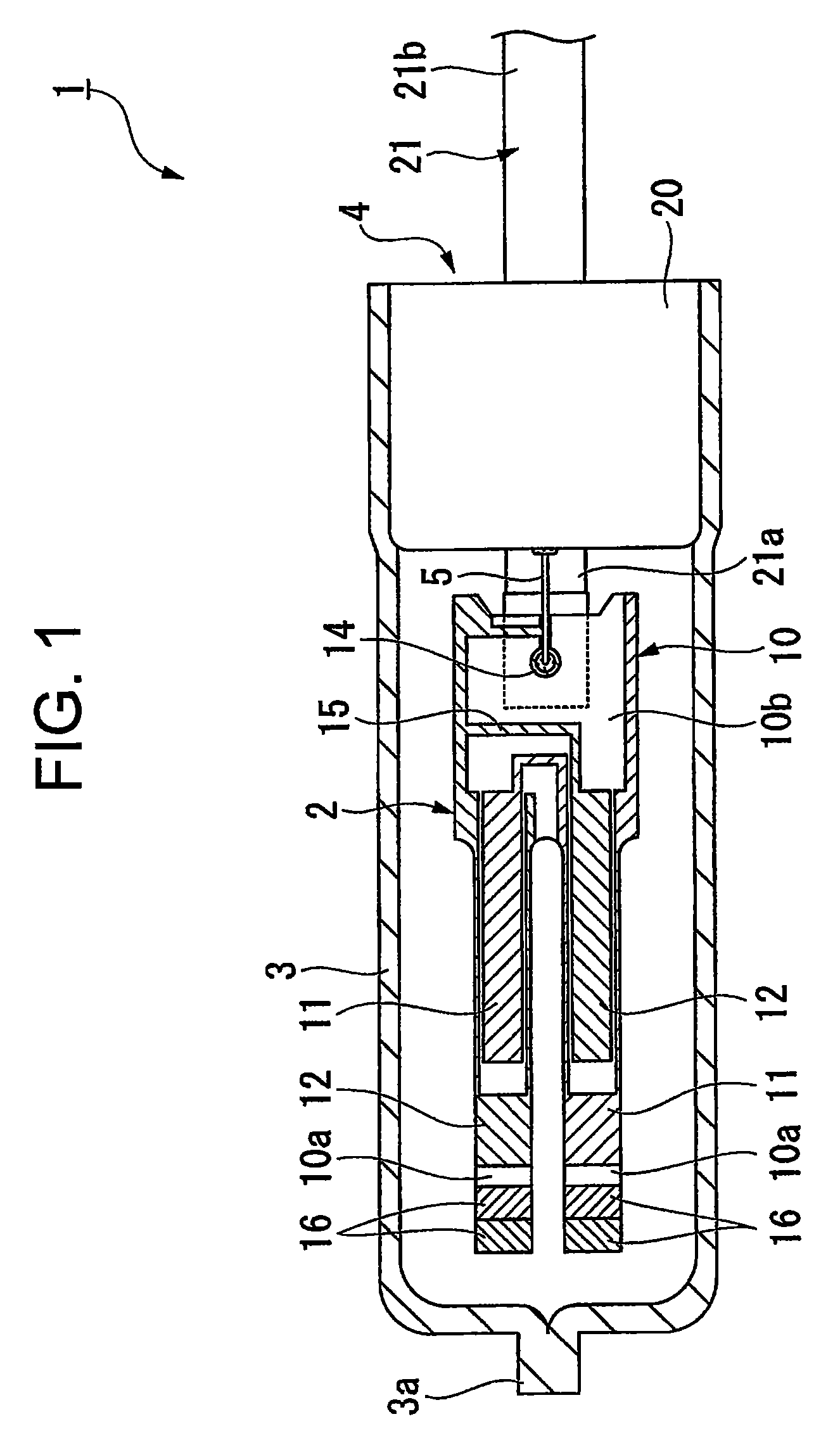

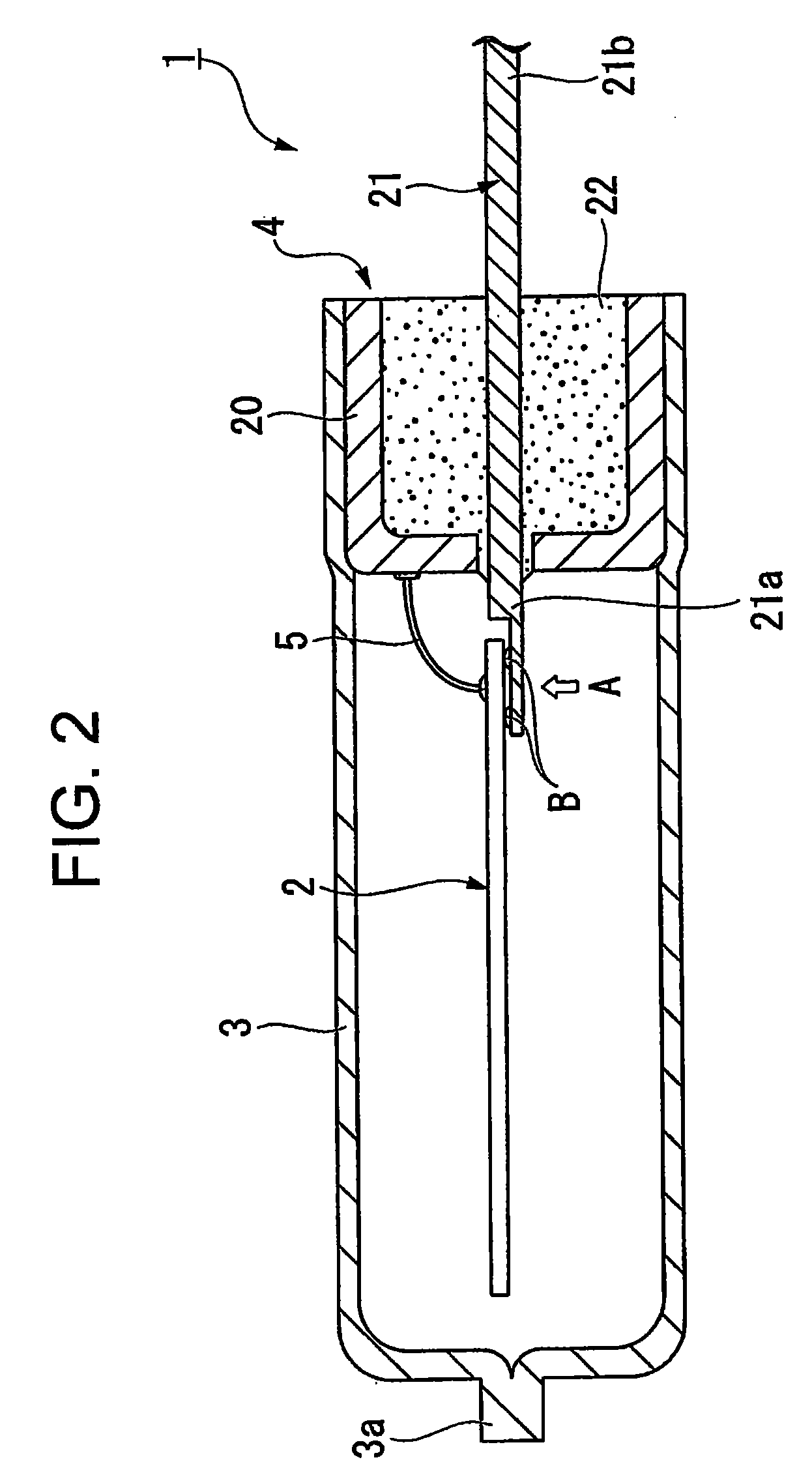

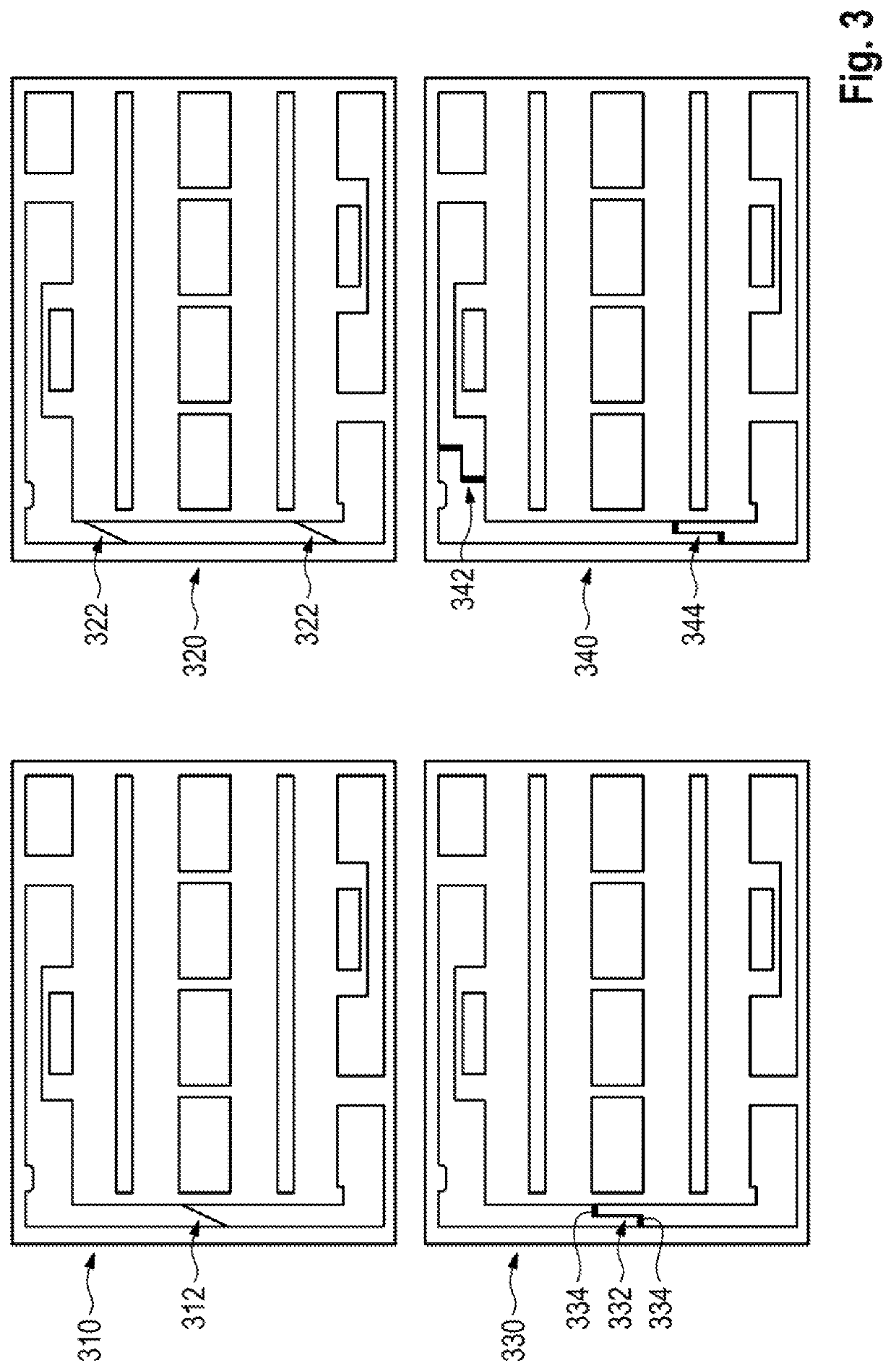

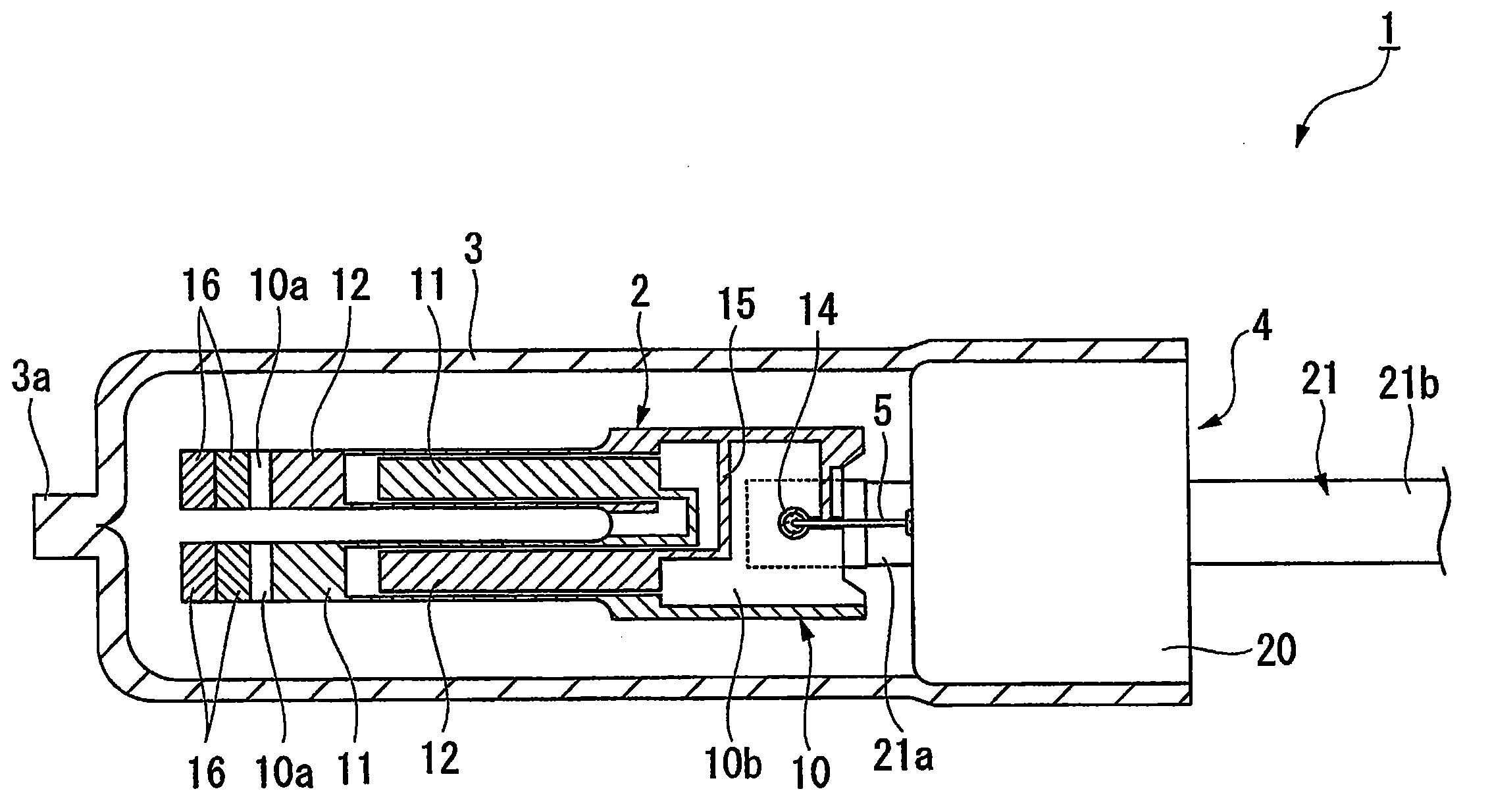

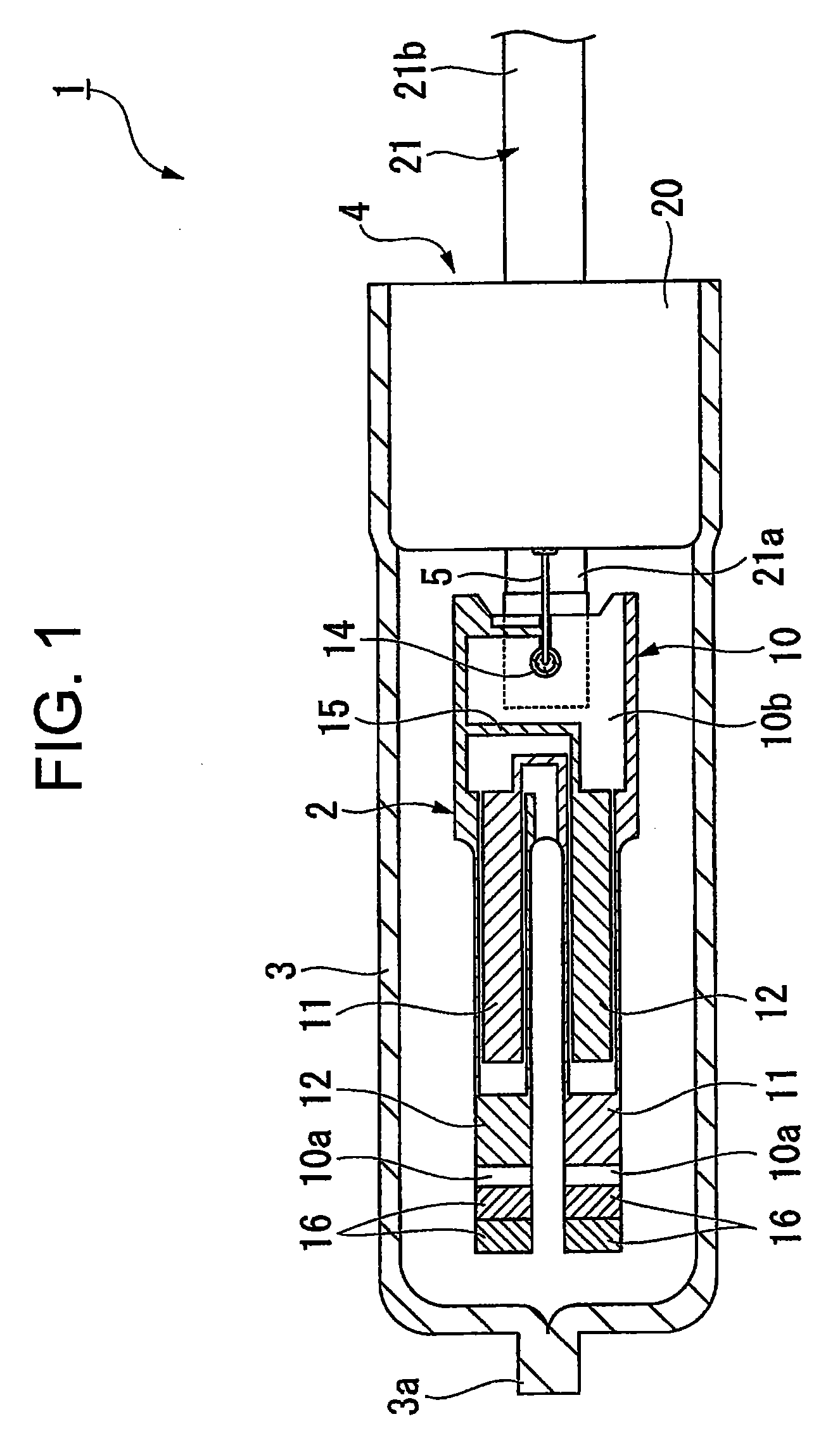

Piezoelectric vibrating reed device having improved electrode design

InactiveUS7872404B2Improve performanceAvoiding characteristicPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesVoltageElectrode

A piezoelectric vibrating reed includes a piezoelectric plate made of a piezoelectric material, a pair of exciter electrodes formed on outer surfaces of the piezoelectric plate and configured to vibrate the piezoelectric plate when a predetermined voltage is applied thereon, and a pair of mount electrodes electrically connected to the pair of exciter electrodes, respectively. One mount electrode in the pair of mount electrodes is formed on one surface (under surface) of the piezoelectric plate and the other mount electrode is formed on the other surface (top surface) of the piezoelectric plate in a state not to oppose the one mount electrode with the piezoelectric plate in between. Accordingly, not only can power be saved, but also higher performance can be achieved by lowering the R1 characteristic and thereby enhancing the vibration characteristic.

Owner:SII CRYSTAL TECH

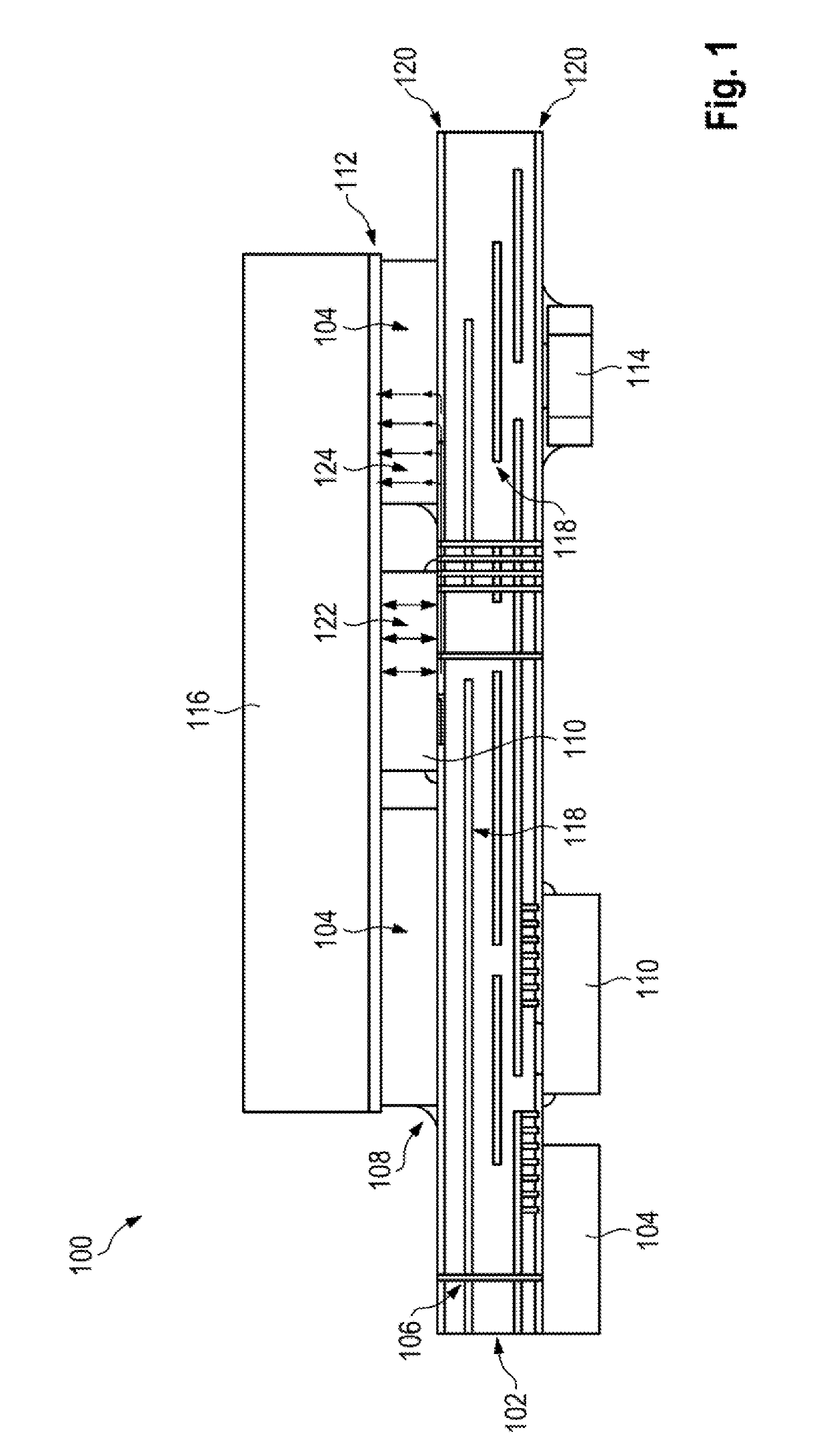

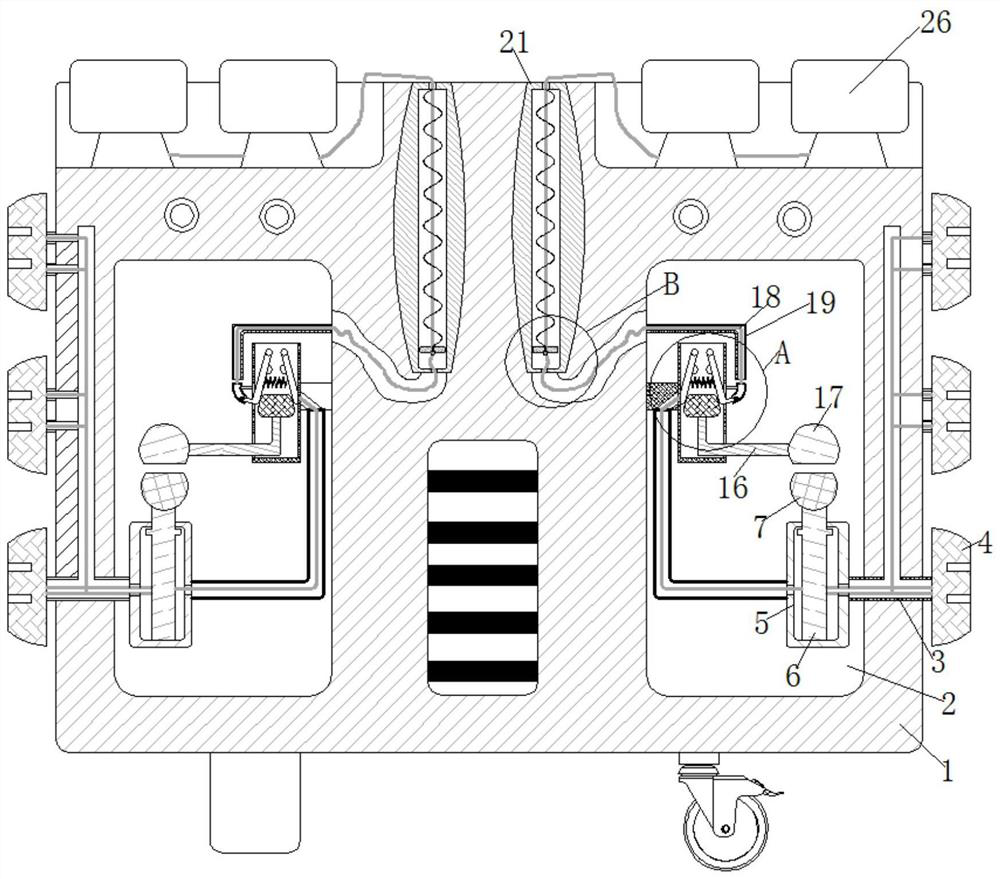

Cooling of power electronics circuits

ActiveUS10980103B2High resolutionPrevent high current densitySemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorEngineering

A method for cooling power electronics circuits, in which a printed circuit board is produced according to a prescribed circuit board process and is populated with at least one power electronics components. Contact connecting at least one location on at least one metallic conductor track running on a surface of the printed circuit board that includes at least one metal element, which is both electrically conductive and heat-conductive and the physical height of which is designed to be at least as large as that of the at least one power electronics component. A cooling plate is placed in a planar manner onto the at least one power electronics component and / or the at least one metal element.

Owner:DR ING H C F PORSCHE AG

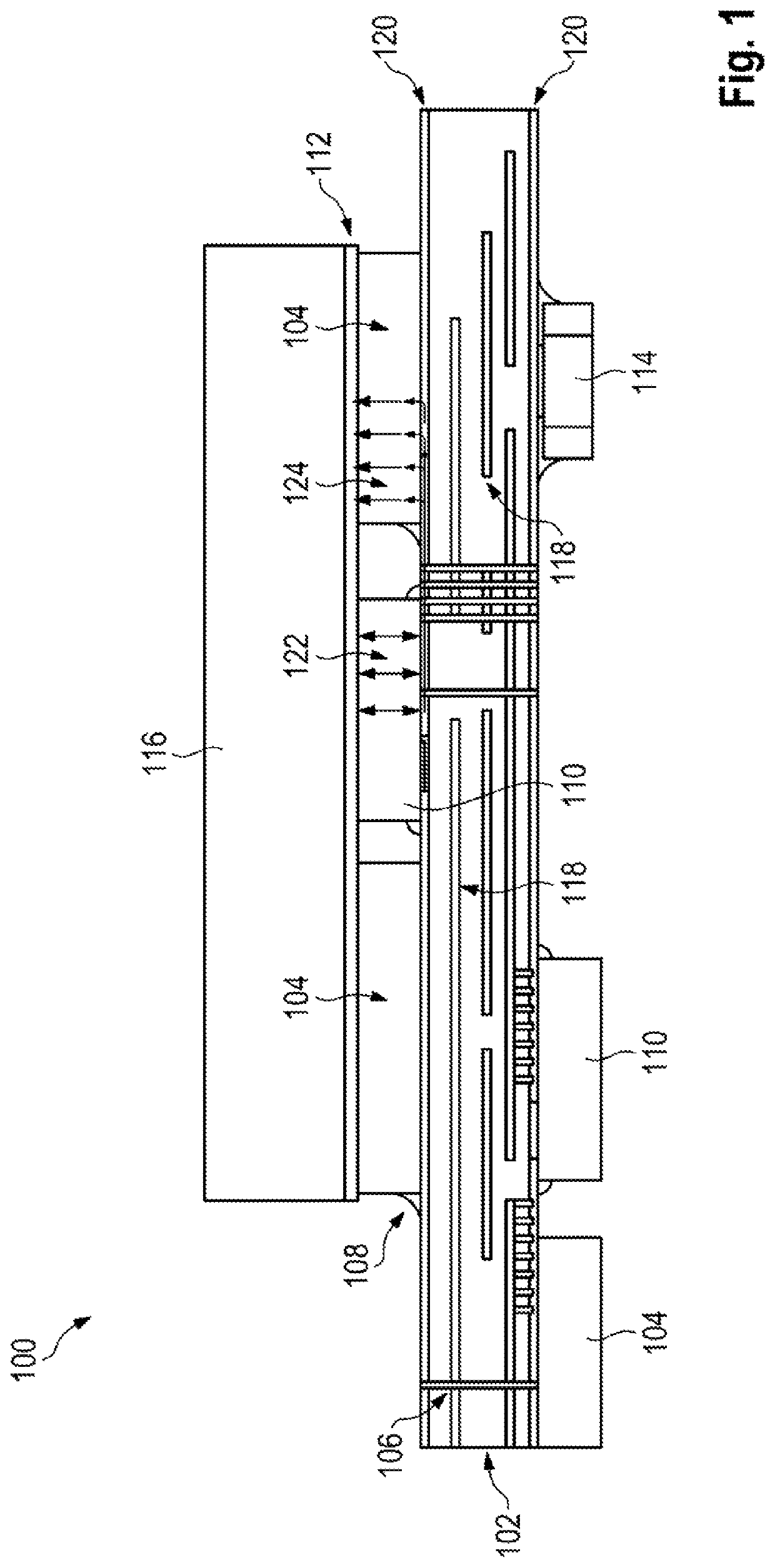

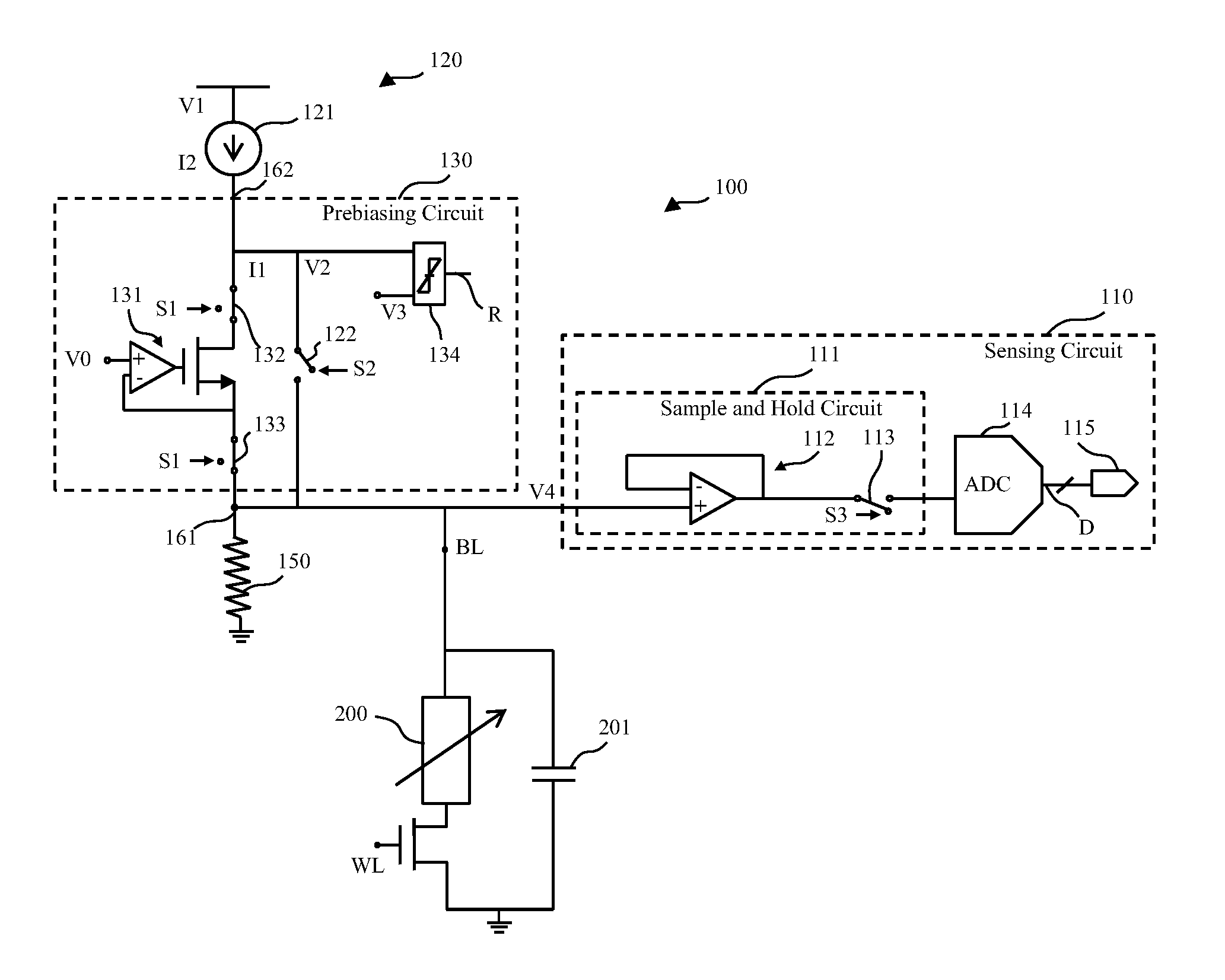

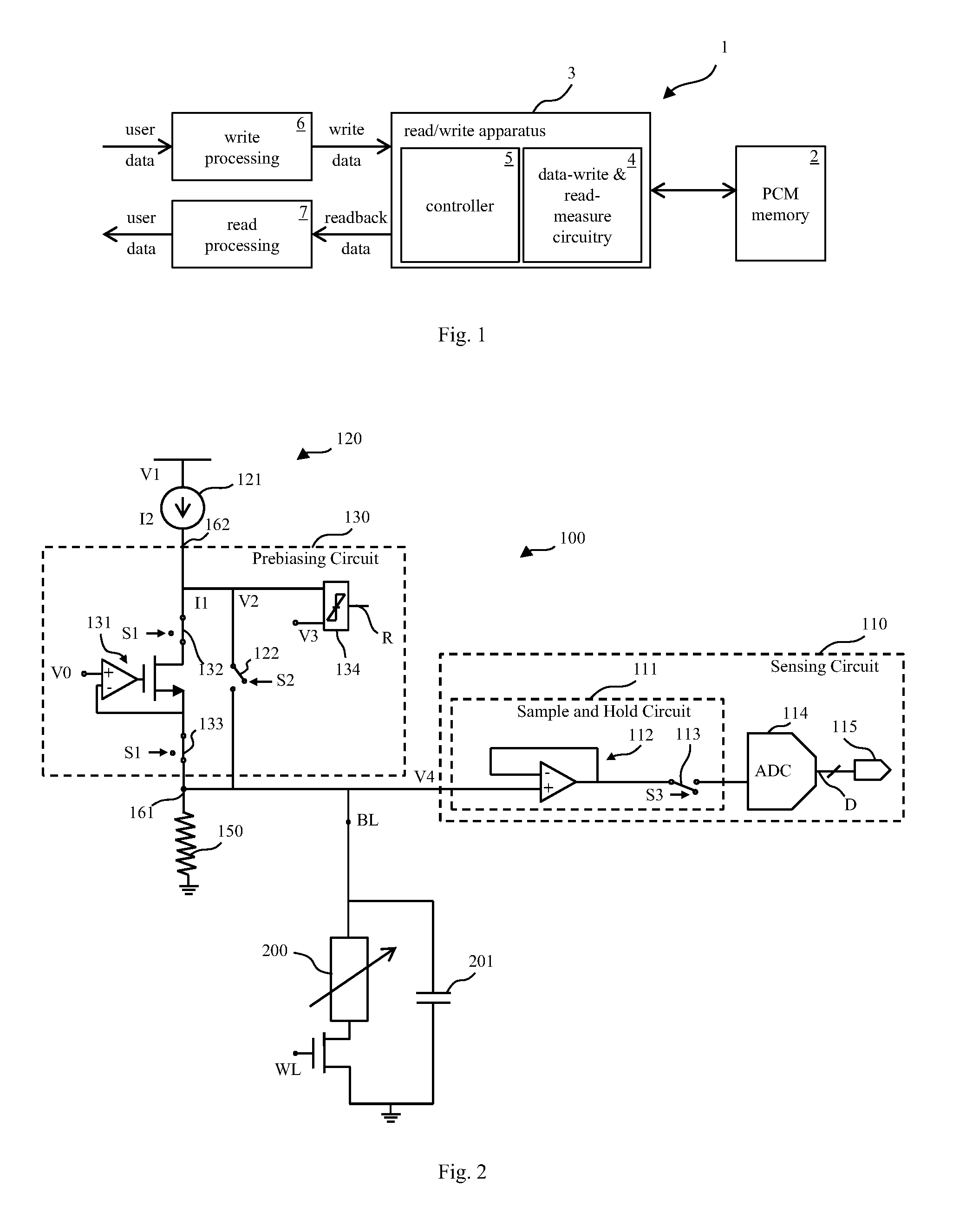

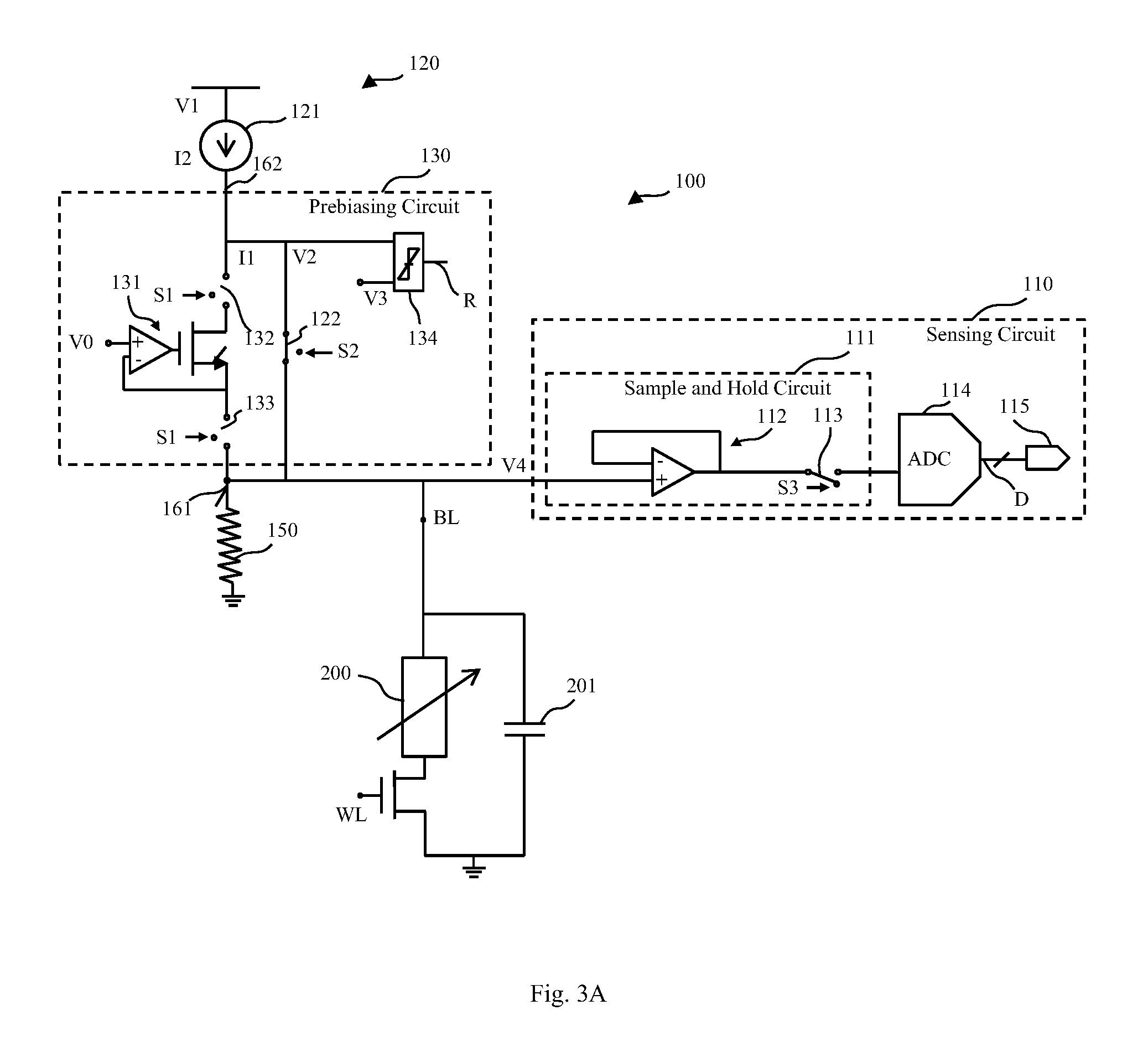

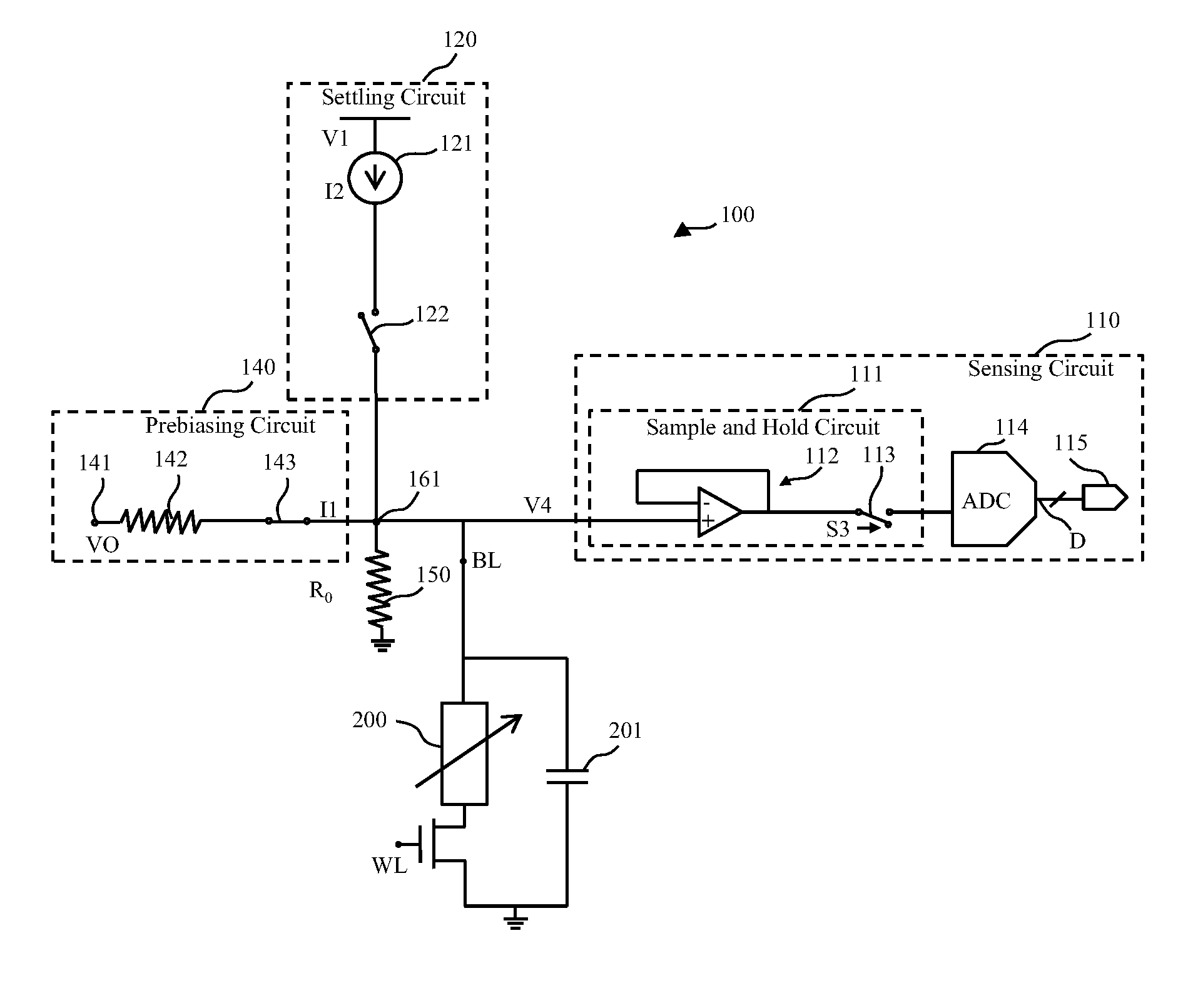

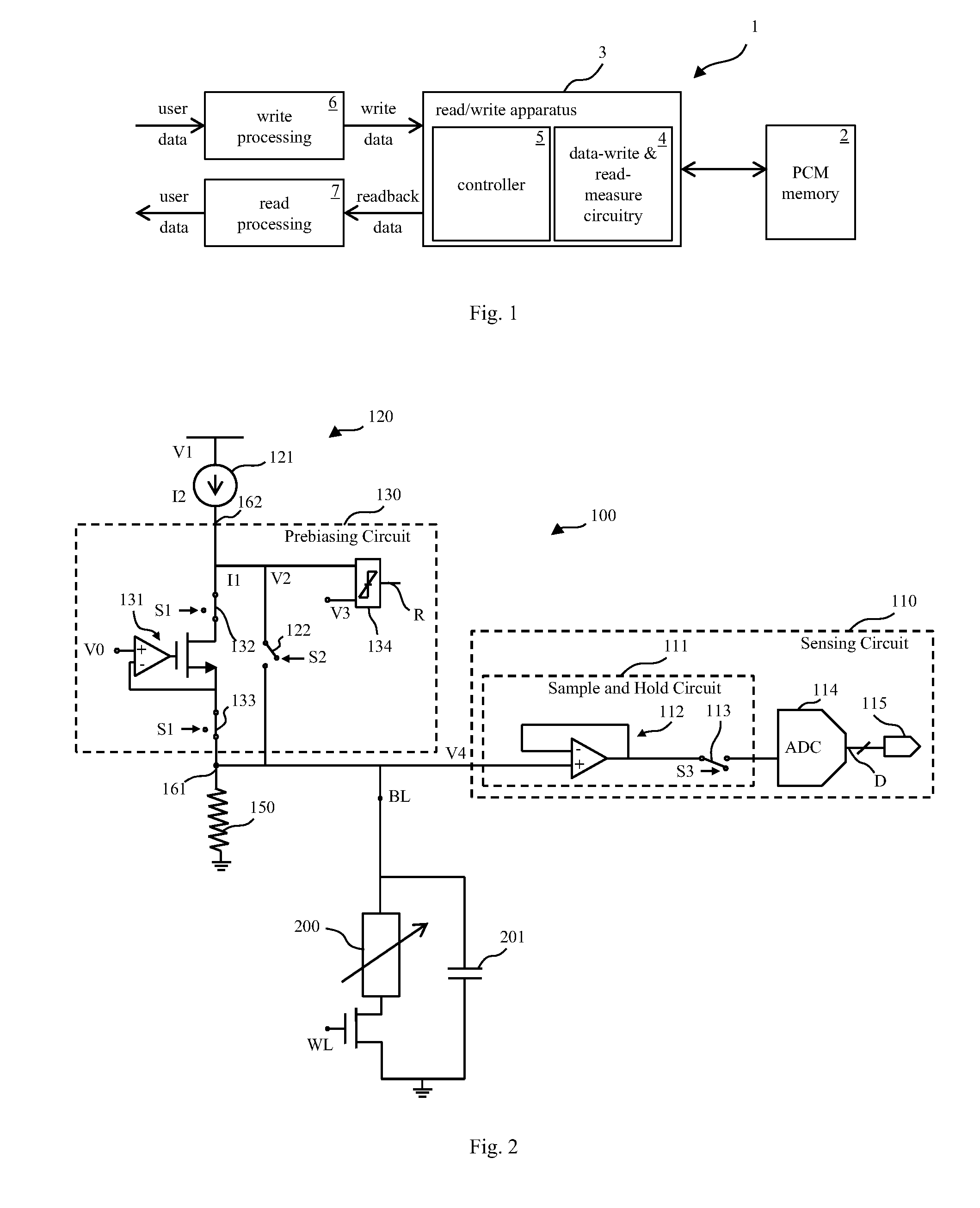

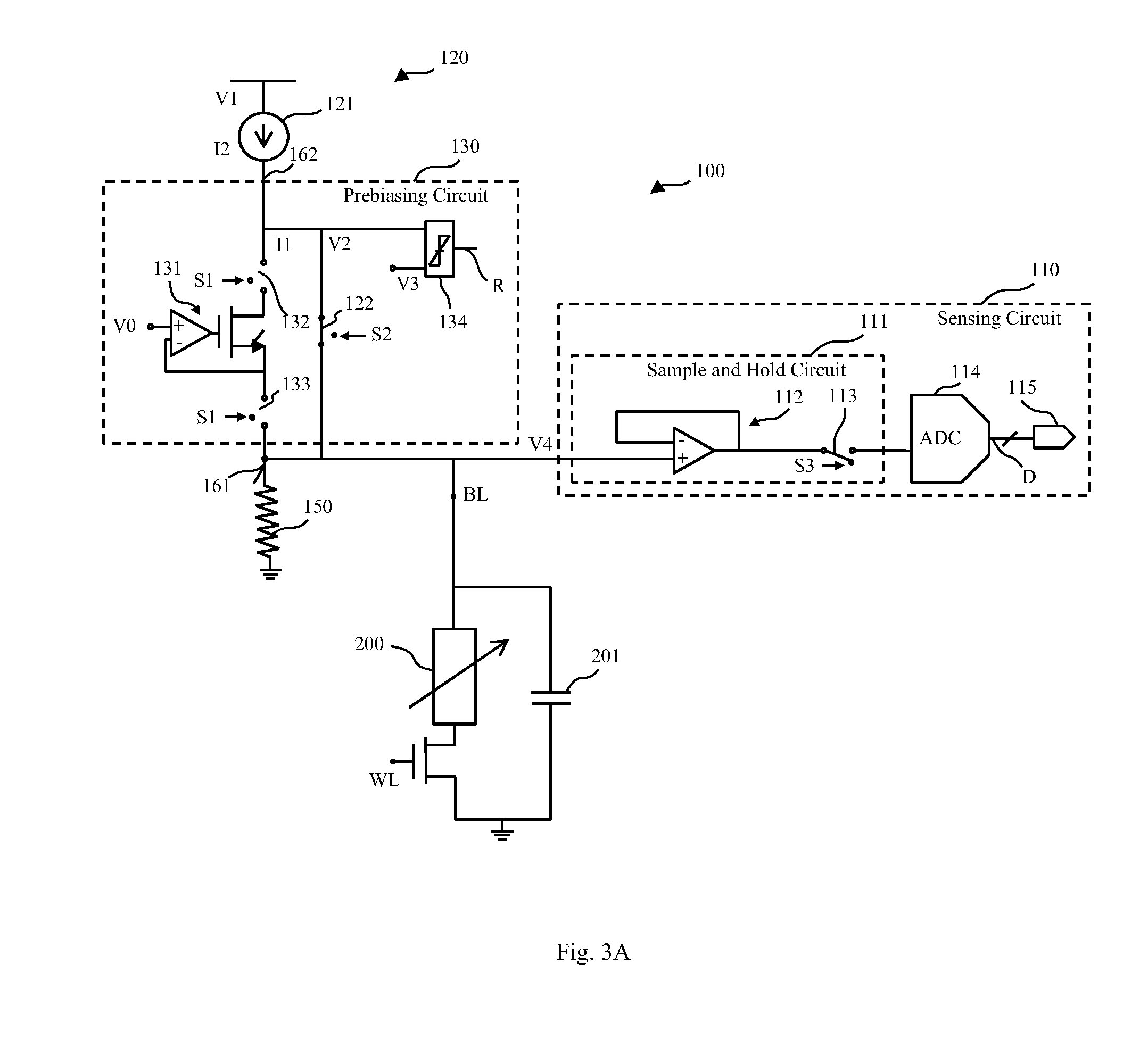

Method and apparatus for faster determination of a cell state of a resistive memory cell using a parallel resistor

A device for determining an actual cell state of a resistive memory cell having a plurality M of programmable cell states comprising a sensing circuit, a settling circuit, a prebiasing circuit, and a resistor coupled in parallel to the resistive memory cell, wherein the resistor is configured to reduce an effective resistance seen by the prebiasing circuit. The sensing circuit is configured to sense a sensing voltage of the resistive memory cell and output a resultant value in response to the sensing voltage which is indicative for the actual cell state. The settling circuit is configured to settle the sensing voltage to a certain target voltage representing one of the M programmable cell states. The prebiasing circuit is configured to prebiase a bitline capacitance of the resistive memory cell such the sensing voltage is close to the certain target voltage.

Owner:INT BUSINESS MASCH CORP

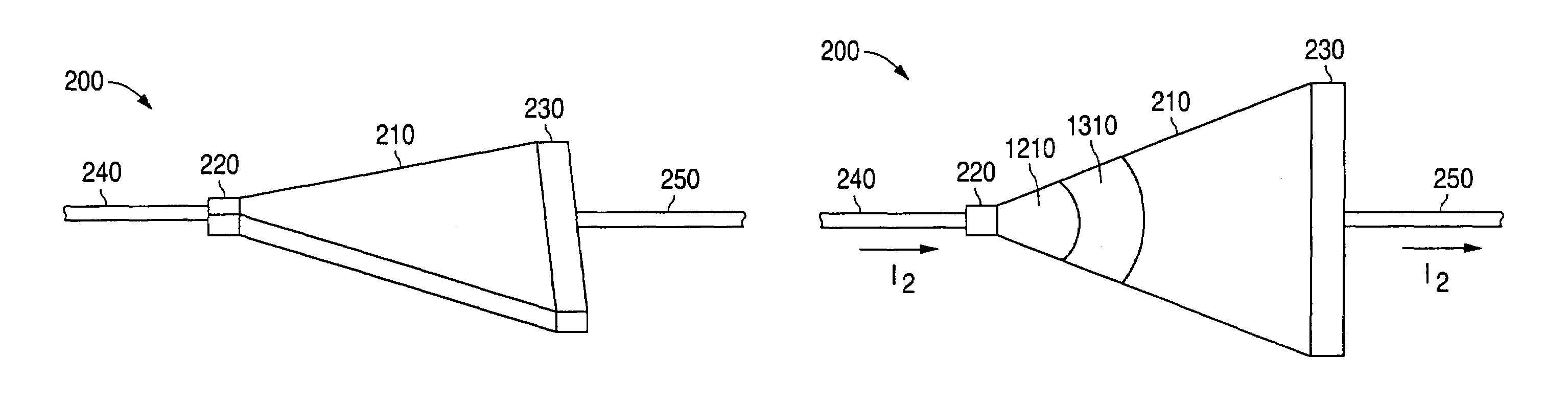

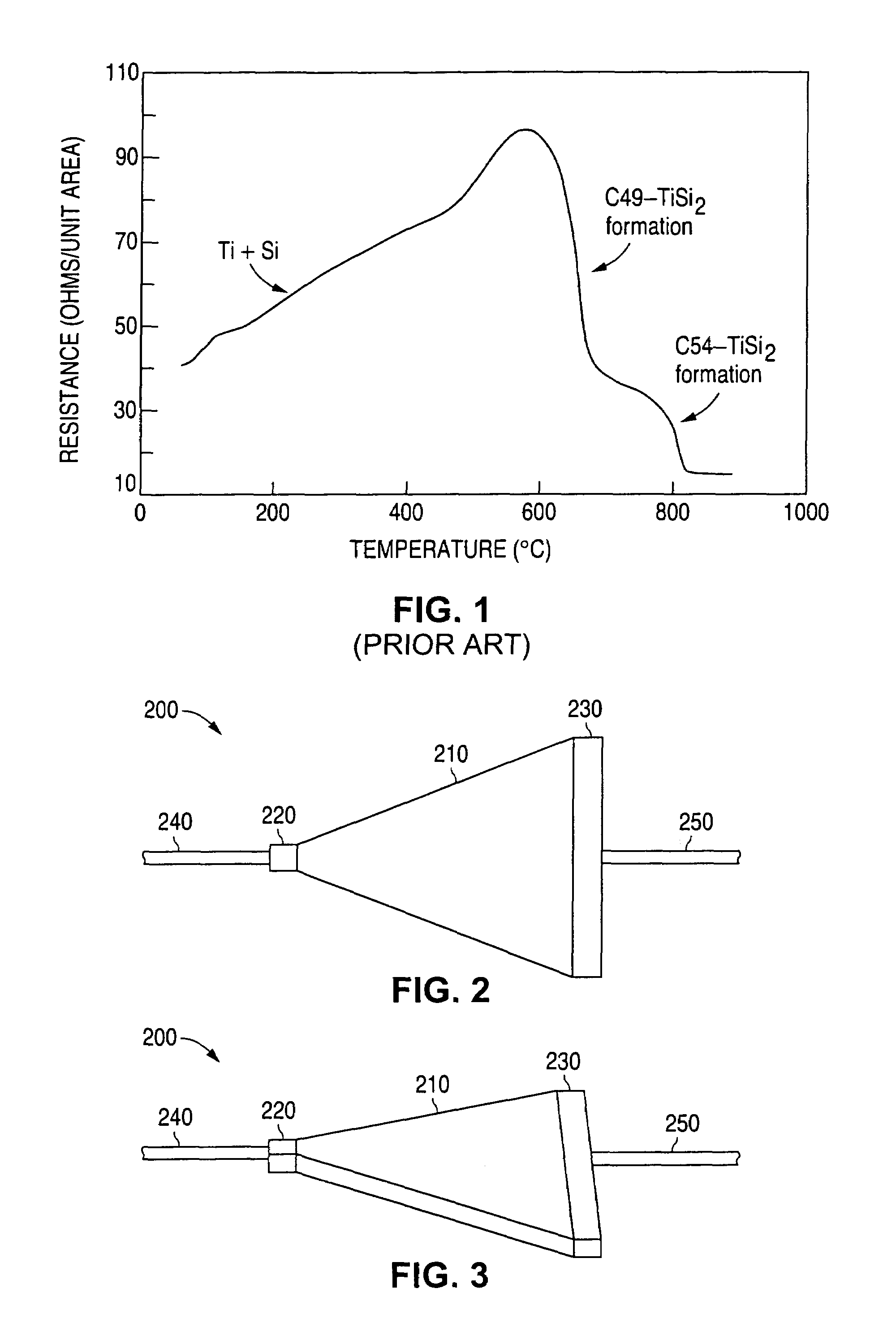

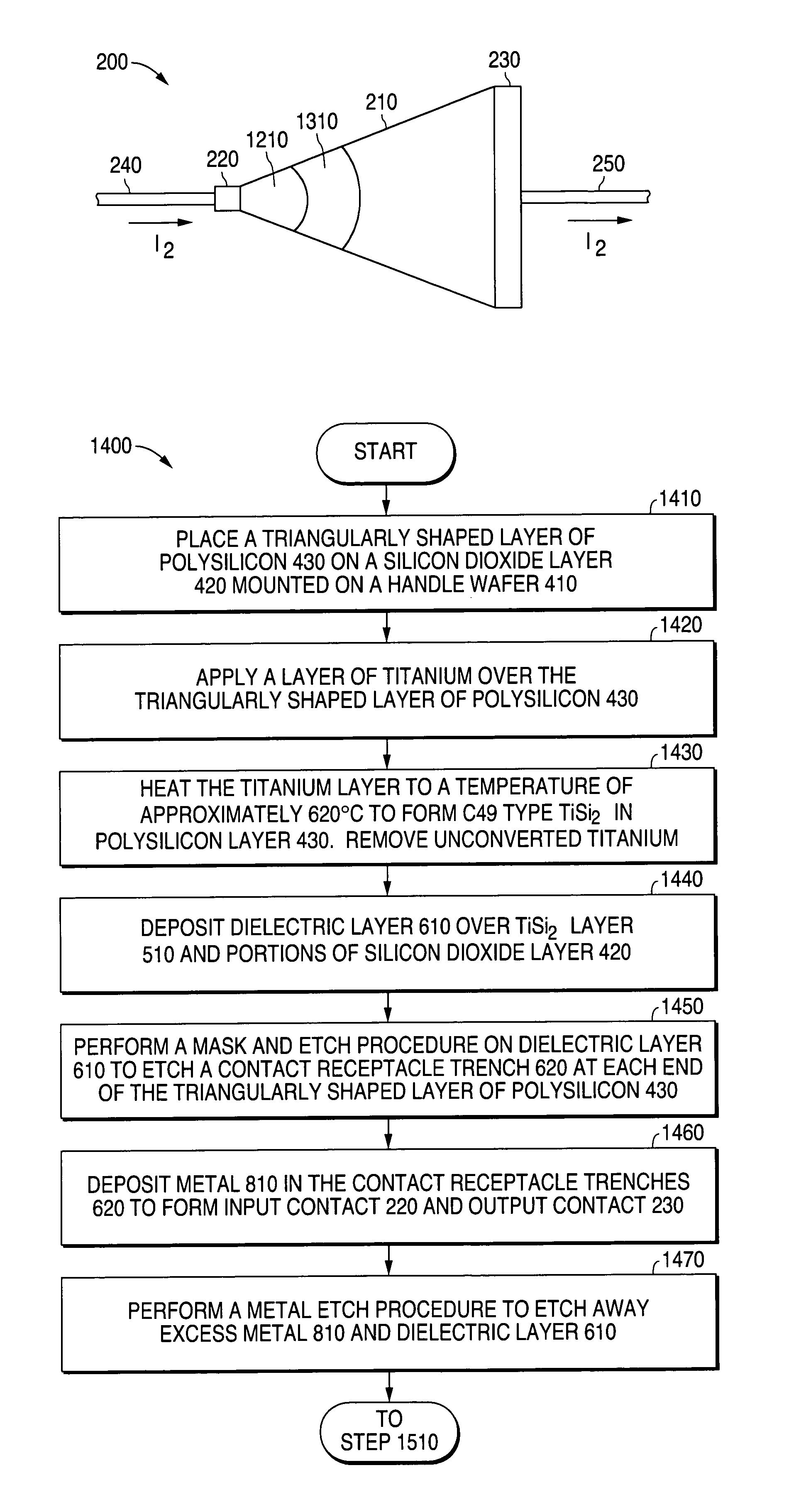

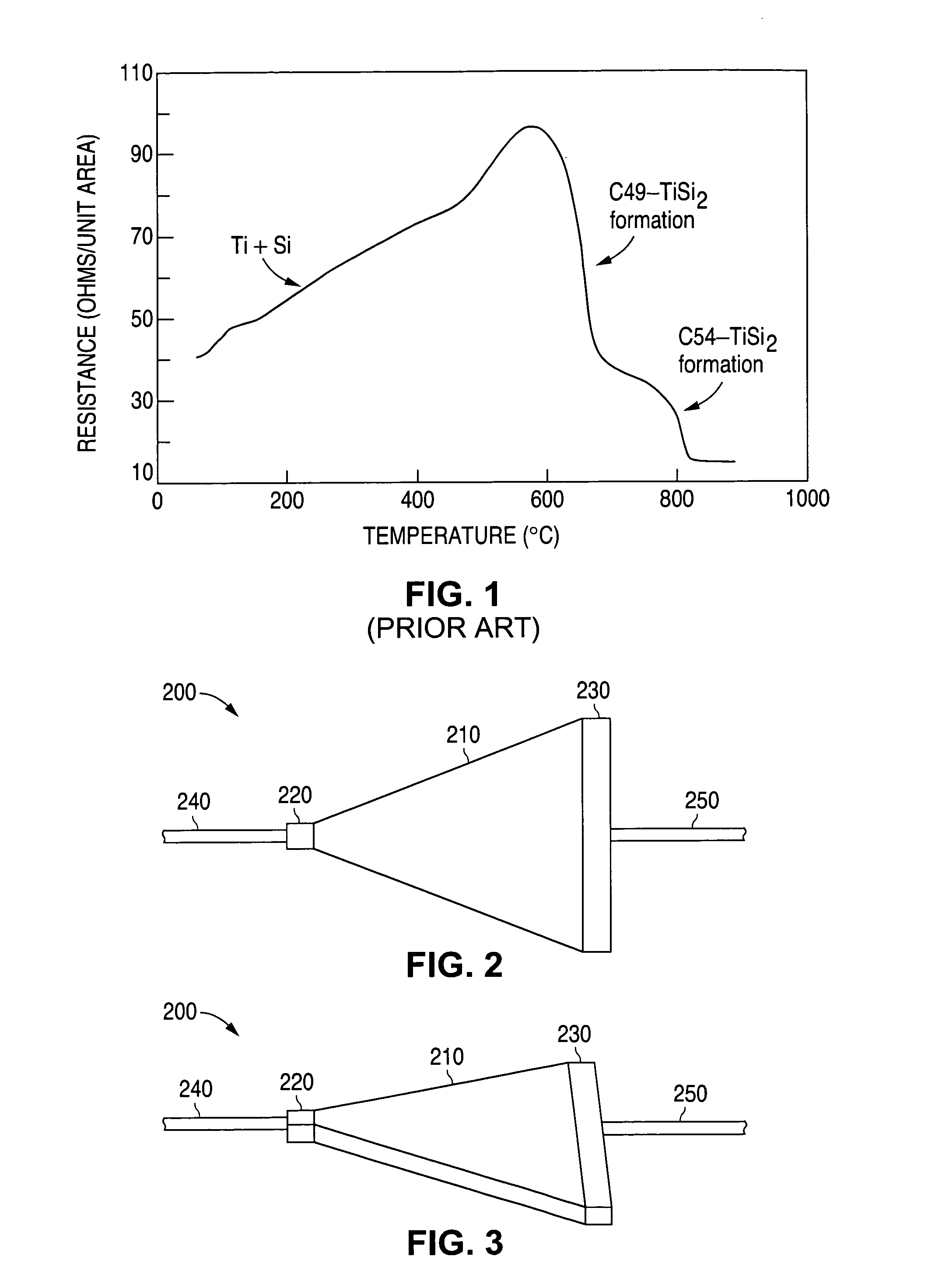

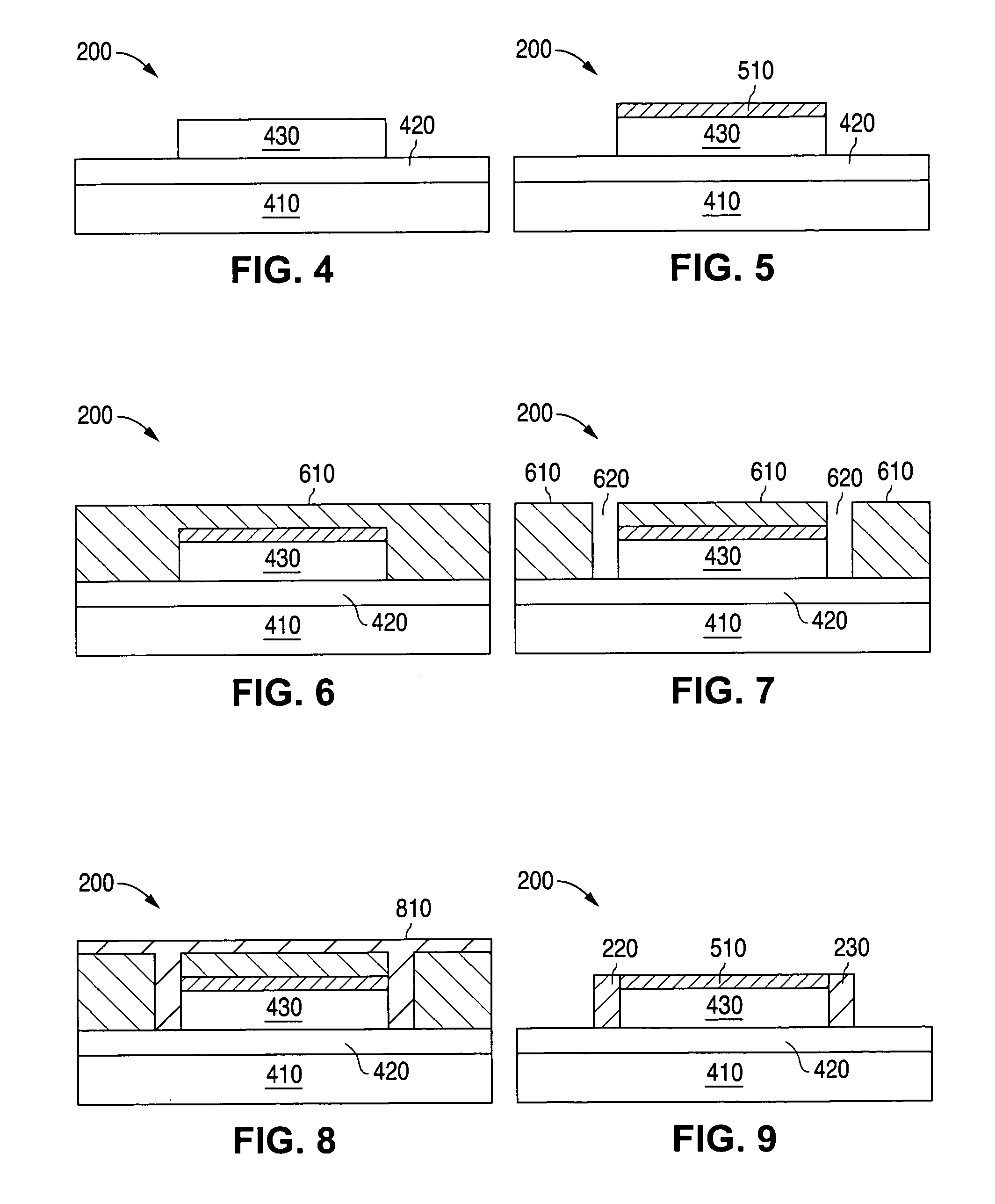

System and method for providing a self heating adjustable TiSi2 resistor

ActiveUS7332794B1Lower resistanceReduce power densitySolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceEngineering

A system and method is disclosed for providing a self heating adjustable titanium disilicon (TiSi2) resistor. A triangularly shaped layer of polysilicon is placed a layer of insulation material. A layer of titanium is applied over the polysilicon and heated to form a layer of C49 type of TiSi2. A current is then applied to the small end of the triangularly shaped layer of C49 TiSi2. The current generates heat in a high resistance portion of the triangularly shaped layer of C49 TiSi2 and converts a portion of the C49 TiSi2 to C54 TiSi2. The lower resistance of the C54 TiSi2 decreases the effective resistance of the resistor. A desired value of resistance may be selected by adjusting the magnitude of the applied current.

Owner:NAT SEMICON CORP

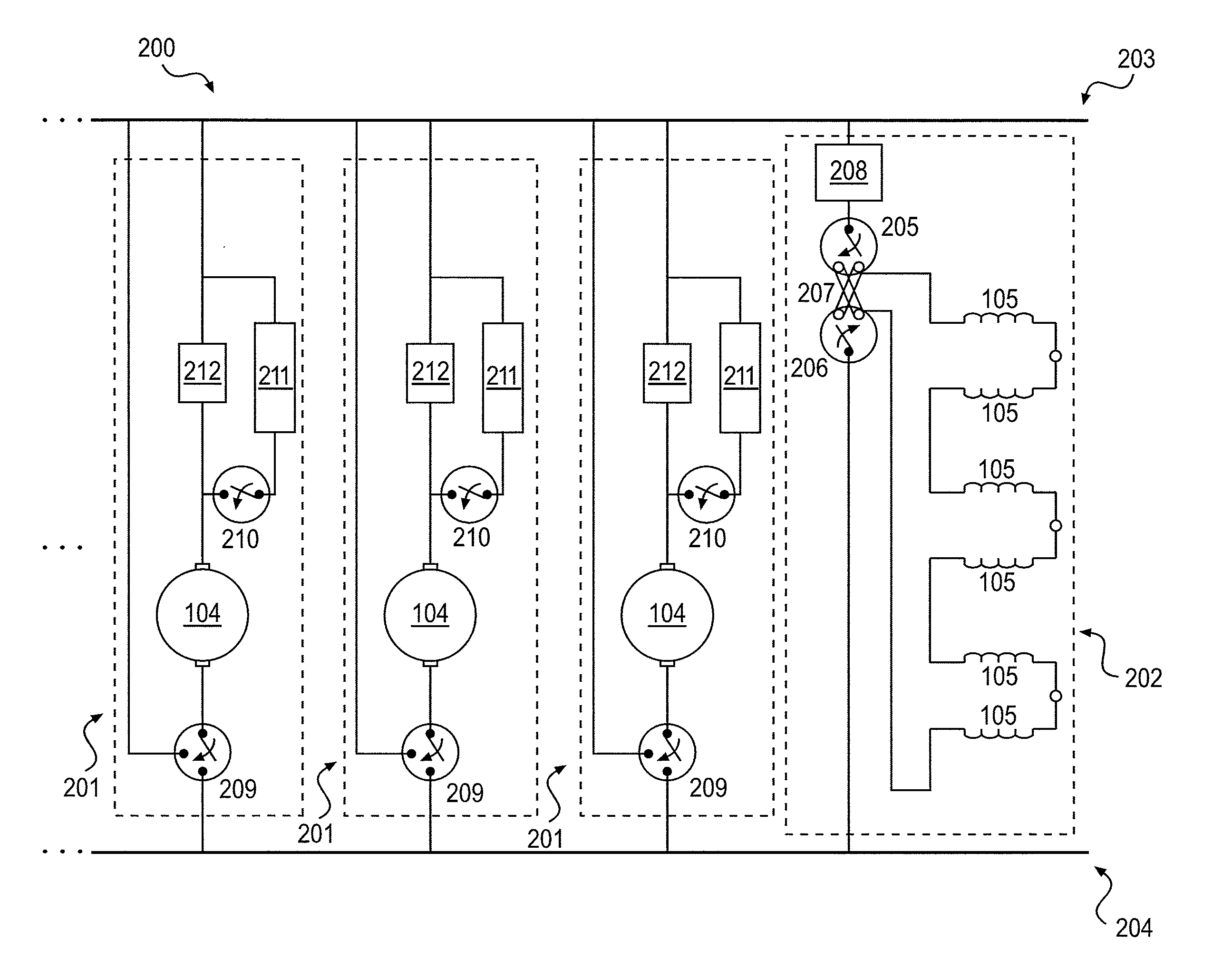

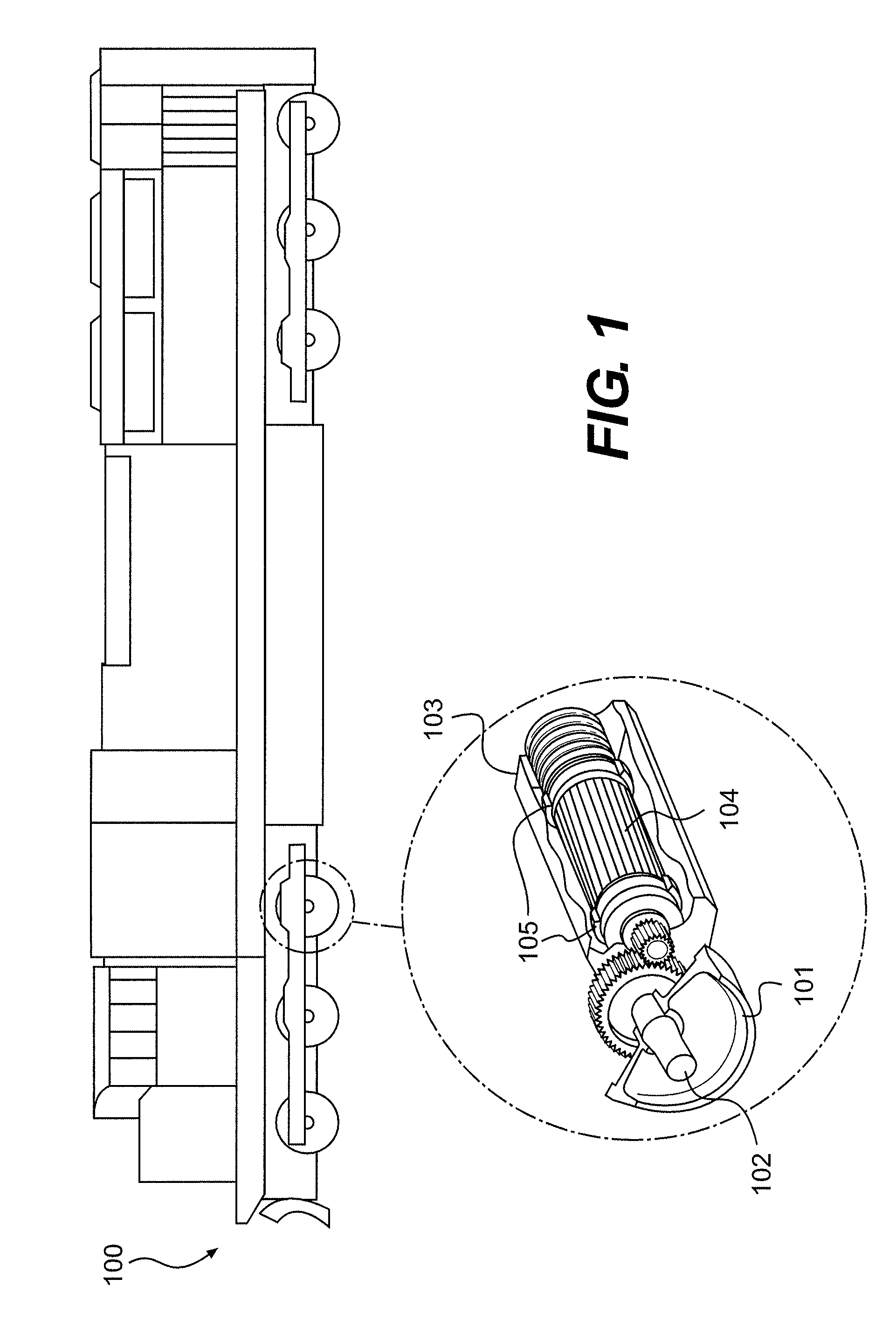

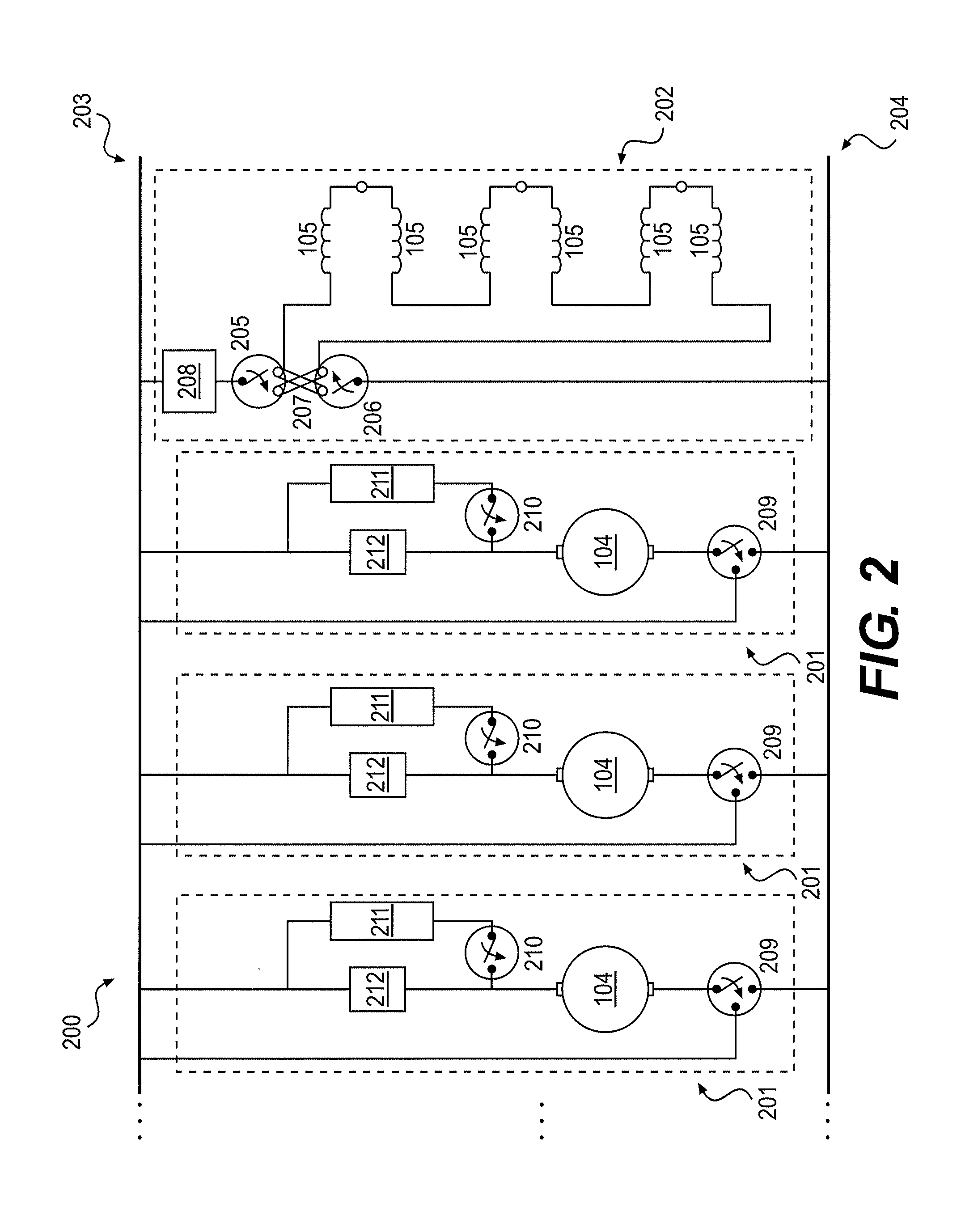

Continuously variable dynamic brake for a locomotive

ActiveUS20130152816A1Lower effective resistanceElectric devicesElectrodynamic brake systemsElectricityPower flow

This disclosure is directed to a traction motor drive system. The traction motor drive system may include a field winding subsystem comprising a field winding associated with a traction motor. The traction motor drive system may also include an armature subsystem arranged in parallel with the field winding subsystem. The armature subsystem may include an armature having first and second armature terminals and a grid resistor selectively electrically coupled in series with the armature. The armature subsystem may also include an armature chopper arranged in parallel with the grid resistor and electrically coupled in series with the armature. The armature chopper may be configured, when the grid resistor is electrically coupled to the armature, to conditionally conduct current to the armature.

Owner:PROGRESS RAIL SERVICES

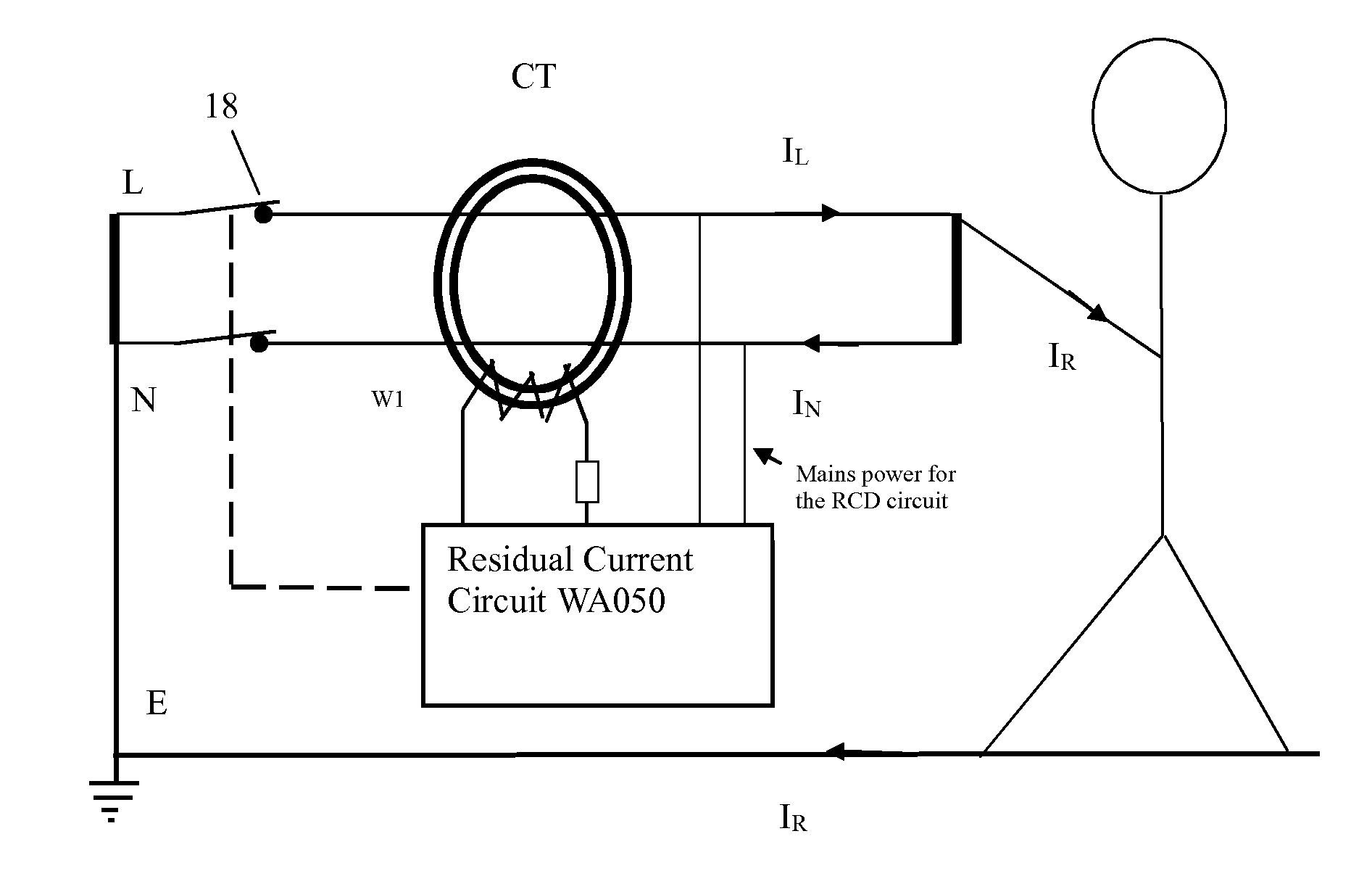

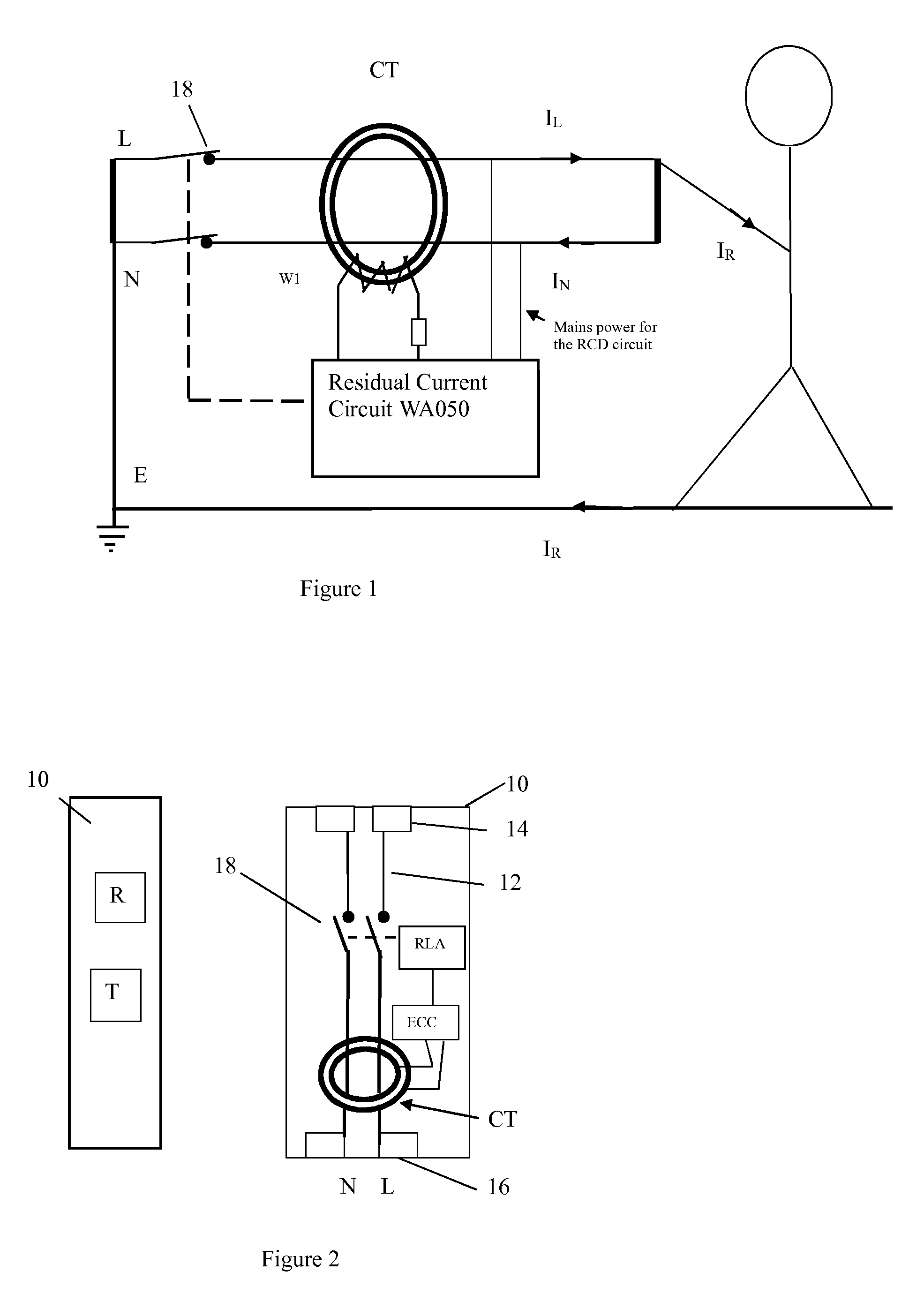

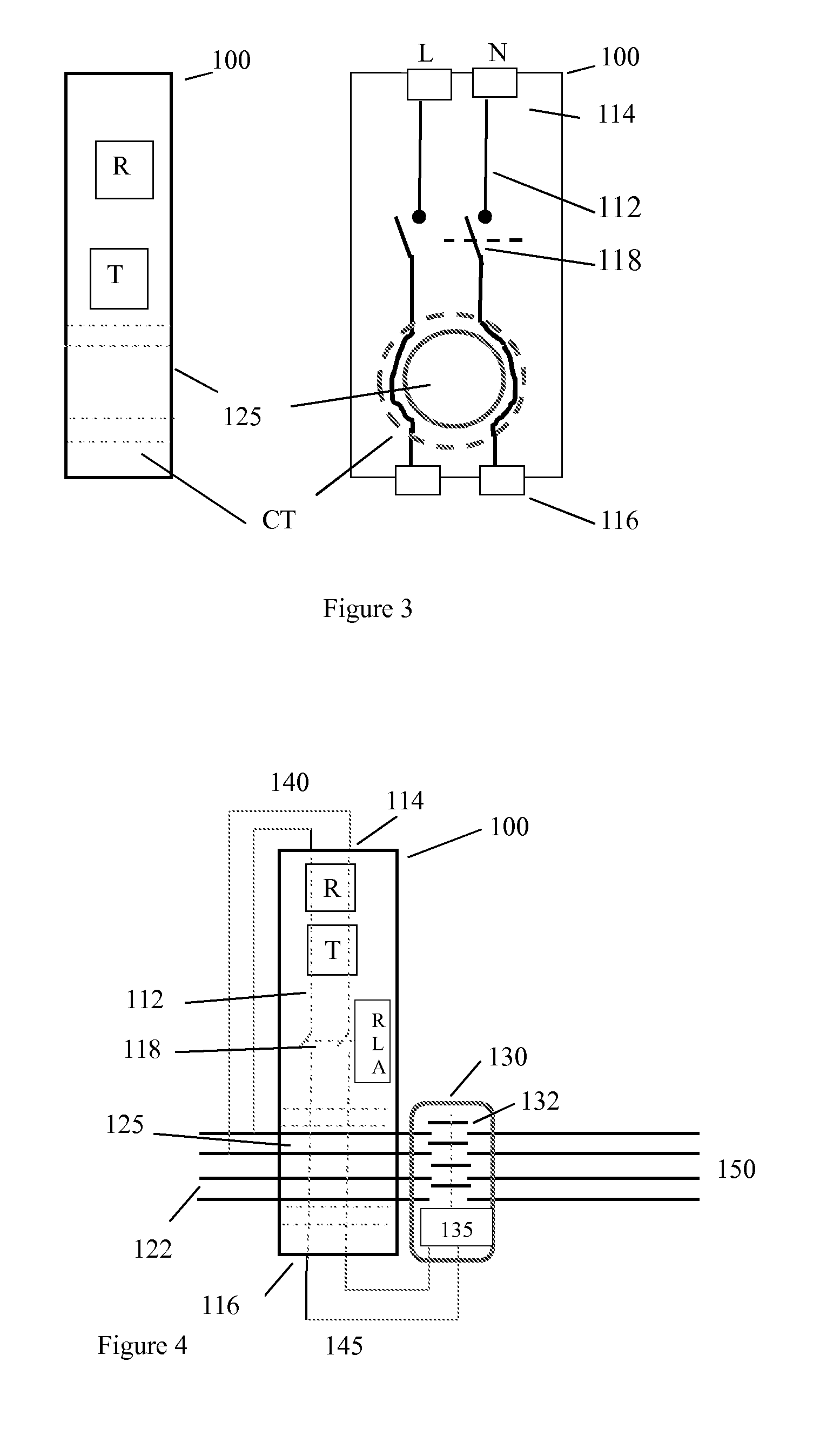

Electrical fault protection device

InactiveUS20150194798A1Lower effective resistanceIncreases operating trip currentSwitch operated by current/voltage unbalanceCircuit-breaking switches for excess currentsElectrical conductorElectrical Failure

Provided is an electrical fault protection device comprising: a housing having supply terminals and output terminals; internal conductors passing between the supply terminals and the output terminals via at least one fault protector relay contact; a fault protector operably connected to the at least one fault protector relay contact and responsive to a fault to open the at least one fault protector relay contact; an aperture defined in the housing so as to facilitate the feeding of at least two external supply conductors through the housing; a contactor driven from the output terminals, the contactor incorporating at least one normally open contact corresponding to a respective external supply conductor, wherein a current rating of the at least one contactor contact is substantially greater than a current rating of each of the at least one fault protector relay contact.

Owner:TRIPCO INC

Cooling of power electronics circuits

ActiveUS20190335577A1Improve thermal conductivityAvoid mechanical stressSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorCooling power

A method for cooling power electronics circuits, in which a printed circuit board is produced according to a prescribed circuit board process and is populated with at least one power electronics components. Contact connecting at least one location on at least one metallic conductor track running on a surface of the printed circuit board that includes at least one metal element, which is both electrically conductive and heat-conductive and the physical height of which is designed to be at least as large as that of the at least one power electronics component. A cooling plate is placed in a planar manner onto the at least one power electronics component and / or the at least one metal element.

Owner:DR ING H C F PORSCHE AG

Piezoelectric vibrating reed, piezoelectric vibrator, oscillator, electronic device, wave clock, and manufacturing method of piezoelectric vibrating reed

InactiveUS20090152994A1Save powerImprove performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectronVoltage

A piezoelectric vibrating reed includes a piezoelectric plate made of a piezoelectric material, a pair of exciter electrodes formed on outer surfaces of the piezoelectric plate and configured to vibrate the piezoelectric plate when a predetermined voltage is applied thereon, and a pair of mount electrodes electrically connected to the pair of exciter electrodes, respectively. One mount electrode in the pair of mount electrodes is formed on one surface (under surface) of the piezoelectric plate and the other mount electrode is formed on the other surface (top surface) of the piezoelectric plate in a state not to oppose the one mount electrode with the piezoelectric plate in between. Accordingly, not only can power be saved, but also higher performance can be achieved by lowering the R1 characteristic and thereby enhancing the vibration characteristic.

Owner:SII CRYSTAL TECH

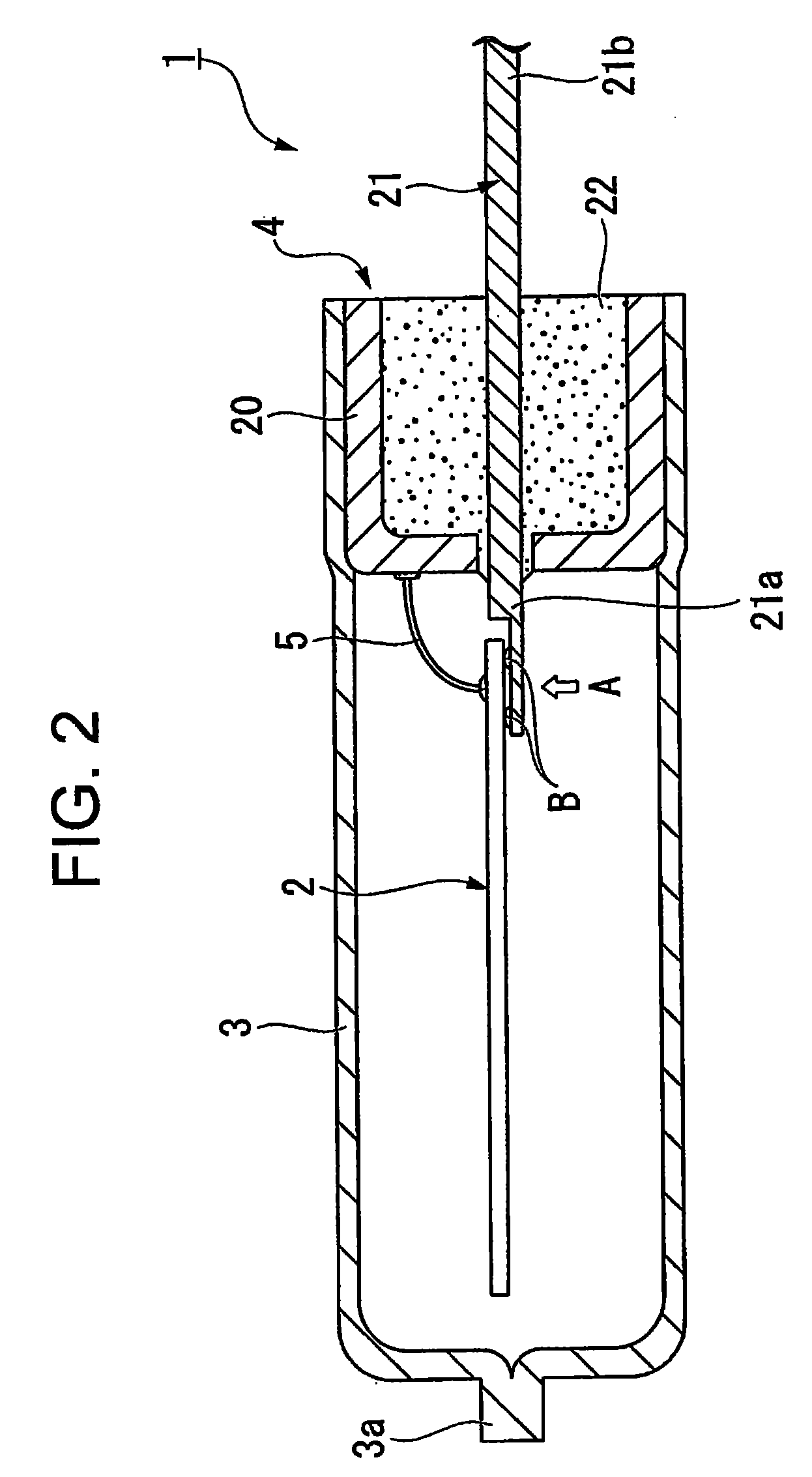

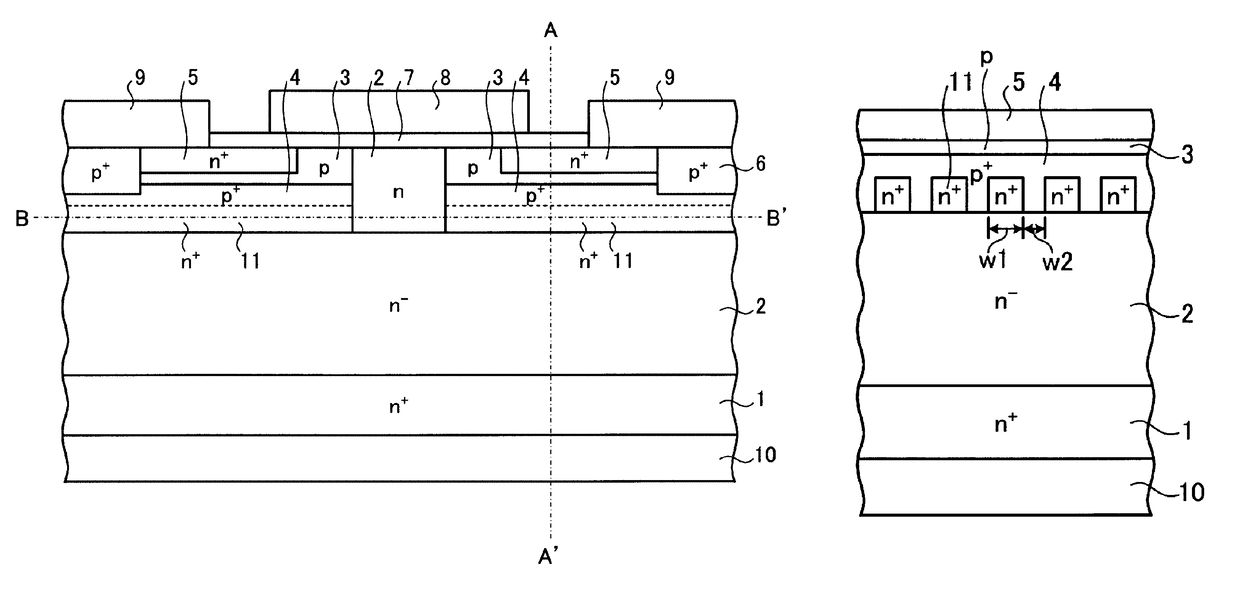

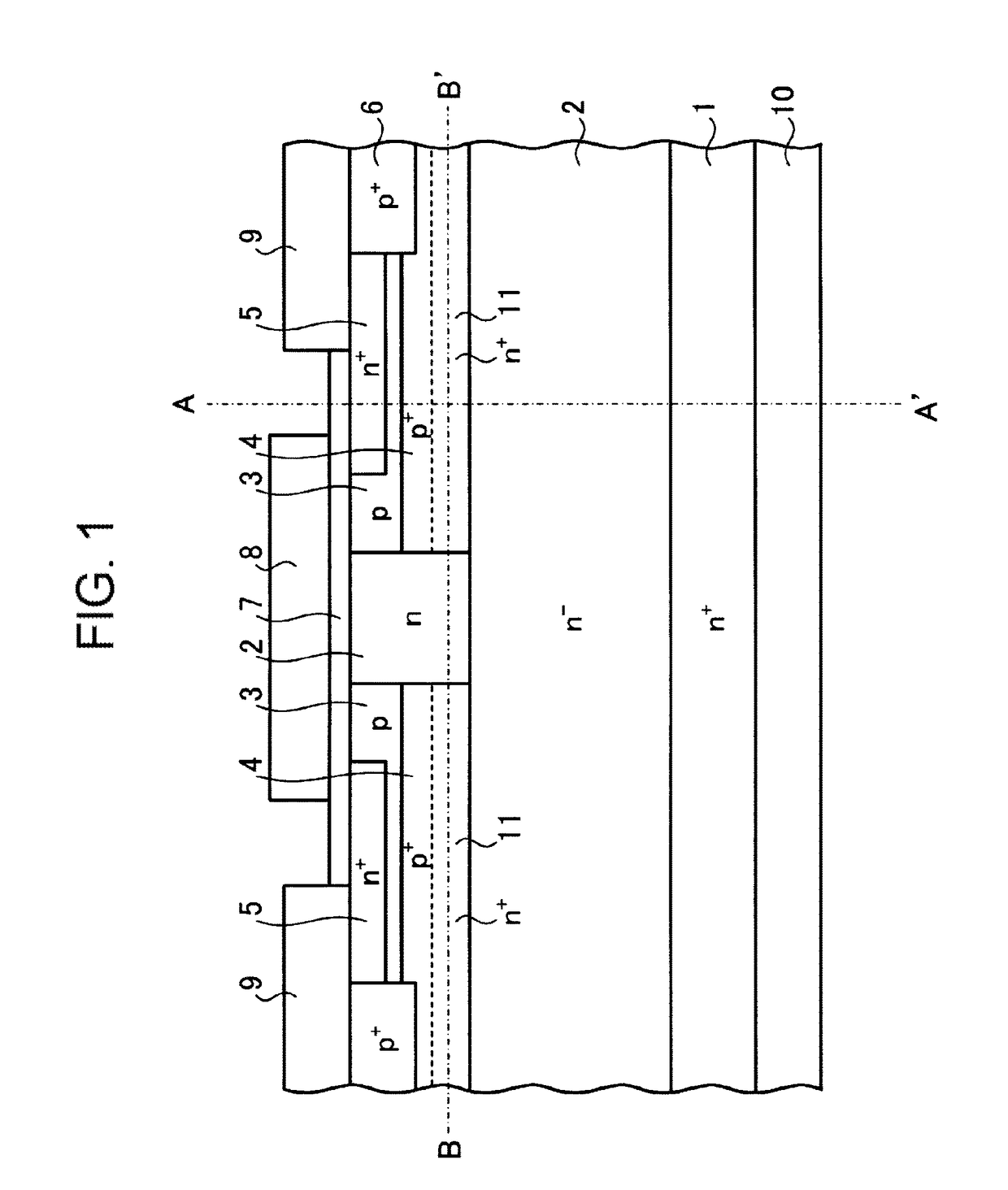

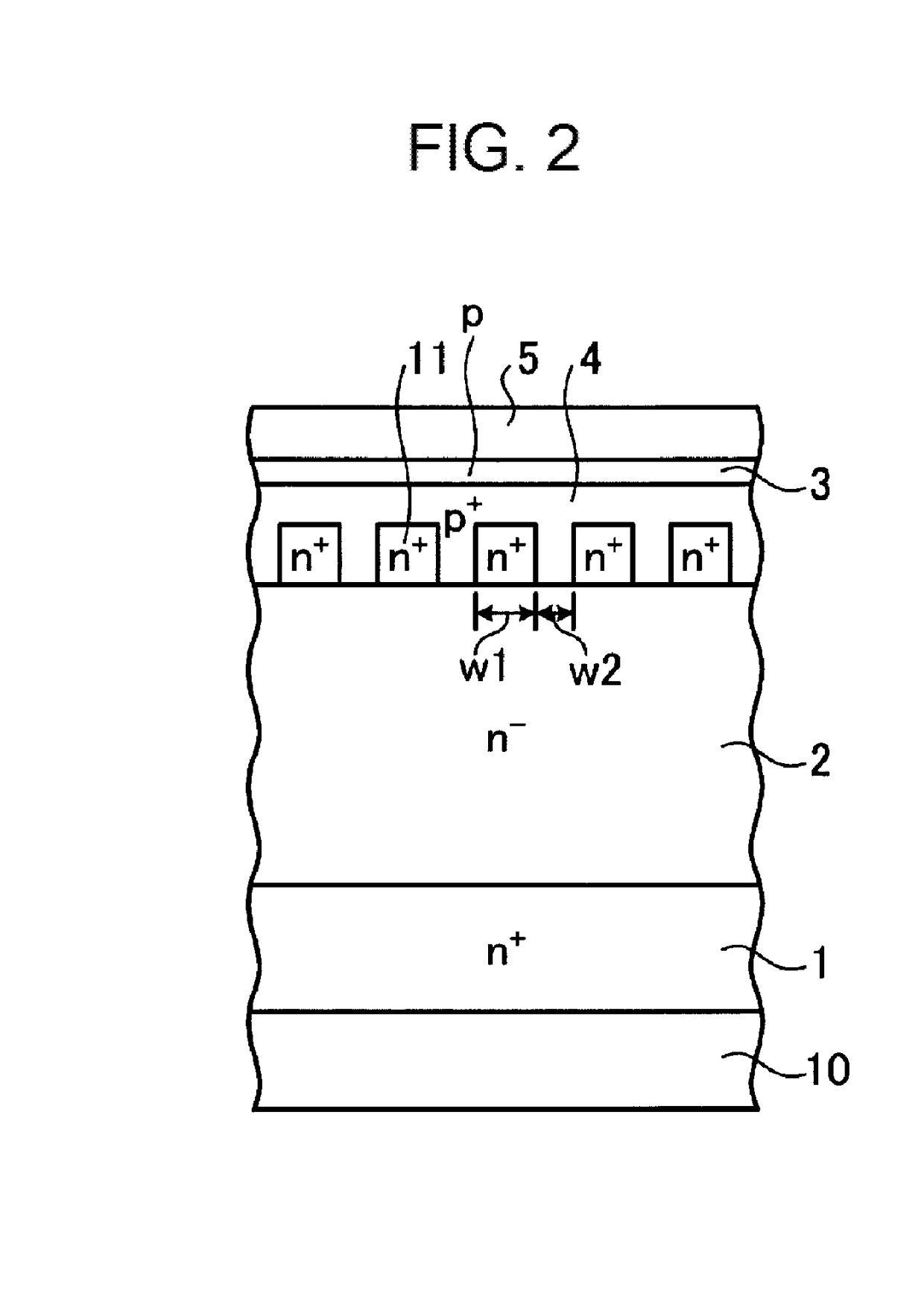

Semiconductor device

InactiveUS9595608B2Lower effective resistancePrevent breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationSurface layer

An n− drift region is disposed on the front surface of an n+ semiconductor substrate composed of a wide band gap semiconductor. A p-channel region is selectively disposed on the surface layer of the n− drift region. A high-concentration p+ base region is disposed so as to adjoin the lower portion of the p-channel region inside the n− drift region. Inside the high-concentration p+ base region, an n+ high-concentration region is selectively disposed at the n+ semiconductor substrate side. The n+ high-concentration region has a stripe-shaped planar layout extending to the direction that the high-concentration p+ base regions line up. The n+ high-concentration region adjoins a JFET region at one end portion in longitudinal direction of the stripe. Further, the n+ semiconductor substrate side of the n+ high-concentration region adjoins the part sandwiched between the high-concentration p+ base region and the n+ semiconductor substrate in the n− drift region.

Owner:FUJI ELECTRIC CO LTD

Determining a cell state of a resistive memory cell

Owner:INT BUSINESS MASCH CORP

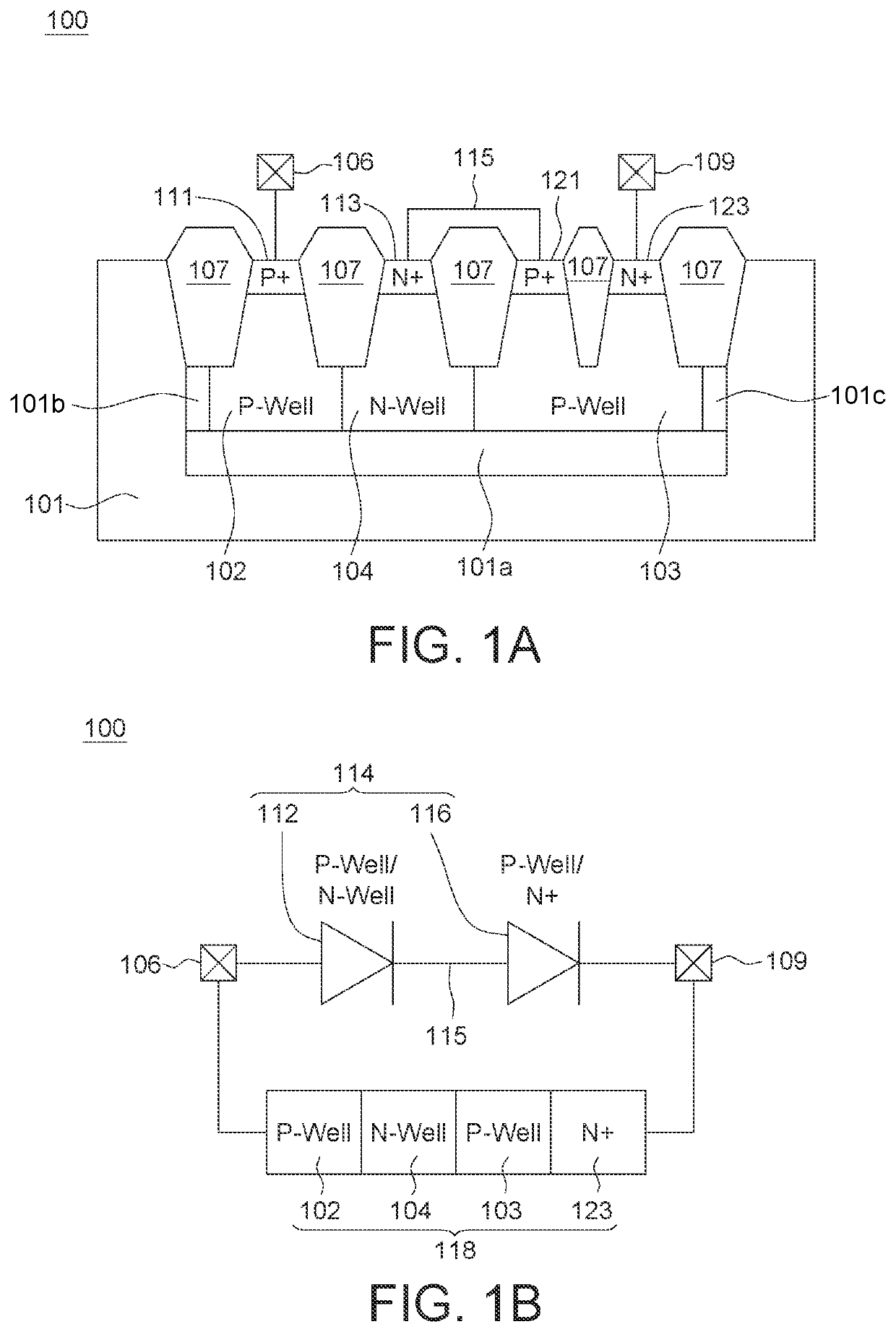

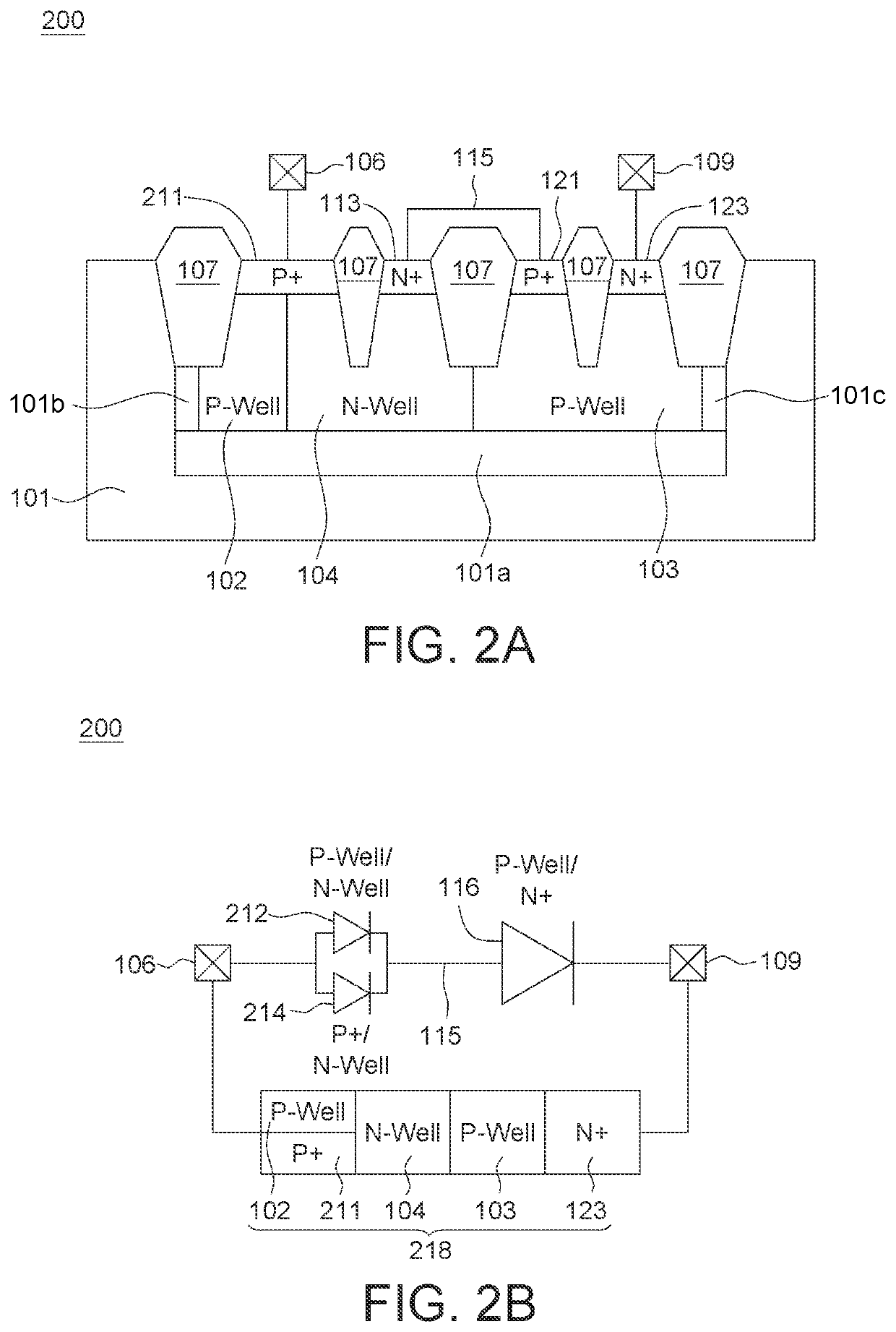

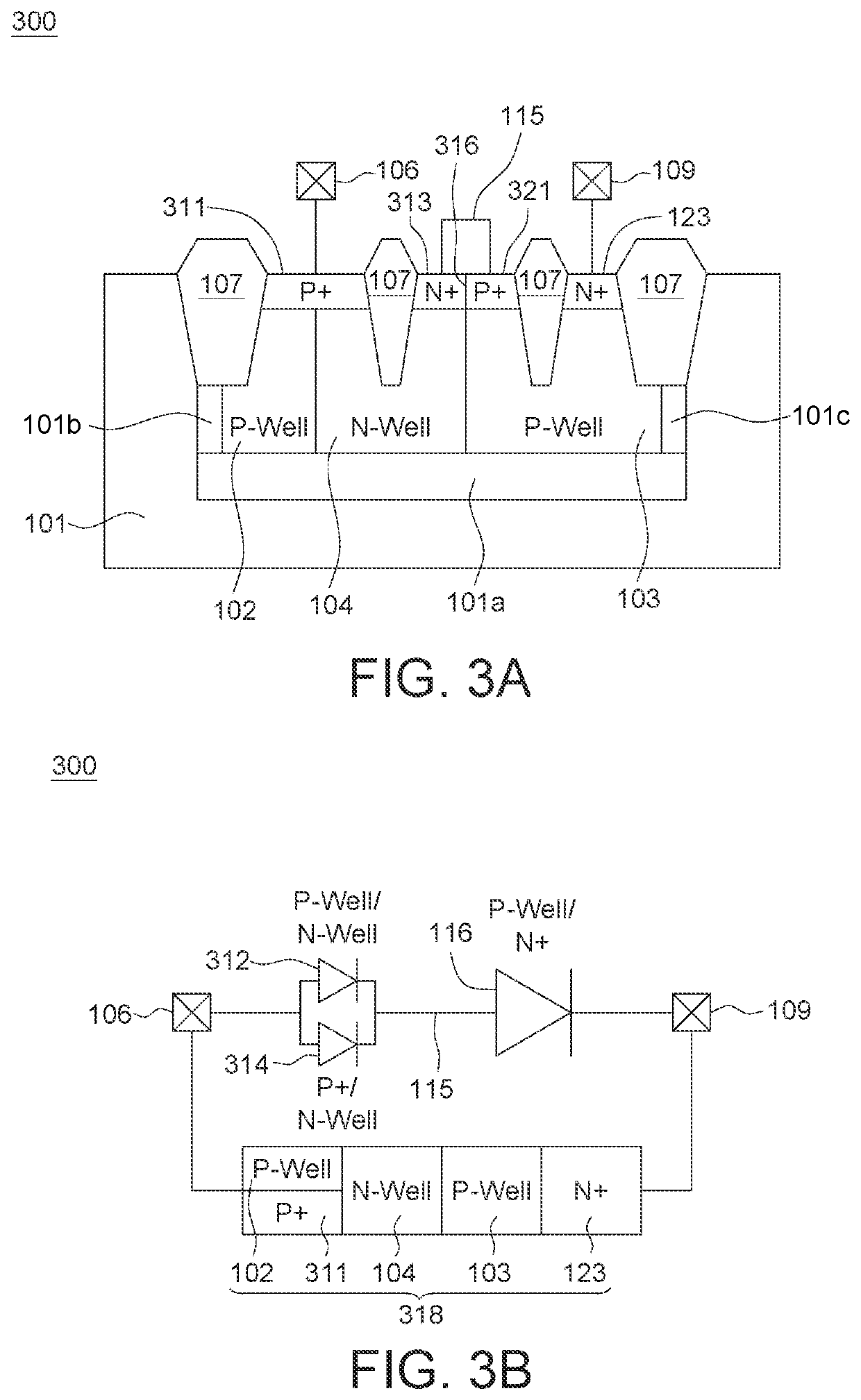

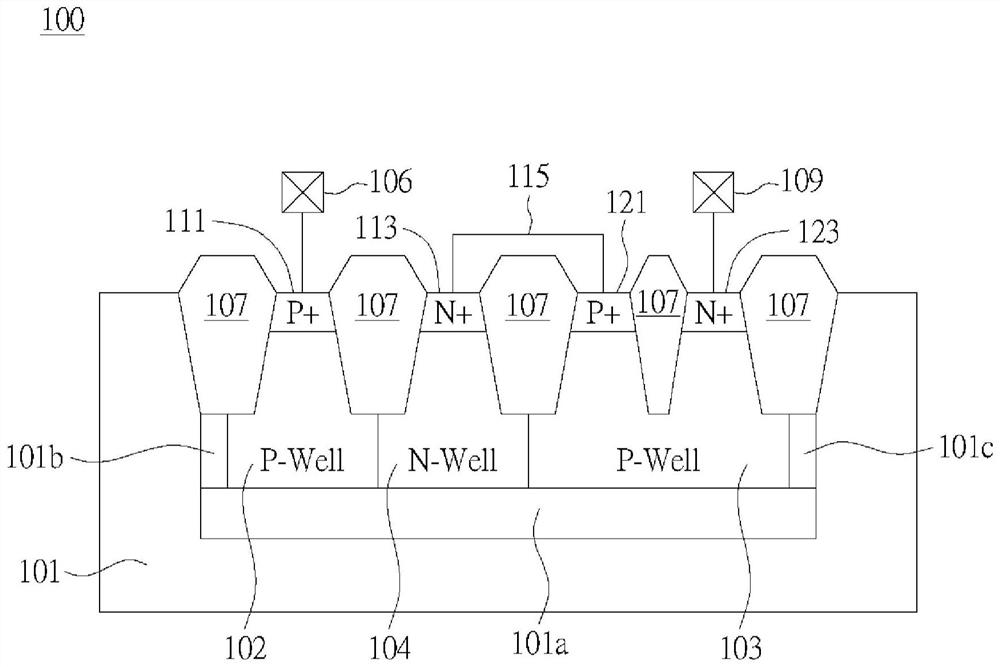

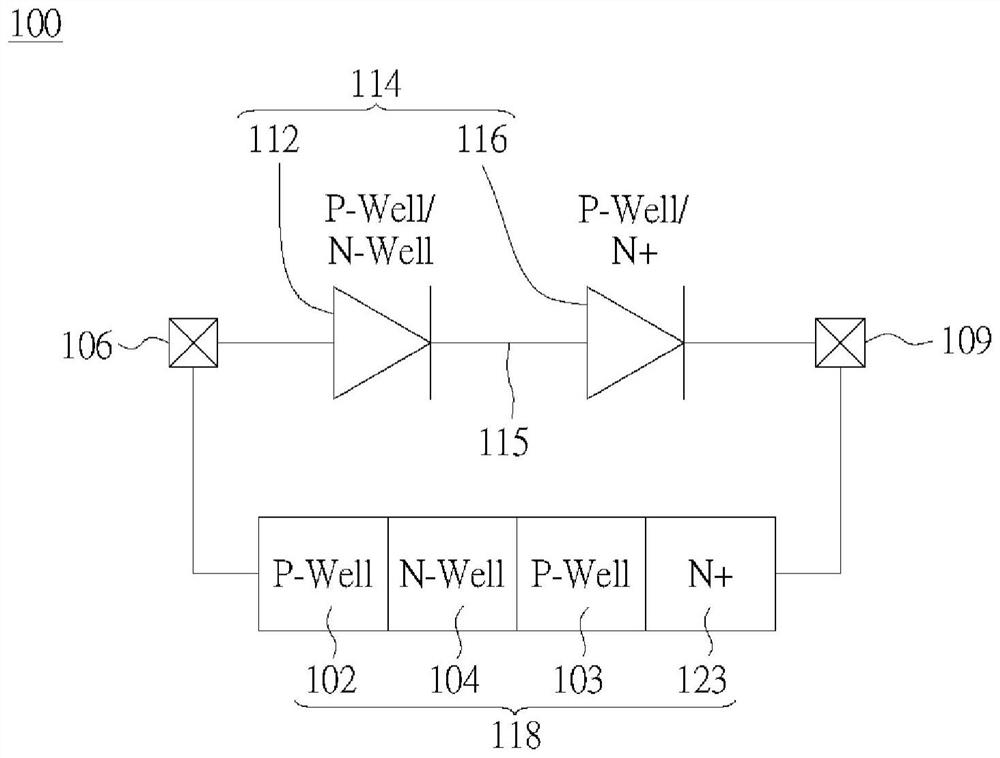

Electrostatic discharge protection device and operating method

PendingUS20220231008A1Reduce effective resistanceLower effective resistanceTransistorThyristorElectrostatic discharge protectionElectric coupling

An ESD protection device includes a semiconductor substrate, a first well, a second well, a third well, a first doping region, a second doping region, a second doping region, a third doping region and a fourth doping region. The first well and the second well have a first conductivity, and the third well has a second conductivity. The first doping region having a first conductivity is disposed in the first well. The second doping region having a second conductivity is disposed in the third well, and the first and the second doping regions are isolated from each other. The third doping region and the fourth doping region have a first conductivity and a second conductivity, respectively. The second doping region and the third doping region are electrically coupled. The first well, the second well, the third well and the fourth doping region form a parasitic SCR.

Owner:MACRONIX INT CO LTD

System and method for providing a self heating adjustable TiSi2 resistor

ActiveUS7166518B1Lower effective resistanceImprove power densitySolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceEngineering

A system and method is disclosed for providing a self heating adjustable titanium disilicon (TiSi2) resistor. A triangularly shaped layer of polysilicon is placed a layer of insulation material. A layer of titanium is applied over the polysilicon and heated to form a layer of C49 type of TiSi2. A current is then applied to the small end of the triangularly shaped layer of C49 TiSi2. The current generates heat in a high resistance portion of the triangularly shaped layer of C49 TiSi2 and converts a portion of the C49 TiSi2 to C54 TiSi2. The lower resistance of the C54 TiSi2 decreases the effective resistance of the resistor. A desired value of resistance may be selected by adjusting the magnitude of the applied current.

Owner:NAT SEMICON CORP

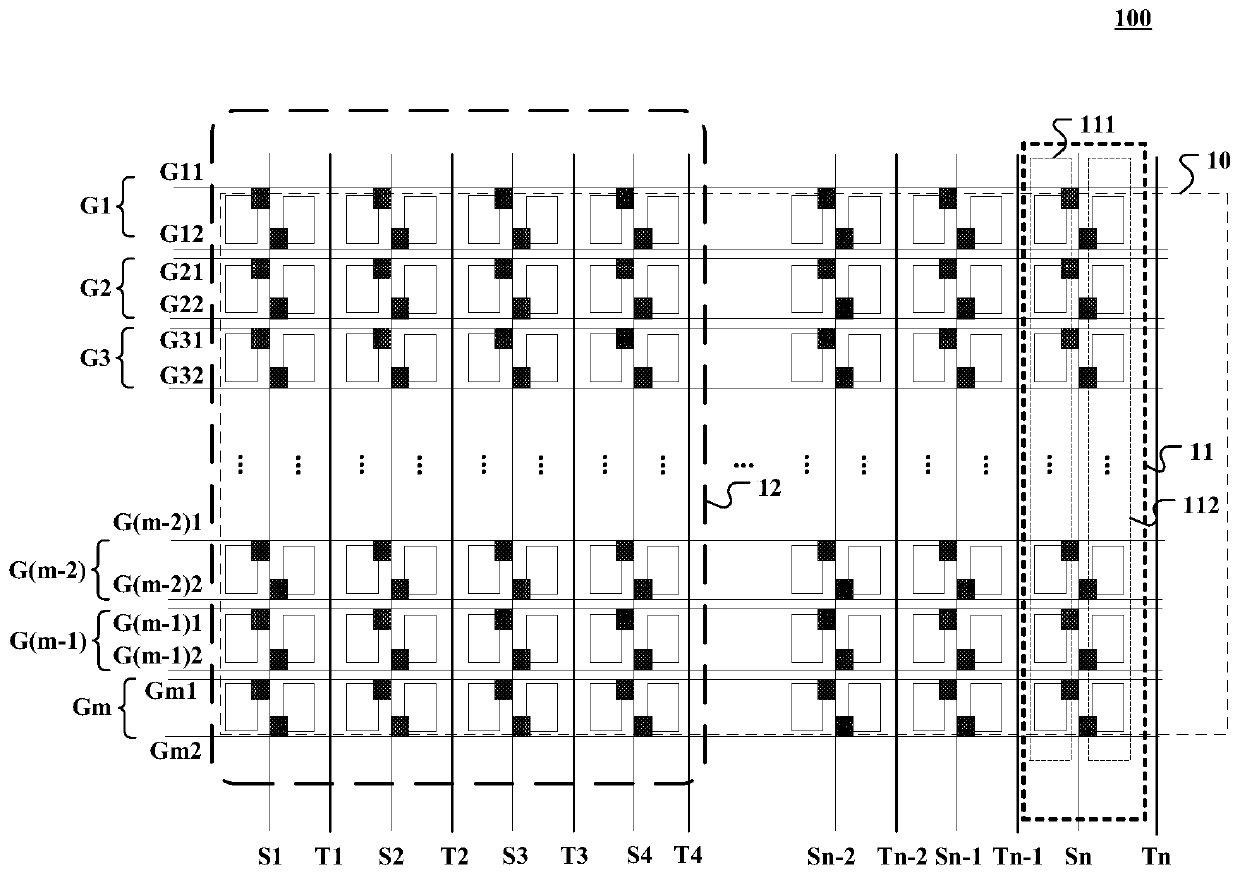

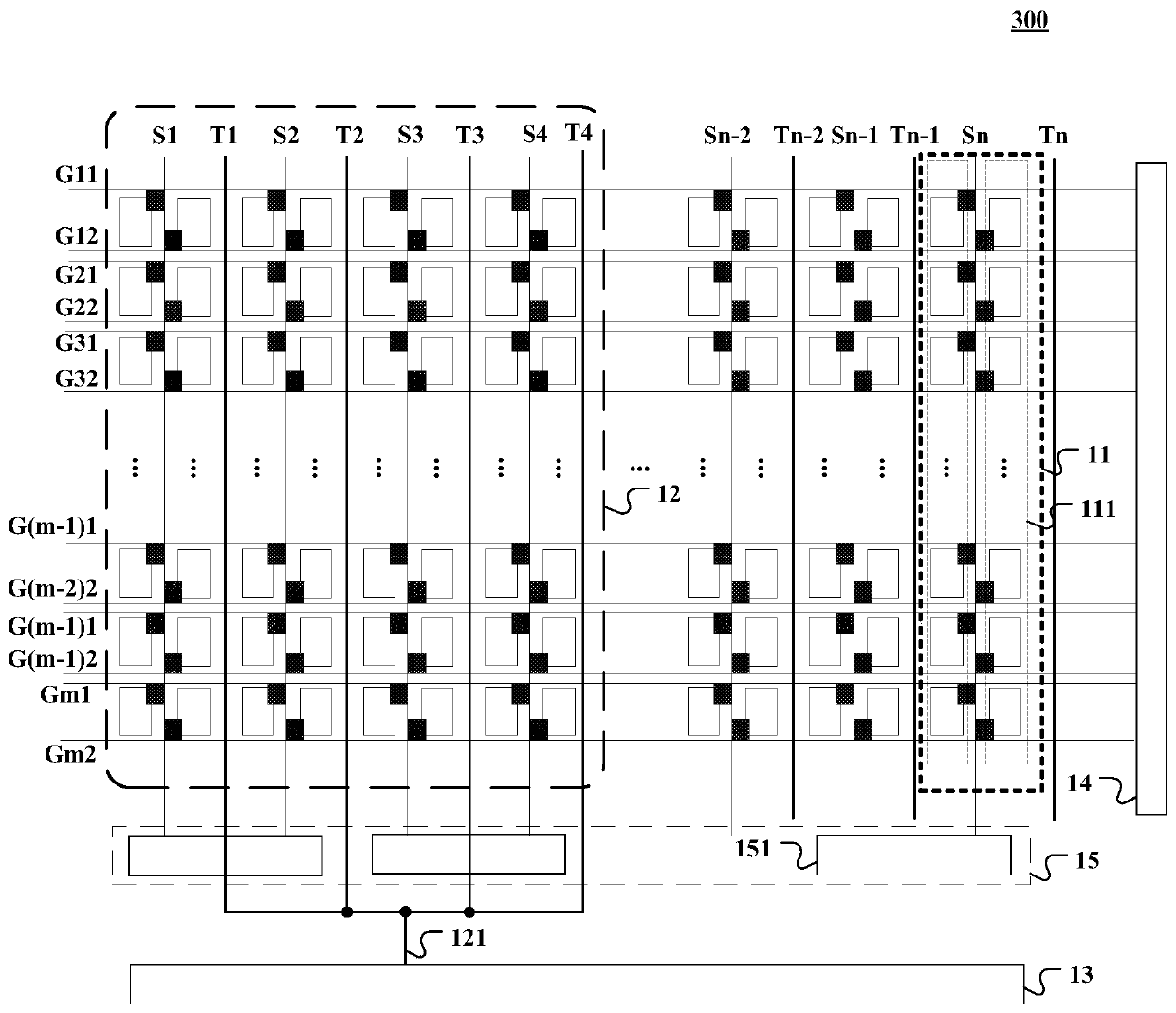

Array substrate, display panel including same, and display device

ActiveCN106406612BLower effective resistanceSmall attenuationInput/output processes for data processingElectrical resistance and conductanceDisplay device

The application discloses an array substrate, a display panel containing the same, and a display device. The array substrate comprises a substrate, a pixel array formed on the substrate, multiple data lines, multiple scanning line groups, multiple touch electrodes and multiple touch signal lines; the pixel array comprises multiple pixel groups, each pixel group comprises a first pixel column and a second pixel column adjacent to each other, the data line is arranged between the first pixel column and the second pixel column, and the touch signal line is arranged between the two adjacent pixel groups; each touch electrode is connected with multiple corresponding touch signal lines, and an orthographic projection of the touch electrode to the substrate covers the orthographic projection of the corresponding touch signal line to the substrate; the scanning line group comprises a first scanning line and a second scanning line at two sides of each column of pixel, and the first scanning line and the second scanning line are respectively connected with the pixels in the first pixel column and the second pixel column in each column of pixel. Through the adoption of the embodiment of the invention, the resistance of the touch electrode can be lowered, and the uniformity of the touch sensitivity is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

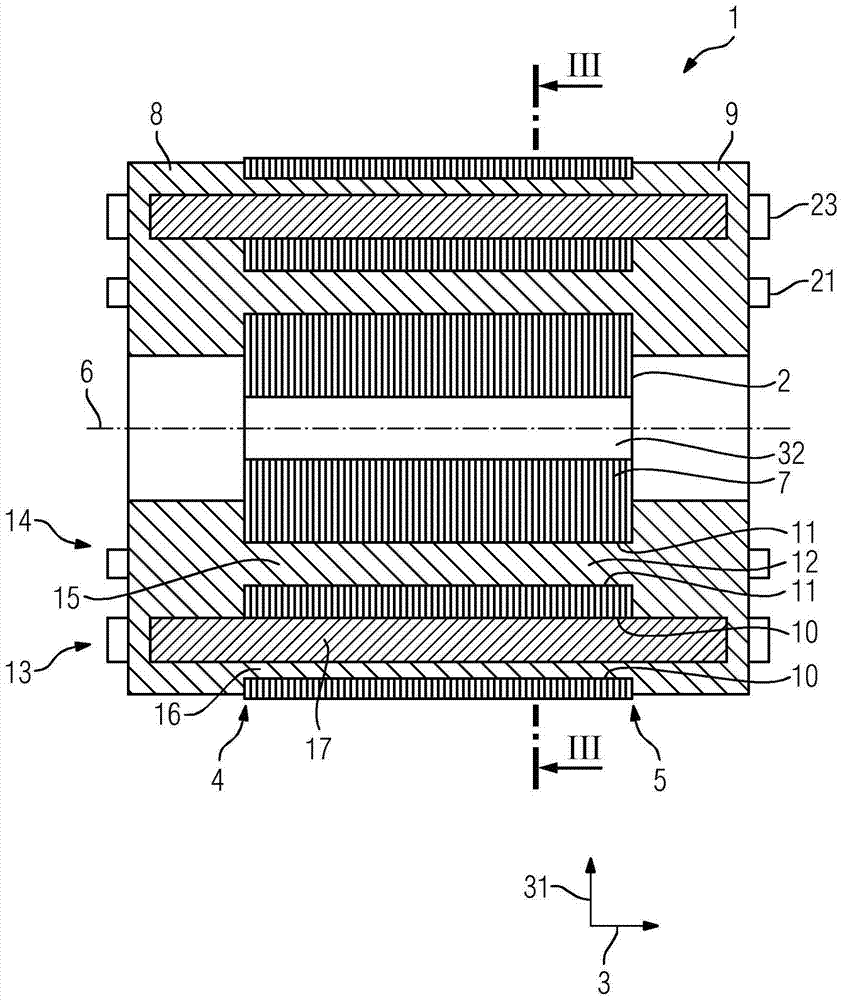

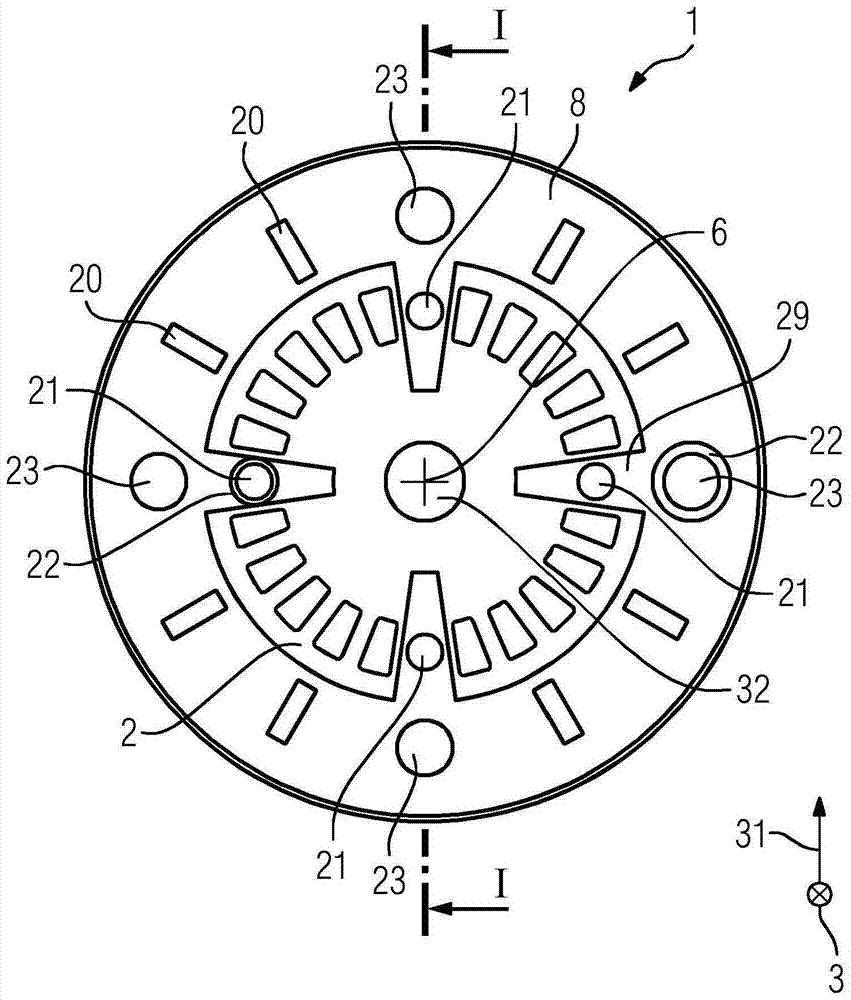

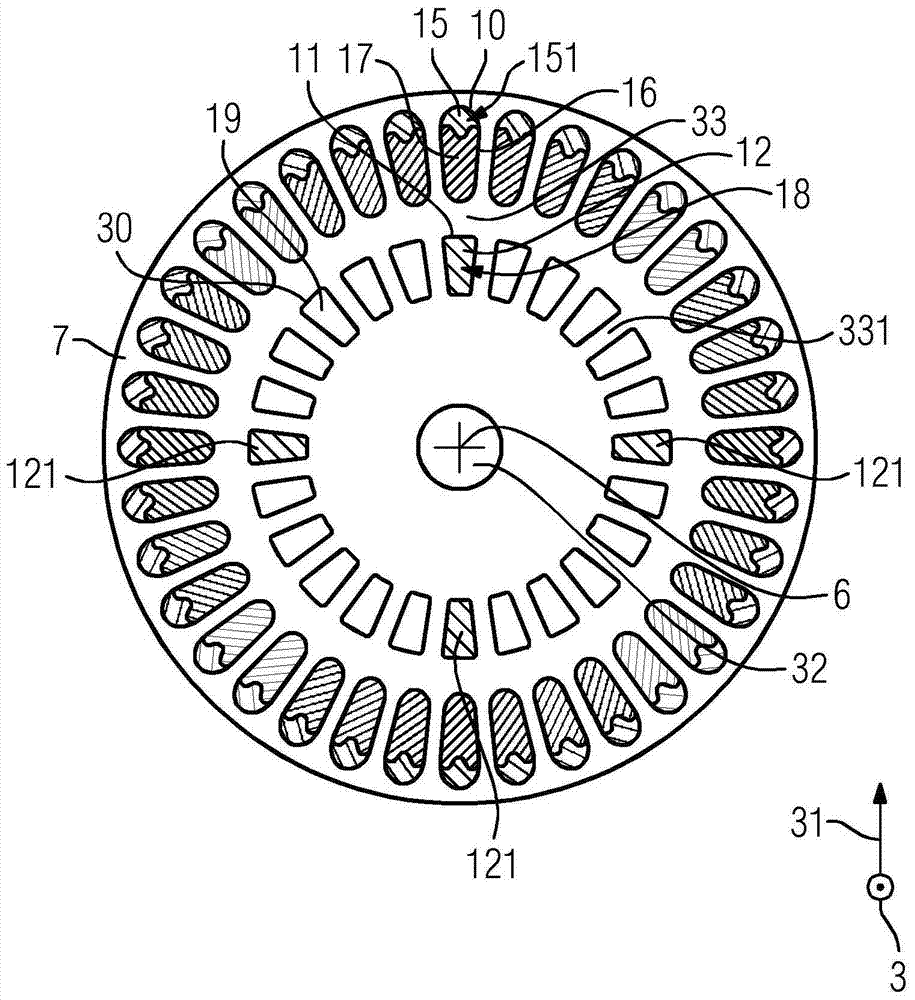

Reliable squirrel-cage rotor

ActiveCN104871415AEvenly spacedTight spatial distributionMagnetic circuit rotating partsAsynchronous induction motorsRotational axisPunching

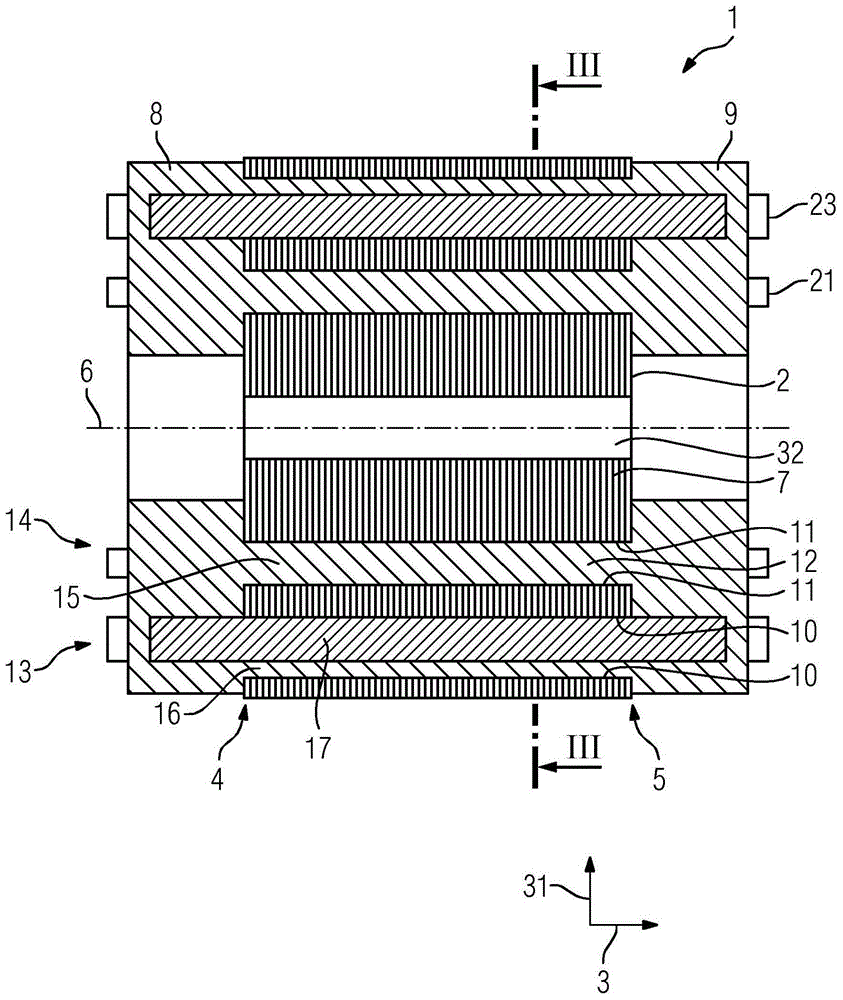

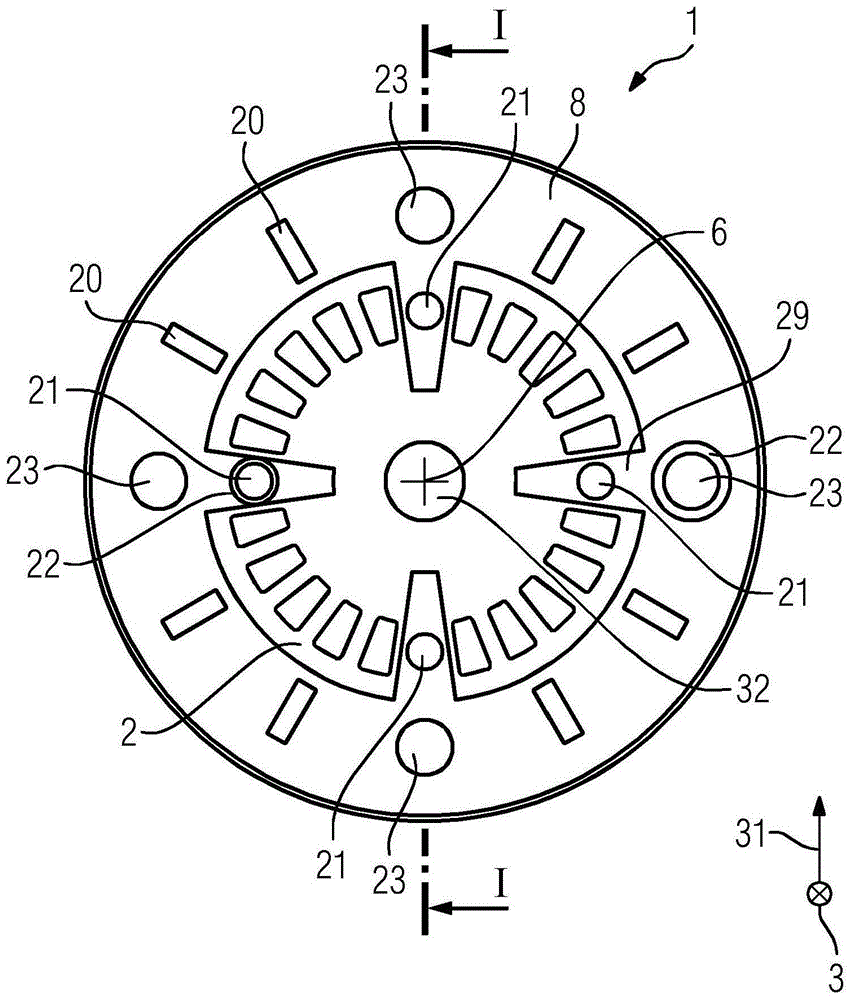

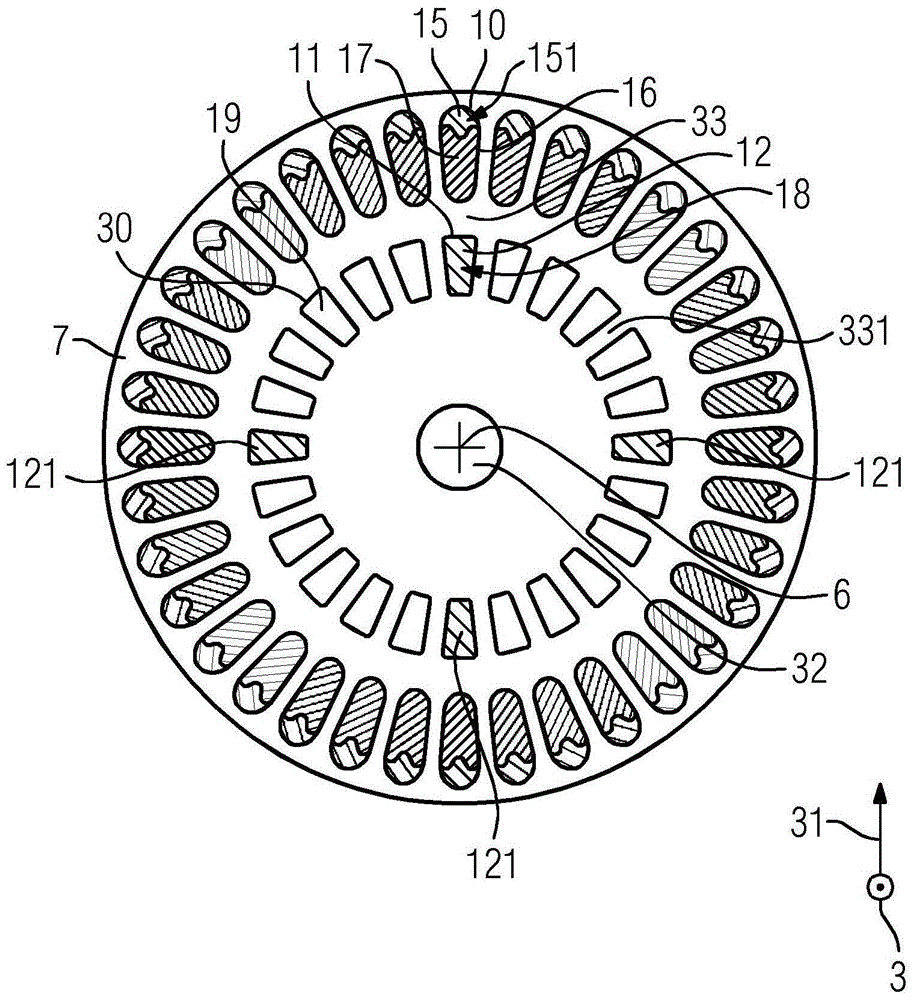

Cage rotor (1) comprises: a rotor core (2) which extends in an axial direction from a first axial end (4) to a second axial end (5) along an axis of rotation and has the coated plates in the axial direction; a short circuit ring which surrounds the rotational axis and which is disposed at the first axial end; and an additional short circuit ring which surrounds the rotational axis and which is arranged at the second axial end. The short-circuit ring and the additional short ring comprise a first material, in which the sheets respectively have first punching. Cage rotor (1) comprises: a rotor core (2) which extends in an axial direction from a first axial end (4) to a second axial end (5) along an axis of rotation and has the coated plates in the axial direction; a short circuit ring which surrounds the rotational axis and which is disposed at the first axial end; and an additional short circuit ring which surrounds the rotational axis and which is arranged at the second axial end. The short-circuit ring and the additional short ring comprise a first material, in which the sheets respectively have first punching, which forms the edges of the grooves of the rotor core extending from the first axial end to the second axial end. The plates respectively have a second punching which forms the edges from a passage extending from the first axial end to the second axial end. The first punching is located in an outer region of the plates, and the second punching is in an inner region of the plates. The passage is filled with a filling material from the first material, which is integrally connected to the short-circuit ring, and the additional short-circuit ring. Independent claims are also included for: (1) an electrical machine (50), comprising a squirrel-cage rotor; (2) producing a squirrel-cage rotor comprising receiving the filler material at least partially through the passage to the second axial end; and (3) series of electrical machines, comprising at least one first electrical machine, which comprises a first cage rotor and at least one second electrical machine, where the second electrical machine having a squirrel-cage version with a rotor core variant comprising a first punching and second punching. The plates edges of grooves of rotor core variant, respectively form first punching which extend from a first axial end of the rotor core variant to a second axial end of the rotor core variant, The edges from an open passage of the rotor core variant form the respective second punching of the plates, which runs from the first axial end of the rotor core variant for the second axial end of the rotor core variant.

Owner:SIEMENS AG

Current transformer

InactiveCN107705970AIncrease the effective cross-sectional areaLower effective resistanceTransformersTransformers/inductances coils/windings/connectionsSkin effectCurrent transformer

The invention discloses a current transformer, which is capable of solving the problem of temperature rise of a primary copper conductor due to a skin effect. The current transformer comprises a primary coil and two primary wiring boards, wherein the primary coil is formed by combining a cylindrical conducting rod and a tubular conducting tube sleeving the cylindrical conducting rod; each wiring board is L-shaped and comprises a connecting arm and a flat wiring board; a connection hole is formed in the upper end of each connecting arm; and the primary coil is connected with the wiring boards through the corresponding connection holes.

Owner:TIANSHUI CHANGKAI MUTUAL INDUCTOR MFR

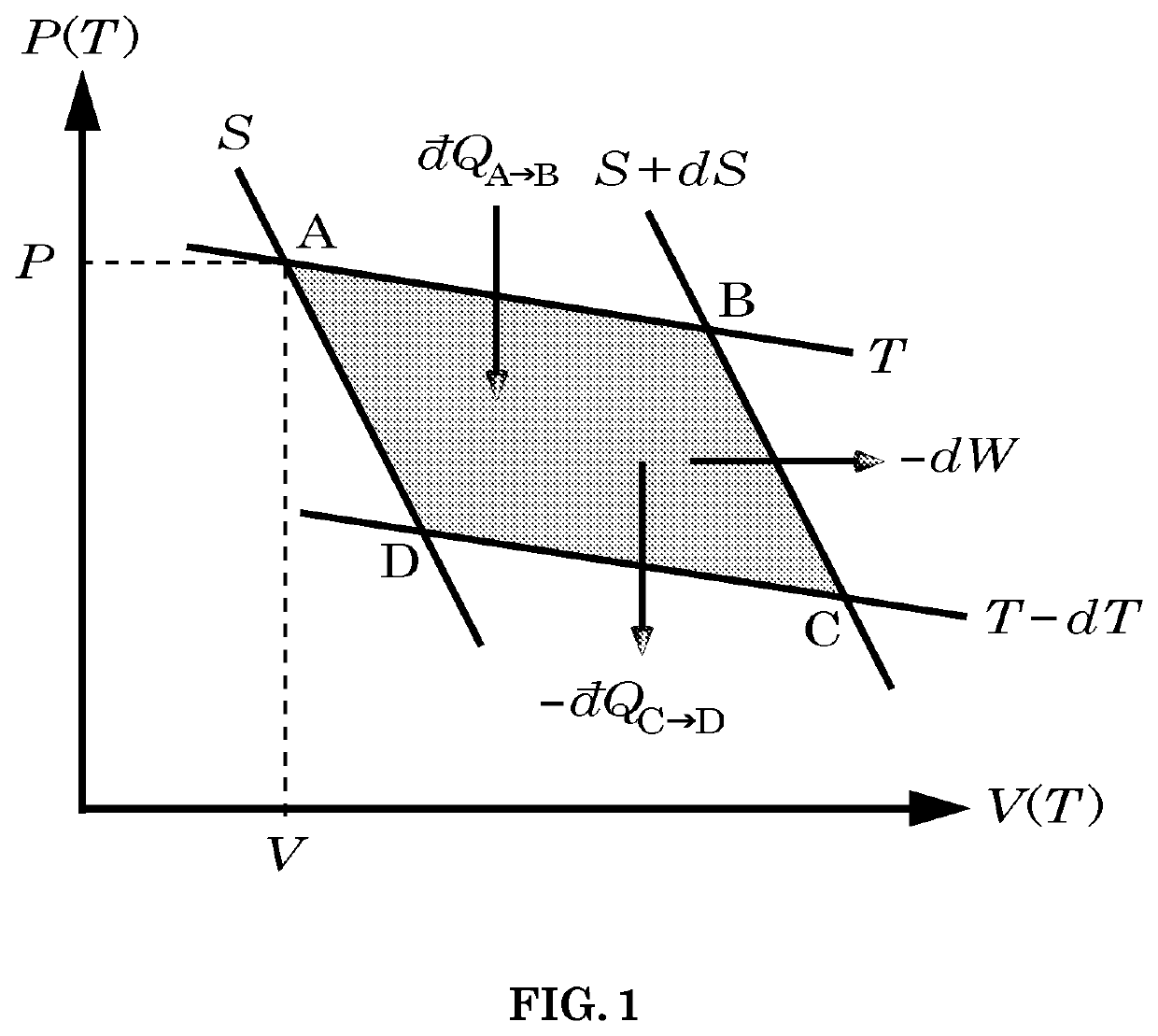

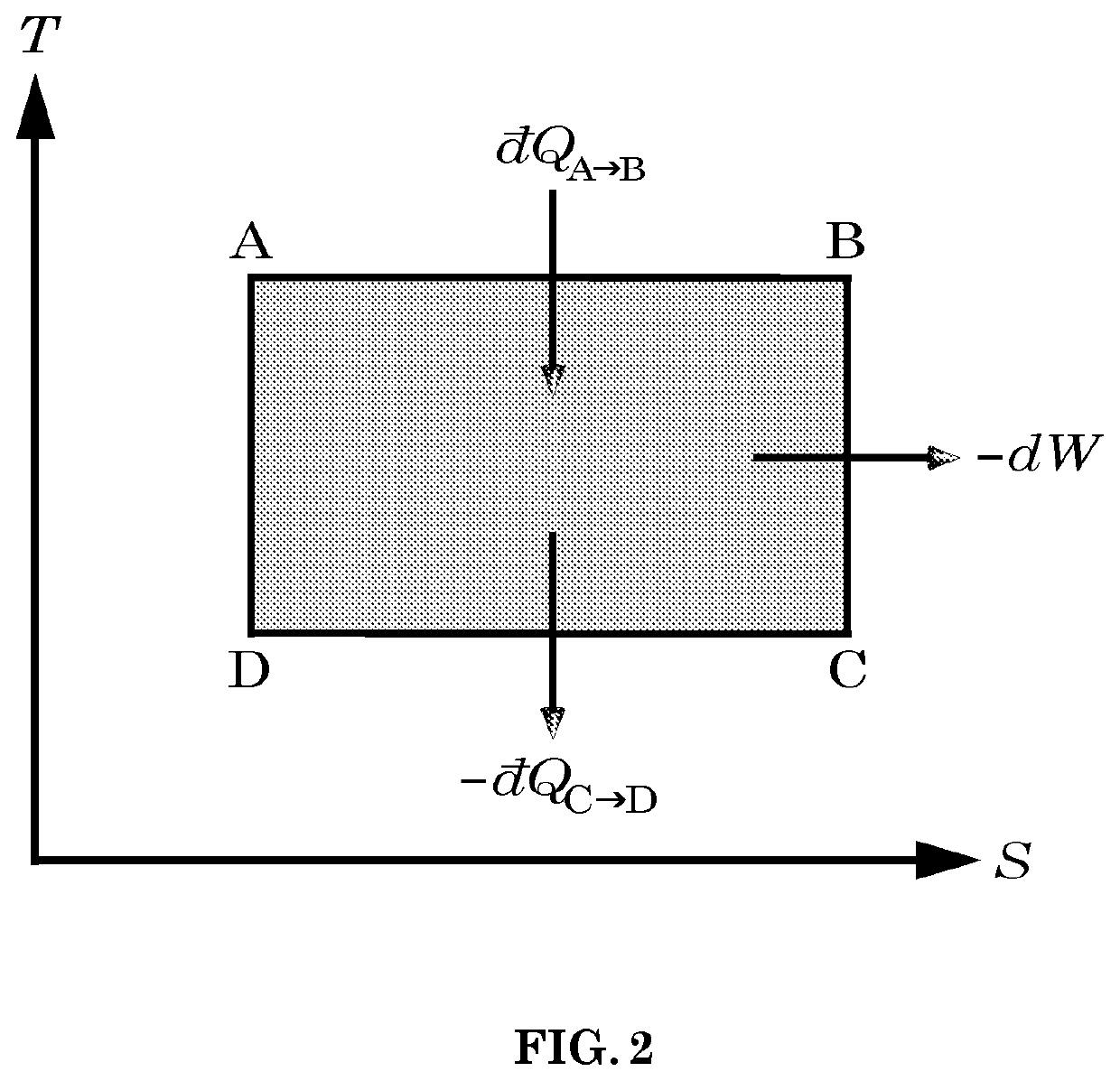

Process and Manufacture of Low-Dimensional Materials Supporting Both Self-Thermalization and Self-Localization

ActiveUS20210104403A1Lower effective resistanceModifies its propertyNon-metal conductorsSilicon organic compoundsElectrical conductorEngineering

Various articles and devices can be manufactured to take advantage of a what is believed to be a novel thermodynamic cycle in which spontaneity is due to an intrinsic entropy equilibration. The novel thermodynamic cycle exploits the quantum phase transition between quantum thermalization and quantum localization. Preferred devices include a phonovoltaic cell, a rectifier and a conductor for use in an integrated circuit.

Owner:SEMINUCLEAR INC

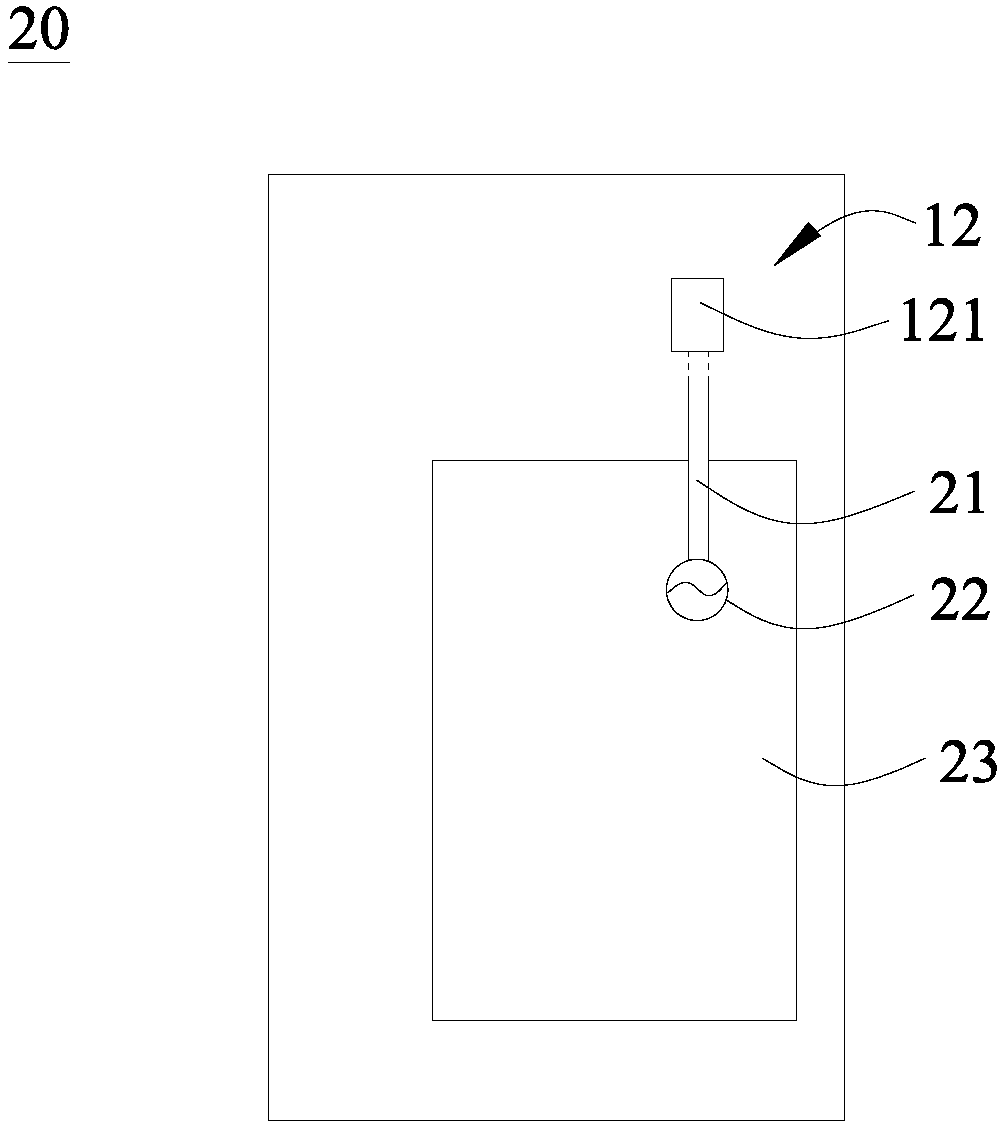

Housing, antenna assembly, and electronic equipment

ActiveCN108417967ALower effective resistanceReduce lossAntenna supports/mountingsRadiating elements structural formsElectricityPower flow

The invention discloses a housing, an antenna assembly, and electronic equipment. The housing serves as an antenna radiator of the electronic equipment, and the housing generates a surface current during the radiation of an electromagnetic signal. The housing comprises a housing base body and a conductive layer disposed on the surface of the housing base body. The conductivity of the conductive layer is greater than the conductivity of the housing base body, so as to enable at least a part of the surface current to pass through the conductive layer. The antenna assembly comprises a feed sourceand the housing, and the feed source is electrically connected with the housing. The feed source is used for providing an excitation signal, and the housing is used for generating an electromagneticsignal according to the excitation signal, and transmitting the electromagnetic signal to the outside. The electronic equipment comprises the antenna assembly. According to the technical scheme of theinvention, the loss of antenna power can be reduced, and the performances of the antenna are improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Single special-shaped efficient energy-saving electric wire

InactiveCN103545037AIncrease the effective resistanceLow conductivityInsulated cablesPower cablesSocial benefitsElectrical resistance and conductance

The invention discloses a single special-shaped efficient energy-saving electric wire with changed section perimeter. Effective resistance of a circular wire is increased by the skin effect of the alternating current, according to the newly discovered theory that the allowed largest current in a conductor is in direct proportion to the section perimeter of the conductor, the section perimeter of the wire needs to be increased while the sectional area of the wire is unchanged, the section perimeter of the elliptical wire is larger than the circular wire with the same section, so that the circular wire is changed into the elliptical wire. Due to the fact that the section perimeter and the surface area of the elliptical wire are increased, effective resistance is reduced, conductivity of the wire is increased, conducting efficiency of the wire is increased, and the wire has significant economical and social benefits.

Owner:陈胜民

Reliable cage rotor

ActiveCN104871415BQuality improvementAchieve homogenization of heatingMagnetic circuit rotating partsStatorsPunchingFilling materials

The invention relates to a cage rotor (1, 62, 72, 82) for an electrical machine (50, 52, 54, 56), comprising: a rotor stack (2, 206, 207, 208) along The axis of rotation (6) extends in the axial direction (3) from the first axial end (4, 163, 173, 183) to the second axial end (5, 164, 174, 184) and has a a lamination (7) layered in the axial direction (3); a short-circuit ring (8) which surrounds the axis of rotation (6) and which is arranged on the first axial end (4, 163, 173, 183); and A further short-circuit ring (9) which surrounds the axis of rotation (6) and which is arranged on the second axial end (5, 164, 174, 184), wherein the short-circuit ring (8) and the further short-circuit ring (9) Comprising a first material, wherein the laminations (7) each have a first stamping (10) forming the edge of a slot (16) of a rotor plate stack (2, 206, 207, 208) from the first The axial ends (4, 163, 173, 183) extend to a second axial end (5, 164, 174, 184), wherein the laminations (7) each have a second punching (11), which Forms the edge of a channel (12, 126) extending from a first axial end (4, 163, 173, 183) to a second axial end (5, 164, 174, 184), wherein the first punch The punched part (10) is located in the outer region (13) of the laminate (7) and the second punched part (11) is located in the inner region of the laminate (7), the channel (12, 126) is made of the first material The filling material (15) is filled, and the filling material is integrally connected with the short-circuit ring (8) and the other short-circuit ring (9). The invention relates to a motor comprising a cage rotor (1, 62, 72, 82), Method for manufacturing cage rotors (1, 62, 72, 82), and sets (60, 70, 80) of electric machines (51, 52, 53, 54, 55, 56).

Owner:SIEMENS AG

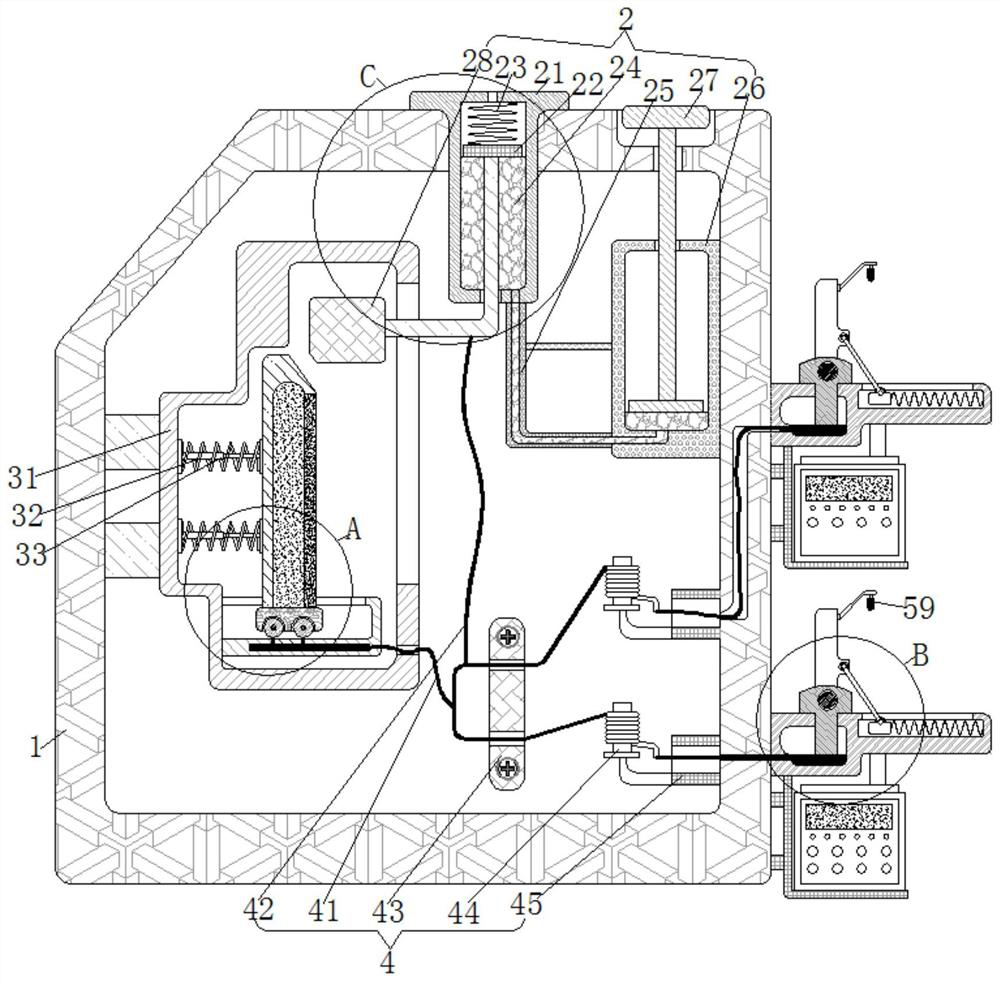

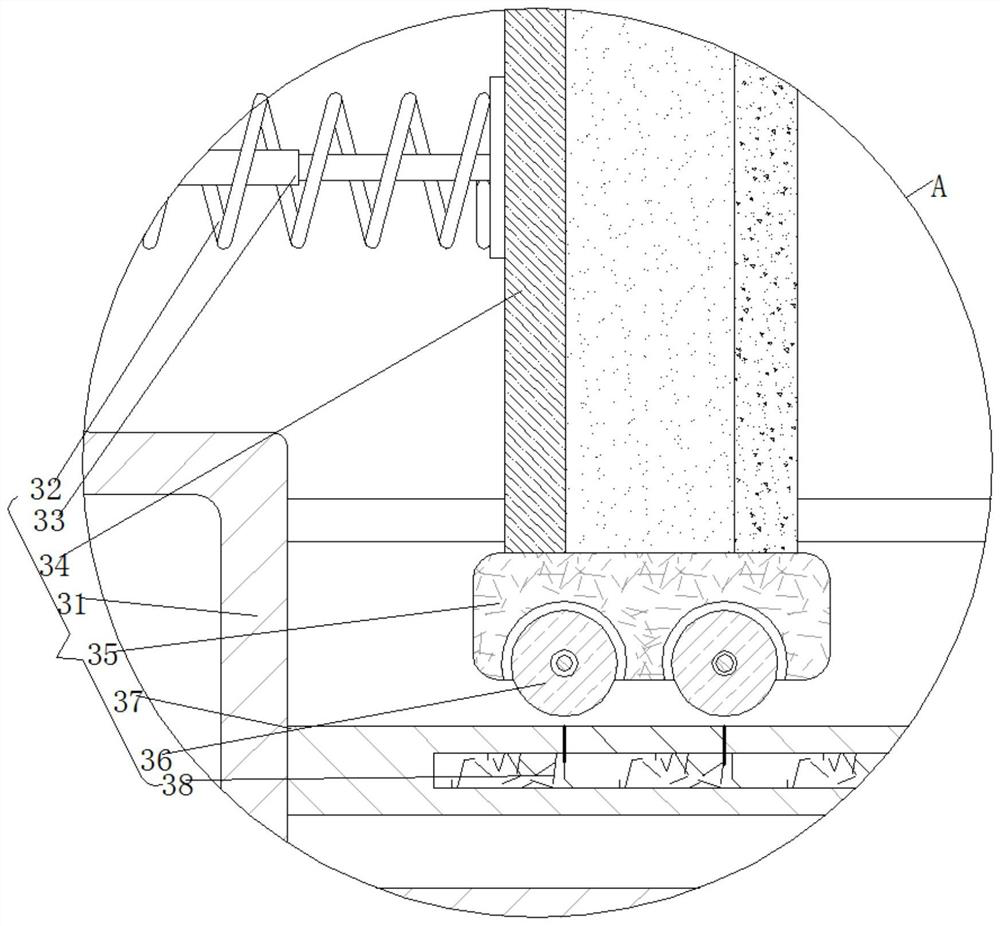

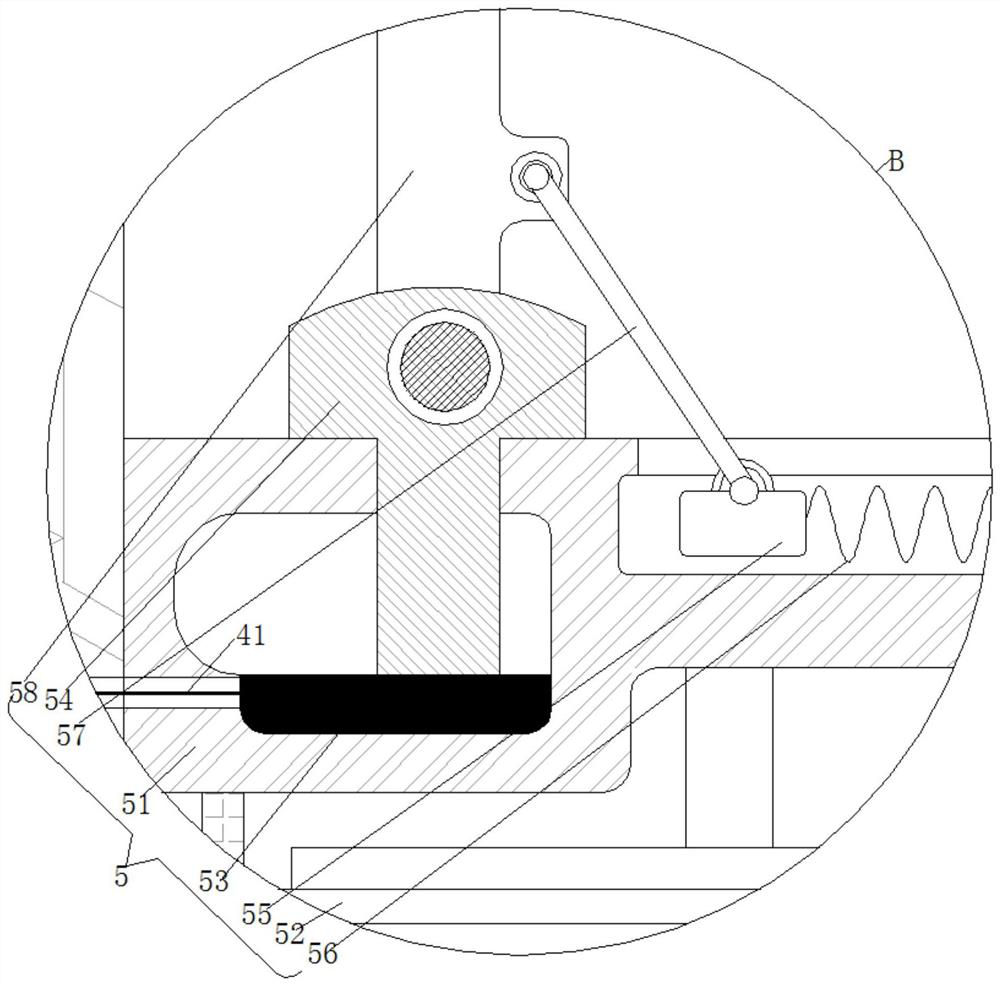

Pre-tightening line management equipment based on machine room alternating current power distribution cabinet

PendingCN114400516ASafe to useTo achieve the effect of combingBus-bar/wiring layoutsAC powerMagnetic tension force

The invention relates to the technical field of AC power distribution management, and discloses a pre-tightening line management device based on a machine room AC power distribution cabinet, which comprises a cabinet body, a control groove is arranged in the cabinet body, a connecting pipe is fixedly inserted in the cabinet body and located at the right end of the control groove, and the left end of the connecting pipe is fixedly connected with a fixed block. A sensing block is fixedly connected to the bottom end in the fixing block, and a fixing frame is fixedly connected to the left end of the control groove in the cabinet body. A magnetic field is generated around an induction block, the magnetic force of a first magnetic block is increased, the repulsive force between the first magnetic block and a second magnetic block is increased, at the moment, the second magnetic block drives a clamping block to move upwards through a connecting rod, the clamping block pushes a flow control rod, the flow control rod pushes a contact to move upwards along a resistor strip, and effective resistance flowing through the resistor strip is reduced; the current in the circuit is increased, so that the insufficient voltage in the circuit is compensated, and the effects of automatically adjusting the voltage and being safe to use when the voltage in the circuit is insufficient are achieved.

Owner:卞东营

Semiconductor device and process for manufacturing the same

InactiveUS20090283855A1Increase the inductance valueEffective resistance valueSemiconductor/solid-state device detailsSolid-state devicesThin layerInductor

An inductor having a helicoidal shape is provided on an insulation film formed on a semiconductor substrate. A conductive thin layer (a plating layer) is provided on a surface of the inductor. A conductivity of the conductive thin layer is higher than that of the inductor. According to the constitution, a Q value can be improved, and a large volume of current can be flowed.

Owner:PANASONIC CORP

Eye observation lamp used for ophthalmology department

The invention relates to the technical field of eye observation illumination, and discloses an eye observation lamp used for the ophthalmology department. The eye observation lamp comprises a shell, wherein a hydraulic control mechanism is arranged on the upper position in the shell and comprises a sleeve; a piston rod is movably inserted in the sleeve; on the upper end of the piston rod, a pre-tightening spring is fixedly connected in the sleeve; on the lower end of the piston rod, the sleeve is filled with water liquid; and a guide pipe is fixedly inserted into the lower part in the sleeve. A movable rod is pulled upwards, the movable rod sucks the water liquid in the sleeve into a buffer barrel through the guide pipe, the water liquid drives a guide block to move downwards through the piston rod, the guide block moves downwards along a guide rod, the effective electrical resistance, which flows through the guide block, of a main line is smaller and smaller, so that the current of the main line is larger and larger, and the brightness of a bulb is gradually increased; and therefore, the effects that hydraulic control type equal-pipe gradual change adjustment of a high-end equipment technology is adopted, stimulation of the eyes of a patient due to sudden light change is avoided, and use safety is guaranteed are realized.

Owner:张勇

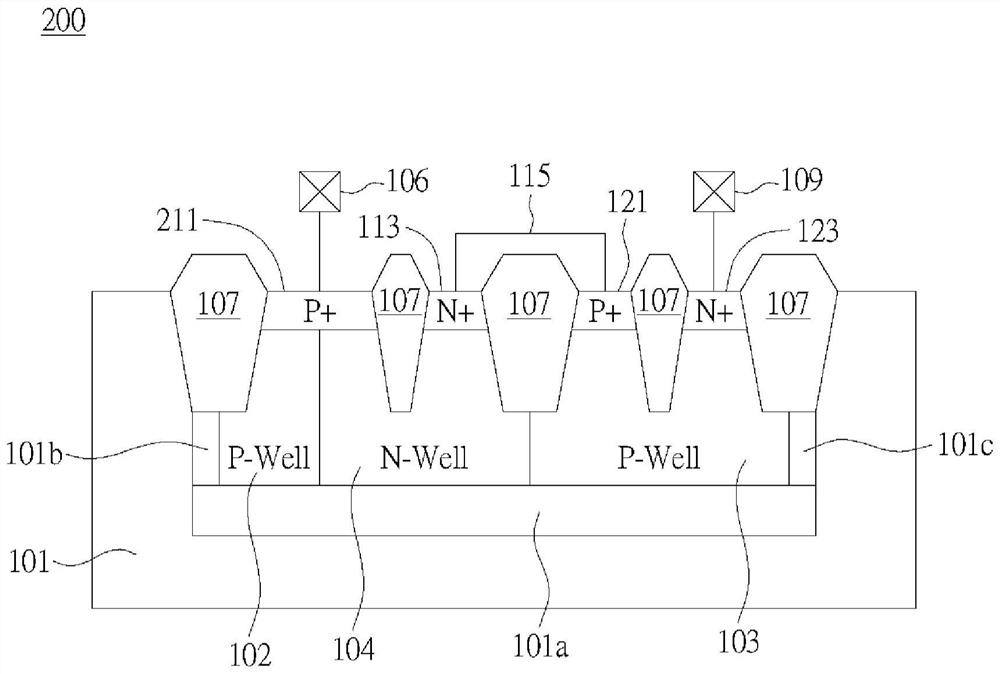

Electrostatic discharge protection device and operation method thereof

PendingCN114823656ALower effective resistanceSolve the problem that cannot be opened smoothlyTransistorSolid-state devicesSilicon-controlled rectifierSemiconductor

The invention discloses an electrostatic discharge protection device and an operation method thereof, and the electrostatic discharge protection device comprises a semiconductor substrate, a first well region, a second well region, a third well region, a first doped region, a second doped region, a third doped region, and a fourth doped region. The first well region, the second well region and the third well region are located in the semiconductor substrate, and the third well region is directly coupled between the first well region and the second well region. The first well region and the second well region have a first electrical property, and the third well region has a second electrical property. The first doped region has a first electrical property and is located in the first well region. The second doped region has a second electrical property and is located in the third well region, and the first doped region and the second doped region are isolated from each other. The third doped region and the fourth doped region have the first electrical property and the second electrical property respectively, are located in the second well region and are isolated from each other, and the second doped region is electrically coupled with the third doped region. The first well region, the second well region, the third well region and the fourth doped region form a parasitic silicon controlled rectifier.

Owner:MACRONIX INT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com