Electrostatic discharge protection device and operation method thereof

An electrostatic discharge protection and electrical technology, applied in the field of electrostatic discharge protection devices, can solve the problems of reducing the effective resistance of electrostatic discharge protection devices, parasitic silicon-controlled rectifiers cannot be turned on smoothly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

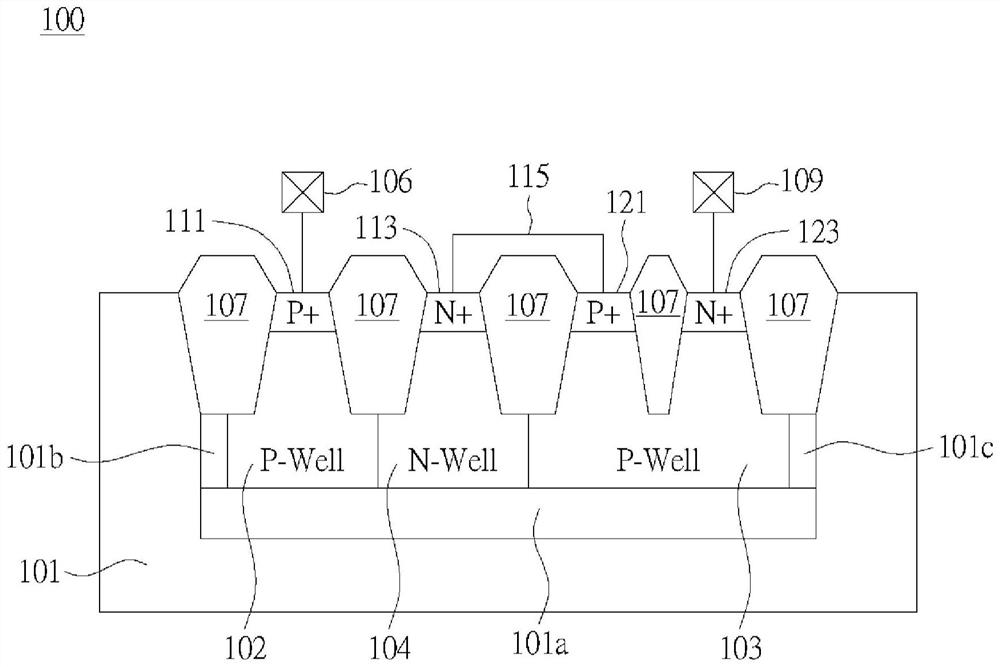

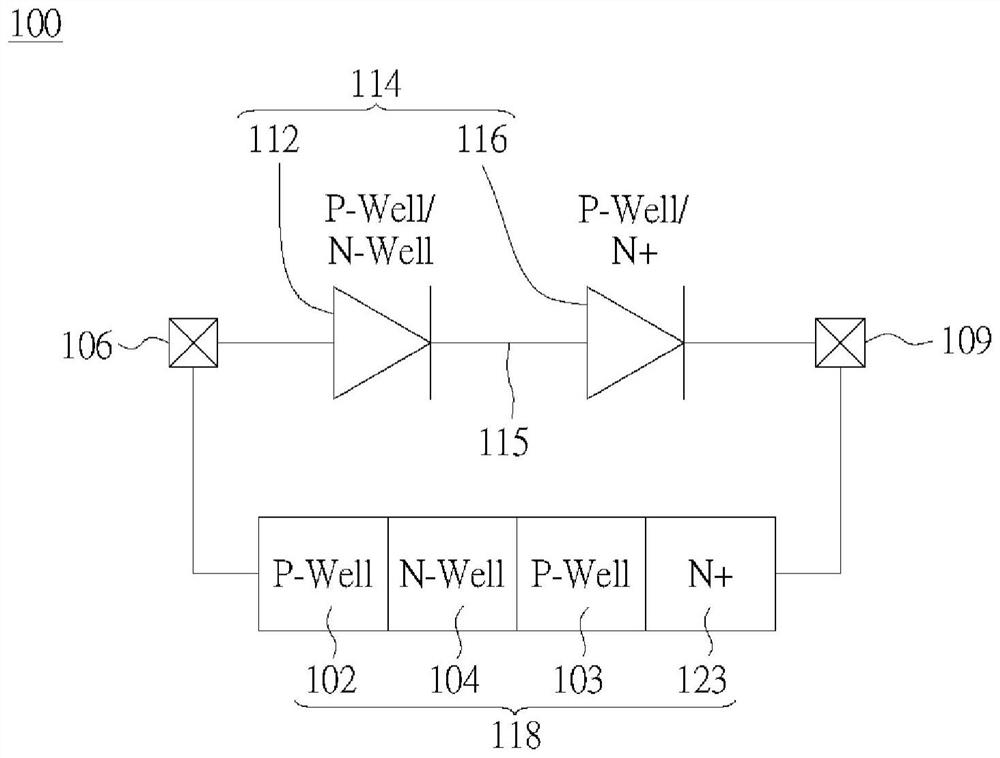

[0038] Please refer to Figure 1A and Figure 1B , which respectively show a cross-sectional schematic diagram of the electrostatic discharge protection device 100 according to an embodiment of the present invention and a schematic diagram of an equivalent circuit thereof.

[0039] According to an embodiment of the present invention, the ESD protection device 100 includes a semiconductor substrate 101 , a first well region 102 , a second well region 103 , a third well region 104 , a first doped region 111 , and a second doped region 113 , the third doped region 121 and the fourth doped region 123 .

[0040] In one embodiment, the semiconductor substrate 101 may be made of any suitable base semiconductor (eg, crystalline silicon or germanium), compound semiconductors (eg, silicon carbide, gallium arsenide, gallium phosphide, iodine phosphide, iodine arsenide, and / or antimony iodine) or a combination of the above. The semiconductor substrate 101 is, for example, a P-type sub...

no. 2 example

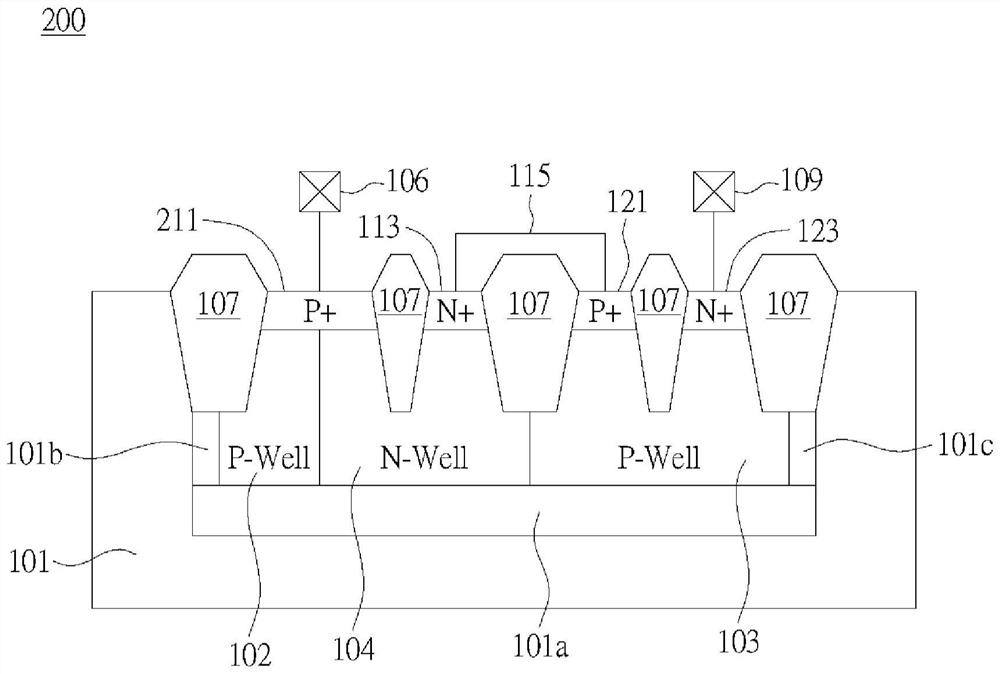

[0049] Please refer to Figure 2A and Figure 2B , which respectively show a cross-sectional schematic diagram of an electrostatic discharge protection device 200 according to another embodiment of the present invention and a schematic diagram of an equivalent circuit thereof. The structure of the ESD protection device 200 is similar to Figure 1A In the structure of the ESD protection device 100 shown, a part of the first doped region 211 is located in the first well region 102 , and another part of the first doped region 211 is located in the third well region 104 . The first doped region 211 is similar to the first doped region 111 .

[0050] In the ESD protection device 200 , there are two parallel diodes, which are coupled through the first well region 102 and the third well region 104 to form a diode 212 , and pass through the first doped region 211 and the third well region 104 Coupled to form another diode 214, thereby increasing the effective circuit path for electr...

no. 3 example

[0055] Please refer to Figure 3A and Figure 3B , which respectively show a cross-sectional schematic diagram of an electrostatic discharge protection device according to another embodiment of the present invention and a schematic diagram of an equivalent circuit thereof. The structure of the ESD protection device 300 is similar to Figure 1A In the structure of the ESD protection device 100 shown, except that a part of the first doped region 311 is located in the first well region 102 , another part of the first doped region 311 is located in the third well region 104 , and the second doped region 313 The third doped region 321 is directly connected to each other to form a junction 316 . The first doping region 311 , the second doping region 313 and the third doping region 321 are similar to the first doping region 111 , the second doping region 113 and the third doping region 121 .

[0056] In the ESD protection device 300 , there are two parallel diodes, which are couple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com