Reliable cage rotor

A rotor and cage-shaped technology, applied in the field of cage-shaped rotors, can solve problems such as crack formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

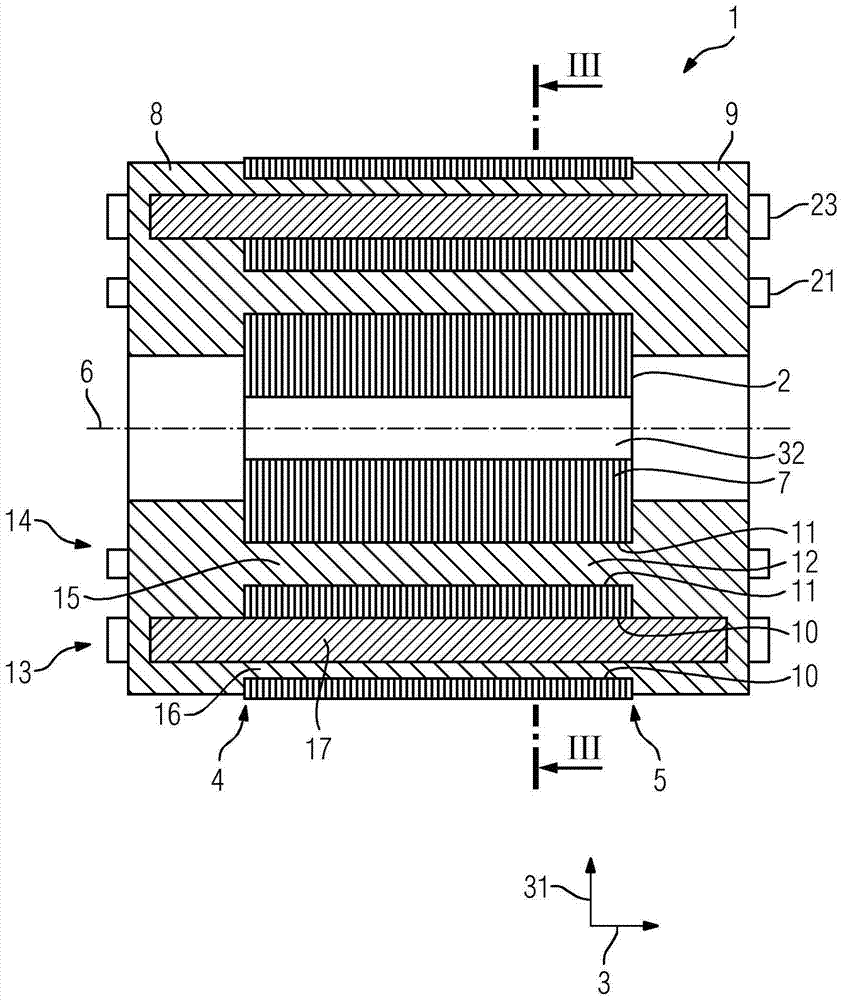

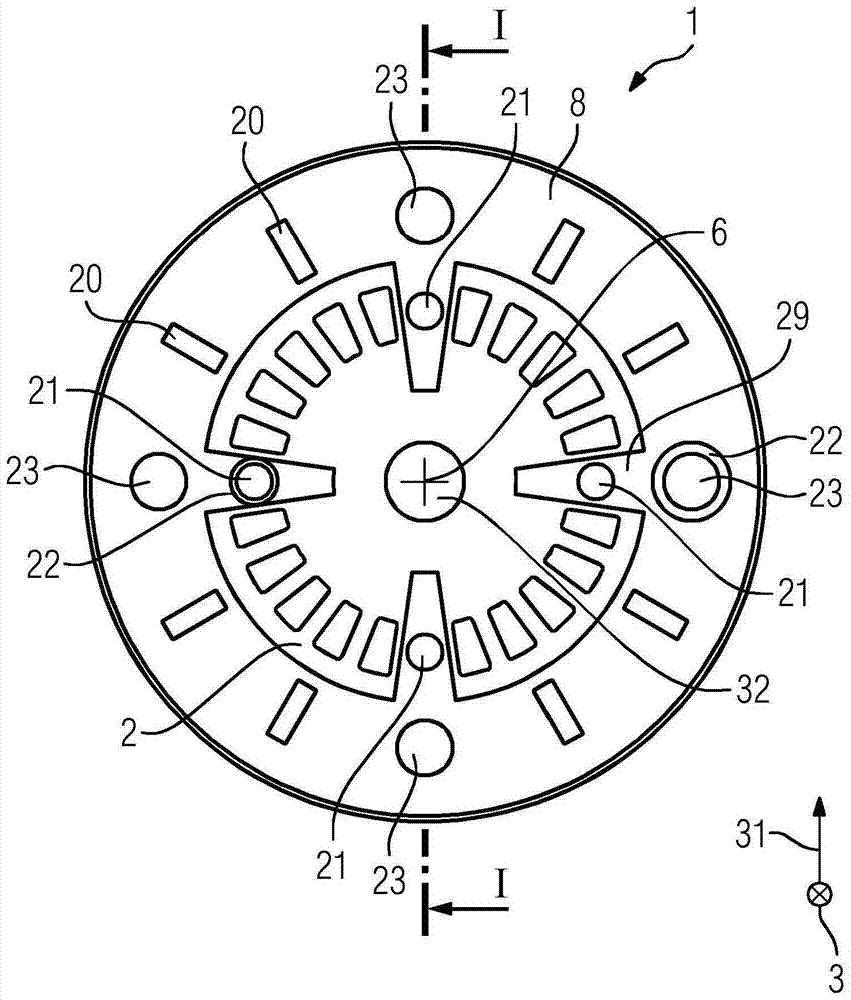

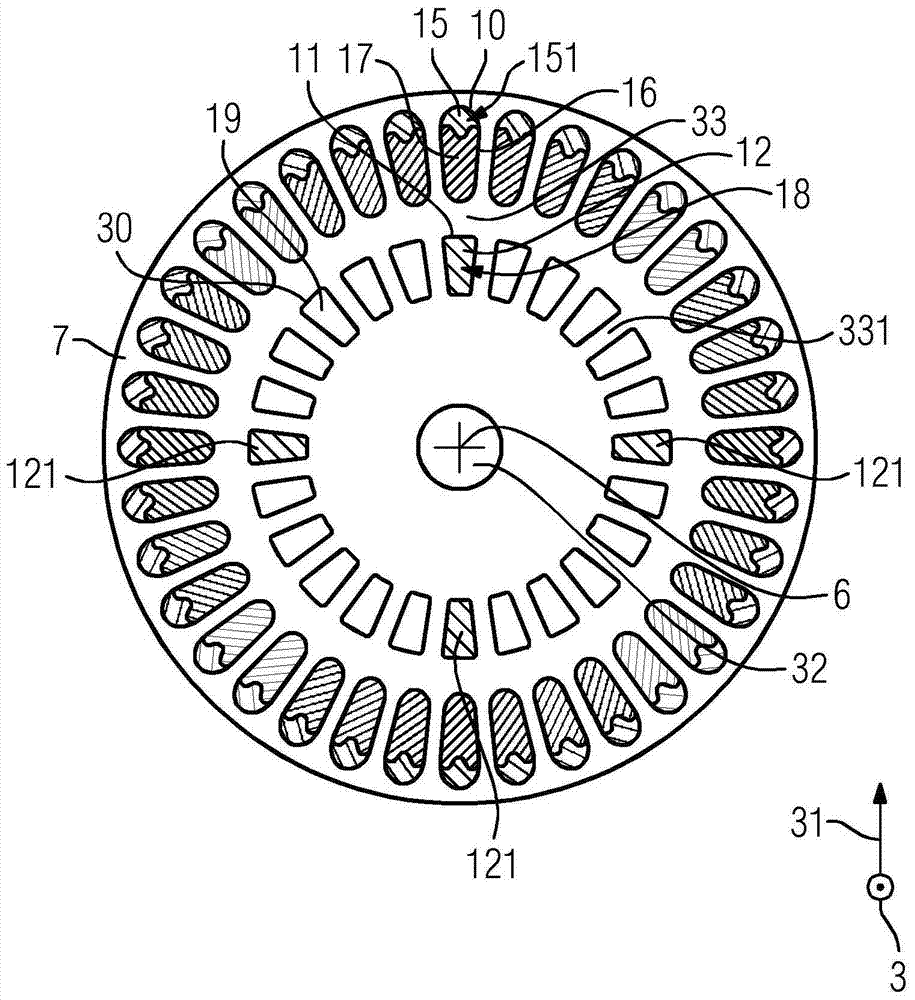

[0071] figure 1 An embodiment of a cage rotor 1 is shown, comprising a rotor plate stack 2 extending in the axial direction 3 from a first axial end 4 along the axis of rotation to a second axial end 5 and having a Lamination 7 layered in axial direction 3 . The cage rotor 1 also has a short-circuit ring 8 which surrounds the axis of rotation 6 and is arranged at the first axial end 4 , and a further short-circuit ring 9 which surrounds the axis of rotation 6 and is arranged at the second axial end Part 9 on. The short-circuit ring 8 and the further short-circuit ring 9 comprise the first material. The first material is suitable for manufacturing a cage rotor by die casting and comprises aluminum in this exemplary embodiment. The laminations 7 of the rotor lamination stack 2 each have a first punching 10 which forms the edge of a groove 16 of the rotor lamination stack which extends from the first axial end 4 to the second axial end 4 . End 5. The laminations 7 also each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com