High-voltage motor convenient to adjust magnetic path characteristic of motor

A technology for high-voltage motors and regulating motors, which is applied to electrical components, electromechanical devices, electric components, etc., and can solve problems such as affecting the service life of magnetic slot wedges, destroying magnetic slot wedges, and mechanical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

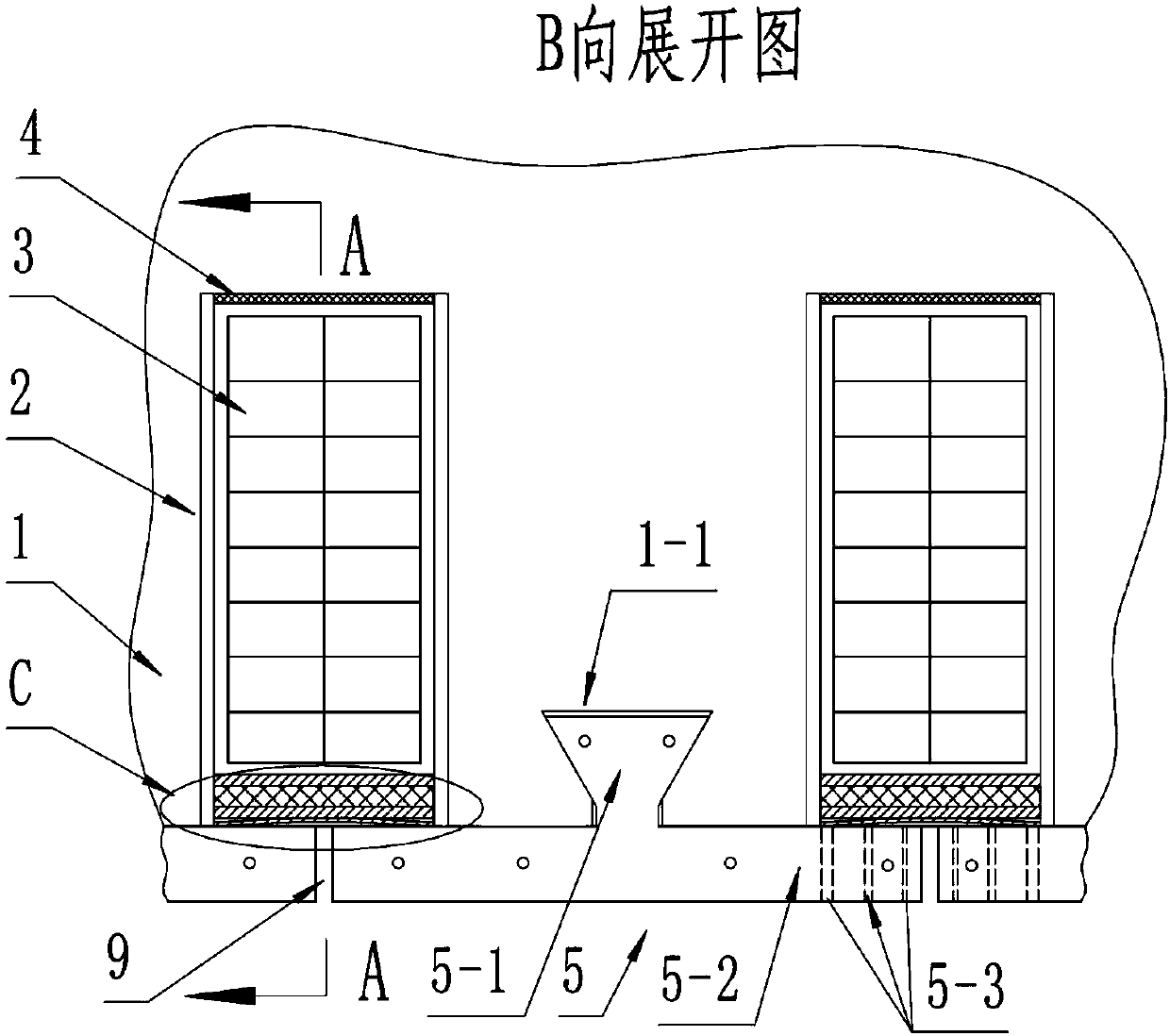

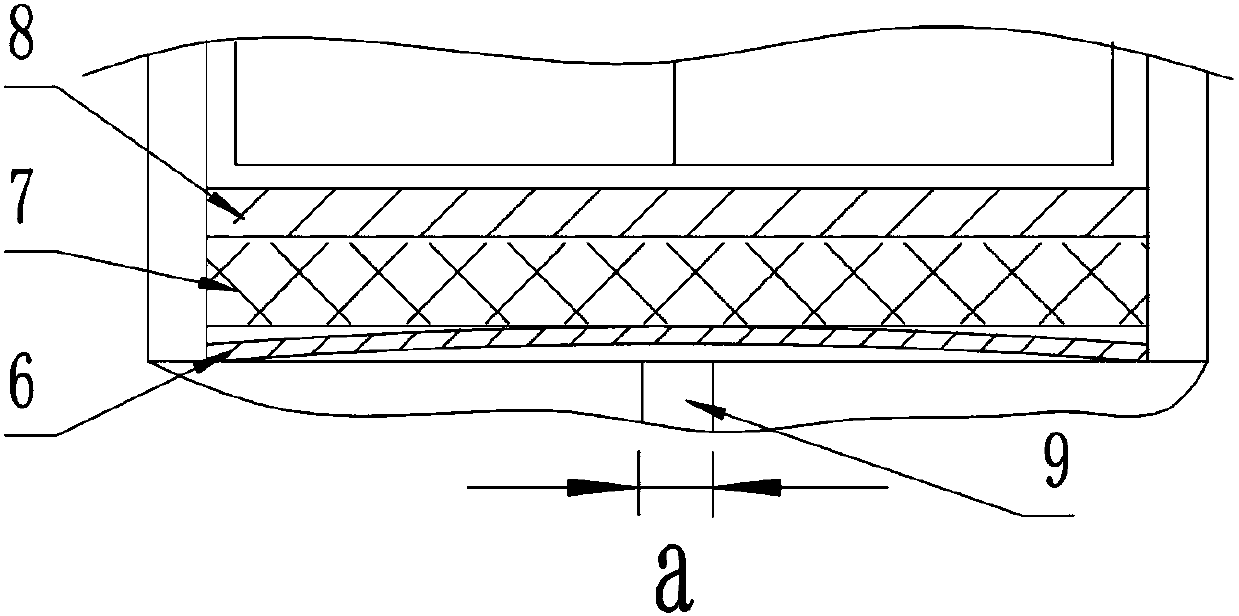

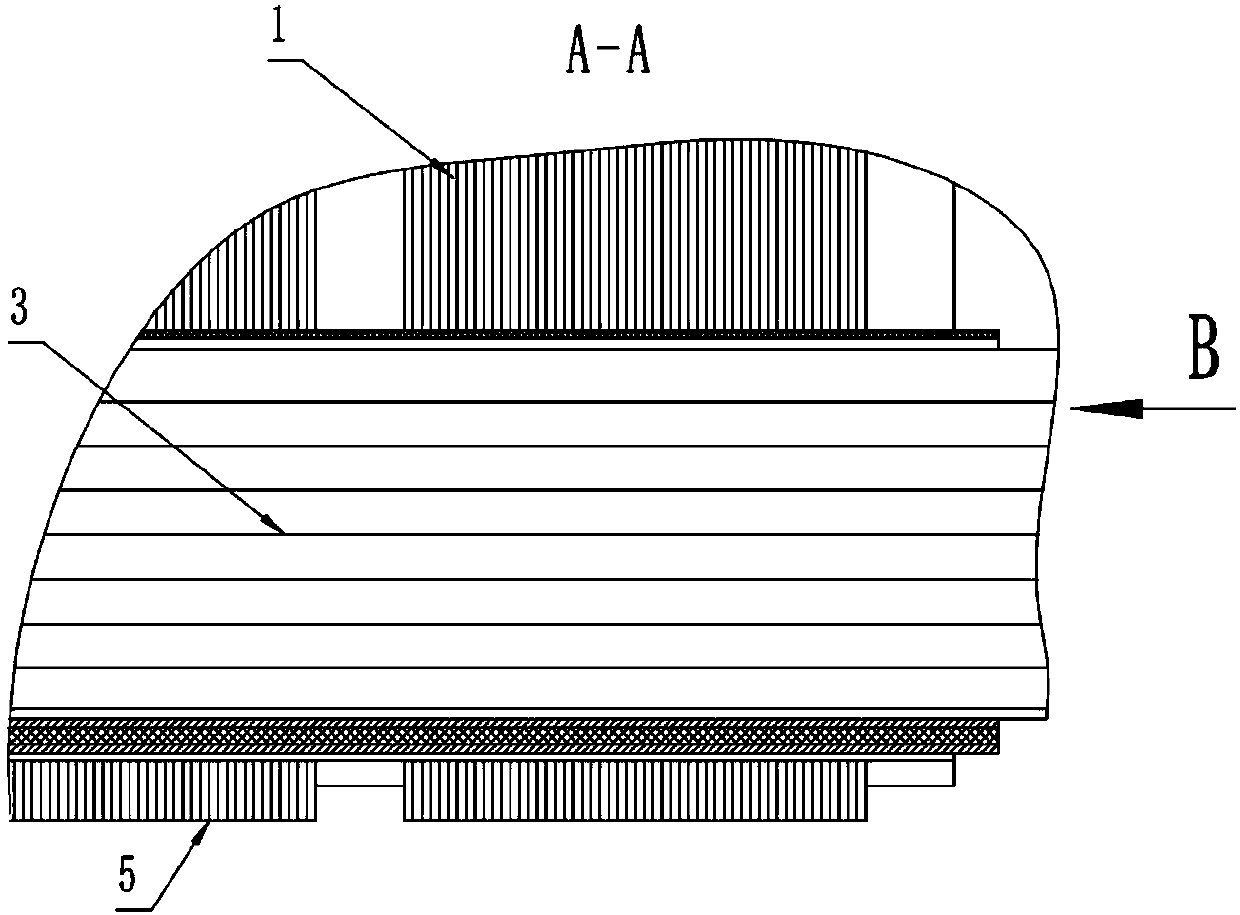

[0022] see Figure 1-3 , the present invention includes a stator 1, the stator distributes stator slots 2 along the circumferential direction, coils 3 are arranged in each stator slot, and slot wedges 5 constrain the coils. The slot wedge is made of the same material as the stator, and the slot wedge is composed of a raised tenon end 5-1 and a slot cover end 5-2 extending in opposite directions on both sides of the tenon end, and the tenon end is dovetail-shaped . The slot wedge adopts a densely stacked riveting structure, and its thickness corresponds to the length of each section of the core. There is a tenon groove 1-1 between the adjacent stator slots, the tenon end is matched and embedded in the tenon groove, the slot cover end of the adjacent slot wedge corresponds to the notch of each stator slot, and two adjacent slot wedges The slot cover ends of the slots jointly constitute a limit for the coil located in the stator slot. The connection between the slot wedge and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com