Armature coil of direct-current motor

A technology of armature coil and direct current, which is applied in the shape/style/structure of winding conductors, which can solve the problems of difficult heat dissipation of coil components, smaller thickness of slicer, and large heating factor, so as to reduce current density and heating factor , reduce the occupied area, and have the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

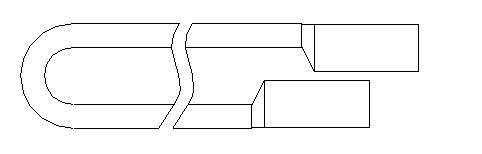

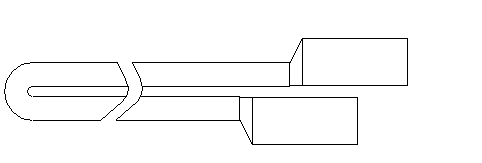

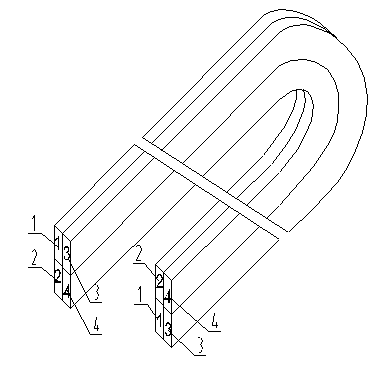

[0014] like figure 1 , 2 , 3, 4, 5, 6, the armature coil of the present invention is wound by four single magnet wire elements, and each armature coil is composed of four elements: two large "U"-shaped coils Elements 1, 3 and two small "U" coil elements 2, 4. The shapes of the large and small "U"-shaped coil elements are the same, but the arc radii of the "U" shape are different, that is, the arc radii of the large "U"-shaped coil elements 1 and 3 are larger than those of the small "U"-shaped coil elements 2 and 4. the arc radius. The four elements are arranged in two layers, inside and outside. When two large "U"-shaped coil elements 1, 3 and two small "U"-shaped coil elements 2, 4 are wound into coils, the two large "U"-shaped coil elements 1 , 3 are arranged on the outside of the small "U"-shaped coil elements 2, 4. Through the knock shape, the four elements respectively form the upper side 7 of the coil and the lower side 8 of the coil, such as Figure 4 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com