Vacuum processing device, vacuum processing method, and computer-readable storage medium

A vacuum processing device and vacuum processing technology, which is applied in the direction of vacuum evaporation coating, manipulators, conveyor objects, etc., can solve the problems of larger occupied area, decreased production volume, and inability to solve problems, so as to suppress the increase of occupied area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Hereinafter, non-limiting illustrative embodiments of the present invention will be described with reference to the drawings. In all the drawings, the same or corresponding components or components are given the same or corresponding reference numerals, and repeated explanations are omitted. In addition, the drawings do not intend to show the relative proportions between components or parts, therefore, the specific dimensions should be determined by those skilled in the art according to the following non-limiting embodiments.

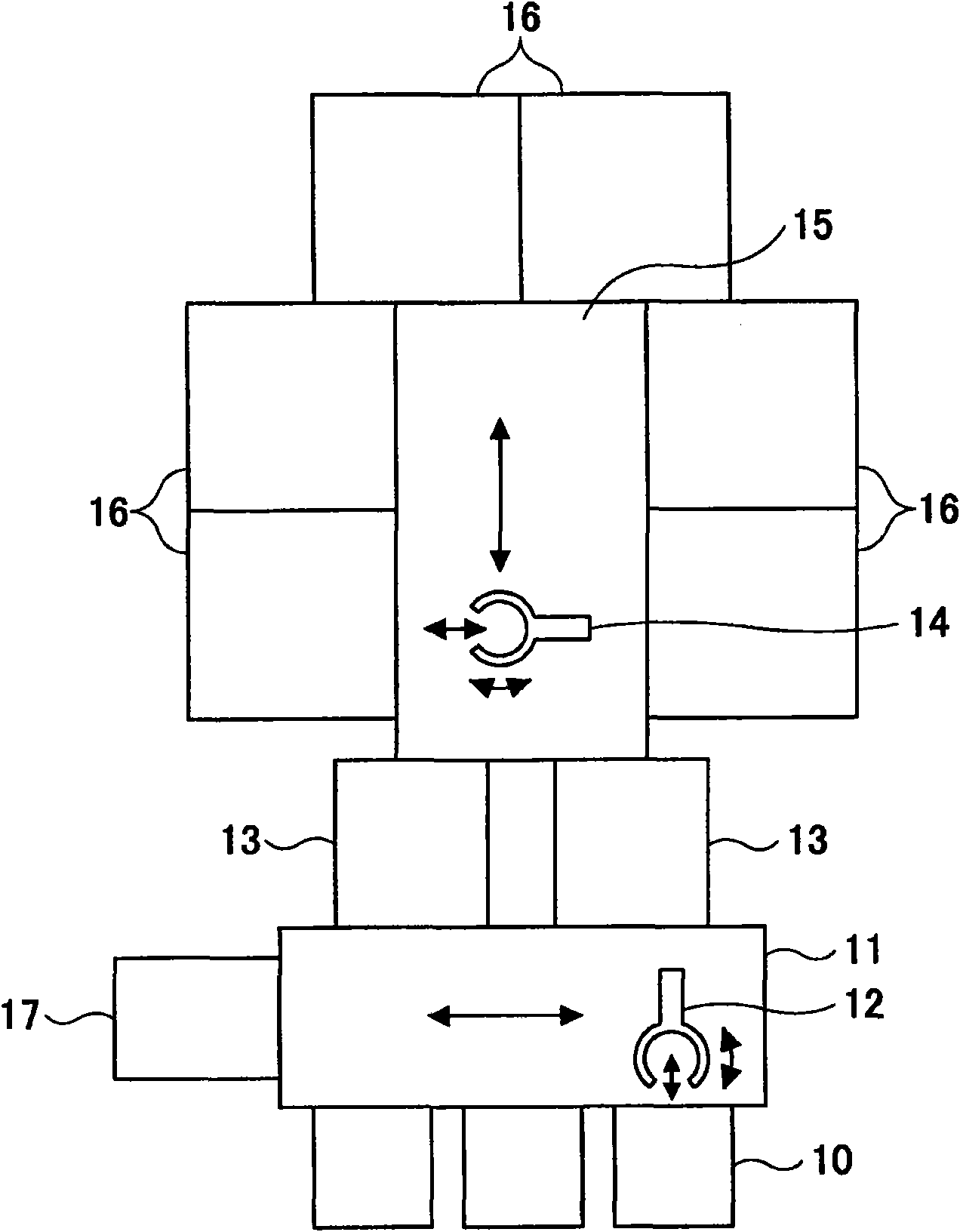

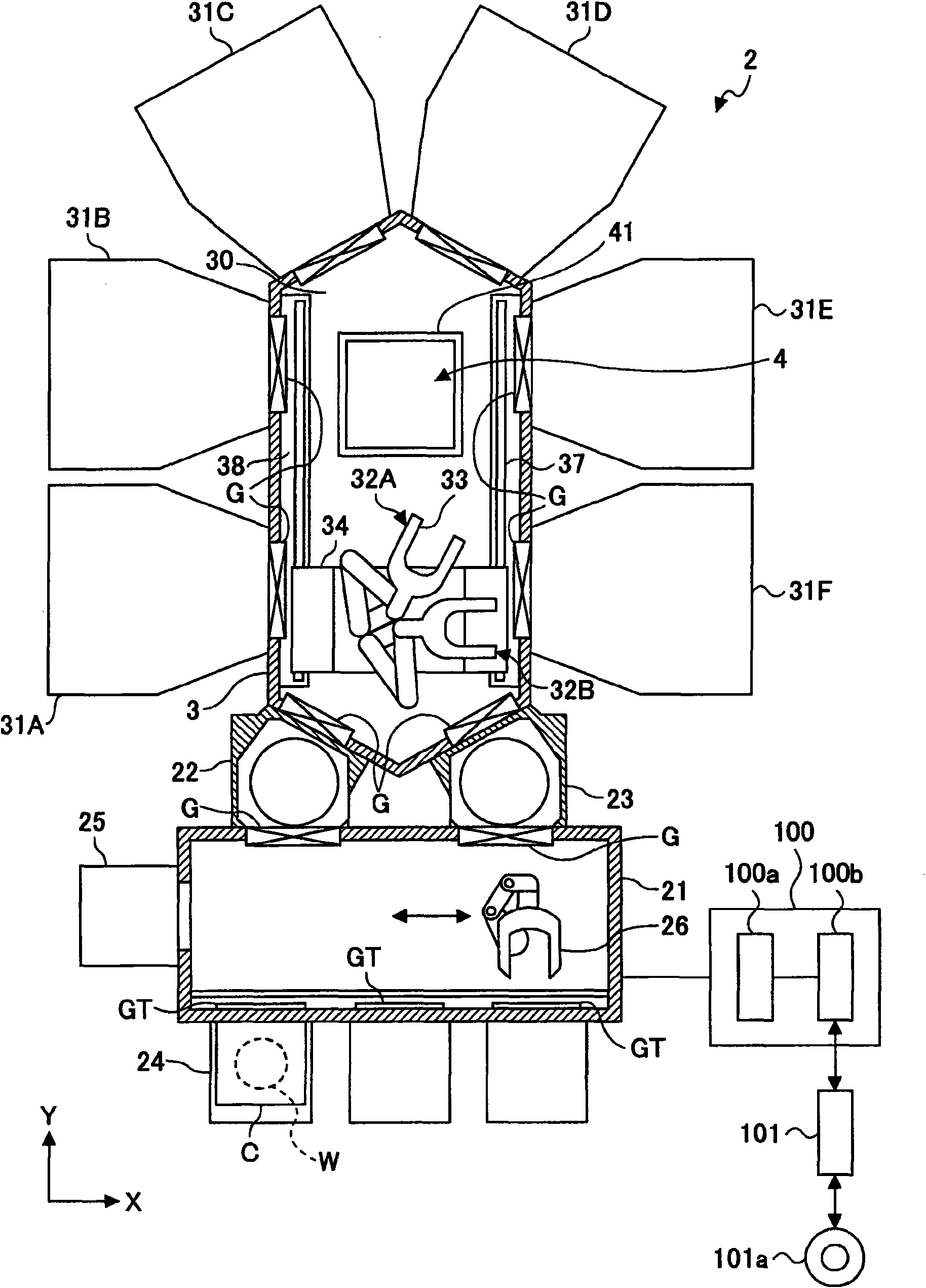

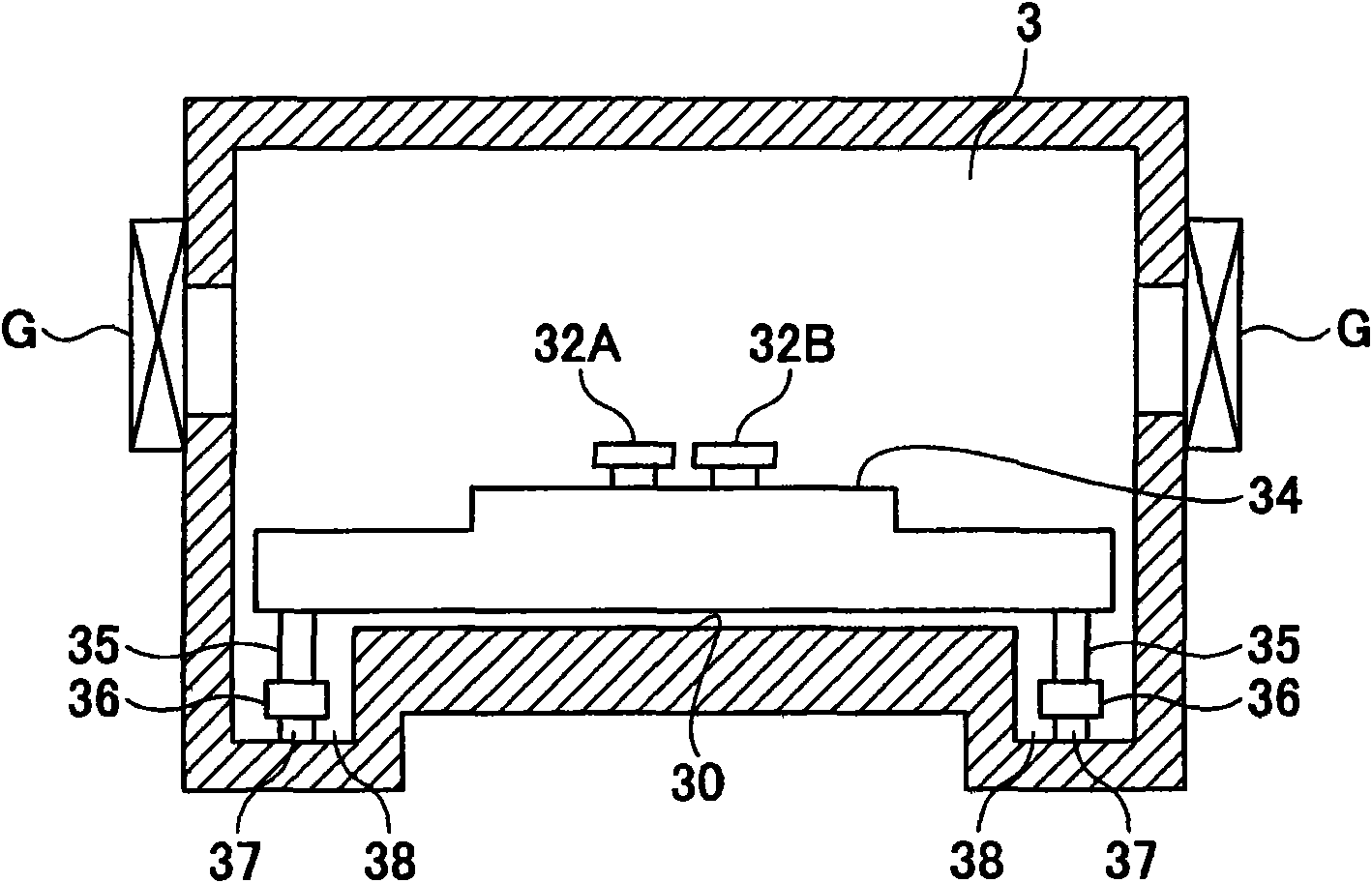

[0075] figure 2 It is a plan view showing the overall configuration of the vacuum processing apparatus 2 . As shown in the figure, the vacuum processing apparatus 2 includes: a first transport chamber 21 as a loader module for loading and unloading a wafer W; load-lock vacuum chambers (preparatory vacuum chambers) 22 and 23; Two transport chambers 3; and vacuum processing chambers 31A-31F. In addition, in the vacuum processing apparatus 2, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com