Over filling interdiction, vent and roll over valve

A technology of flipping valves and valve seats, which is applied in safety valves, balance valves, valve devices, etc., and can solve problems such as unsuitable discharge of fuel gas and delay of sealing membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

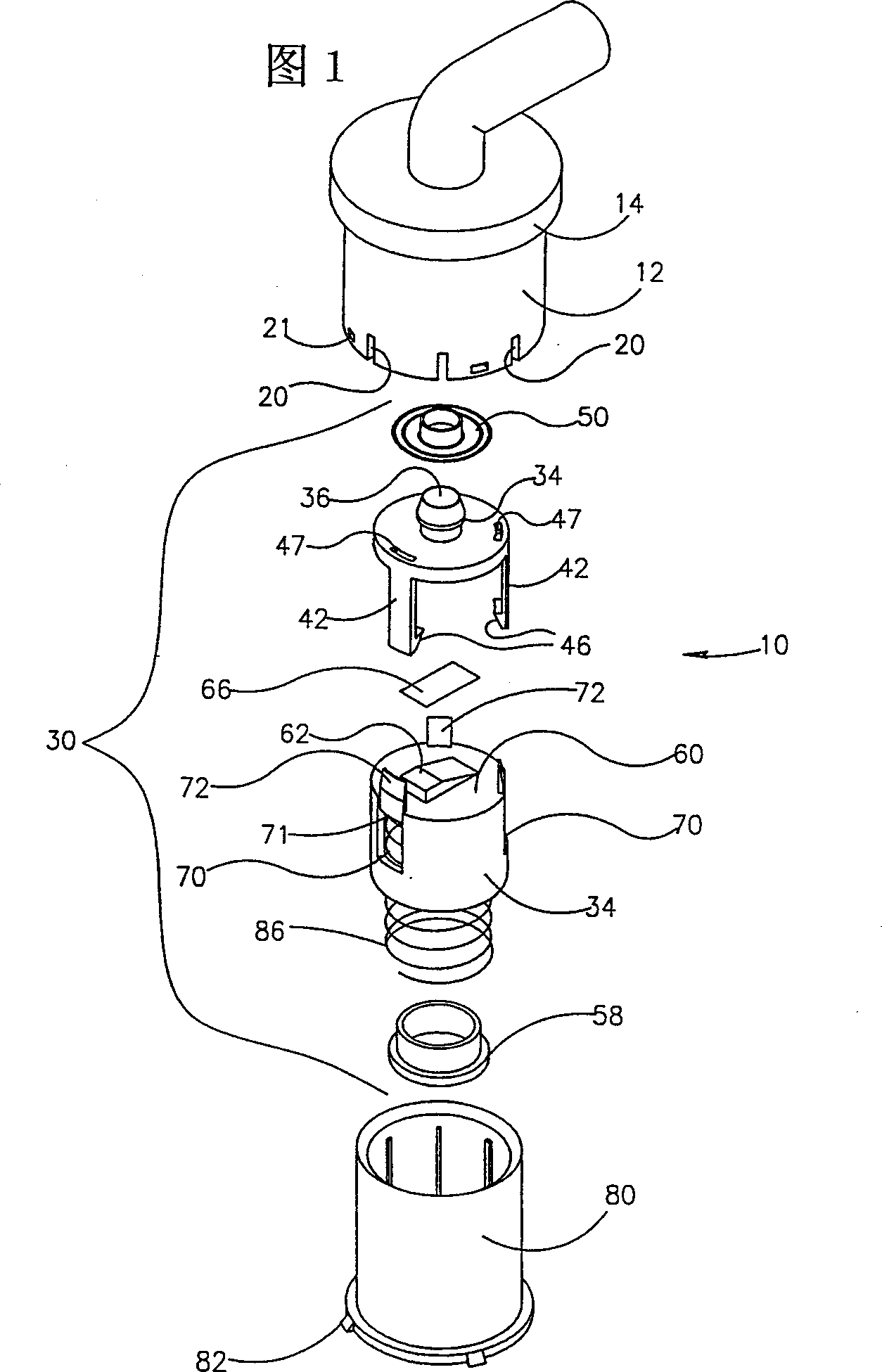

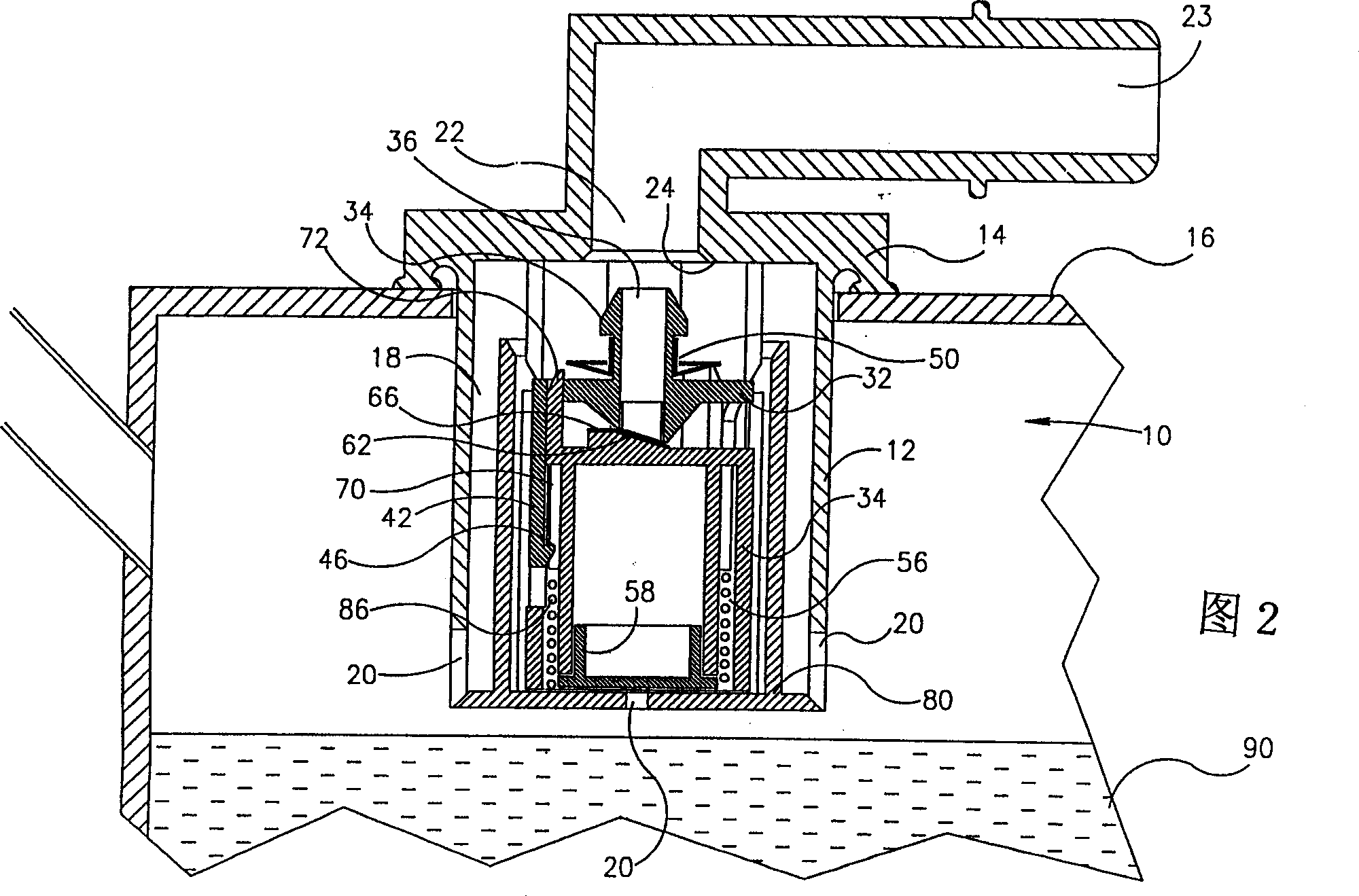

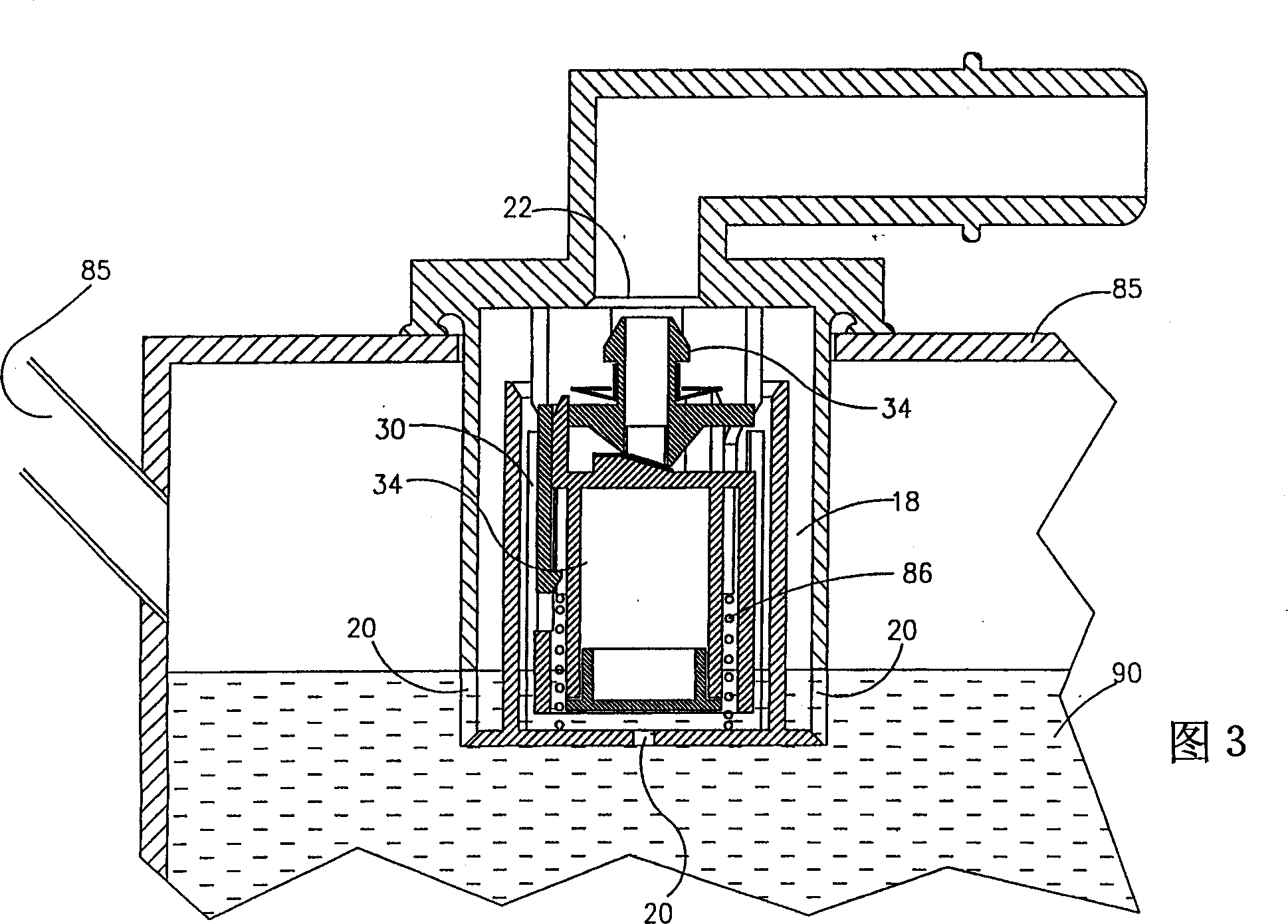

[0032] Attention is first directed to FIGS. 1 and 2 to understand the structure of the valve generally represented by numeral 10 . The valve comprises a cylindrical housing portion 12 on which a flange 14 is formed on an upper portion for being connected to an outer surface of a fuel tank 16 by heat welding; wherein the cylindrical housing portion 12 protrudes into the fuel tank 16 . A duct portion 23 is provided in flow connection with the outlet portion 22 .

[0033] As best seen in Figure 2, the housing defines an enclosed space 18 having a plurality of liquid inlets 20 and at a top of the enclosed space an outlet portion 22 defined by a valve seat 24. The housing 12 also includes a recess 21 in its lower part.

[0034] A valve assembly 30 includes a first stage 32 and a second stage 34 . The first stage 32 has a conical protrusion 34 at a top thereof, in which an outlet hole 36 is formed. The first stage 32 is formed at a bottom thereof with an elongated slit-shaped in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com