Chemical treatment and processing method of overrunning clutch wedge

An overrunning clutch and chemical treatment technology, applied in the field of chemical treatment and processing of overrunning clutch wedges, can solve the problems of wedge manufacturing precision error, error accumulation, and difficulty of wedges meeting product requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

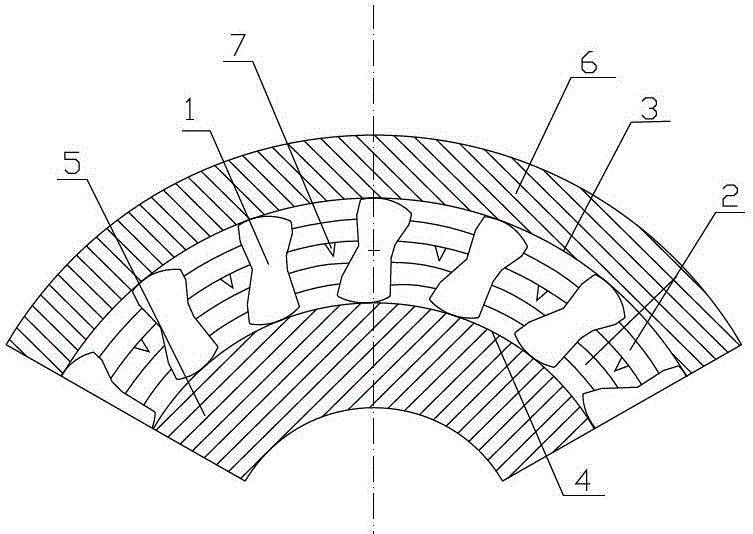

[0023] figure 1 Schematic diagram of the sprag type overrunning clutch. exist figure 1 Among them, each mark is: 1 wedge; 2 cage; 3 outer slideway; 4 inner slideway; 5 inner ring; 6 outer ring; 7 spring belt.

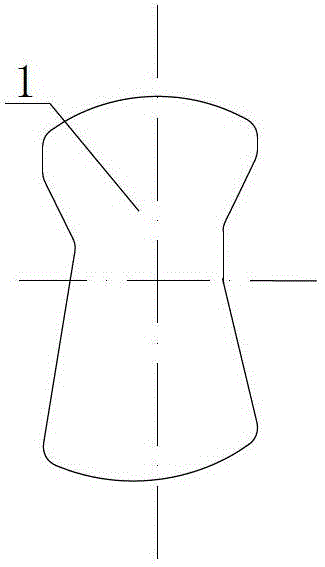

[0024] figure 2 It is a schematic diagram of a sprag of a sprag type overrunning clutch. exist figure 2 , labeled: 1 Wedge.

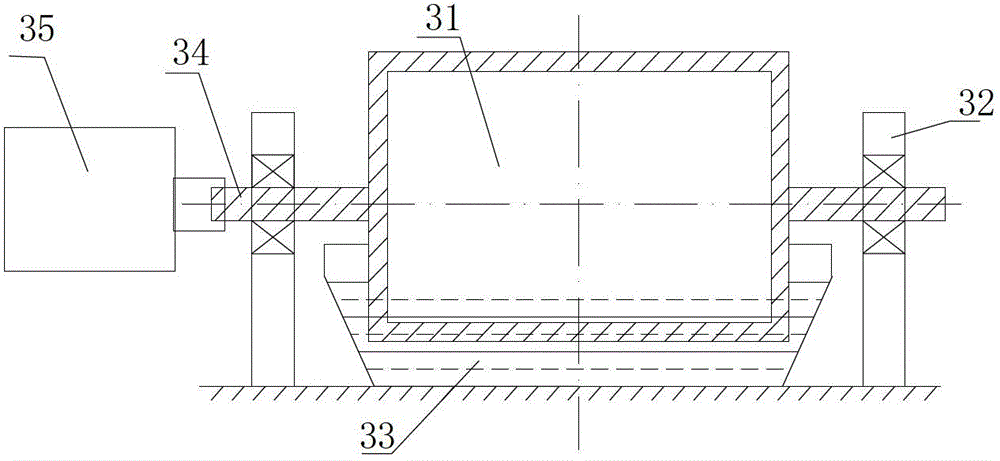

[0025] image 3 It is a schematic diagram of the hydrochloric acid corrosion processing process of the embodiment of the present invention. exist image 3 Among them, each mark is: 31 drum (the surface of the drum is hollowed out to facilitate the penetration of hydrochloric acid); 32 drum support frame; 33 hydrochloric acid pool; 34 drum shaft; 35 motor.

[0026] Figure 4 It is the purpose of the extrusion molding die of the present invention. exist Figure 4 Among them, each mark is: 41 supporting wall; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com