Processing method for wedge block of wedge block-type overrunning clutch

A technology of overrunning clutch and processing method, which is applied in the processing field of overrunning clutch, and can solve the problems of wedge manufacturing precision error, error accumulation, wedges that are difficult to meet product requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

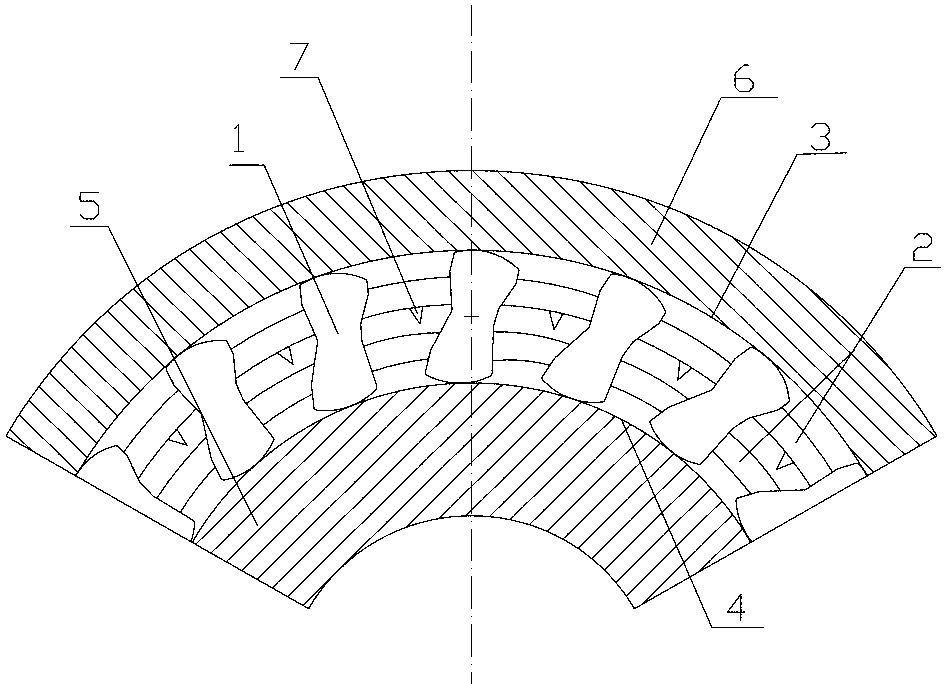

[0017] The processing method embodiment of sprag type overrunning clutch sprag is given below (referring to Figure 1~3 ):

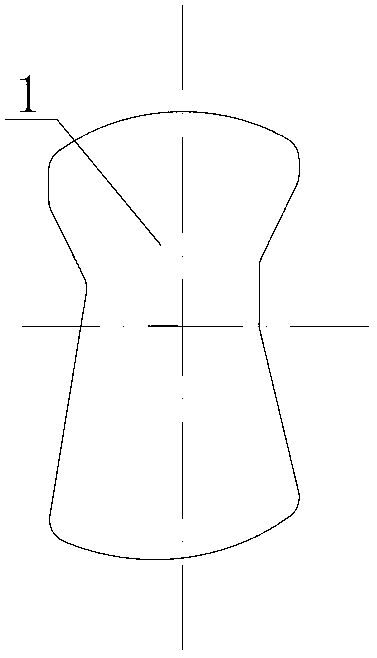

[0018] 1. Using bearing steel (GCr15), after cold drawing and cutting, a wedge with a margin of 0.02~0.04mm on one side is manufactured (see figure 2 ), after vacuum quenching and tempering, the hardness reaches HRC60~64, and then polishing (20~40min) with a polishing machine to remove surface oil and corners.

[0019] 2. Carry out sandblasting treatment on the wedge, and use corundum as the sand grain. The compressed air used for sandblasting must be clean and dry, and the air pressure is 6-8MPa. The blasting depth is 0.02-0.04mm.

[0020] 3. Clean the formed wedges: put the wedges into the mixer, then add hot water with a temperature of 40-80°C, and stir and clean them;

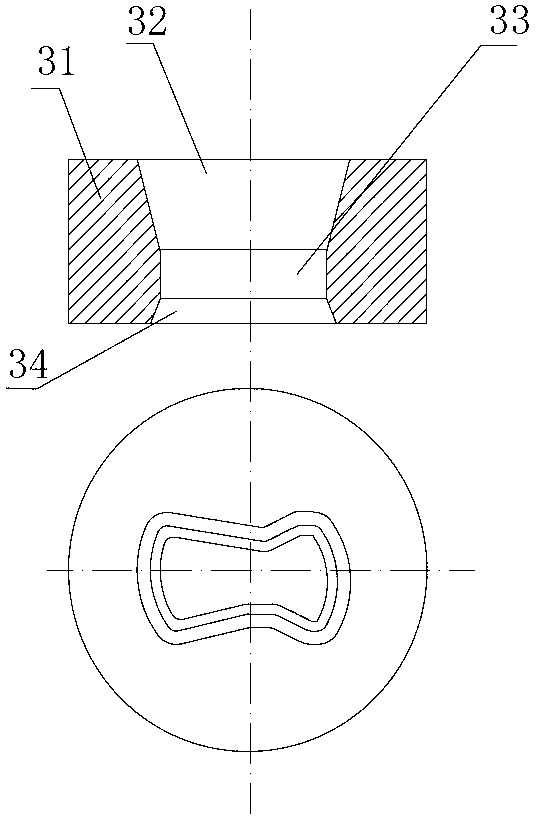

[0021] 4. Use the extruder to pass the cleaned wedge through the forming die (see image 3 ). The dimensional accuracy and surface roughness of the obtained wedge are close to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com