Advance support structure of large dip angle coal mining face

A technology of coal mining face and advanced support, applied in mining equipment, earthwork drilling, shaft equipment and other directions, can solve the problem of not designing an economical and practical advanced support method, etc., to reduce the effective cross-sectional area, save time, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

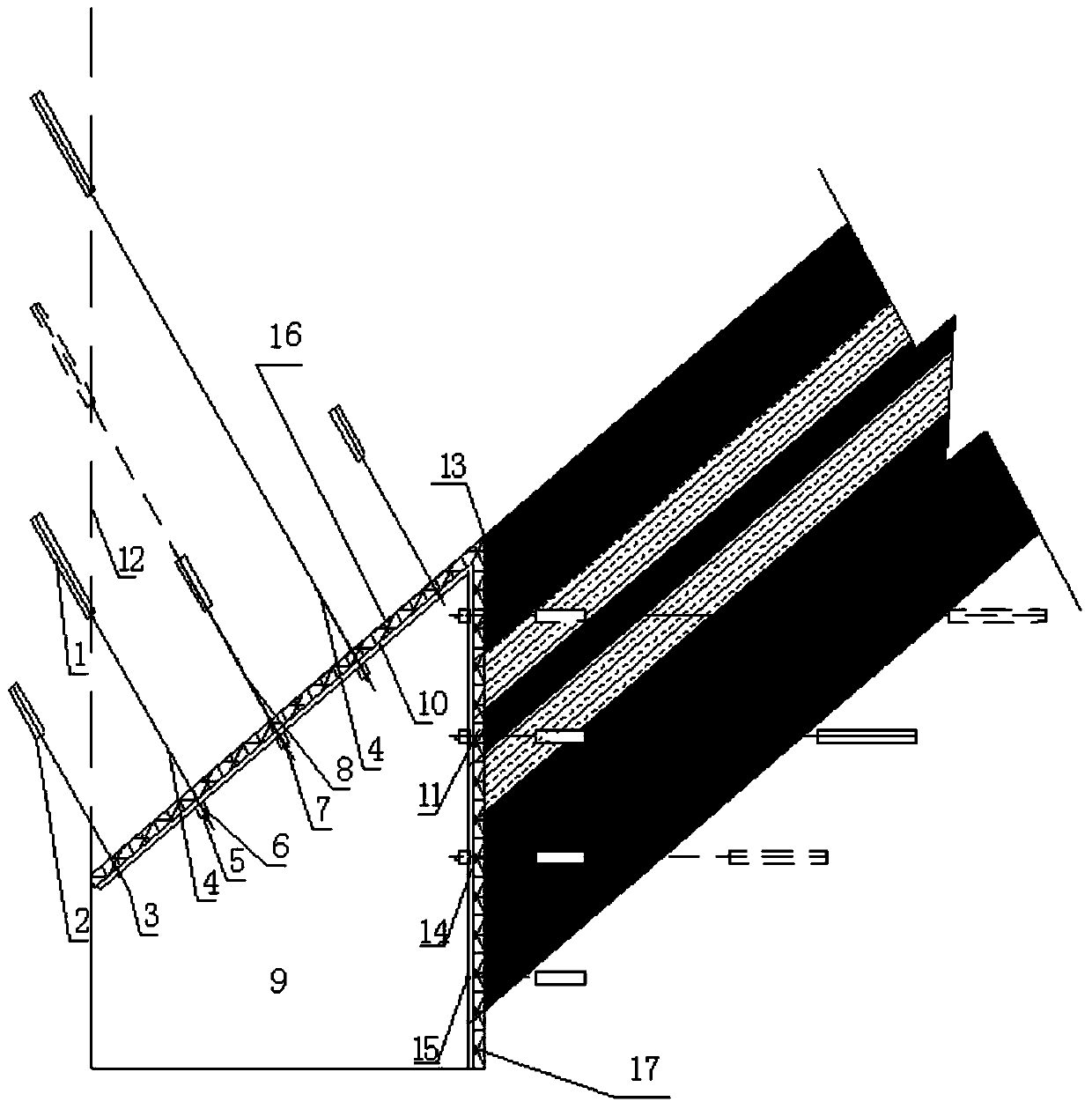

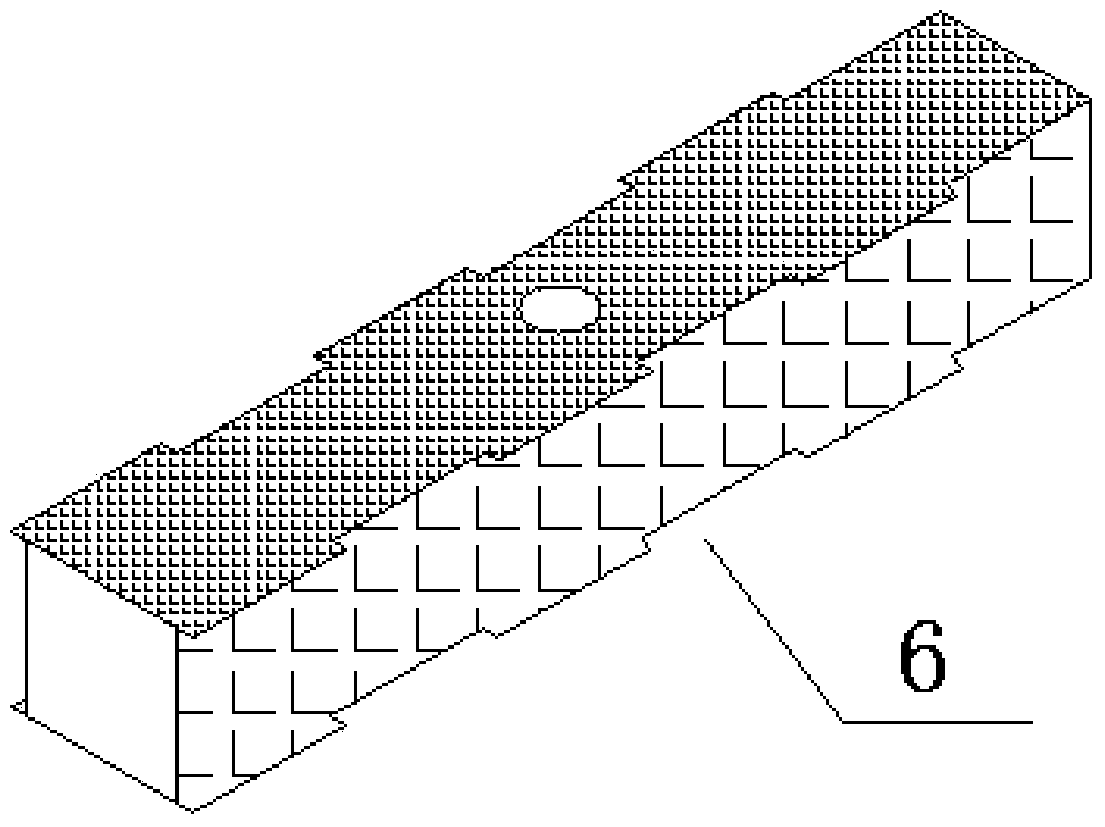

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , figure 2 The advanced support structure of the large-inclination coal mining face shown includes a special-shaped section 9, including a top plate 16 on the top of the special-shaped section 9 and an upper side plate 17 arranged on the upper side of the side wall of the special-shaped section 9, wherein the The roof 16 is fixedly connected to the anchor cable anchor section 1 through the reinforced anchor cable 4 and the middle anchor cable 8, and the roof 16 is also fixedly connected to the anchor anchor section 2 through the roof anchor 3; It is fixedly connected with the upper anchor cable 11, wherein the top plate 16 and the upper side plate 17 meet at the upper side line 13 on the top plate and the roadway.

[0014] In the actual construction, it is first necessary to design the special-shaped cross-sections of the two lanes of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com