Coating for lithium-battery diaphragm, diaphragm and preparation method for diaphragm

A lithium battery separator and coating technology, used in battery pack parts, circuits, electrical components, etc., can solve the problems of difficult control of the thickness of the metal lithium layer, complicated transfer processing of the pole pieces, and prone to lithium precipitation, etc. Rechargeability, preventing the precipitation of excess lithium, and improving the puncture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

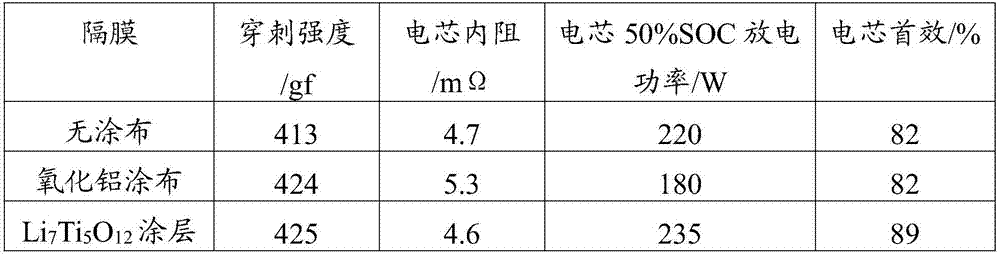

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0025] The present invention proposes a lithium battery diaphragm coating, including lithium titanium compound powder and a binder, and the lithium titanium compound includes Li 4+x Ti 5 o 12 , Li 1+x Ti 2 (PO 4 ) 3 One or more of , where 0≤x≤3.

[0026] The titanium-lithium compound powder in the embodiments of the present invention refers to lithium titanate or lithium titanium phosphate.

[0027] Lithium titanium phosphate has good electrochemical properties and can be used as a solid electrolyte and electrode material for lithium-ion batteries, and can also be used as a negative electrode for aqueous lithium-ion batteries. Lithium titanium phosphate has poor electronic conductivity.

[0028] With Li 4 Ti 5 o 12 represented by Li 4+x Ti 5 o 12 It is a kind of composite oxide composed of metal lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com