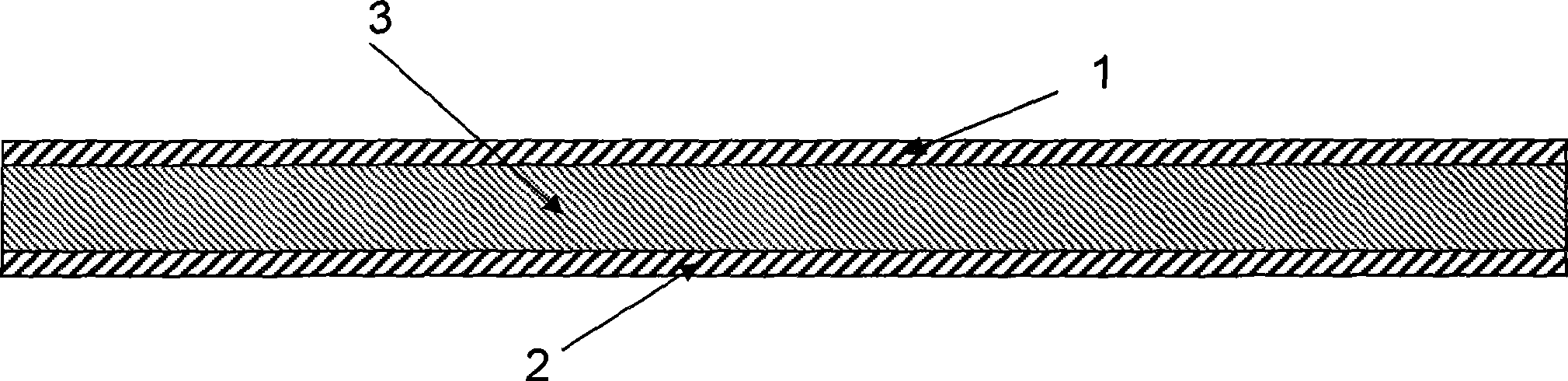

Method of manufacturing diaphragm used for high security lithium ion secondary battery

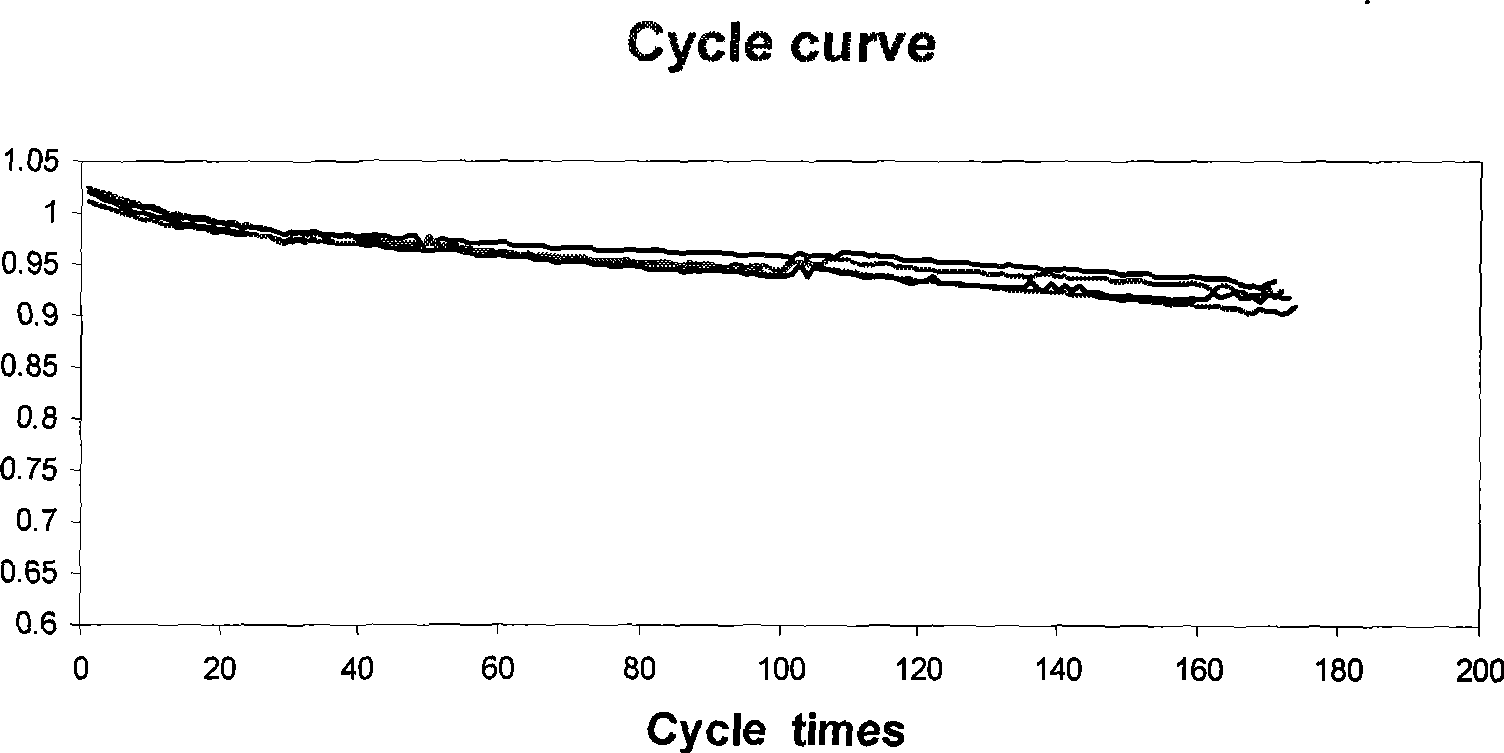

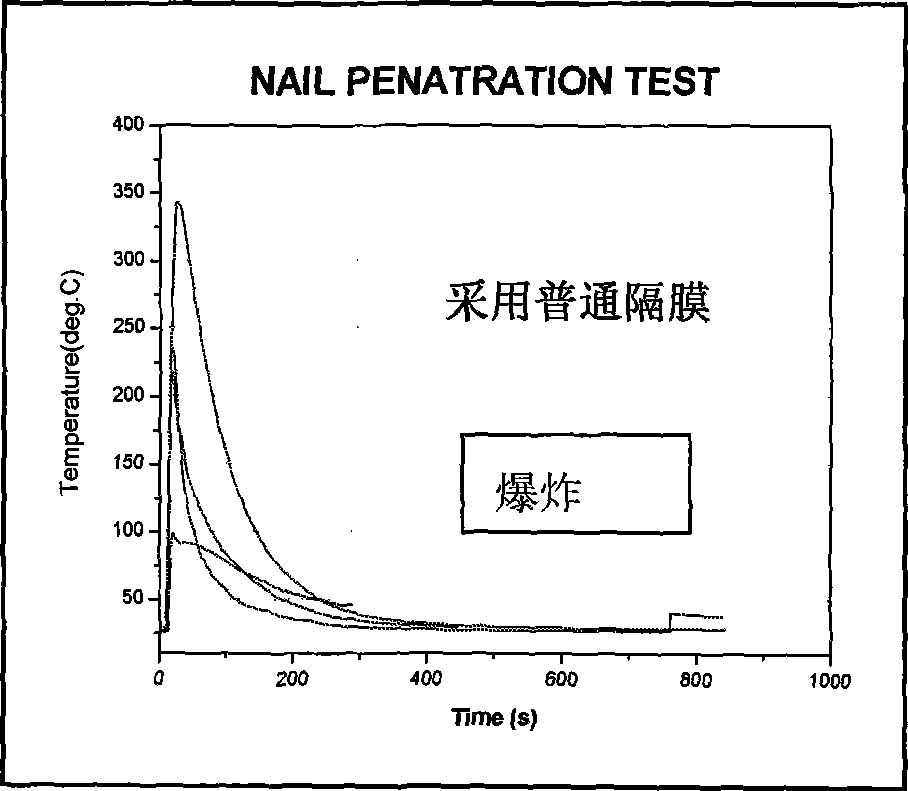

A secondary battery, high-safety technology, used in battery pack parts, circuits, electrical components, etc., can solve problems such as uncontrollable violent chemical reactions, and achieve excellent safety performance, good cycle performance, and maintain the effect of cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The diaphragm substrate adopts celgard2320 20μm diaphragm, and the surface tension of the diaphragm reaches 40 dynes through surface corona treatment;

[0028] Preparation of inorganic ceramic glue for diaphragm coating:

[0029] The composition of the inorganic ceramic glue is as follows: 42 parts of Al2O3 powder (primary particle size 15nm, modified by organosilicon coupling agent) whose surface has been modified by lipophilic dispersion stabilizer, 20 parts of methyl acrylate polymerized monomer, Oil-soluble initiator: di-tert-butyl peroxy idiobutyrate, its addition amount is 0.4% of polymerized monomers; 18 parts of cyclohexane solvent.

[0030] Preparation steps:

[0031] 1) Mix 20kg of the above-mentioned polymerized monomers and organic solvents, and stir evenly, using ordinary paddle-type stirring blades, and the stirring tank is 60L;

[0032] 2) Add 22.1 kg of the above-mentioned aluminum oxide powder, first use a common high-speed turbine mixer to stir for 1...

Embodiment 2

[0037] The diaphragm substrate adopts Tonen 20μm diaphragm, and the surface tension of the diaphragm reaches 38 dynes through surface corona treatment;

[0038] Preparation of inorganic ceramic glue for diaphragm coating:

[0039] The composition of inorganic ceramic glue is as follows: 45 parts of silicon dioxide powder (primary particle size 23nm, modified with organic boric acid coupling agent) whose surface has been modified by lipophilic dispersion stabilizer, 25 parts of acrylonitrile polymerized monomer, oil-soluble Initiator: di-tert-butyl peroxyspecific butyrate, the addition amount is 0.8% of the polymerized monomer; 30 parts of tetrahydrofuran solvent.

[0040] Preparation steps:

[0041] 1) Mix 30kg of the above-mentioned polymerized monomers and organic solvent, and stir evenly, using ordinary paddle-type stirring blades, and the stirring tank is 80L;

[0042] 2) Add 24.5kg of the above-mentioned silicon dioxide powder, first use a common high-speed turbine mixe...

Embodiment 3

[0048] The diaphragm substrate adopts celgard2320 20μm diaphragm, and the surface tension of the diaphragm reaches 40 dynes through surface corona treatment;

[0049] Preparation of inorganic ceramic glue for diaphragm coating:

[0050] The composition of the inorganic ceramic glue is as follows: 32 parts of Al2O3 powder (primary particle size 15nm, modified by organic silicon coupling agent) whose surface has been modified by lipophilic dispersion stabilizer, 10 parts of methyl acrylate polymerized monomer, Oil-soluble initiator, di-tert-butyl peroxy idiobutyrate, its addition amount is 0.4% of polymerized monomer; 20 parts of cyclohexane solvent.

[0051] Preparation steps:

[0052] 1) Mix 20kg of the above-mentioned polymerized monomers and organic solvent, and stir evenly, using ordinary paddle-type stirring blades, and the stirring tank is 60L;

[0053] 2) Add 21.4 kg of the above-mentioned aluminum oxide powder, firstly use an ordinary high-speed turbine mixer to stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com