Preparation method of maleic anhydride drafted polypropylene resin graft polymer

A technology of polypropylene resin and grafted polypropylene, which is applied in the field of preparation of polypropylene resin grafts, can solve problems such as the inability to completely solve the problem of polypropylene degradation, and achieves the advantages of reducing the degree of thermal oxidative degradation and improving melt elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

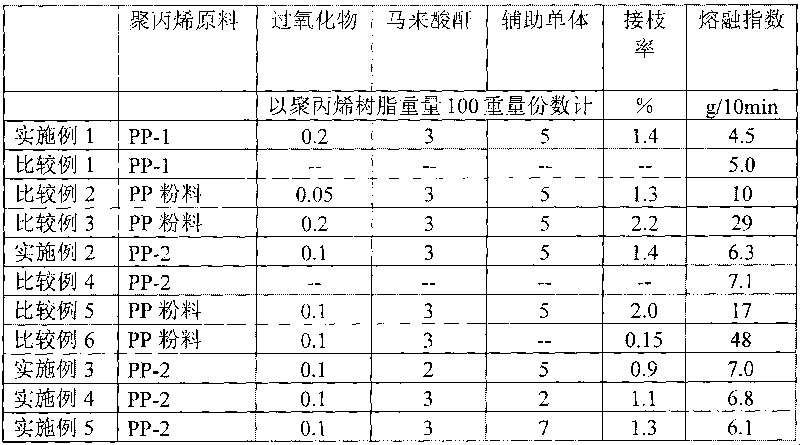

Embodiment 1

[0039] Mix 2 kg of polypropylene powder (Bluestar Group Tianjin Petrochemical 3# special material, powder without antioxidant, melt index 3.0-5.9g / 10min) and 8 grams of antioxidant 1010 / 168 (mixing weight ratio 1:1, produced by Ciba-Geigy, Switzerland) after uniform mixing in a high-speed mixer, melt blending and granulation on a WP ZSK25 twin-screw extruder (melt temperature is 205 ° C). The obtained granules are crushed with a plant breaker to obtain small particles with a diameter of about 1 mm, so as to properly increase the contact area with the auxiliary monomers. The crushed polypropylene resin particles containing antioxidant are used as raw materials for grafting reaction, code-named PP-1.

[0040] 0.08 g of initiator dicumyl peroxide (produced by Beijing Duxin Fine Preparation Factory) was added and dissolved in 2 g of tripropylene trimellitate (Bailey Pharmaceutical Raw Materials Co., Ltd.). 40 grams of polypropylene PP-1 small particles and 1.2 grams of ground mal...

Embodiment 2

[0048] 2 kilograms of polypropylene powder (Bluestar Group Tianjin Petrochemical 3# special material, powder not containing antioxidant, melt index 3.0~5.9g / 10min) and 3 grams of antioxidant 1010 / 168 (same as the embodiment 1) After mixing uniformly in a high-speed mixer, melt blending and granulation on a WP ZSK25 twin-screw extruder (melt temperature is 205° C.). The obtained granules are crushed with a plant breaker to obtain small particles with a diameter of about 1 mm, so as to properly increase the contact area with the auxiliary monomers. The crushed polypropylene resin particles containing antioxidant are used as raw materials for grafting reaction, code-named PP-2.

[0049] 0.04 g of initiator dicumyl peroxide (produced by Beijing Duxin Fine Preparation Factory) was added and dissolved in 2 g of tripropylene trimellitate (Bailey Pharmaceutical Raw Material Co., Ltd.). 40 grams of polypropylene PP-2 small particles and 1.2 grams of ground maleic anhydride powder are ...

Embodiment 3

[0057] Using the PP-2 obtained after granulating the polypropylene powder in Example 2 as raw material, the amount of maleic anhydride powder was changed to 0.8g, and the other conditions of the grafting reaction were the same as in Example 2, and the test results of the grafted samples Listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com