Viscous modified aliphatic-aromatic copolyester and preparation method thereof

A technology of aromatic copolyester and copolyester, which is applied in the field of viscosity-increasing modified aliphatic-aromatic copolyester and its preparation, can solve the problems of high melt index, low polymer viscosity, and influence on product use, and achieve increased Melt viscosity and melt strength, effects of increasing melt viscosity and improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the present invention comprises the following steps:

[0053] In the first step, the raw material 1, raw material 2 and raw material 3 are mixed together according to the following mass ratio, fully stirred and mixed,

[0054] Raw material 2: Raw material 1 = 0.0001~0.001:1; for example: the ratio can be 0.0001:1, 0.0002:1, 0.0003:1, 0.0004:1, 0.0005:1, 0.0006:1, 0.0007:1, 0.0008:1, 0.0009:1 or 0.001:1;

[0055] Raw material 3: Raw material 1 = 0.0001~0.0002:1; for example: the ratio can be 0.0001:1, 0.00012:1, 0.00014:1, 0.00016:1, 0.00018:1 or 0.0002:1;

[0056] Preferred:

[0057] Raw material 2: Raw material 1=0.0001~0.0005:1;

[0058] Raw material three: raw material one = 0.0001~0.0002:1;

[0059] In the second step, the mixture obtained in the first step is added to a twin-screw extruder for extrusion reaction; the temperature distribution of each temperature zone of the extruder is 100-170-170-165°C;

[0060] The value of the melt ...

Embodiment 1

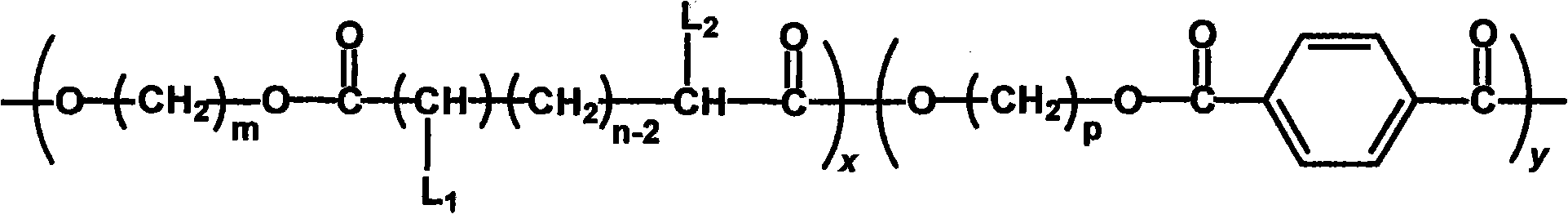

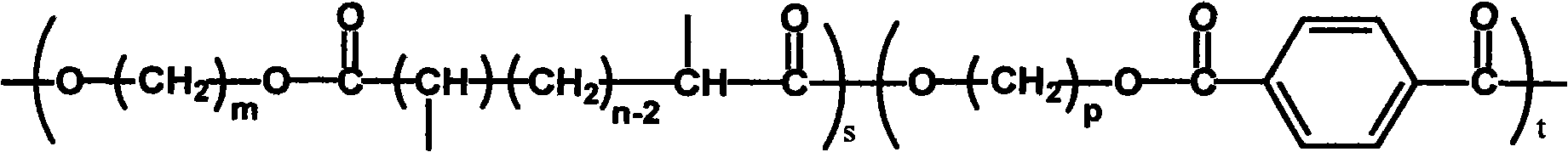

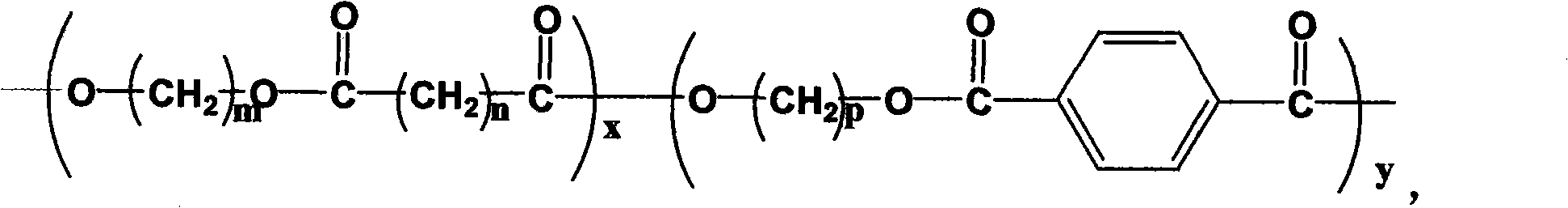

[0073] 0.03 g of 2,5-dimethyl-2,5-bis(t-butyl)peroxide hexane was added to 300 g of poly(butylene adipate-butylene terephthalate) copolyester (PBAT ), and then add 0.03g of triethylene glycol bis-β-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate (abbreviated as 245), and the mixture is fully mixed. The mixed materials are put into a twin-screw extruder for extrusion expansion modification. The melt viscosity of the product increases significantly, and the melt index decreases significantly to 7.2, which proves that the product is a branched copolyester product, and its structure is as shown in structural formula (1), wherein m, n and p are all 4.

Embodiment 2

[0075] 0.06 g of 2,5-dimethyl-2,5-bis(t-butyl)peroxide hexane was added to 300 g of poly(butylene adipate-butylene terephthalate) copolyester (PBAT ), and then add 0.03g of triethylene glycol bis-β-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate (abbreviated as 245), and the mixture is fully mixed. The mixed materials are put into a twin-screw extruder for extrusion expansion modification. The melt viscosity of the product increased significantly, and the melt index decreased significantly to 3.4, which proved that the product was a branched copolyester product, and its structure was as shown in structural formula (1), wherein m, n and p were all 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com