Preparation method of easily-processed easily-crystallized polylactic acid

A crystalline polylactic acid and easy-to-process technology, which is applied in the preparation field of the chemical industry, can solve the problems of difficulty in the processing and molding process, low melt strength, etc., and achieve the effects of high crystallization performance, high melt strength, and high modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

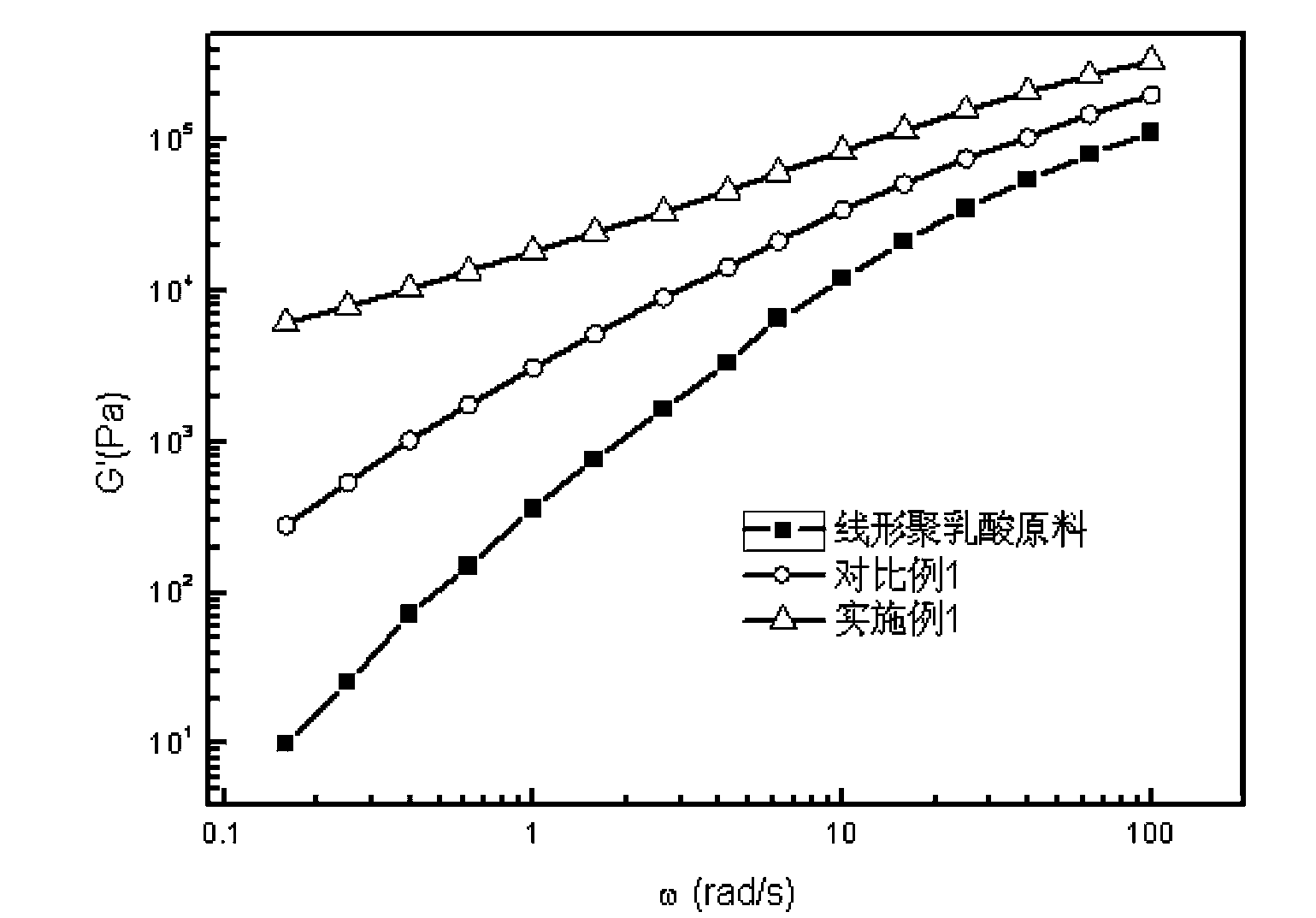

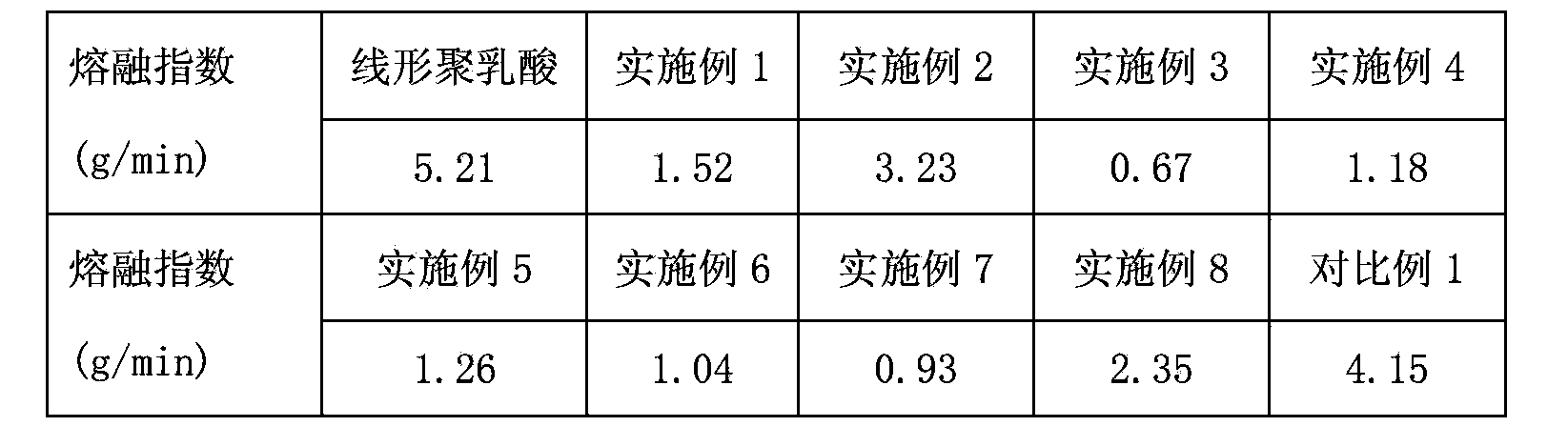

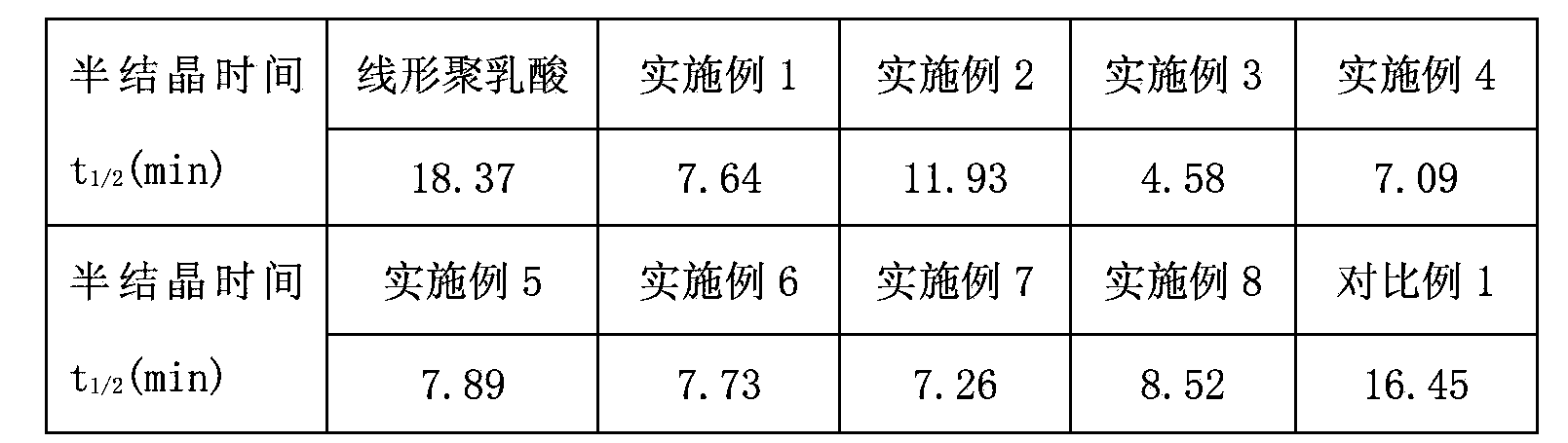

Embodiment 1

[0023] Add 100 parts of linear polylactic acid to an internal mixer at 190°C until it melts completely, then add 0.2 parts of 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl -4-hydroxybenzyl)benzene, 5 parts of nano-silica functionalized with 2,4-toluene diisocyanate, 0.3 part of antimony trioxide catalyst, react and mix for 10min, the speed of internal mixer is 60rpm; then add 0.3 parts of triglycidyl isocyanurate were mixed until the reaction was terminated to obtain a polylactic acid with high crystallinity and high melt strength. Table 1 shows the melt index results of the obtained reaction product material measured according to the ASTM D1238 standard. The obtained reaction product material was subjected to isothermal crystallization half-crystallization time test, and the results are shown in Table 2.

[0024] The test conditions for isothermal crystallization half-crystallization time are as follows: The test is carried out on a differential scanning calorimeter under nitroge...

Embodiment 2

[0027]Add 100 parts of linear polylactic acid to an internal mixer at 210°C until it melts completely, then add 0.5 parts of 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl -4-Hydroxybenzyl)benzene, 2 parts of nano-silica functionalized with 2,4-toluene diisocyanate, 0.1 part of antimony trioxide catalyst, mixed for 5 minutes, and the speed of internal mixer was 40rpm; then added 0.2 parts of triglycidyl isocyanurate, mixed until the reaction stops, to obtain a polylactic acid with high crystallinity and high melt strength. The test results are shown in Table 1 and Table 2.

Embodiment 3

[0029] Add 100 parts of linear polylactic acid to an internal mixer at 220°C until it melts completely, then add 0.2 parts of 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl -4-hydroxybenzyl)benzene, 9 parts of nano-silica functionalized with 2,4-toluene diisocyanate, 0.5 part of antimony trioxide catalyst, mixed for 15 minutes, and the speed of internal mixer was 80rpm; then added 0.5 parts of triglycidyl isocyanurate, mixed until the reaction stops, to obtain a polylactic acid with high crystallinity and high melt strength. The test results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com