Ethylene polymerization method and polyethylene

A technology for ethylene polymerization and polymerization reaction, applied in the field of polyethylene, can solve the problems of poor thermal stability and hydrothermal stability, low ethylene polymerization activity, affecting loading effect, etc., and achieve stable mesoporous structure, improve fluidity, and facilitate application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

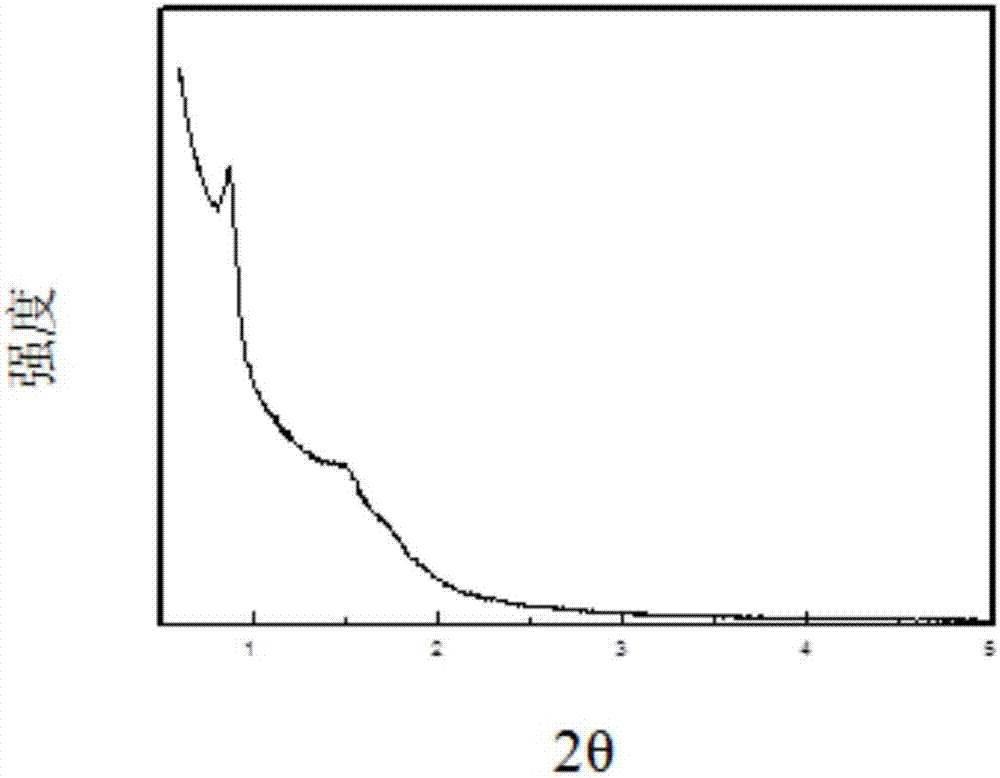

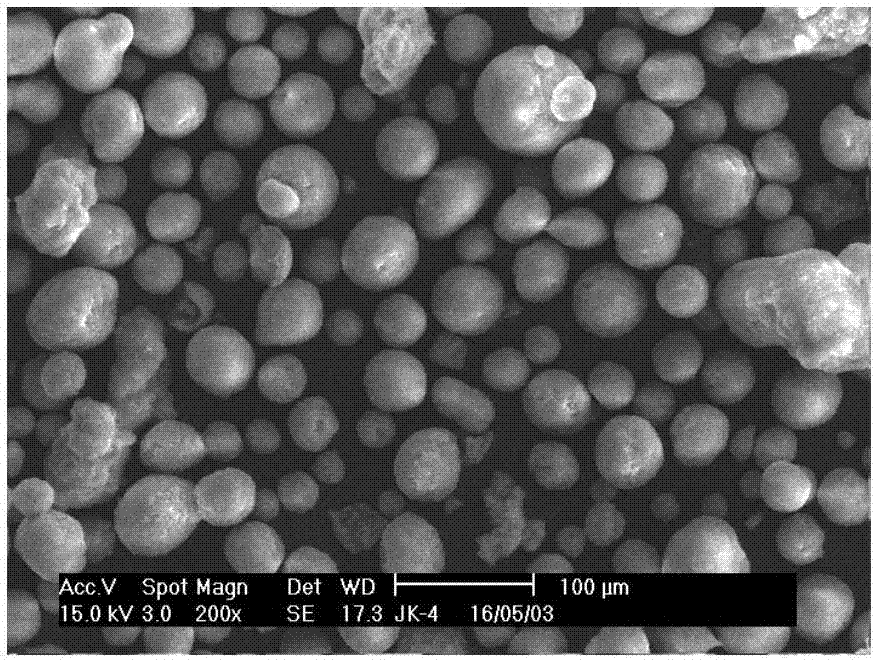

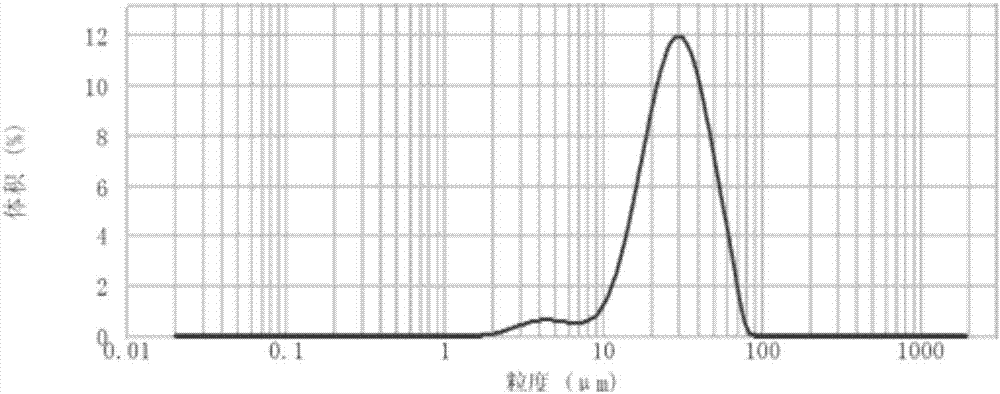

[0021] According to a preferred embodiment of the present invention, the average particle diameter of the spherical porous mesoporous composite material is 22-28 microns, the specific surface area is 220-300 square meters per gram, and the pore volume is 1.1-1.7 milliliters per gram, The pore size has a trimodal distribution, and the three peaks correspond to the first most probable pore diameter of 6-9 nanometers, the second most probable pore diameter of 22-32 nanometers and the third most probable pore diameter of 42-50 nanometers;

[0022] According to a more preferred embodiment of the present invention, the average particle diameter of the spherical porous mesoporous composite material is 23-27 microns, the specific surface area is 220-275 square meters per gram, and the pore volume is 1.2-1.5 milliliters per gram , the pore size is distributed in three peaks, and the three peaks correspond to the first most probable pore diameter of 7-8 nanometers, the second most probab...

Embodiment 1

[0095] This embodiment is used to illustrate the ethylene polymerization method of the present invention and the obtained polyethylene

[0096] (1) Preparation of spherical porous mesoporous composites

[0097] Add 1g (0.00017mol) of template agent P123 and 1.69g (0.037mol) of ethanol into 28mL of acetic acid and sodium acetate buffer solution with pH = 4.4, stir at 15°C until the template agent is completely dissolved, and add 6g (0.05mol) of three Add methylpentane to the above solution, stir at 15°C for 8h, then add 2.13g (0.014mol) tetramethoxysilane to the above solution, stir at 15°C for 20h, then transfer the solution to the agate lining After crystallizing in an oven at 60°C for 24 hours in a reaction kettle, filter and wash with deionized water for 4 times, and then filter with suction to obtain a filter cake A11 of mesoporous molecular sieve material with a one-dimensional straight-through channel structure.

Embodiment 2

[0116] This embodiment is used to illustrate the ethylene polymerization method of the present invention and the obtained polyethylene

[0117] (1) Preparation of spherical porous mesoporous composites

[0118] Add 1g (0.00017mol) template agent P123 and 1.4g (0.03mol) ethanol to 28mL of acetic acid and sodium acetate buffer solution with pH = 4.4, stir at 10°C until the template agent is completely dissolved, add 4.56g (0.04mol) Add trimethylpentane to the above solution, stir at 10°C for 8h, then add 1.83g (0.012mol) tetramethoxysilane to the above solution, stir at 10°C for 30h, then transfer the solution into agate In a lined reactor, crystallize in an oven at 80°C for 20 hours, then filter and wash with deionized water for 6 times, and then suction filter to obtain filter cake A21 of mesoporous molecular sieve material with a one-dimensional hollow spherical pore structure.

[0119] At 50°C, cetyltrimethylammonium bromide and tetraethyl orthosilicate are added to the amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com