Chain-extended modified and copolymerized formaldehyde resin and preparation method thereof

A formaldehyde resin and modification technology, which is applied in the field of chain-extended modified polyoxymethylene resin and its preparation, can solve the problems of restricting the application field of polyoxymethylene copolymer, difficulty in realizing industrial production, and harsh control conditions, etc., so as to enrich the variety of polyoxymethylene resin, Reduce the melt index and implement the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

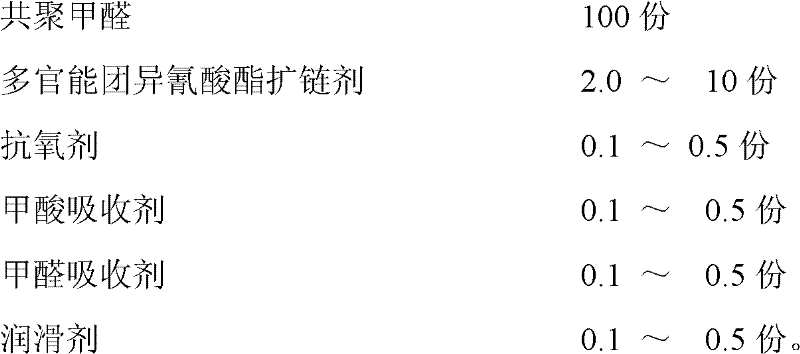

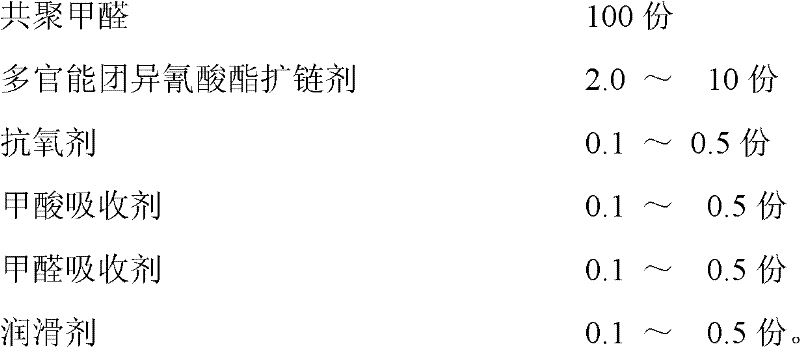

Method used

Image

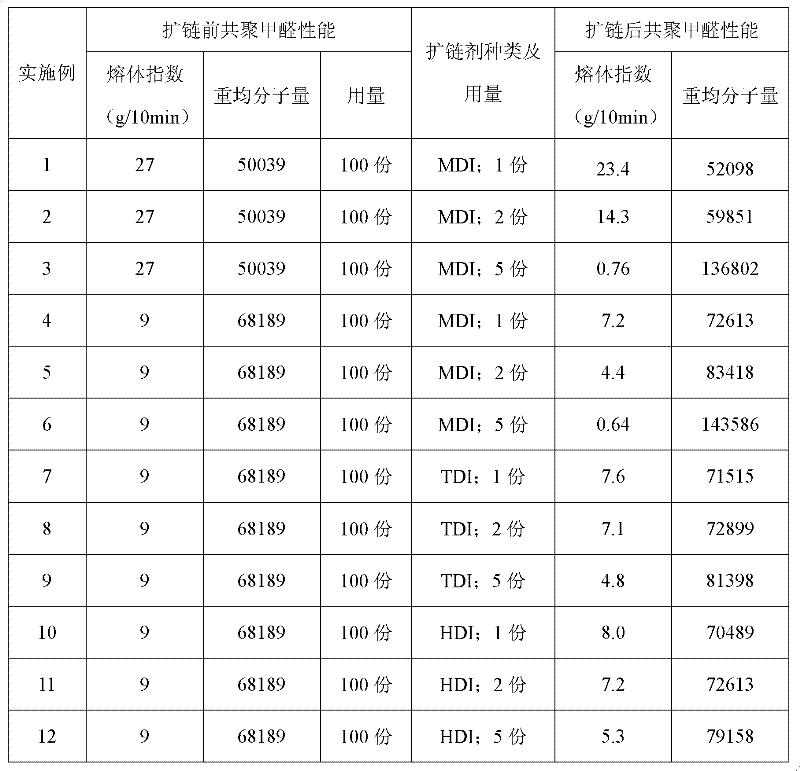

Examples

Embodiment 1

[0023] Copolyoxymethylene (MI: 27g / 10min) 10Kg, 4,4'-diphenylmethane diisocyanate (MDI) 100g, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid ]Pentaerythritol ester 10g, calcium stearate 10g, melamine 20g, glycerol monostearate 10g are uniformly mixed and then melted and extruded by a vented twin-screw extruder at an extrusion temperature of 180°C to 220°C and a screw speed of 100 After granulation, dry at 80°C for 3 hours to obtain a chain-extended modified polyoxymethylene resin.

Embodiment 2

[0025] Copolyoxymethylene (MI: 27g / 10min) 10Kg, 4,4'-diphenylmethane diisocyanate (MDI) 200g, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid ] 30g of pentaerythritol ester, 30g of magnesium hydroxide, 40g of melamine, and 10g of bisstearamide are evenly mixed and then melted and extruded by a vented twin-screw extruder. The extrusion temperature is 180°C to 220°C, and the screw speed is 100 rpm , After granulation, dry at 80°C for 3 hours to obtain a chain-extended modified polyoxymethylene resin.

Embodiment 3

[0027] Copolyoxymethylene (MI: 27g / 10min) 10Kg, 4,4'-diphenylmethane diisocyanate (MDI) 500g, β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate octadecanoic acid Carbon alcohol ester 50g, calcium stearate 50g, polyamide PA650g, glyceryl monostearate 50g are uniformly mixed and then melted and extruded by vented twin-screw extruder, the extrusion temperature is 180℃~220℃, the screw speed 100 rpm, after granulation, dry at 80°C for 3 hours to obtain chain extension modified polyoxymethylene resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com