Biodegradable polyester and preparation method thereof

A technology for degrading polyester and biology, applied in the field of preparation of biodegradable polyester, can solve the problems of gel, environmental impact, toxic substances, etc., and achieve the effect of low melt index, good mechanical properties, and favorable processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

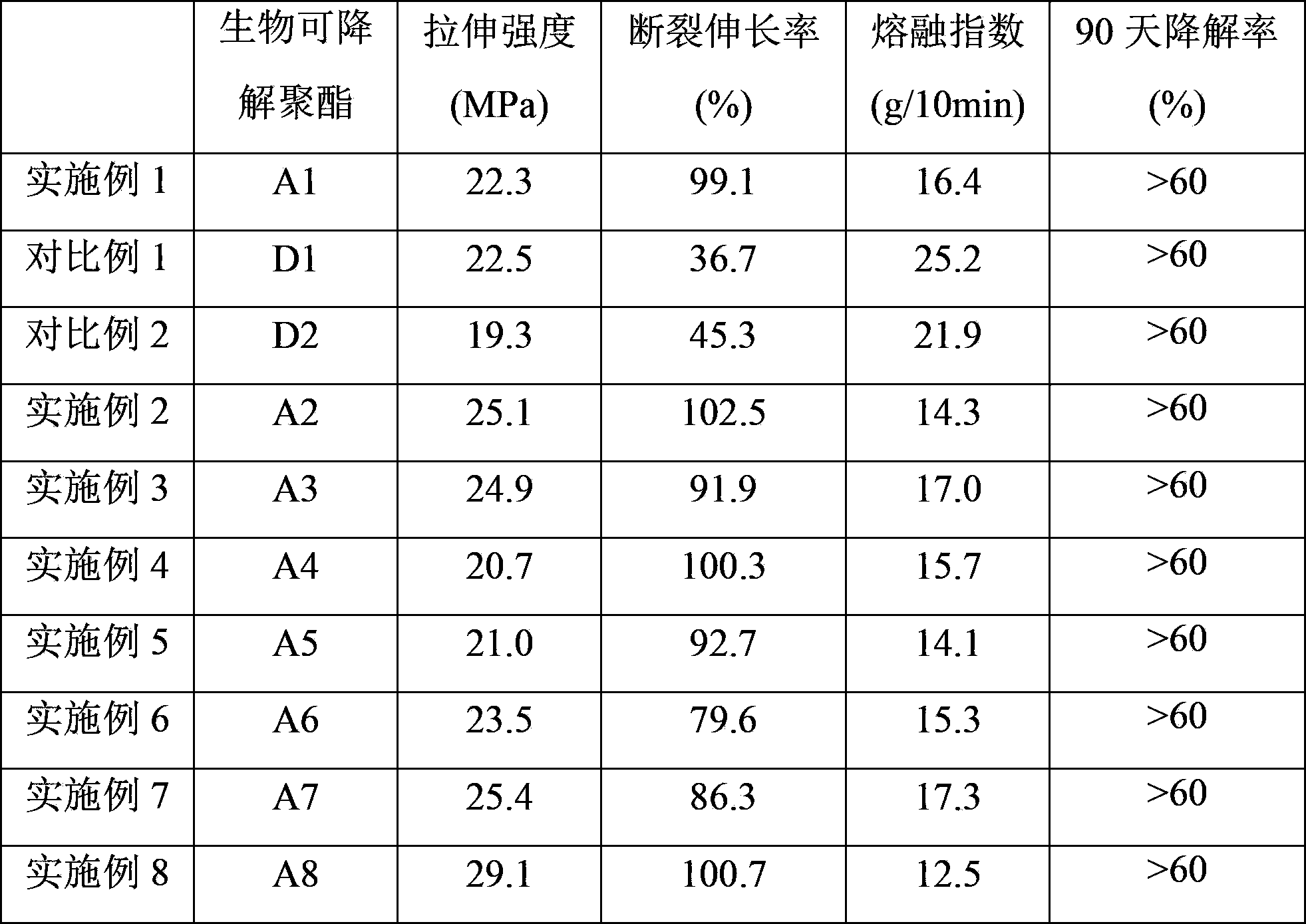

Examples

preparation example Construction

[0011] The invention provides a method for preparing biodegradable polyester. The method comprises: mixing and contacting a branched aliphatic aromatic copolyester with an organotin catalyst, and then mixing and contacting the obtained mixture with lactate Ester contact reaction.

[0012] In the method, the purpose of mixing and contacting the branched aliphatic aromatic copolyester with the organotin catalyst is to complex the organotin catalyst with the branched aliphatic aromatic copolyester, Then catalyze the ring-opening polymerization of lactide. The process of mixing and contacting may include: maintaining the mixture of the branched aliphatic aromatic copolyester and the organotin catalyst at a vacuum degree below 200 Pa and a temperature of 30-80°C for 0.5-1 hours, and then kept at 140-170°C for 0.5-1 hour under an inert atmosphere. The inert atmosphere may be provided by a gas that does not react with the branched aliphatic aromatic copolyester and the organotin ca...

Embodiment 1

[0060] This example is used to illustrate the biodegradable polyester of the present invention and its preparation method.

[0061] (1) Preparation of branched aliphatic aromatic copolyesters

[0062]Catalyst: The catalyst contains 57.8% by weight of lanthanum stearate (prepared according to the method of Example A5 in CN1807485A, the same below), 23.2% by weight of tetrabutyl titanate (purchased from Beijing Chemical Reagent Company, the same below), 10.0% by weight of dibutyltin oxide (purchased from Beijing No. 3 Chemical Plant, the same below) and 9.0% by weight of triphenylhydroxytin (purchased from Beijing Chemical Reagent Company, the same below).

[0063] Add terephthalic acid, 1,4-butanediol and the above catalyst into a 2.5L reactor, stir and heat to reflux under a nitrogen atmosphere, adjust the temperature to 230°C and react at this temperature, the water to be reacted When it is completely evaporated (the reaction is about 100 minutes), add 1,4-butanedioic acid, ...

Embodiment 2

[0071] This example is used to illustrate the biodegradable polyester of the present invention and its preparation method.

[0072] According to the method of Example 1, the aliphatic aromatic copolyester with branching is prepared, and the specific preparation process of the biodegradable polyester is: 30g of the aliphatic aromatic copolyester is added to the reactor, and then Add 200mg of stannous octoate, followed by purging with high-purity nitrogen, mix evenly, keep at 50°C and absolute pressure of 200Pa for 1 hour, then purse with high-purity nitrogen for 0.5 hour, then place at 140°C under nitrogen atmosphere 0.5 hours. Afterwards, add 70g of L-lactide under the range of nitrogen, vacuumize, and purge three times with nitrogen, keep the nitrogen atmosphere, and raise the temperature to 170°C. After reacting for 5 hours, cool and open the reaction bottle, and chloroform the reaction bottle The mixture in the solution is dissolved, then added to anhydrous methanol for pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com