Sputter source, sputtering device, and sputtering method

A sputtering device and sputtering source technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve problems such as difficult large-scale substrate films, large deviations in film quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

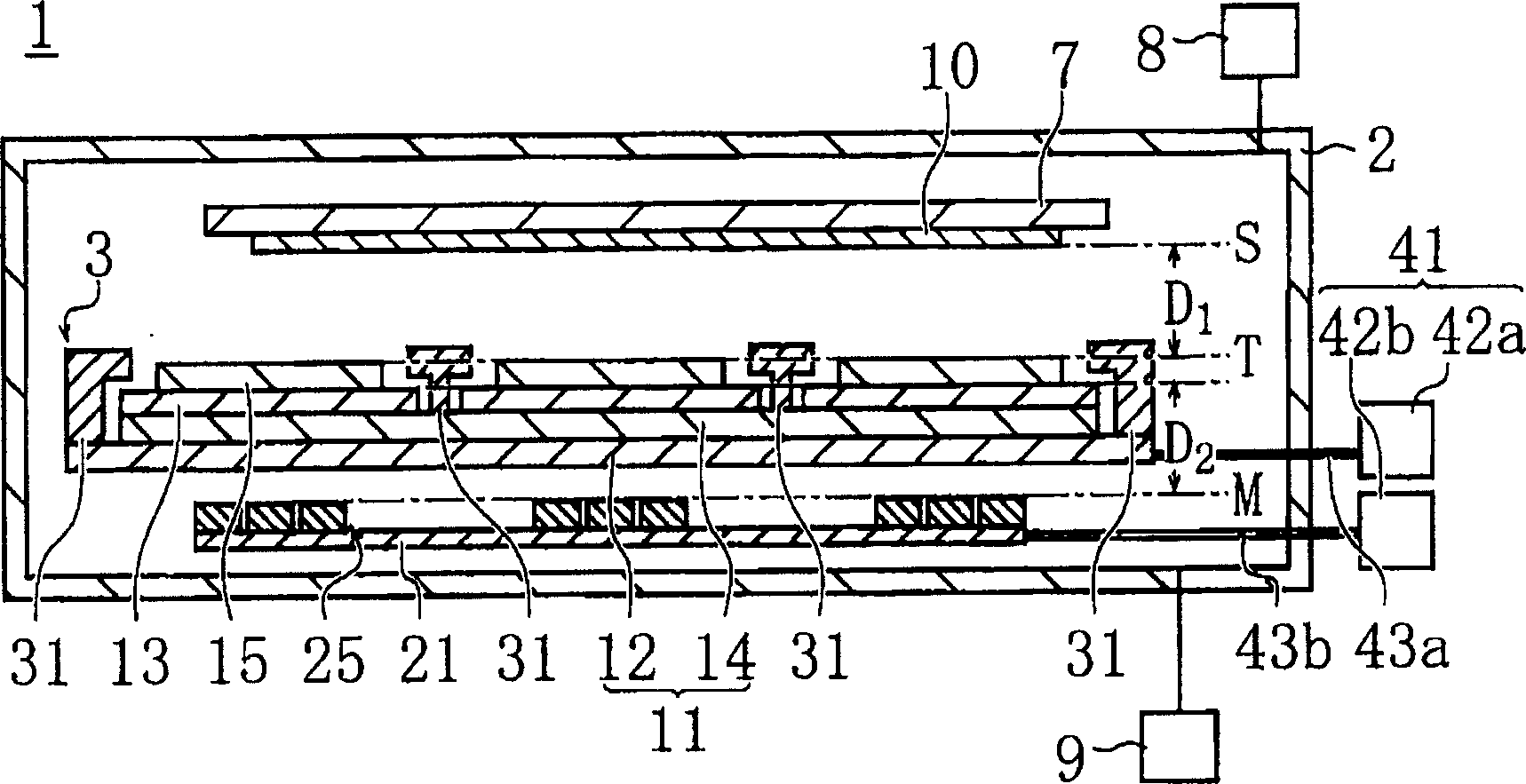

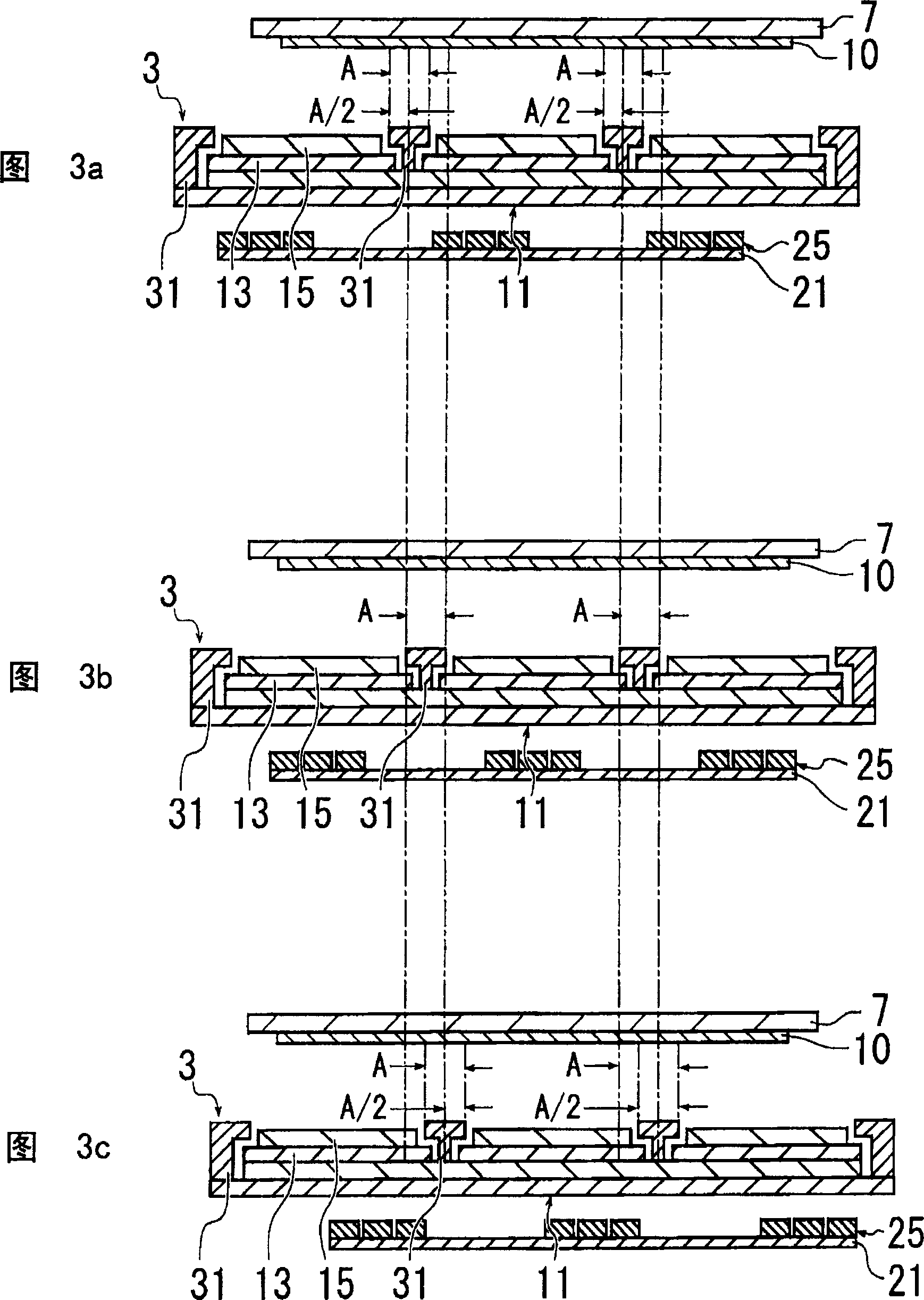

[0032] Embodiments of the present invention are described below with reference to the drawings. figure 1 Symbol 1 in represents a sputtering apparatus using the sputtering source of the present invention. This sputtering apparatus 1 has a vacuum chamber 2, a substrate holder 7 arranged on the ceiling side inside the vacuum chamber 2, and a sputtering source 3 arranged at a position opposite to the lower side of the substrate holder 7 inside the vacuum chamber 2. .

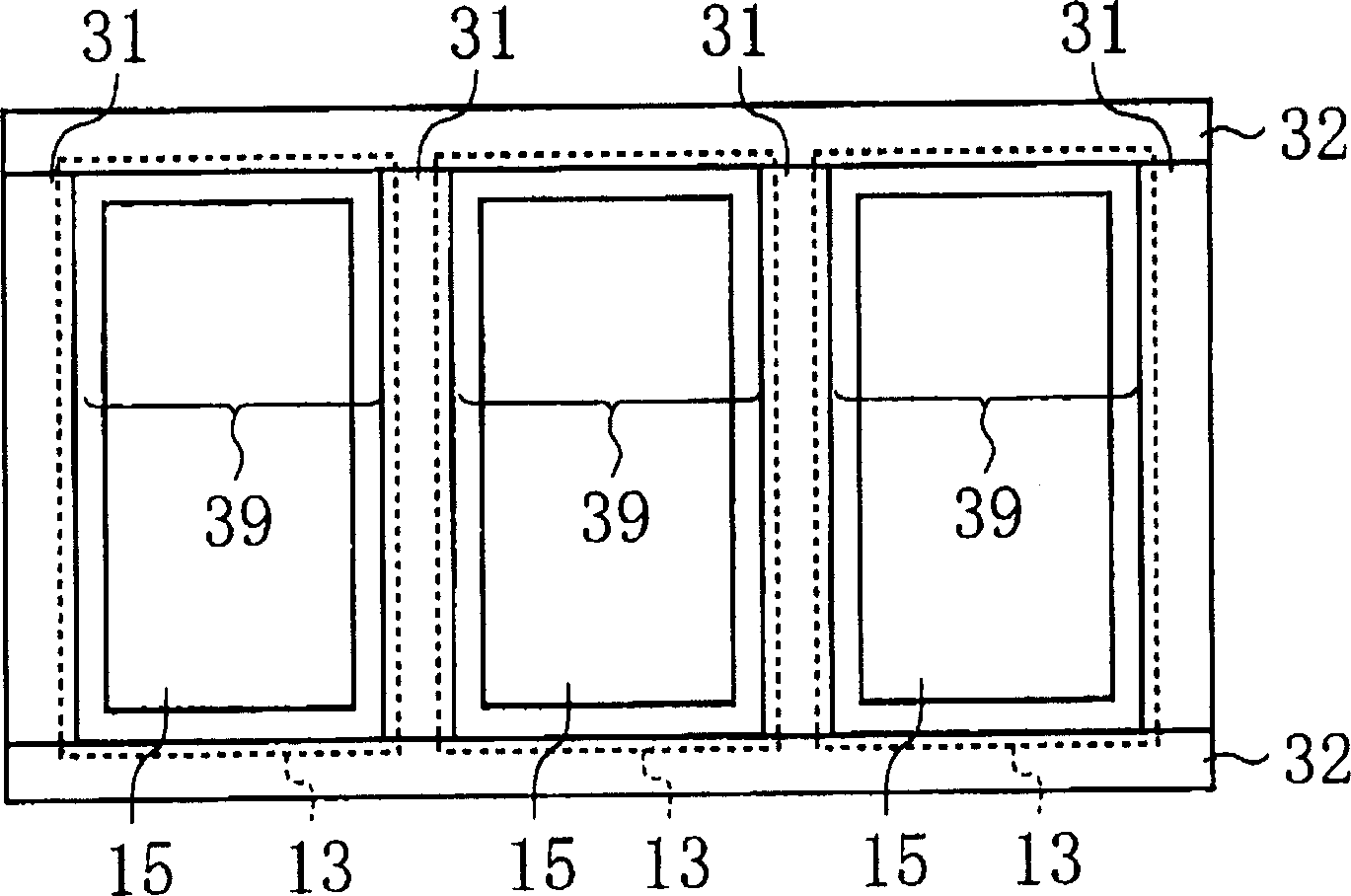

[0033] The sputtering source 3 has a target mounting plate 11 . A plurality of elongated anode electrodes 31 are separately arranged on the target mounting plate 11 in parallel with each other. like figure 2 As shown, elongated connection electrodes 32 are arranged at both ends of each anode electrode 31 . Each anode electrode 31 and connection electrodes 32 at both ends are connected to each other, and an opening 39 is formed through these electrodes 31 , 32 .

[0034] The cathode electrode 13 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com