Preparation method of mixed type regenerated cut stems

A mixed-type and shredded-stem technology, which is applied in the field of cigarette processing, can solve problems such as hindering the use ratio of cigarette formula and mixed-type cigarette formula, lack of aroma, and flat taste, so as to improve product quality, increase aroma, and enhance satisfaction and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

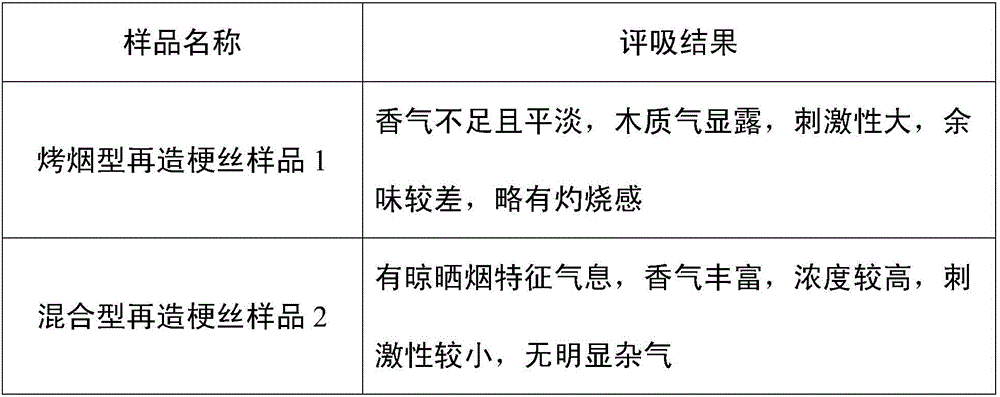

Embodiment 1

[0020] A method for preparing mixed reconstituted shredded stems, characterized in that it comprises the following steps:

[0021] S01, preparation of blank cut stems: cut the pretreated tobacco stems into cut stems with a width of 0.12 mm, extract the cut stems for 60 min at a solid-liquid ratio of 1:9, and extract at an extraction temperature of 60°C. In the process of separation and drying, the moisture content of cut stems is controlled at 26%, and blank cut stems with uniform quality are obtained;

[0022] S02, mix the mixed tobacco raw material (including flue-cured tobacco powder and air-cured tobacco powder) according to the following proportions, the mass percentage of each component in the mixed tobacco raw material is: spiced tobacco powder 5%, sun-cured tobacco powder 15% %, Burley tobacco minced powder 25%, Maryland tobacco minced powder 5% and flue-cured tobacco minced powder 50%; weigh the mixed tobacco raw material according to the above ratio and stir evenly. ...

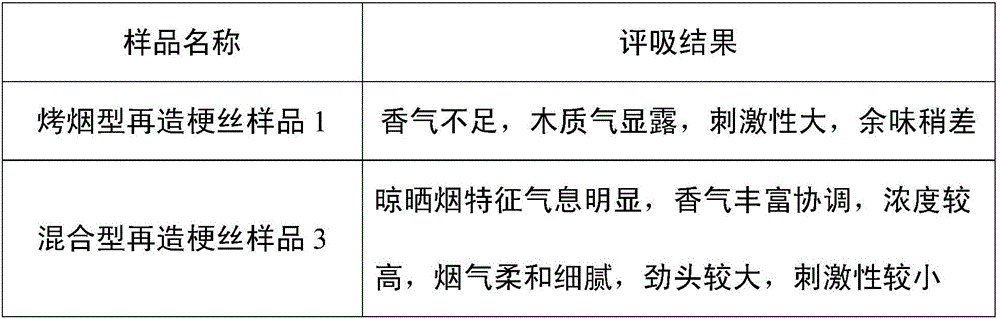

Embodiment 2

[0030] A method for preparing mixed reconstituted shredded stems, characterized in that it comprises the following steps:

[0031] S01, preparation of blank cut stems: cut the pretreated tobacco stems into cut stems with a width of 0.12 mm, extract the cut stems for 60 min at a solid-liquid ratio of 1:9, and extract at an extraction temperature of 60°C. In the process of separation and drying, the moisture content of cut stems is controlled at 26%, and blank cut stems with uniform quality are obtained;

[0032] S02, mixing mixed tobacco raw materials (including flue-cured tobacco powder and air-cured tobacco powder) according to the following proportions, the mass percentage of each component in the mixed tobacco raw material is: spiced tobacco powder 10%, sun-cured tobacco powder 10% %, Burley tobacco minced powder 30%, Maryland tobacco minced powder 10% and flue-cured tobacco minced powder 40%; weigh the mixed tobacco raw material according to the above ratio and stir evenly...

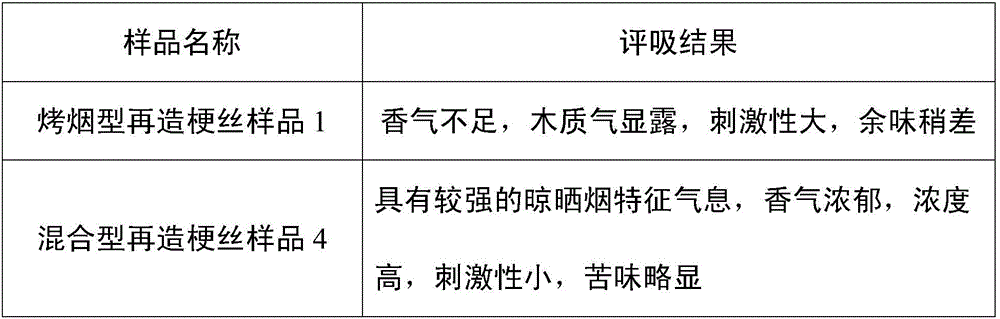

Embodiment 3

[0040] A method for preparing mixed reconstituted shredded stems, characterized in that it comprises the following steps:

[0041] S01, preparation of blank cut stems: cut the pretreated tobacco stems into cut stems with a width of 0.12 mm, extract the cut stems for 60 min at a solid-liquid ratio of 1:9, and extract at an extraction temperature of 60°C. In the process of separation and drying, the moisture content of cut stems is controlled at 26%, and blank cut stems with uniform quality are obtained;

[0042] S02, mixing mixed tobacco raw materials (including flue-cured tobacco powder and air-cured tobacco powder) according to the following proportions, the mass percentage of each component in the mixed tobacco raw material is: spiced tobacco powder 15%, sun-cured tobacco powder 10% %, Burley tobacco powder 30%, Maryland tobacco powder 10% and flue-cured tobacco powder 35%; weigh the mixed tobacco raw materials according to the above ratio and stir them evenly. Extract unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com