High purity linear silicon carbide powder and preparation method

A silicon carbide powder, silicon carbide technology, applied in silicon carbide, carbide and other directions, can solve the problems of complex preparation process and consume a lot of energy, and achieve the effects of high product purity, low production cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

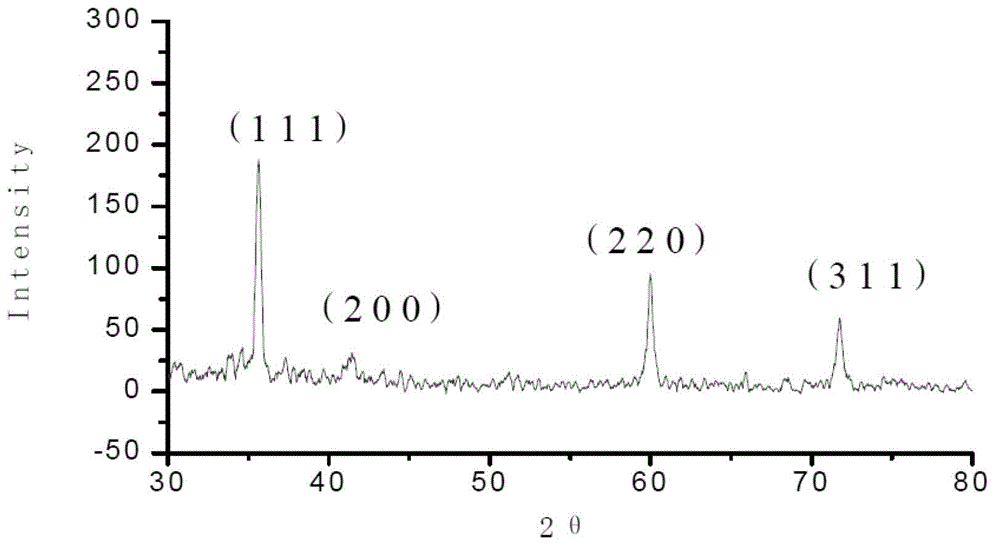

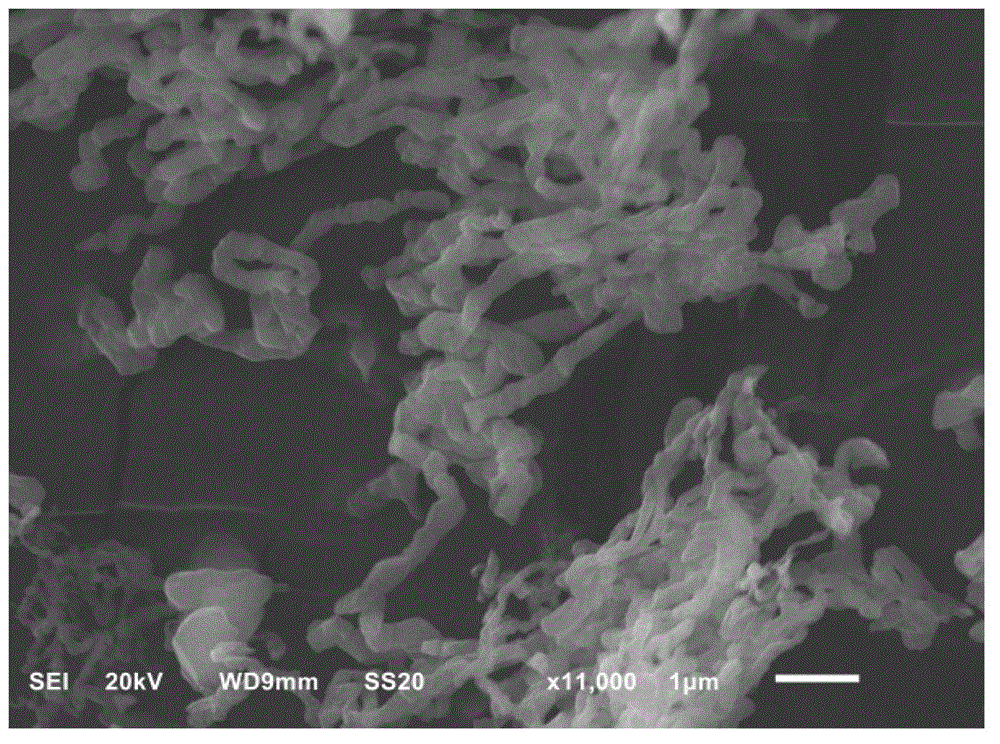

Image

Examples

Embodiment 1

[0027] (1) After mixing 5.0 grams of silica sol and 1.15 grams of graphene oxide evenly, first undergo ultrasonic treatment for 30 minutes at an ultrasonic frequency of 20-120 kHz, and then stir for 3 hours under strong mechanical stirring to obtain a composite precursor; the selected acid The silicon dioxide content in the silica sol is 30%, the pH value is 2.0, and the particle size is 6nm;

[0028] (2) The obtained composite precursor was solidified and dried in a blast drying oven for 48 hours, and then ground by a high-speed ball mill for 2 hours to obtain a fine and homogeneous powder precursor;

[0029] (3) Put the powdery precursor into a high-temperature tube furnace, pass in high-purity argon, and perform a carbothermal reduction reaction at 1500°C for 6 hours; obtain a crude silicon carbide micropowder;

[0030] (4) Soak the crude silicon carbide micropowder in 20% hydrofluoric acid for 2 hours, then filter it with suction, and sinter the filter residue at 400°C for...

Embodiment 2

[0032] (1) After mixing 7.2 grams of silica sol and 1.15 grams of graphene oxide evenly, first undergo ultrasonic treatment for 15 minutes at an ultrasonic frequency of 20 kHz, and then stir for 2 hours under strong mechanical stirring to obtain a composite precursor; the selected acidic silica sol The silica content in the medium is 20%, the pH value is 2.4, and the particle size is 20nm;

[0033] (2) The obtained composite precursor was solidified and dried in a vacuum drying oven for 24 hours, and then ground for 2 hours with a high-speed ball mill to obtain a fine and homogeneous powder precursor;

[0034] (3) Put the powdery precursor into a high-temperature tube furnace, pass in high-purity argon, and perform a carbothermal reduction reaction at 1400°C for 8 hours; obtain a crude silicon carbide micropowder;

[0035] (4) Soak the crude silicon carbide micropowder in 10% hydrofluoric acid for 2 hours, then filter it with suction, and sinter the filter residue at 700°C for...

Embodiment 3

[0037] (1) After mixing 5.0 grams of silica sol and 1.8 grams of graphene oxide evenly, first undergo ultrasonic treatment for 20 minutes at an ultrasonic frequency of 80 kHz, and then stir for 4 hours under strong mechanical stirring to obtain a composite precursor; the selected acidic silica sol The silica content in the medium is 30%, the pH value is 2.0, and the particle size is 6nm;

[0038] (2) The obtained composite precursor was solidified and dried in a blast drying oven for 24 hours, and then ground by a high-speed ball mill for 2 hours to obtain a fine and homogeneous powder precursor;

[0039] (3) Put the powdery precursor into a high-temperature tube furnace, feed high-purity argon, and carry out carbothermal reduction reaction at 1600°C for 2 hours; obtain crude silicon carbide micropowder;

[0040] (4) Soak the obtained silicon carbide micropowder in a mixed acid composed of 10% hydrofluoric acid and 10% nitric acid for 3 hours, then suction filter, and sinter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com