Self-densifying concrete as well as preparation method and application thereof

A self-compacting concrete, selected technology, applied in the direction of roads, tracks, buildings, etc., can solve the problems of shrinkage of filling layer materials, achieve the effect of enhancing integrity, improving structural integrity and service life, and ensuring volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

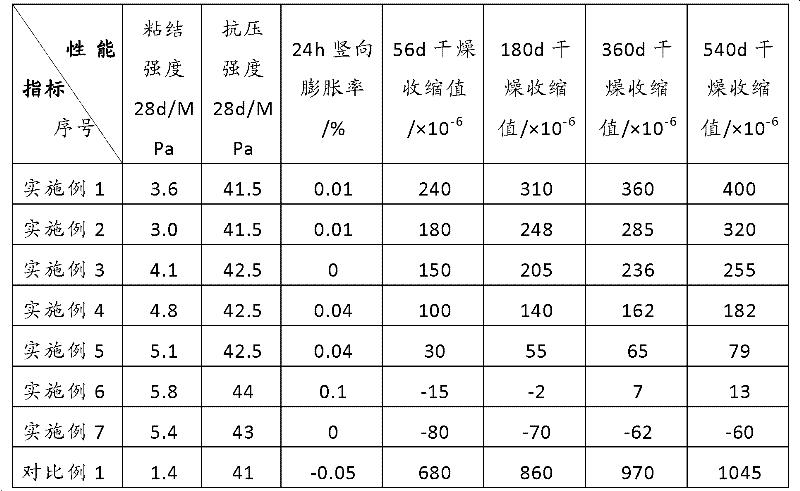

Examples

Embodiment 1

[0041] This example is used to illustrate the self-compacting concrete of the present invention and its preparation method.

[0042] The formula of the self-compacting concrete of the present embodiment is (by weight):

[0043] 100 parts of P·O 42.5 cement, 20 parts of fly ash, 150 parts of river sand with a fineness modulus of 2.4-3.1, 150 parts of gravel with a particle size of 5-16mm, and 20 parts of shale ceramsite with a particle size of 0.3-4.75mm part, 0.6 part of polyacrylamide resin, 5 parts of acrylic emulsion of commercial model Acronal 430 purchased from BASF, and the specific surface area of ground steel slag powder is 400m 2 / kg, MgO content is 10%, 20 parts in total, 1 part of calcium oxide expansion agent, 1.2 parts of naphthalene-based water reducer, 60 parts of water and 0.005 parts of aluminum powder with a fineness of 100 mesh.

[0044] After weighing the above ingredients, transfer them to the blender and stir evenly for 30 seconds. The test is carried...

Embodiment 2

[0046] This example is used to illustrate the self-compacting concrete of the present invention and its preparation method.

[0047] The formula of the self-compacting concrete of the present embodiment is (in parts by weight):

[0048] 100 parts of P.O 52.5 cement, 40 parts of fly ash, 200 parts of river sand with a fineness modulus of 2.4-3.1, 250 parts of gravel with a particle size of 5-16mm, and 120 parts of fly ash ceramsite with a particle size of 0.3-4.75mm 0.1 part of polyacrylamide resin, 40 parts of styrene-acrylic emulsion of Acronal 400 purchased from BASF, and the specific surface area of ground steel slag powder is 500m 2 / kg, MgO content is 10%, a total of 5 parts, U-type expansion agent 3 parts, sodium dodecylsulfonate air-entraining agent 0.01 part, melamine water reducer 1.2 parts, water 60 parts and fineness of 100 mesh aluminum Powder 0.005 parts.

[0049] After weighing the above-mentioned ingredients, transfer them to the blender, and stir evenly for...

Embodiment 3

[0051] This example is used to illustrate the self-compacting concrete of the present invention and its preparation method.

[0052] The formula of the self-compacting concrete of the present embodiment is (by weight):

[0053] 100 parts of P·II cement, 40 parts of fly ash, 250 parts of machine-made sand with a fineness modulus of 2.7, 300 parts of pebbles with a particle size of 5-16mm, 50 parts of shale ceramsite of 0.3-4.75mm, polyacrylamide resin 3 parts, 15 parts of styrene-butadiene latex of Styrofan 623 purchased from BASF, the specific surface area of ground steel slag powder is 500m 2 / kg, MgO content is 8%, a total of 10 parts, 8 parts of aluminum calcium sulfate expansion agent, 0.05 parts of sodium dodecylbenzenesulfonate air-entraining agent, 1.2 parts of polycarboxylate water reducer, 50 parts of water, silicone disinfectant 0.02 parts of foaming agent and 0.002 parts of aluminum powder with a fineness of 120 mesh. After weighing the above-mentioned ingredien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com