Medium-frequency induction furnace bottom impervious castable

A technology for induction furnaces and castables, which is applied in the field of furnace lining materials and can solve problems such as sticky slag penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

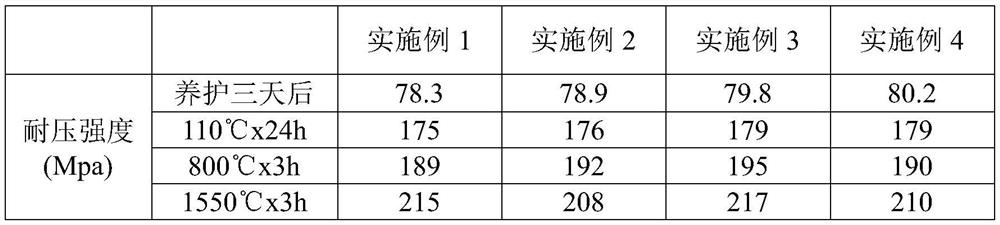

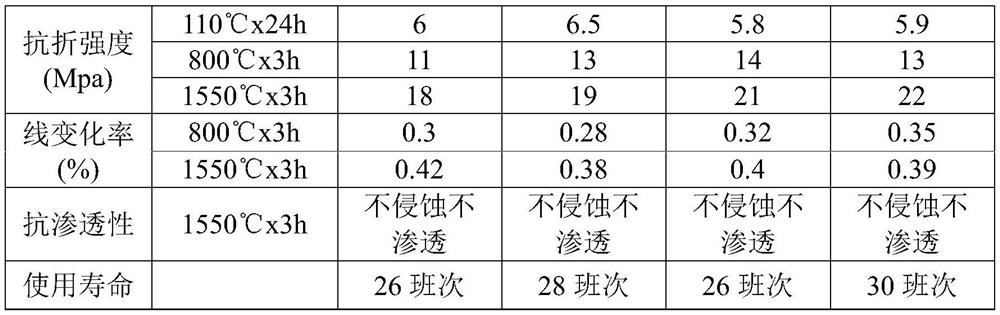

Examples

Embodiment 1

[0032] The anti-seepage castable at the bottom of the intermediate frequency induction furnace in this embodiment includes the following components by weight: 47 kg of dense corundum particles, specifically 10 kg of dense corundum particles with a particle size of 5-3 mm; 10 kg of dense corundum particles with a particle size of 3-1 mm 27 kg of dense corundum aggregates; 10 kg of dense corundum aggregates with a particle size of 0-1mm; Active α-Al with D50≈1.7μm 2 o 3 3 kg of fine powder; 2 kg of zirconia fine powder with particle size ≤ 0.074 μm; 3 kg of pure aluminate cement CA-71 cement; 0.5 kg of dispersible alumina fine powder; 0.05 kg of water reducing agent.

[0033] During on-site construction, after the above-mentioned components are accurately weighed according to the ratio, add water and stir to mix evenly before pouring and construction.

Embodiment 2

[0035] The anti-seepage castable at the bottom of the intermediate frequency induction furnace in this embodiment includes the following components by weight: 30 kilograms of dense corundum particles; specifically, 5 kilograms of dense corundum particle aggregates with a particle size of 5 to 3 mm; 17 kg of dense corundum aggregate with a particle size of 1mm; 8 kg of dense corundum aggregate with a particle size of 0-1 mm; 2 o 3 4 kg of fine powder; 2.5 kg of zirconia fine powder; 5 kg of pure aluminate cement CA-71 cement; 0.6 kg of dispersible alumina fine powder; 0.06 kg of water reducer.

[0036]During on-site construction, after the above-mentioned components are accurately weighed according to the ratio, add water and stir to mix evenly before pouring and construction.

Embodiment 3

[0038] The anti-seepage castable at the bottom of the intermediate frequency induction furnace in this embodiment includes the following components by weight: 50 kg of dense corundum particles; specifically, 9 kg of dense corundum particle aggregates with a particle size of 5-3 mm; and a particle size of 3-1 mm The dense corundum granular aggregate is 28 kg; the dense corundum aggregate with a particle size of 0-1mm is 13 kg; 2 o 3 5 kg of fine powder; 3 kg of zirconia fine powder; 4 kg of pure aluminate cement CA-71 cement; 0.8 kg of dispersible alumina fine powder; 0.02 kg of water reducing agent.

[0039] During on-site construction, after the above-mentioned components are accurately weighed according to the ratio, add water and stir to mix evenly before pouring and construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com