Composite cementing material with double efficacies for curing and improving salted silt soil

A composite cementitious material and dual-effect technology, applied in the field of composite cementitious materials, can solve problems such as it is difficult to meet the needs of engineering construction and development, and achieve sustainable development, low soluble salt content, strength and stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

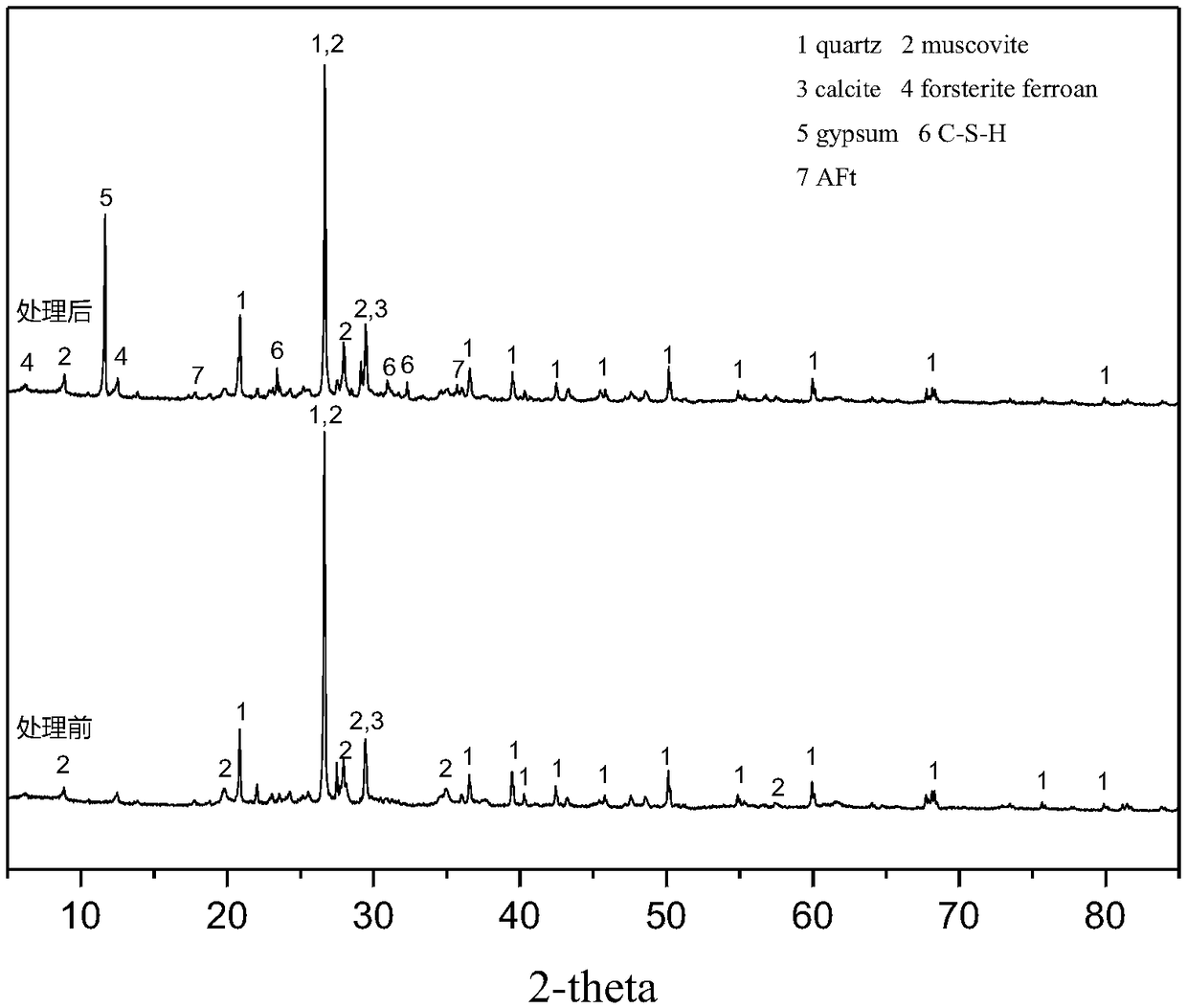

[0044]In this embodiment, the compounding ratio of the saline silt composite solidification improvement material is: 6% of phosphogypsum, 7.5% of metallurgical waste residue, 1.5% of activator A, 0.6% of modifier, after the curing agent is mixed evenly, the salted The silt and curing agent are placed in a stirring pot and mixed evenly, and stirred for 5 minutes. For discharging, the mixed cured material is pressed into shape by a testing machine, and a cylindrical sample with a size of Φ50*50mm is prepared. Standard maintenance and engineering performance test results are shown in Table 1. The dried raw soil was crushed, and the sample particles were passed through a 3mm sieve. Then weigh 100g of the sample, place it in a 2L Erlenmeyer flask, add 500mL of deionized water, adjust the oscillation frequency to 110±10 times / min, and the amplitude to 40mm, shake at room temperature for 8h, and put the upper layer after standing for 16h. The supernatant was filtered through a 0.45 ...

Embodiment 2

[0052] In this embodiment, the compounding ratio of the saline silt soil composite curing improvement material is: 6% of phosphogypsum, 7.5% of metallurgical waste residue, 1.5% of activator A, 0.9% of modifier, after the curing agent is mixed evenly, the salted The silt and curing agent are placed in a stirring pot and mixed evenly, and stirred for 5 minutes. For discharging, the mixed cured material is pressed into shape by a testing machine, and a cylindrical sample with a size of Φ50*50mm is prepared. Standard maintenance and engineering performance test results are shown in Table 1. After the specimen is cured to a certain age, the cured body is broken, and the sample particles pass through a 3mm sieve. Then weigh 100g of the sample, place it in a 2L Erlenmeyer flask, add 500mL of deionized water, adjust the oscillation frequency to 110±10 times / min, and the amplitude to 40mm, shake at room temperature for 8h, and put the upper layer after standing for 16h. The supernata...

Embodiment 3

[0059] In this embodiment, the compounding ratio of the saline silt soil composite curing improvement material is: 10% of phosphogypsum, 12.5% of metallurgical waste residue, 2.5% of activator A, 0.8% of modifier, and after the curing agent is mixed evenly, the saline The silt and curing agent are placed in a stirring pot and mixed evenly, and stirred for 5 minutes. For discharging, the mixed cured material is pressed into shape by a testing machine, and a cylindrical sample with a size of Φ50*50mm is prepared. Standard maintenance and engineering performance test results are shown in Table 1. After the specimen is cured to a certain age, the cured body is broken, and the sample particles pass through a 3mm sieve. Then weigh 100g of the sample, place it in a 2L Erlenmeyer flask, add 500mL of deionized water, adjust the oscillation frequency to 110±10 times / min, and the amplitude to 40mm, shake at room temperature for 8h, and put the upper layer after standing for 16h. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com